Transcription

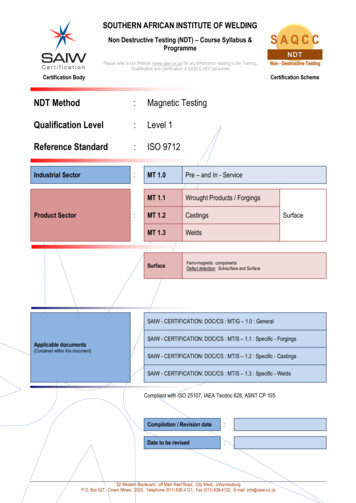

SOUTHERN AFRICAN INSTITUTE OF WELDINGNon Destructive Testing (NDT) – Course Syllabus &ProgrammePlease refer to our Website (www.saiw.co.za) for any information relating to the Training,Qualification and Certification of SAQCC-NDT personnelCertification BodyCertification SchemeNDT Method:Magnetic TestingQualification Level:Level 1Reference Standard:ISO 9712Industrial Sector:MT 1.0Pre – and In - ServiceMT 1.1Wrought Products / ForgingsMT 1.2CastingsMT 1.3WeldsSurfaceFerro-magnetic componentsDefect detection: Subsurface and Surface:Product SectorSurfaceSAIW - CERTIFICATION: DOC/CS : MT/G – 1.0 : GeneralApplicable documents(Contained within this document)SAIW - CERTIFICATION: DOC/CS : MT/S – 1.1 : Specific - Forgings:SAIW - CERTIFICATION: DOC/CS : MT/S – 1.2 : Specific - CastingsSAIW - CERTIFICATION: DOC/CS : MT/S – 1.3 : Specific - WeldsCompliant with ISO 25107, IAEA Tecdoc 628, ASNT CP 105Compilation / Revision date:Date to be revised:52 Western Boulevard, off Main Reef Road, City West, JohannesburgP.O. Box 527, Crown Mines, 2025, Telephone (011) 836-4121, Fax (011) 836-4132, E-mail info@saiw.co.za

