Transcription

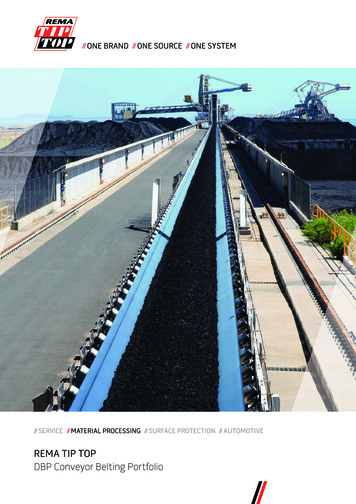

REMA TIP TOPDBP Conveyor Belting Portfolio

CONTENTCopyright 2016 REMA TIP TOP AGAll information is given to the best of our knowledge.All specifications are to be considered non-bindinginformation. Any claim for damages of any kind is excluded.We reserve the right to change technical specificationswithout prior notice, provided that they ensure productimprovement.The information presented is based on technical experiencebut does not guarantee a product’s suitability for specificapplications, and does not relieve the users of the responsibility to undertake their own testing, including where anythird-party trademark rights are concerned.For special applications and operating conditions with regardto temperature, UV light, ozone, acids and alkaline solutions,dynamic and static forces, tensions, elongations and otherinfluences, we recommend application-technical consultation.2DBP Conveyor belting portfolio03POWAPLY Multiply fabric belting range06POWACORD Steel cord conveyor belting range07POWASOL Solid woven conveyor belting range08DBP WearTECH10DBP LavaTECH11DBP OilTECH12DBP FlameTECH13DBP LiftTECH14DBP FlexTECH15DBP REMAWELL16SPECIAL BELT CONSTRUCTIONS18REMA TECHNOLOGIES20REMAPRESS IVE –state of the art conveyor belt presses22Guidance for conveyor technology24

REMA TIP TOPDBP Conveyor belting portfolioREMA TIP TOP offers a full range of conveyor belting.All products are available through the global REMA TIP TOPnetwork of subsidiaries and alliance-partners.If your requirement calls for a fabric, steel cord or specialcarcass, with or without breaker, we can supply the rightproduct at the right time to the required place: Belt construction with fabric,steel cord or aramid carcass Solid woven and straight warp Vertical and incline belts High abrasion, low rolling- and highimpact-resistant rubber, PVC and PVG covers Heat-, oil- and chemical resistant Flame-retardant and self-extinguishing Pipe and tunnel beltsStandard conveyor belts starting with EP 400 up toEP 1000 are immediately available from our localstock and logistic centers.REMA TIP TOP does not only deliver products, we alsodesign, install, fabricate and maintain your conveyingand material handling system:With our 24 / 7/365 service mentality weguarantee system and process availability.3REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

REMA TIP TOPDBP Conveyor belting portfolioREMA TIP TOP Portfolio of Conveyor BeltingDescriptionPropertiesCarcassMin. breaking strengthCoverDBP WearTECHWear-resistantEP315 - 2500AA*- W/D - X/H - YPP800 - 2500ST500 - 5400Heat-resistant150 – 200 CEP315 - 2500ST500 - 5400Oil and grease resistantEP315 - 2500ST500 - 5400Flame-resistant according to ISO340 DBP-LEVEL 1EP315 - 2500ST500 - 5400Flame-resistant /Self-extinguishing according to DIN EN 12882surface DBP-LEVEL 2EP315 - 2500ST500 - 5400Flame-resistant /Self-extinguishing according to DIN EN 14973underground DBP-LEVEL 3EP315 - 2500ST500 - 5400Aramide fabric conveyor beltsD400 - 3150All categoriesFLEX-conveyor beltsEPP400 - 2500All categoriesELEVATOR conveyor beltsEP315 - 2500All categoriesST500 - 5400EP315 - 2500ST500 - 5400DBP OilTECHDBP FlameTECHDBP ForceTECHDBP LiftTECHDBP FlowTECH4PIPE conveyor beltsT1-150 / T2-220 G/G /G1K/S/G1Fire-resistantFire-resistantAll categoriesDBP SlideTECHSliding conveyor beltEP315 - 2500All categoriesDBP SolidTECHSOLID WOVEN conveyor beltsEP/B/PB630 - 3150AA*- W/D - X/H - YDBP ChevronTECHSteep-incline beltsEP400 - 1000All categoriesDBP REMAWELLSidewall conveyor beltsEP400 - 2000All categoriesST500 - 5400DBP AntiripTECHDBP Self-AdjustTECHDBP CrossTECHDBP LavaTECHFurtheroptions

