Transcription

Motors Automation Energy Transmission & Distribution CoatingsW22Three-Phase Electric MotoralotAaNEMnical ChTecg

www.weg.netW22 LineThe increasing demand for electrical energy to sustainglobaldevelopment requires consistent heavy investments inpower supply generation. However, in addition tocomplex medium and long term planning, theseinvestments rely on natural resources, which arebecoming depleted due to constant pressures uponthe environment. The best strategy, therefore, tomaintain energy supply in the short term is to avoidwastage and increase energy efficiency. Electric motorsplay a major role in this strategy, since around 40% ofglobal energy demand is estimated to be related toelectric motor applications. Consequently, any initiativesto increase energy efficiency, by using high efficiencyelectric motors and frequency inverters, are to bewelcomed, as they can make a real contribution toreductions in global energy demand.At the same time as efficiency initiatives make animpact in traditional market sectors, the application ofnew technologies in emerging sectors is resultingin profound changes in the way that electric motors areapplied and controlled. By integrating these changes2W22 Electric Motortogether with the demands for increased energyefficiency, WEG has taken up the challenge andproduced a new design of high efficiency motor, onethat exceeds the performance of the previous WEG’sW21 motor line, which is recognised worldwide for itsquality, reliability and efficiency.Using the latest generation of computerised tools, suchas structural analysis software (finite element analysis)and computer fluid dynamics, as well as electricaldesign optimization software, an innovative - nextgeneration - product has been developed: the W22motor.Several key objectives have been achieved in thedesign of the W22 motor:g Reduction of noise and vibration levels;g Increased energy efficiency and reduced carbonfootprint;g Easy maintenance;g Compatibility with present & future generations offrequency inverters;g Flexible and modular design.

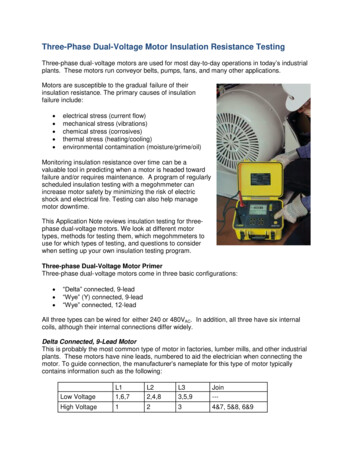

www.weg.netFrame 143T to 215TFrame 254T to 326TFrame 364/5T to 444/5TFrame 445/7T to 588/9TReducing Carbon Footprint and Cutting Costs with the W22W22 range of three-phase induction motors, designed to offer not only significantly lower energy consumption, butlower noise and vibration, higher reliability, easier maintenance and lower cost of ownership.Consisting of three products, each designed to exceed the requirements of the NEMA MG 1-2009, the W22 SuperPremium Efficiency, NEMA Premium Efficiency and High Efficiency can reduce energy losses by between 10% and50% compared with other typical motors. It’s an extremely effective way to reduce your carbon footprint, as well asyour energy costs.W22 motors fully comply with the energy efficiency requirements of the EISA 2007 (Energy Independence andSecurity Act 2007) from USA and EcoAction from Canada.W22 Electric Motor3

www.weg.netVisual Index4W22 Electric Motor3.1FramePage 63.2EyeboltsPage 63.4Earth terminalsPage 73.5Terminal boxPage 73.8EndshieldsPage 93.10Fan coverPage 93.11NameplatePage 94.1Cooling systemPage 10Page 115.1Shaft5.2BearingsPage 117.2Sealing systemPage 137.3PaintingPage 13

