Transcription

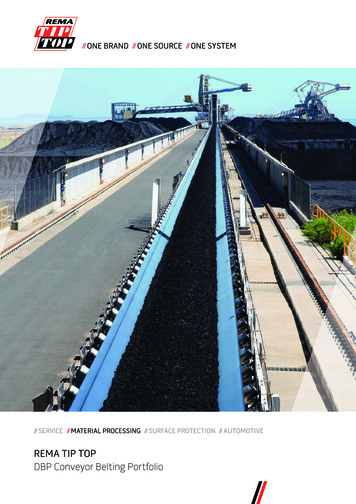

Drag ConveyorMaintenanceMark CloudTramco Inc.Agosto 2005 ”Conveyor Systems That Deliver!”1

Drag ConveyorsEn-Masse ConveyorsAgosto 2005 ”Conveyor Systems That Deliver!”2

The Every Day New Challenges ability ceAir pollutionEtc.Agosto 2005 ”Conveyor Systems That Deliver!”3

Model GEn-Masse Conveyor Conveys a widevariety of freeflowing bulkmaterial. Horizontal to15º inclineAgosto 2005 ”Conveyor Systems That Deliver!”4

Bulk-Flo Horizontal to Incline, L-Path,S-Path, and Loop DesignsAgosto 2005 ”Conveyor Systems That Deliver!”5

Model G – Fully Assembled with Covers RemovedFlight return assembliesHeavy duty chains.are capped with 1/4” x 4” 380Brinell wear bars for extended life.Size is selected to satisfyThe requirements ofeach application.UHMW FlightsFor quiet operation, long life, smooth,cushioned starts (even under full load),and minimum replacement costs10 gauge (2.66 mm)Standard housingReplaceable abrasion resistant linersBolted abrasion resistant bottomHeavy dutyCenter pullHinged Inspection Doortake-upsAgosto 2005 ”Conveyor Systems That Deliver!”6

Model G Head SectionInspection DoorHinged ReliefDoor WithLimit SwitchBracketBolt on CoverHead ShaftExtendedFor DriveMountingHeavy DutyLong LifePillow BlockRoller BearingsAgosto 2005 ”Conveyor Systems That Deliver!”7

Model G Tail SectionLarge Removable Bolt On CoverHingedRelief DoorAllowing shaft and sprocketAssembly to behoisted out vertically.Heavy DutyRoller BearingHeavy DutyCenter PullTake-Up FrameTail ShaftAgosto 2005 ”Conveyor Systems That Deliver!”8

Advantages & Disadvantagesof Chain Conveyors Totally Enclosed. Dust &Weather Tight Multiple Inlets & MultipleDischarges Discharges Can BeAutomated Low Maintenance when usedappropriately and per design Can Be Inclined Up To 90Degrees Can Be Reversed Has The Highest InitialInvestment Larger Horsepower ThanBelt Conveyors & BucketElevators But Lower ThanScrew Type Conveyors Shorter Length Than BeltConveyors Are Not ManufacturedUnder CEMA StandardsAgosto 2005 ”Conveyor Systems That Deliver!”9

Products to be Handled inChain Conveyors Corn Products (Whole, Meal, Bran, Feed, Gluten, Fiber)Cottonseed Products (Delinted, Meats, Hulls, Cake, Meal)Linseed and Flaxseed Products (Cake, Screenings, Meal)Peanut Products (Shelled, Unshelled, Meal)Soybeans Products (Whole, Meal, Flakes, Hulls)All Other Grains (Rice,Sorghum,Wheat,etc.)Others (Coal, Salt, Cement, Coke, Fertilizer, Wood Chips, Fiberetc.)Agosto 2005 ”Conveyor Systems That Deliver!”10

Chain Assembly Direction& Return CupsAgosto 2005 ”Conveyor Systems That Deliver!”11

Hold Down AssemblyAgosto 2005 ”Conveyor Systems That Deliver!”12

Scoop Plate AssemblyAgosto 2005 ”Conveyor Systems That Deliver!”13

G-Model InletsAgosto 2005 ”Conveyor Systems That Deliver!”14

Bypass InletsAgosto 2005 ”Conveyor Systems That Deliver!”15

Agosto 2005 ”Conveyor Systems That Deliver!”16

Intermediate Discharge FlangeAgosto 2005 ”Conveyor Systems That Deliver!”17

Intermediate GatesAgosto 2005 ”Conveyor Systems That Deliver!”18

Agosto 2005 ”Conveyor Systems That Deliver!”19

“C” Style Vs. “L” Style GatesAgosto 2005 ”Conveyor Systems That Deliver!”20

Intermediate Gates - ManualAgosto 2005 ”Conveyor Systems That Deliver!”21

Intermediate Gate - Motorized¾ HP or 2 HPDodge TiGearGear MotorAgosto 2005 ”Conveyor Systems That Deliver!”22