REMA TIP TOPDBP Conveyor belting portfolioRange of qualitiesCoverCover classificationTemperatur range CPolymer basisAbrasion mm³Elongation atbreak min. in %Min. ambienttemperatureConstant materialtemperatureMax. 00-208090SBR/NBRG 8090SBRVT/V175350-208090CRPVG SBR90400-105060SBRPVG C1**12040005060CRPVG C2**16040005060CR The development and production of the products is based on the relevant European standardsAll listed conveyor belts are available in belt widths of 500 – 2000 / 2400 mm* DBP highly wear-resistant cover quality** PVG conveyor belts correspond to the safety class according to EN-ISO 14973All information is given to the best of our knowledge. All specifications are to be considered non-binding information. Any claim for damages ofany kind is excluded. We reserve the right to change technical specifications without prior notice, provided that they ensure product improvement. The information presented is based on technical experience but does not guarantee a product’s suitability for specific applications, anddoes not relieve the users of the responsibility to undertake their own testing, including where any third-party trademark rights are concerned.For special applications and operating conditions with regard to temperature, UV light, ozone, acids and alkaline solutions, dynamic and staticforces, tensions, elongations and other influences, we recommend application-technical consultation.5REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

POWAPLY MULTIPLY FABRIC BELTING RANGEWear-resistant and versatileDBP POWAPLY conveyor belting is an all synthetic multiplyconstruction available in a very wide range of strengths andnumber of plies.High performance industrial polyester and polyamide yarns arewoven together, then given a special treatment to ensureexceptional long lasting ability to bond to the interply rubber.The interply rubber is formulated to provide not only highadhesion to prevent separation even in the most arduousapplications but also to impart exceptional impact absorbingproperties. Polyester warp yarns and polyamide weft in thetraditional EP fabrics result in low elongation, exceptional fatigueand impact resistance and the ability of the belt to be joined byeither vulcanised splice or mechanical fasteners. Breaking awayfrom tradition, many of the belt fabrics are also available in highperformance, economic all polyester (EE) construction.DBP POWAPLY can be offered with a wide range of rubber coversto suit a diverse range of applications from extreme abrasion,cutting and gouging to light duty conveying of non abrasivematerials.Fabric constructionSpecificationsBelt classMaximum Tension (kN/m)CMMS*PropertyNon 03202503150400315Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Mass (kg/m2)Thickness (mm)Number of 916.112.918.416.1* Computer Maintenance Management System - a unique maintenance management system that maximises system efficiency,reduces downtime and optimises availability.6

POWACORD STEEL CORD CONVEYOR BELTING RANGEHigh quality and extremely durableDBP POWACORD is a steel cord reinforced conveyor belt incorporating the most current technology, many components havetaken years of refinement to attain this technological precision.Every belt is guaranteed to provide maximum performance andmaximum life.DBP POWACORD with galvanised steel cord strength carryingmembers embedded in a matrix of high performance rubbermeets all demands for high strength, low elongation conveyorbelting. The bonder rubber in the core is formulated to penetratedeep into the cords providing high cohesive and adhesivebond for long lasting protection and extreme join efficiency.DBP POWACORD can be offered with a wide range of rubbercovers to suit a diverse range of applications from extremeabrasion, cutting and gouging to less arduous conveying ofnon abrasive materials.Steel cord constructionSpecificationsBelt classCord Diameter (mm)Maximum Tension (kN/m)CMMS*Non ManagedMinimum cover thickness T540011.310808108.0* Computer Maintenance Management System - a unique maintenance management system that maximises system efficiency,reduces downtime and optimises availability.7REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