www.weg.netTable of Contents1. Versions Available. 062. Standards. 063. Construction Details. 063.1 Frame. 063.2 Eyebolts. 063.3 Points for Vibration Monitoring. 063.4 Earth Terminals. 073.5 Terminal Box. 073.6 Power Supply Connection Leads. 083.7 Accessory Connection Leads. 083.8 Endshields. 083.9 Drains. 083.10 Fan Cover. 093.11 Nameplate. 094. Cooling System and Noise Level / Vibration Level / Impact Resistance. 104.1 Cooling System and Noise Level. 104.2 Vibration Level . . . . .104.3 Impact Resistance . . . .105. Shaft / Bearings . . .115.1 Shaft . . 115.2 Bearings . . 115.2.1 Permissible Loads.115.2.2 Bearing Monitoring. 136. Mounting Forms. 137. Degree of Protection / Sealing System / Painting. 137.1 Degree of Protection . . . 137.2 Sealing System . . . 137.3 Painting . . . 147.3.1 Internal Anti-Corrosive Painting. 148. Voltage / Frequency . .149. Ambient / Insulation . . . 149.1 Space Heaters. 1510. Motor Protections. 1510.1 Protection Based on Operating Temperature. 1510.1.1 RTD. 1510.1.2 Thermistor (PTC). 1510.1.3 Thermostats . 1510.2 Protection Based on Operating Current. 1611. Variable Speed Drive Application. 1611.1 Considerations Regarding Voltage Spikes and The Insulation System . . . 1611.2 Torque Restrictions on Variable Speed Drive Applications . . 1611.3 Considerations Regarding Bearing Currents . .1711.4 Forced Ventilation Kit . . . . 1711.5 Encoders. 1712. Construction Features. . . 1813. Optional Features . . 2014. Electrical Data . . 2415. Mechanical Data . . 3416. Terminal Box Drawing . . 3717. Drip Cover Data. 3818. Distance from Fan Cover to Wall. 3819. Packaging. 3919.1 Frames 143T to 215T . . . 3919.2 Frames 254T to 588/9T . . . 3920. Spare Parts.40Tor sintion seriorehenda volut quatem nis et lani ut vel eosant et di asitatibusam harum andus, odit idipsamW22 Electric Motor5

www.weg.net1. Versions AvailableW22 NEMA Motors are available in three versions: W22High Efficiency, NEMA Premium Efficiency and SuperPremium Efficiency. These versions are in accordance withthe tables 12-11 and 12-12 from NEMA MG-1.The motor feet are completely solid for better mechanicalstrength (figure 2), allowing easier alignment and installation.2. StandardsW22 motors meet the requirements and regulations of thelatest version of the following Standards:CSA C22.2 No. 100-04CSA C390Motor and GeneratorsTest Methods, Marking Requirements and EnergyEfficiency Levels for Three-Phase Induction MotorsIEEE STD 112IEEE Standard Test Procedure for Polyphase InductionMotors and GeneratorsNEMA MG-1Motors and GeneratorsUL 1004-1Rotating Electrical Machines - General RequirementsTable 1 - Standards3. Construction DetailsThe information included in this document refers to standardconstruction features and the most common variations forW22 motors in low voltage for general applications in framesizes from 143T to 588/9T.W22 motors for special and/or customized applications areavailable on request. For more information, please contactyour WEG office or distributor.3.1 FrameThe W22 frame (figure 1) is manufactured in FC-200 cast ironto provide high levels of mechanical strength to cater for themost critical applications. The cooling fins are designed tominimize the accumulation of liquids and dust over the motor.Figure 1 - W22 Frame.Figure 2 - Solid feet.3.2 EyeboltsEyebolts are available from frame size 182T. The quantity ofeyebolts for each frame and mounting is shown in the table 2.Number ofDescriptioneyeboltsFrames 182T to 326T1Motors with feet and with side mounted terminal boxFrames 182T to 444/5T2Motors with feet and with top mounted terminal box2Frames 182T to 444/5T - Motors without feet and with C or D flange2mounted terminal box. These motors have four threaded holes in theFrames 445/7T to 5

NEMA MG-1 Motors and Generators UL 1004-1 Rotating Electrical Machines - General Requirements Table 1 - Standards. www.weg.net W22 Electric Motor 7 3.5 Terminal Box The terminal box of W22 motors is made with FC-200 cast iron, which is the same material used to produce the frame and endshields. It is diagonally split for easier handling of leads and connections. For frame sizes 445/7T