Magnetic Testing Level 1 – MT 1.0 - SyllabusINFORMATIONObjectiveTo provide the Level 1 candidate with adequate knowledge and skill to be ableto inspect and report sector specific components in accordance with writteninstructions which are based on international codes and procedures.Target GroupNDT Operators or Practitioners wanting to perform surface as well assubsurface inspections on castings, forgings, welds and tubes manufacturedfrom ferromagnetic material.COURSE:1.Grade 10 with Maths and ScienceOrEligibility2.Pass ( 70%) in applicable Proficiency test(No charge, available of Thursdaysjansenh@saiw.co.za for booking).@8am,contactEXAMINATION:1.2.Qualification ExaminationTraining : 32 hrs (100% Attendance & formative assessments)Vision Acuity40 Multiple Choice Questions : Pass 70%40 Multiple Choice Questions : Pass 70%Weld, Casting, Forging samplesGeneral :Specific :Practical :INITIAL : INDUSTRIAL EXPERIENCE1.2.1 months / 176 hrsSubmit Industrial Experience and Training Matrix & Vision AcuityRENEWAL : After 5 yearsCertification1.2.3.4.5.Full practical examinationAnnual NDT Activity Report & Vision AcuityValid CertificationIf lapsed 1 year : Spec & Practical ExamIf lapsed 1 year : Full examinationRECERTIFICATION : After 10 years1.2.3.DOC / CS / MT 1.0Full examination : General, Specific & PracticalAnnual NDT activity report & Vision AcuityValid CertificationPage 2 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEXDescriptionDurationMT1 - Sect 1. Foreword1.1.Welcome to SAIW : Student Induction1.2.Course objective1.3.Course Format, Formative assessment and outcomes1.4.Code of Ethics1.5.South African NDT Industry1.6.SAQCC – NDT System : Qualification and Certification of NDT Personnel1.7.Professional Designation1.8.Career progress in NDT(ISO 9712)MT1 - Sect 2. Introduction : Non Destructive Testing2.1.Task of NDT2.1.1What is testing? Destructive vs. Non Destructive.2.1.2What is the purpose of NDT?2.1.3When and why is NDT performed?2.1.4NDT Methods and Techniques2.2.Historical Timeline of NDT2.3.Task of NDT Personnel2.4.NDT Terminology:2.5.2.4.1General: discontinuities, indications, defects, interpretation, evaluation, etc.2.4.2Quality: Code, Standard, Procedure, written instructionGeneral Safety Considerations(Occupational Health & Safety)MT1 - Sect 3. NDT Method in a NutshellDOC / CS / MT 1.03.1.Single sentence tions3.5.ApplicationsPage 3 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 4. Physical Principals and associated knowledge4.1.Magnetism4.1.1MagnetismaMagnetic PolesbPermanent Magnets : Bar, horseshoecTemporary MagnetsdMagnetisation : Passing of flux from magnetic medium tononmagnetic medium4.1.2Magnetic fields & Lines of force4.1.3Material Characteristics : Ferromagnetism, diamagnetism, paramagnetism,4.1.4Hysteresis curve4.1.5aRetentivity, residual magnetism, coercive force, reluctancebPermeabilitycSaturationMagnetic Flux, Magnetic Flux Density, Magnetization Force (Units & Typicalvalues)4.1.6Flux Leakage: formation, influence of depth and orientation on detection ofdiscontinuities4.1.74.2.Curie pointElectromagnetism4.2.1ElectricityaDOC / CS / MT 1.0CurrentiDirect CurrentiiAlternating CurrentbVoltagecResistance4.2.2Magnetic field around Conductor4.2.3Magnetic Field around Coil / solenoidPage 4 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 5. Product knowledge, method capabilities and derivative techniques5.1.Manufacturing process and related discontinuities in castings, forgings, rolled products andwelds5.2.Relevant, non-relevant and false indications5.3.Testing irculariiiVerticalbPermanent MagnetscMagnetizing Currentd5.3.2Methods of magnetizationiAlternating Current (AC)iiDirect Current (DC)iiiHalf Wave Rectified Current (HWRC)ivFull wave rectified current (FWRC) Single or three phaseElectromagnetic YokesiCurrent Flow – Passage of currentiiInduction methods – Central conductor, CoilsMagnetic FieldaDistribution, strength, directionbDetection / measurementDetection mediumaMagnetic Particle CharacteristicsbDry PowderscInks / Wet ParticlesdiCharacteristics and Control of Petroleum SuspensionsiiCharacteristics and Control of Water SuspensionsPastesi5.3.4DOC / CS / MT 1.0Characteristics and Control of Rubber SuspensionseConcentratesfHealth and Safety considerationsDemagnetisationPage 5 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 6. Equipment & Consumables6.1.Types of Current , Test Current Capacity6.2.Portable equipment6.3.6.2.1Permanent Magnet Yokes6.2.2Electromagnetic yokes6.2.3Prods6.2.4Coils6.2.5Other DevicesStationary / Heavy Duty Equipment6.3.1Power supplies6.3.2Bench equipmenta6.3.3Automatic units6.3.4Special purpose units6.4.Demagnetization equipment6.5.Conditions of use6.5.1Equipment operation6.5.2Equipment t points6.6.Vessels for checking inspection baths6.7.Magnetic field indicators6.8.DOC / CS / MT 1.0Multidirectional equipment6.7.1Portable field strength meters (magnetometers/Gauss meters)6.7.2Shim/type/ foil strips (trade name Castrol Strips/Ely Strips)6.7.3The ASME field indicator6.7.4The berthold panameter6.7.5Hall Effect Meters6.7.6Performance checks / Calibration pieces6.7.7Calibration Test Pieces (JIS)Viewing conditions6.8.1Non Fluorescent inks and powders6.8.2Fluorescent inks and powders6.8.3Safety6.8.4Electromagnetic spectrum6.8.5Light : Ultraviolet, Visible, Ambient, ExtraneousPage 6 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusDOC / CS / MT 1.0Page 7 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 7. Information prior to test7.1.7.2.Magnetic Particle Testing Practices7.1.1Fundamentals7.1.2Choice of equipment7.1.3Effects of test object variablesInspection techniques7.2.1Remnant fields7.2.2Continuous field7.2.3Wet method7.2.4Dry method7.2.5Demagnetization techniques and verification of remnant fields7.3.Written Instruction7.4.Report SheetMT1 - Sect 8. Testing according to Written instruction8.1.8.2.8.3.Surface preparation8.1.1Pre cleaning /machining8.1.2Contrasting backgroundMagnetization8.2.1Type, current, duration and sequence8.2.2Grid / coverage of surface areaApplication of detection medium8.3.1DOC / CS / MT 1.0Residual or Continuous8.4.Verification of adequate magnetic field / control of magnetization conditions8.5.Interpretation and recording of