POWASOL SOLID WOVEN CONVEYOR BELTING RANGEExtra-strong fabric conveyor beltsDBP POWASOL with SolidTECH technology is a solid wovenconstruction conveyor belting having ultrafine polyesterfilaments combined with cotton yarn in the warp membersand high strength polyester/cotton blend weft members.The combination allows deep penetration of PVC into the carcassthat ensures the belt will not burn, meeting the most stringentstandards of fire safety. Also the design ensures a tough belt thathas superior rip resistance, excellent fastener holding capabilityand good abrasion resistance. DBP POWASOL conveyor belting isoffered with abrasion resistant synthetic rubber covers that arechemically cross-linked to the PVC impregnation to ensure manyyears of trouble free service.The cover thickness can be varied according to customerrequirements.SpecificationsMinimum recommended pulleydiameters (mm)Belt ClassCarcass Take-up,HT BendLT 0800630* Mass of each millimetre of cover (NBR-F) 1.32 kg/m².To obtain the total belt mass per unit of length, add the carcass mass plus mass of each cover then multiply the result bythe belt width in metres.8

POWASOL SOLID WOVEN CONVEYOR BELTING RANGEExtra-strong fabric conveyor beltsRecommended maximum belt width (mm)for correct load supportMaterial classificationLD - Lump size (mm) x Density (t/m3)Belt ClassALD 1 - 20BLD 21 - 60CLD 61 - 600DLD 600180018001800180020001800180018001800Recommended minimum belt width (mm)for correct empty belt troughingTrough angle (degree)Belt 008001000200010001000100010009REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

DBP WEARTECHThe conveyor belt cover benchmark for wear-resistanceThe combination of tensile strength, abrasion resistance andelasticity of the conveyor cover are chosen to best suit theapplication in a range of cover types.DBP covers are in a league of their own when it comes tomatching the life to the application. The mechanism of wear toconveyor belts is highly complex. An infinite mix of product size,sharpness and shape that strikes the belt surface at manydifferent velocities all play a role. Also affecting rate of wear arethe operating conditions.Developing belt conveyors that perform well in all thesecombinations can be a challenge without the huge database ofknowledge gathered from continuous real time monitoring at amicro-level of the entire belt thickness profile. The BTM BeltThickness Monitoring System designed by REMA TIP TOPTECHNOLOGIES system is the first conveyor belt monitoringsystem to continuously and automatically monitor the thicknessof the belt. Data captured by numerous units installed around theworld is being used to monitor the performance of rubbercompound. This information has led to the development of beltcover rubber compounds that uniquely fit the application.SpecificationsCoverCover classificationTemperatur range CPolymer basisAbrasion mm³Elongation atbreak min. in %Min. ambienttemperatureConstant materialtemperatureMax. /SBR10

DBP LAVATECHHeat-resistant HR GRADEOur range of DBP LavaTECH is descriptive and includes theresistance to heat and heated material conveyed.We have allowed for this in our temperature range and describethis in the table below. It is always important to understand this,so as to benefit from the conveyor belt.With all of this in mind we have developed and continue todevelop and test our rubber covers so as to optimize heatrequirement with optimal abrasion and tensile properties.DBP LavaTECH conveyor belting allows for permanent andintermittent temperatures from 100 to 220 degrees Celsius.We realize that there are not only an enormous range ofdifferent materials conveyed but also different temperatureranges that exist. First and foremost we understand thatthere needs to be differentiation between consistent orpermanent heat and that of intermittent . breakingstrengthCoverDBP LavaTECHHeat-resistant150 – 220 CEP315 - 2500T1-150 / T2-220 ST500 - 5400CoverCover classificationTemperatur range CPolymer basisAbrasion mm³Elongation atbreak min. in %Min. ambienttemperatureConstant materialtemperatureMax. 200400-20200220EPDM11REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