Intermediate Gate - AirAgosto 2005 ”Conveyor Systems That Deliver!”23

Pneumatic Gate Air Cylinder andSolenoid ValveAgosto 2005 ”Conveyor Systems That Deliver!”24

Agosto 2005 ”Conveyor Systems That Deliver!”25

Slack Chain DetectorAgosto 2005 ”Conveyor Systems That Deliver!”26

Head and Tail SealsAgosto 2005 ”Conveyor Systems That Deliver!”27

G-Model Two Way AssemblyAgosto 2005 ”Conveyor Systems That Deliver!”28

Recycling Head AssemblyAgosto 2005 ”Conveyor Systems That Deliver!”29

Reloading Head SectionAgosto 2005 ”Conveyor Systems That Deliver!”30

Sprocket and ChainAgosto 2005 ”Conveyor Systems That Deliver!”31

Relief Tooth SprocketAgosto 2005 ”Conveyor Systems That Deliver!”32

Ceramic TileAgosto 2005 ”Conveyor Systems That Deliver!”33

Mr. Mark’s Maintenance TipsChain TensionAgosto 2005 ”Conveyor Systems That Deliver!”34

Mr. Mark’s Maintenance TipsChain Failure is PredictableWhen measuring 10 links of 6” pitch:Agosto 2005 ”Conveyor Systems That Deliver!”35

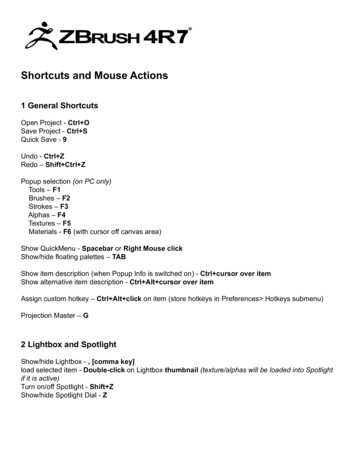

Mr. Mark’s Maintenance TipsDo Not Grind Chain Pins The shoulder is in good condition on this pin. It is needed sothat the pin can be pressed into the side bar. The shoulder on this pin has been grinded down.This may allow easier installation but will cause theChain link to wear down at an accelerated rate.When the pin shoulder has been grindeddown it allows movement inside the pinholeon the link, which wears down the inside ofthat pinhole.Agosto 2005 ”Conveyor Systems That Deliver!”36

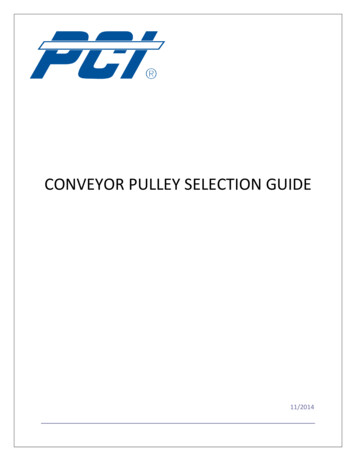

Mr. Mark’s Maintenance TipsSprocket ReplacementExcellentTime to ReplacePast ReplacementPossibly wearing down chainWhen Sprocket is worn or hooked from 3/16” to 1/4”, it is very important to avoidirreversible harm to the barrel of the chain. As Tramco sprockets are symmetricallymade, after you wear off one side of the tooth, you can turn it over and wear the other side.Agosto 2005 ”Conveyor Systems That Deliver!”37

Mr. Mark’s Maintenance TipsSquaring the Steel Shaft In order to get the maximum life fromyour tail bearings it is extremely importantthat the tail shaft is adjusted in its finalposition completely square with the flangeon the intermediate box. When the bearing is under misalignmentearly failure is possible. That is why it isvery important to square the steel shaftwhen adjusting proper chain tension.Agosto 2005 ”Conveyor Systems That Deliver!”38

Questions?THANKS!Agosto 2005 ”Conveyor Systems That Deliver!”39

"Conveyor Systems That Deliver!"Agosto 2005 37 Mr. Mark's Maintenance Tips Sprocket Replacement Excellent Time to Replace Past Replacement Possibly wearing down chain When Sprocket is worn or hooked from 3/16" to 1/4", it is very important to avoid irreversible harm to the barrel of the chain. As Tramco sprockets are symmetrically