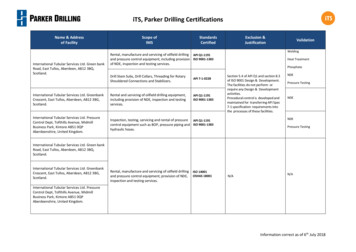

Transcription

IADCPresentation2016Mike SmithManaging DirectorDrilling StructuresInspectionAndAdvanced Corrosion ToDrilling Structures

IntroductionDRILLING DERRICKS - OFFSHOREBiggest Piece of Lifting and Handling equipment onyour rigYour average Offshore Derrick on a jack up has alifting capacity of 500t and only requires a visualinspection every 2 yearsAn average Offshore Crane will have a liftingcapacity of roughly 30 - 50t and is subject toinspection every six months

IntroductionCOMPLACENCY REGARDING DERRICKS?WHY DO WE HAVE COMPACENCY TOWARD DERRICKSHIGH AND RELATIVELY INACCESSABLE AREAS FOR CREWRIG MAINTANENCE NOT NORMALLY INCLUSIVE OF STRUCTURE EXPERTISERESTRICTED ACCESS OPPORTUNTIES DUE TO RIG OPERATIONSLACK OF INTERNAL INSPECTION PROCEDURESLACK OF TRAININGSCARED OF HEIGHTS

IntroductionMAINTENANCE SCARED OF HEIGHTS?DON’T BE SURPRISED!RESEARCH HAS SHOWN THAT;49% OF 18 – 24 YEAR OLDS ARE SCARED OF HEIGHTS61% OF 40 – 59 YEAR OLDS ARE SCARED OF HEIGHTSIF YOU ARE OVER 60 YOU DON’T EVEN WANT TO KNOW THE %DON’T BE SURPRISED IF THERE IS RELUCTANCE BY SOME TOCARRY OUT DERRICK RELATED MAINTANENCE

IntroductionDERRICK INSPECTION STANDARDSAPI RP 4G IS THE INDUSTRY STANDARD FOR DERRICK INSPECTIONSTHE RP STILL HAS A STRONG BIASE TOWARD LAND RIGSRP CAN BE SUBJECT TO, AND OFTEN IS INTERPRETATION, LEADING TOINEXPERIENCED INDIVIDUALS AND/OR COMPANIES UNDERTAKINGINSPECTIONSOFFSHORE DERRICKS TOTALLY EXCLUDED FROM CAT IV INSPECTIONSQUALIFICATION REQUIREMENTS OF DERRICK INSPECTORS STILL NOT CLEARLYDEFINED

API RP 4G Recommended PracticeInspection Periods - Land Rigs Category III Inspections Every 2 Years Category IV Inspections Every 10 YearsInspection Periods – Offshore Structures Category III Inspections Every 2 Years Category IV Inspections – API States Not Required

Why are Cat IV Inspections excluded from Offshore DrillingDerricks No definitive answer from API but suggested that when introduced in original andsubsequent issues of the RP 4G, it was assumed that it would be necessary to dismantlethe structure to inspect it, much the same as is done on a Cat IV on land rigs Standards committee now advised that with rope access and NDT technics of today it isnot necessary to dismantle a derrick to inspect it to 4G CAT IV A new subcommittee of API RP 4G has subsequently been established to incorporate CatIV inspection of offshore drilling derricks included in 4G 5th edition 2017 Some Drilling Contractors already carry out Cat IV inspections in line with the five yearlyinspections of the hoisting equipment

Why do we need a Category IV Inspection on an OffshoreDerrickTHE PRESENCE OF ADVANCED CORROSION INHOLLOW SECTION MEMBERS SUCH AS;DERRICK STEM MEMBERSBOX GIRDERS (CROWN & R/BOARD)RACKING BOARD SUPPORT FRAMESACCESSORIES SUCH AS HANDRAILSPicture shows total through thickness corrosion from the insideout on a primary load bearing member of the derrick

More examples of corrosionTotal through thickness corrosion to hollowsection membersOnceLimitinga defect ispotentiallycostlyselected,suggesteduser errors.correctiveactionsare also shownto the user.