DBP OILTECHOil-resistant G gradeDBP OilTECH covers provide good tear,cut and abrasion resistance and also areresistant to swelling when caused byabsorption of oils and grease.The oil resistant cover is available in twogrades, DBP OilTECH and DBP OilTECH .They are used when the materialtransported contains oils such as fuel oilin coal or fertilizers, lubrication oilsin metal recycling, foundries, steelprocesses, waste industries or in thecase of special processes such as glassor chemical.The presence of oil in the transportedmaterial can have detrimental effectson standard rubber covers: it will degrade the physical propertiessuch as abrasion resistance, tensilestrength and tear strength the belt covers will absorb the oilcausing them to swell and looseadhesion with the carcassThe extent of degradation is dependant onthe type of oil and the temperature.There is an exponential increase in rate ofdegradation and amount of swelling withrespect to the increase in temperature.Therefore, it is important to considerthe operating temperature and types ofoily substances when choosing the mostsuitable DBP OilTECH cover.Oil resistance of a belt cover is evaluatedby measuring the swelling of the rubberafter immersion in oil. For purposes ofcomparison specifications of oils usedfor the evaluation are standardised.The two standard oils: IRM902, a medium aggressiveness oil IRM903, is an aggressive oil containingnaphthenic, aromatic and aliphaticconstituentsSpecificationsCover TypeCharacteristicCover PropertiesSwelling TestTensileStrength h(MPa)Elongation@ Break(%)AbrasionLoss(mm3)% swell afterimmersion inIRM 302 for 2815DBP OilTECH GMedium Oil resistance16400130DBP OilTECH G Superior oil resistance16400130DBP OilTECH G1Medium oil resistance &fire resitant according toDIN ISO 3401645017012% swell afterimmersion inIRM903 for 72h515

DBP FLAMETECHFire retardent V gradeDBP FlameTECH conveyor belting has rubber covers that providegood tear, cut, impact and abrasion resistance and is also fireretardant.The belt is available in a complete range of multiply strengthsand also with steel cord reinforcement. Tests carried out onDBP FlameTECH conveyor belting for determining fire retardingproperties.1) Flame test - ISO 340:2013 test method2) Electrical conductivity of the belt surface ISO 284:2012 test method3) Fire propagation test - EN 12881-1 test methodSafety levelStandard norm/testsBelting nameRisk1ISO 340DBP FlameTECHEP or ST Level 1Prevention of the propagation of accidental fire from a minor firesource aboveground and the risk of explosion due to the accumulationof static electricity.1GISO 340DBP FlameTECHEP or ST G1 - Level 1Idem safety level 1 and additionally oil-resistant.2DIN EN ISO 12882 according tocustomer specificationDBP FlameTECHEP or ST Level 2Prevention of the propagation of accidental fire from an extensive firesource aboveground and the risk of explosion due to the accumulationof static electricity.3DIN EN ISO 14973 according tocustomer specificationDBP FlameTECHEP or ST Level 3Prevention of the propagation of accidental fire from an minor orextensive fire source underground, the risk of explosion due to theaccumulation of static electricity and the risk of belt blockage.SpecificationsCoverAbrasion mm³Elongation atbreak min. in %Min. ambienttemperatureConstant materialtemperatureMax. temporarymaterialtemperaturePolymer basisK/S200350-208090SBRVT or V175350-208090CRFire retarding propertiesFlame test - ISO 340:2013Electrical ConductivityISO 284: 2012Fire propogation - EN 12881 - 1 Method CTotal of 6 samples extinguishwithin 45 seconds Maximumduration of flame or glow for anysingle sample is 15 seconds 300 Megaohma) the length of the test piece that remains undamaged acrossthe whole width of the test piece shall be not less than 600 mm;orb) the maximum average temperature rise shall not exceed 140 C,the length of belting consumed by mass shall not exceed 1250 mmand the length of the test piece that remains undamaged shall benot less than 50 mm across the whole width of the conveyor belt.13REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