results8.6.Treatment of components after test8.6.1Residual field8.6.2Demagnetization8.6.3Post cleaningPage 8 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 9. Interpretation and reportingEvaluation (Level 2 only)9.1.Welding:ISO 176389.2.Casting:ISO 4986 (EN 1369)9.3.Forging:BS EN 10228 – 19.4.Rolled / wrought products9.5.Viewing condition according to reference block9.6.Verification of indication quality9.7.Report of simple welding, forging, casting and rolled product indications9.8.Discontinuities : Types, identification & parameters9.9.Indications:9.10.ISO 30599.9.1Relevant, non-relevant and rent tape, coating transfers lacquer developersbphotographicFactors affecting interpretation: surface prep, detecting medium, applicationMT1 - Sect 10. Assessment10.1.Depth, width, shape, position, orientationMT1 - Sect 11. Quality aspects11.1.Personnel Qualification & Certification11.2.Equipment verification11.2.111.2.211.2.3DOC / CS / MT 1.0Functionality checksaConsumable concentration and mobilitybColour contrastOperational calibrationaMagnetic field strength & directionbLight IntensityMaintenance checksaElectrical current measurement and supplybUV / White lightPage 9 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusINDEX (Continued)DescriptionDurationMT1 - Sect 12. Environmental and safety conditions12.1.Electrical risks hazards12.2.Magnetic field risks12.3.Risks related to consumables12.4.Risks related to UV radiation12.5.Disposal of effluents and environmental conditions12.6.Safety data sheetsMT1 - Sect 13. DevelopmentsN/AMT1 - Sect 14. Appendices14.1.Appendix 1 : Method specific terminology / definitionsISO 1271814.2.Appendix 2 : Core reference codes, standards & procedures14.3.Appendix 3 : Quality related terminology and examples14.4.Appendix 4 : Formulae & Reference Tables14.5.Appendix 5 : Answers to end of chapter and homework assignments14.6.Appendix 6 : Preparation for qualification examination14.7.Appendix 7 : Example questions and answers14.8.Appendix 8 : Additional reading material / internet sites for further studyLevel 1 certified personnel shall neither be responsible for the choice of test method or technique to beused, nor for the evaluation of test results.Total Training : GeneralDOC / CS / MT 1.0Page 10 of 16TRAININGEXAMINATION32 HrsCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusApplicationIn accordance with ISO 9712 & SAQA Unit Standard No. 119523DOC. REF.SectionSAIW - CERTIFICATION: DOC/CS : MT/S – 1.1 : CastingsDescriptionPage1Product Knowledge2Typical Discontinuities3Signal response & Detectability4Specific TheoryWritten Instruction & Report Sheets(Based on Codes, Standards or Specifications)OUTCOME 1 :Setup magnetic particle testing equipment1.1The principles of magnetic particle testing are described with reference to basicphysical principles.1.2The principles of operation of testing equipment and accessories are applied in1.3Type of equipment required is identified in terms of approved written instructions.accordance with manufacturer specifications.Range: Written instruction includes equipment selection, operating modes,component/object, defect type and detection1.4Magnetic particle testing equipment for specific applications is set-up andcalibrated in accordance with written instructions.Range: Field strength meters, lifting blocks, settling flasks, UV meters1.5Equipment checks and equipment performance are verified in accordance withPRACTICAL : Product Sectorwritten instructions.OUTCOME 2 :Perform magnetic particle testing2.1The testing technique is implemented in accordance with the applicable workinstruction.2.22.3The equipment is used in accordance with the work instructions.The equipment and accessories are verified and checked in accordance with thework instructions.2.4Equipment problems are identified and communicated in accordance with worksprocedures.Range: Problems include out of range measurements, incorrect responsesfrom meters and lifting blocks and UV light meters2.5Inspection progress and scope of coverage is monitored and documented inaccordance with written instructions.OUTCOME 3 :Record and classify the results of test3.1Data recording sheets are completed in accordance with written instructions.3.2The quality of the data is in accordance with written instructions.Range: interfering parameters, data storage and accessibility3.3Discontinuities are interpreted and recorded according to parameters stipulatedin working instructions.DOC / CS / MT 1.0Page 11 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusApplicationIn accordance with ISO 9712 & SAQA Unit Standard No. 119523DOC. REF.SAIW - CERTIFICATION: DOC/CS : MT/S – 1.3 : WeldsOUTCOME 4 :Specific TheoryReport the results4.1The relevant results are reported in accordance with the written instruction.4.2The language and terminology used is appropriate to the method and can beinterpreted by the recipient.4.3DOC / CS / MT 1.0The format is in accordance with the written instruction.Page 12 of 16TRAININGEXAMINATIONCERTIFICATION

Magnetic Testing Level 1 – MT 1.0 - SyllabusApplicationIn accordance with ISO 9712 & SAQA Unit Standard No. 119523DOC. REF.SectionSAIW - CERTIFICATION: DOC/CS : MT/S – 1.2 : Forgings / Wrought ProductsDescriptionPage1Product Knowledge2Typical Discontinuities3Signal response & Detectability4Specific TheoryWritten Instruction & Report Sheets(Based on Codes, Standards or Specifications)OUTCOME 1 :Setup magnetic particle testing equipment1.6The principles of magnetic particle testing are described with reference to basicphysical principles.1.7The principles of operation of testing equipment and accessories are applied in1.8Type of equipment required is identified in terms of approved written instructions.accordance with manufacturer specifications.Range: Written instruction includes equipment selection, operating modes,component/object, defect type and d

(ISO 9712) 1.7. Professional Designation 1.8. Career progress in NDT MT1 - Sect 2. Introduction : Non Destructive Testing 2.1. Task of NDT 2.1.1 What is testing? Destructive vs. Non Destructive. 2.1.2 What is the purpose of NDT? 2.1.3 When and why is NDT performed? 2.1.4 NDT Methods and Techniques 2.2. Historical Timeline of NDT 2.3. Task of NDT Personnel