Transcription

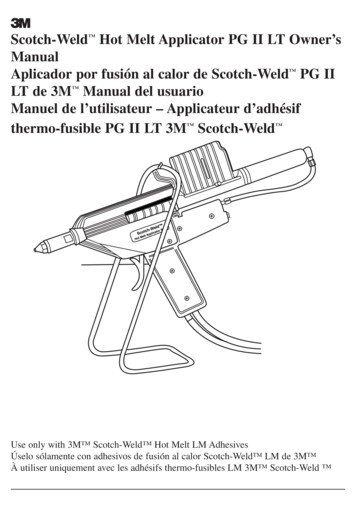

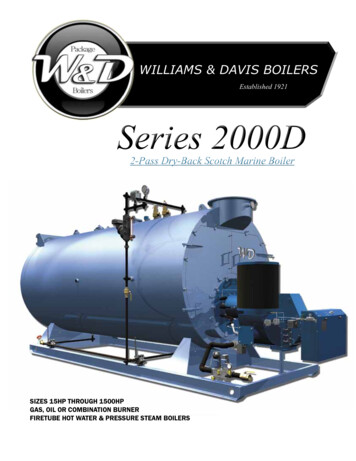

Williams & Davis BoilersEstablished 19212-Pass Dry-Back Scotch Marine BoilerSIZES 15HP THROUGH 1500HPGAS, OIL OR COMBINATION BURNERFIRETUBE HOT WATER & PRESSURE STEAM BOILERS

2000D Standard Features(Shown w/ Powerflame Nova Plus Burner) Engineered and Built in Accordance With theLatest ASME Boiler Codes.McDonnell Miller Combination Pump Controllerand Primary Low Water Cutoff.Completely Wired and Piped for ServiceConnections.Fully Modulating Burner Operation.Premium 2” Thick High-Density Insulation.“Off-the-Shelf” Industry Standard Parts UsedWhere Possible for Serviceability.Probe Type Auxiliary Low Water Cutoff.Epoxy Painted 20ga. Galvanized Steel Jacket.Solid State Honeywell Combination PressureControl, Automatic Operating Control, and HighLimit Manual Reset Control. Exceeds Industry Standards for HeatingSurface Area for Exceptional Efficiency.Pressure Tested to 1.5X Operating Pressure.(225psi for 150psi Vessels)Flanged Exhaust Stack – Includes AdditionalFlange for Installation.Furnace Diameters and Combustion AreaVolume Optimized For Lox NOx Operation.Standard Available Options Customizable Controls and ConnectionsAdditional Hand Holes and Manway AccessDavited Front and Rear Doors.Burner Make and ModelO2 Trim System"Linkage-less" Modulation

The Williams & Davis 2000D fortifies oureverlasting reputation for building the mostrugged and serviceable scotch marine boilerin the industry. The 2000D further offers ahigh efficiency design built to maximize fluegas velocities and transfer as much heatenergy as possible to the process waterinstead of exhausting it through the stack orradiating heat into the boiler room. Throughstringent and methodical building practicesperfected over almost 90 years in theindustry,Williams & Davis guarantees each of ourboilers will meet, and typically exceed, everyASME standard. All units are operationallytested and shipped as an integrated packagewhen practical, ready for quick connection toutilities. As such, we demonstrate ourconfidence in our boilers by offering theindustry's best pressure vessel warranty of10 years (25 year available) with anapproved water testing and treatmentprogram.(Shown w/ Powerflame Nova Plus Burner)Stainless Steel Jacket Available 2Pass Dry-backLow Radiant Heat LossesHigh Gas VelocitiesHigh EfficiencySpace Saving Design

Flanged Exhaust StackAll 2000D boilers are equipped with a vertical flanged exhauststack and are supplied with a matching installation flange.Flanges ease vent positioning during installation and providemore reliable exhaust seals during operation.BurnerBurners are available to operate with natural gas, a variety offuel oils, or a combination of gas and oil. NOx output levelsmay be specified as low as sub 7 PPM when burning naturalgas and 70 PPM for burning #2 fuel oil when the fuel-boundnitrogen is at 0.02% or less. Control cabinet is typically mountedto the front of the burner. Side mounting or remote boiler roommounting is available upon request.Safety Relief ValvesWide hex on valve nozzle provides wrenching service clearancefor easy installation and maintenance. Dual control rings offereasy adjustability for precise opening with minimum pre-open orsimmer and exact blow-down control.Tubes & TurbulatorsAll fire tubes are industry standard 2.5” outside diameter and0.109" typ. wall thickness. The fire tubes are inserted withuniquely-shaped corrosion resistant alloy steel Turbulatorsdesigned to break up laminar flow and maximize heat transfer.Pressure ControllerStandard Honeywell P7810 Pressuretrol provides solid stateautomatic operating control, automatic limit protection, manualreset limit protection, and 4-20ma modulating firing rate controlfor pressure systems up to 300 psi. Other pressure andtemperature controllers are available upon request.Structural SkidThe 2000D's rugged structural steel skid provides stability duringtransport and installation. Wide beam flanges distribute weightevenly across the boiler room floor during flooded operation.Low Water ControlsMcDonnell Miller 157S float level system provides reliablefeedwater pump control and primary low-level shut down. Probetype sensor and Warrick relay are used for reliable secondaryshutdown and to provide code-required manual reset. 2010, Williams & Davis Boilers. All rights reservedE1001-03

(Shown w/ Powerflame Nova Plus Burner)2000D Heating PassesFirst Pass - The burner fires at the entrance of thefurnace, transferring up to 70% of the available heatenergy into the water.Second Pass From the refractory-backed turnaroundchamber, flue gas is directed vertically into the top rowsof submerged tubes, travels across the length of thepressure vessel, and exits the system through the exhauststack. 2010, Williams & Davis Boilers. All rights reservedE1001-03

Wide Range of ApplicationsAsphalt CementBottling CompaniesClothingFeed MillsHospitalsHotelsLaundryLumber MillMeat ProcessingNat. Gas RefineriesOil DrillingPharmaceuticalPolystyrene FoamPower GenerationResearchSchools 2010, Williams & Davis Boilers. All rights reservedE1001-03

Additional Product OfferingWWNENEFully Condensing Hydronic BoilersElectric BoilersBlow-down Separators 2010, Williams & Davis Boilers. All rights reservedHeat Recovery SystemsVertical Tube and Tubeless BoilersVertical or Horizontal Feed-water SystemsE1001-03

Your Authorized Williams & Davis RepresentativeP.O. Box 5392044 S. I-45Hutchins, Texas 75141(800) 8-BOILER(800) 826-4531(972) 225-2356(972) 225-5739 FAXwww.wdboiler.cominfo@wdboiler.com 2010, Williams & Davis Boilers. All rights reservedE1001-03

The Williams & Davis 2000D fortifies our everlasting reputation for building the most rugged and serviceable scotch marine boiler in the industry. The 2000D further offers a high efficiency design built to maximize flue gas velocities and transfer as much heat energy as possible to the process water instead of exhausting it through the stack or