DBP LIFTTECHThe cover quality especifically suited for bucket elevatorsThe DBP LiftTECH range of belting is specifically suited touse in bucket elevators.The tightly woven carcass is available in 4 and 5 ply constructionsor as a solid woven carcass construction. The 4 and 5 plyDBP LiftTECH belts are offered with a very wide range of highperformance rubber covers to suit any bucket elevator applicationthat transports abrasive materials and/or hot materials.DBP LiftTECH conveyor belts with a solid woven carcass construction have PVC impregnated carcass and Nitrile rubber covers.This alternative is suited to elevator buckets transporting grains,pea and duff coal, dry cement powder and similar products.For very high elevators where tensions are large, DBP LiftTECH STis recommended.This high strength belt has galvanised steel cord reinforcement.The cords are spaced so that bolts holding the buckets align withthe space between cords thereby ensuring that the bolts aresecurely retained for the maximum bucket stability.SpecificationsBelt classMaximumTension (kN/m)PropertyNumber of PliesSteel CordCarcass456Solid WovenCarcass50050Mass (kg/m )Thickness (mm)5.34.36.35.2––13.83.663063Mass (kg/m2)Thickness (mm)5.34.36.65.57.56.314.33.610.56.280080Mass (kg/m2)Thickness (mm)6.35.76.96.27.96.715.93.611.06.91000100Mass (kg/m2)Thickness (mm)6.35.58.27.28.27.617.83.611.77.41250125Mass (kg/m2)Thickness (mm)7.36.38.57.010.28.518.64.413.08.41600160Mass (kg/m2)Thickness (mm)23.15.215.09.92000200Mass (kg/m2)Thickness (mm)25.76.218.212.22500250Mass (kg/m2)Thickness (mm)27.96.722.614.6142

DBP FLEXTECHTextile straight-warp belts from 400 N/mm in 1 ply to 2500 N/mm in 2 pliesDBP FlexTECH is a polyester «straight- warp» belt composed ofone or two plies protected on both top and bottom sides by weftlines in polyamide.Due to the thin carcass, DBP FlexTECH can be used with smallerpulley diameters than textile plied or steelcord belts.Straight-warp conveyor belts are used on heavy duty conveyorswhere resistance to the effects of heavy impacts and resistanceto tearing are important characteristics, typically seen inquarrying, open cast mining and steel industries or in applicationswhere heavy-duty and yet narrow belts are required, such as intunnelling.The carcass frame thus constructed is adhered RFL and may becoated of different types of rubber cover, anti-abrasive ( X , Y , etc.),oil-resistant (G, G ), heat-resistant (T150 , T200 ), etc.SpecificationsCoverCover classificationTemperatur range CPolymer basisAbrasion mm³Elongation atbreak min. in %Min. ambienttemperatureConstant materialtemperatureMax. 00-208090SBR/NBRG 8090SBRV/VT175350-208090CR15REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

DBP REMAWELLSidewall conveyor beltsREMA TIP TOP has further extended itscomprehensive portfolio for industrialapplications and now offers both thedesign and production of REMAWELLsidewall conveyor belts from a singlesource.REMAWELL special conveyor belts permitthe steeply inclined or vertical transportof all kinds of bulk material. The components are: the base belt, sidewalls andcleats, which define a constant transportvolume and thus ensure a reliabletransport of material even if the conveyorrouting is skewed.Order-based design and manufacture,together with the REMA TIP TOPworldwide service network, forms thebasis of professional original manufacturer support and includes allaspects of maintenance and overhaulservices through to replacement ofcomplete belts.Conventionalmultiply carcass16Cross stabilisedCross stabilised

DBP REMAWELLSidewall conveyor beltsDBP REMAWELL belts are mainly supported at the free edge forredirection by the deflection wheels and in the area of the stubrollers in the return strand. It is therefore especially importantthat the belt offers a high degree of lateral rigidity.The REMAWELL base belt therefore contains cross stabilisedplies in the top and bottom cover in addition to conventionalmultiply carcass. Their use ensures a high lateral rigidity of thesidewall belts and thus minimum lateral sagging when runningaround the deflection wheels or on the stub rollers.Due to its wear resistant properties and high resistanceagainst ozone, the rubber cover gives the greatest possibleservice life.DBP REMAWELL belts are designed and customised individually for each application. The components needed to manufacture the DBP RemaWELL belts are available ex-warehousein many different sizes.SpecificationsBelt typeNominaltensilestrengthN/mmNo. of crossrigid pliesNo. ltthicknessmmMax availablewidthsmmXE 250/2250-2**3/290SBRXE 400/3400-3**3/2100SBRXE 500/3 2500235/390NRXE 630/4 2630245/390NR/SBRXE 800/5 2800255/3170SBR* Effective cover thickness above the cross stabilised plies** Cross rigid versionOther belt types and cover grades on request.17REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