More examples of corrosionThrough thickness corrosion to derrickhorizontal girtOnceLimitinga defect ispotentiallycostlyselected,suggesteduser errors.correctiveactionsare also shownto the user.

More examples of corrosionThis picture illustrates that it is not just the concealeddefects that are getting overlooked.Believe it or not this rig is still working and to ourknowledge this defect has not been addressed.OnceLimitinga defect ispotentiallycostlyselected,suggesteduser errors.correctiveactionsare also shownto the user.

More examples of corrosionNot particularly difficult for the “DerrickInspector” to find this particular issue,So why didn’t he?

Why has this corrosion gone unnoticed on Offshore DrillingStructures API 4G category IV recommends thickness gauge checks to hollow section members The exclusion of Category IV inspections in API 4G for offshore drilling structures hasresulted in most all hollow section members to develop unchecked advancedinternal corrosion Unqualified inspectors and inspection companies have not identified these issues Single inspector undertaking derrick inspection will not be able to use rope accessin accordance with safety requirements, therefore he will not be able to accessareas away from ladders and platforms

What were the potential consequences of the internalcorrosion on the hollow section member DSL carried out a structural analysis of the derrick in question based upon its condition at thetime of inspection It was revealed that the derrick could only safely accommodate 40% of the original design load ofthe derrick in its current condition The rig owner was previously unaware of this corrosion or its potential consequences of thederrick incurring loads above that percentage. There was a high probability of complete member failure in one or more of the load bearingmembers which in turn would have overloaded corresponding members and could have led to acomplete collapse of the derrick

Contributing factors to the development of such defects; Inconsistency in standard with regard to API 4G Category IV inspections due to therecommendations in current and past editions of 4G Lack of drill crew training for drilling structures inspection Qualification for drilling structures inspectors only recently established Inspections being carried out by unqualified individuals and/or unqualified companies Failure of inspectors to raise the seriousness of issues with the rig owner one man inspection teams unable to access all areas Failure to act upon the recommendations of inspections

The way forward for offshore derrick inspection Next edition of API 4G (5th edition) will include Category IV inspections for offshore structures (DSLare represented on the API 4G sub committee) Recommend that thickness gauging of hollow section members on offshore structures isIncorporated into your next Cat III or IV inspection Drill crews should receive training on drilling structure inspection to reduce the accumulation ofunidentified defects in the structure between periodical inspections Industry to drive up the Inspection standards going forward

IntroductionDERRICK INSPECTION PROCUREMENT GUIDEANCE PROCUREMENT OF DERRICK INSPECTIONS Qualification of proposed inspectors should be verifiedprior to mobilisation Ensure that the deliverables of contractor includes a“recommended corrective actions report” for any defectsfound Do not consider one man inspection teams for derrickinspections Due to recent findings request thickness gauge testing onany hollow section members in your derrick Consider API 4F Licenced companies that have the internalexpertise to comment on actual or potential issues

The way forwardVendors need to be encouraged to committo providing qualified inspectors to ensureintegrity in the inspection and to avoidserious defects going undetectedThis will in turn lead to an increase ininspection standardsDSL has created a training andexamination course for API 4G drillingstructures inspectors that is API and IADCapproved

The way forward for offshore derrick inspectionDrill crews to be taught API4G category I & II inspectionrequirementsDSL provides an e-learningsolution for drill crews

Summary Next edition of API 4G will require Cat IV inspections on offshore structures In the meantime particular attention should be given to the inspection of hollow sectionmembers in offshore derricks, especially those over 10 years old Cat I & II training of drill crews will help early detection of defects and avoid long list of correctiveactions after periodical inspection Specifying qualified drilling structures inspectors will help to drive up standards in the industry toeliminate poor inspections and reporting Ensure that you obtain a corrective actions report from your supplier for 4G inspections Complete corrective actions to avoid further deterioration

Better safe than sorry

No definitive answer from API but suggested that when introduced in original and subsequent issues of the RP 4G, it was assumed that it would be necessary to dismantle the structure to inspect it, much the same as is done on a Cat IV on land rigs Standards committee now advised that with rope access and NDT technics of today it isFile Size: 1MBPage Count: 22