SPECIAL BELT CONSTRUCTIONSDBP FlowTECH – Pipe conveyor beltingPipe conveyor systems offer manyadvantages in terms of space utilisation.They also provide potential for a cleaneroperating environment as the product isfully enclosed in the belt formed into apipe for the length of the conveyingroute.DBP FlowTECH is a special adaption ofeither DBP POWAPLY or DBP POWACORDconveyor belting.The unique carcass design, either usingtextile plies or, for higher strength andreduced elongation, a combination ofsteel cords and textile ensures that thepipe form provides optimum fill crosssection throughout the service life ofthe belt. Also the more flexible beltedges allow tight pipe closure withoutincreasing resistance to movementthrough the encircling idler rollers.DBP SlideTECHDBP SlideTECH incorporates a specialhigh density fabric weave preventingrubber striking through duringvulcanization. There is no rubber onthe bottom.The belt slides effortlessly across thesupporting solid plate that replacescarrying idler rollers.18

SPECIAL BELT CONSTRUCTIONSDBP ChevronTECHA variety of chevron patterns aremoulded into the top cover to allowconveying at an angle in the rangefrom 16 to 35 .DBP Self-AdjustTECHDBP Self-AdjustTECH is a beltconstruction used to ensure propercentring of the troughed belt.In many instances belt trackingmisalignment occurs and this invariablyleads to belt edge damage, materialspillage and damage to the conveyorstructure.These special belts have an additional plyof stiffened fabric extended across thecentre third. A mistracking force isopposed by the correcting force as thestiff upper ply moves away from the flatcentre area of the trough.19REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

REMA TECHNOLOGIESMaximizing the profitability and sustainability of your conveying systemsREMA TIP TOP TECHNOLOGIES focus on optimizingthe use of our products and services to remain marketleaders. We offer unique solutions for specificoperations that focus on profitability andsustainability.Our systems have been designed to provide our clientswith greater insight into the current status of theirconveyor belts by providing real time data showing anyform of damage, allowing planned maintenance andshortening production downtime.REMA TIP TOP TECHNOLOGIES constantly develop newsystems that will significantly prolong the lifetime of ourclients conveyor belts. As conveyor belts are the backbone of any mine and their greatest expense, our newsystems can be utilized on all types of conveyor beltswhilst in full operation.211 BTM BELT THICKNESS MONITORING S hows all wear and damage to theconveyor belt A ccurate reporting of belt wear or damage P redicts the remaining lifetime of the belt G enerates a belt image after the first revolution202 STEEL CORD SCAN A vailable as a modular or fixed installation S hows all cord damage to the conveyor belt I ndicates the health of all splices O perates continuously while the beltis in full operation

43Without the use of REMA M³equipment. The possible loss ofthe full length of installed conveyorbelt with downtime in excess of135 hours.600550500450400350300250200150100 12 hours5004 RFID BELT RIP DETECTION U nique RFID Antenna ID Code S tops the belt when longitudinal rips are detected A ntennas can be detected at 15m/s Antennas installed at shorter intervals to offergreater protection160 135 hours140120100with REMA M³80without REMA M³60Downtime - hoursBelt Length - m3 INDUCTIVE SENSOR LOOP DETECTION C ompatible with all inductive antenna sensor loops Stops the belt when longitudinal rips are detected Generates a belt image of embeddedsensor loops after one revolution Inductive sensor loops and RFID antennas aremonitored simultaneously40200Comparison Graph21REMA TIP TOPDBP CONVEYOR BELTING PORTFOLIO

REMAPRESS IVEState of the art conveyor belt pressesNew vulcanizing presses „REMAPRESS IVE“ with pressure bags, heating plates and silicone heating mats developed and marketed byREMA TIP TOP impress with highest quality features, application oriented design and certification by German TÜV.Components1 Crossbeams2 Pressure distribution sheet3 Pressure bag,certified by German TÜV4 Heating plate5 Conveyor belt6 Edge rail7 Heating plate8 Tension bolt9 Crossbeams10 RackOur characteristic features Rotable carrying handle for crossbeams andheating plates Equal surface pressure over the complete splicing due toREMA TIP TOP pressure bag certified by German TÜV Pressure bag with aramid inlays meets highest safetystandards 20% less deflection of crossbeams 20% less liquid requirement, therefore faster build-up ofpressure than comparable presses from market competitors Tension bolt threads protected against damage Despite being made of high-strength steel, the tension boltsweigh 2kg less apiece than conventional steel tension bolts Tension bolts sealed up and that way protected against soiling Lightweight, high-strength pressure distribution sheet madeof aluminium Pressure water system:AIR: For pressures up to 70 N/cm² (100 Psi)FLUID: For pressures up to 140 N/cm² (200 Psi)22 CE-, CSA- and UL-certified electronics Heating plate connection, protection classIP 64 certified by German TÜV Optimized monitoring of temperature difference Available for voltages from 230 to 600 Volt Control cabinet, protection class IP 44 Optional data recording within control cabinet,data export via USB interface Usable in admissable ambient temperature from -20 C to 55 C Distinct colours for pressure hoses (red/black)and cooling water hoses (blue/white) Silicone heating mat with vulcanized-onintermediate plate Transport-proof, plugable connection cable

TECHNICAL DATAREMAPRESS IVE AIR/FLUIDSLA Plate widthB Plate lengthBW Belt widthSL Splicing length Rhombic 16 42‘ABWBRef. No.SpecificationBelt widthBW (mm)Plate width(A) (mm)Splicinglength (SL)(mm)Plate length(B) (mm)Crossbeamsdimensions(mm)Crossbeamslength (mm)No. ofcrossbeams(pairs)Technical data REMAPRESS IVE AIR595 9460REMAPRESS IVE AIR 650-600650750600800150 x 1021.1004595 9470REMAPRESS IVE AIR 800-600800900600800150 x 1021.2504595 9490REMAPRESS IVE AIR 1000-6001.0001.100600800150 x 1021.4504595 9580REMAPRESS IVE AIR 1200-6001.2001.300600800200 x 1021.6505595 9540REMAPRESS IVE AIR 800-8008009008001.046 150 x 1021.2506595 9560REMAPRESS IVE AIR 1000-8001.0001.1008001.046 150 x 1021.4506595 9590REMAPRESS IVE AIR 1200-8001.2001.3008001.046 200 x 102 1.6506595 9610REMAPRESS IVE AIR 1400-8001.4001.5008001.046 256 x 1121.9006595 9550REMAPRESS IVE AIR 800-10008009001.0001.200 150 x 1021.2507595 9570REMAPRESS IVE AIR 1000-10001.0001.1001.0001.200 150 x 1021.4507595 9600REMAPRESS IVE AIR 1200-10001.2001.3001.0001.200 200 x 102 1.6506595 9620REMAPRESS IVE AIR 1400-10001.4001.5001.0001.200 200 x 102 1.9007595 9630REMAPRESS IVE AIR 1600-10001.6001.7001.0001.200 256 x 11262.100Other dimensions available on request.Technical modifications reserved.Ref. No.SpecificationBelt widthBW (mm)Plate width(A)

DBP SlideTECH Sliding conveyor belt EP 315 - 2500 All categories DBP SolidTECH SOLID WOVEN conveyor belts EP/B/PB 630 - 3150 AA*- W/D - X/H - Y DBP ChevronTECH Steep-incline belts EP 400 - 1000 All categories DBP REMAWELL Sidewall conveyor belts EP 400 - 2000 All categories ST 500 - 5400 REMA TIP TOP Portfolio of Conveyor Belting