Transcription

Fast.Flexible.Drilling.Our CNC Processing CentersDRILLTEQ H-600YOUR SOLUTION

02HOMAG DRILLTEQ H-600Contents

HOMAG DRILLTEQ H-600ContentsDRILLTEQ H-600 –Drilling just for professionals.Never before was our drilling competence packaged in such a clear, competentand innovative way. For years, the DRILLTEQ H-600 has impressed by speed andprecision – in workpiece handling as well as in processing. Every drill is executedwith an extreme repeat accuracy. The same applies to routing and groovingoperations. The workpiece surfaces are perfectly protected despite extremely highprocessing speeds. The possibility to process two workpieces simultaneously leadsto extreme efficiency and the varied connection possibilities of the machine provideextreme flexibility. The result: CNC-Xtreme. Finest coordinated technology whichcan be combined.YOUR SOLUTIONMORE: HOMAG.COMDRILLTEQ H-600CONTENTS04DRILLTEQ H-600 – There’s no limit to flexibility06DRILLTEQ H-600 – 3D-model08All inclusive – Hardware10Configuration12Connection possibilities14Additional equipment – Options15tapio16powerTouch218Life Cycle Services19Technical data03

04HOMAG DRILLTEQ H-600There’s no limit to flexibilityThere’s no limit to flexibilityUP TO 104 SPINDLES can provide precise processing in any fields of application. Choose from a clever variety of equipmentsthe correct one for your application. And when horizontal drilling is required. no problem for the DRILLTEQ H-600.

HOMAG DRILLTEQ H-600There’s no limit to flexibilityLIKE A CHAMELEON.Never was a processing center more flexible regardingits connection possibilities – whether robot or gantryfeeder, right or left hand side, manual or automatedINCREDIBLY FAST.A travel speed of up to 130 m/min provides a rapidexecution of the tasksEVERYTHING UNDER CONTROL.Two CNC-controlled clamping devices ensurepermanently firm and precise positioning of theworkpieces – regardless of the speedEASY HANDLING.Even a workpiece thickness of up to 80 mm (2 x 40mm) is easy to handleCYCLES ARE PROTECTED.Thickness control and length measuring ensure safeprocess cyclesPRECISE IN DEPTH.The patented spindle clamp ensures an alwaysaccurate drilling depth for all drillingCONSTANTLY AT TOP LEVEL.The closed straight guiding system is protected againstdust and dirt and thus very durableBEING SMOOTH – ENSURING QUALITY.The Smooth-Pressure System provides for aprotecting air cushion below the workpiece and thus fora high-quality workpiece handling05

06HOMAG DRILLTEQ H-6003D-modelDiscover the possibilities.FOR THE ORIENTATION IN THE MACHINE LOGIC OF THIS SERIES, theDRILLTEQ H-600 with pre-positioning unit is exemplified here as 3D-model.1122Pre-positioning (optional)CNC-controlled clamping system··Fast and easy automation of the process chain··Easy handling by fence guidance··Safe positioning by clamping cylinder··Quick and precise – no setting times··Integrated measuring system for workpiece length··Integrated control system for workpiece thickness··Workpiece thickness up to 80 mm (2 x 40 mm)3

HOMAG DRILLTEQ H-600434ABCDoweling aggregates (optional)Aggregate for processing of 6th side (optional)··High flexibility even with low batch sizes··Each one dowel inserting tool at the left and right hand side of the··Complete processing of the workpiece··Routing aggregate with 2 spindles (A)··Corner notching saw (0 / 90 / 180 ) (B)··Drilling aggregate with 3 spindles (C)aggregate3D-model07

All inclusive – HardwareTHE STANDARDS IN THE HARDWARE OF THE DRILLTEQ H-600 leads this machine to a premium level with regard toquality assurance, flexibility and performance. Even at highest speeds precision and repeat accuracy are guaranteed for alloperations.CNC-controlled clamping system··Quick and precise – no setting times··Integrated measuring system forworkpiece length··Integrated control system for workpiecethickness··Workpiece thickness up to 80 mm(2 x 40 mm)Divided tableTBO-System ··The front part of the table can be moved··Clamping device opens at top and atupwards and downwards for easyprocessing at the zero linebottom – no contact with the workpiece··No friction points

HOMAG DRILLTEQ H-600All inclusive – Hardware„The simple way“··As required, the operator gets fast and easy access to the processing aggregates··Cleaning and maintenance tasks are easier to handle12341Air cushion3Table2Pressure beam4WorkpieceSmooth-Pressure System Automatic spindle clamping··Pressure beam and table create a small, but very solid air cushion··Optimal and smooth feeding of workpieces··Controlled air consumption··Patented system··Always exactly the same drilling depth – irrespective of materials··Constant quality by high repeat accuracy09

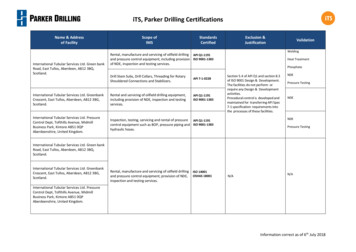

10HOMAG DRILLTEQ H-600Configuration and equipmentConfiguration and equipmentCLOSE TO PERFECTION! The configuration variety of the drilling equipment for the DRILLTEQ H-600 provides all possibilitiesregarding your requirements.56Configuration 0026 23-spindles··2 x 23 vertical drilling spindles··2 x 4 horizontal drilling spindles in X··2 x 1 horizontal drilling spindle in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle84Configuration 0037 36-spindles0026··2 x 36 vertical drilling spindles··2 x 4 horizontal drilling spindles in X··2 x 2 horizontal drilling spindles in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle92Configuration 0025 36-spindles0037··2 x 36 vertical drilling spindles··2 x 8 horizontal drilling spindles in X··2 x 2 horizontal drilling spindles in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle

HOMAG DRILLTEQ H-600Configuration and equipment96Configuration 0034 38-spindles··2 x 38 vertical drilling spindles··2 x 8 horizontal drilling spindles in X··2 x 2 horizontal drilling spindles in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle98Configuration 0032 41-spindles0034··2 x 41 vertical drilling spindles··2 x 6 horizontal drilling spindles in X··2 x 2 horizontal drilling spindles in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle104Configuration 0033 42-spindles0032··2 x 42 vertical drilling spindles··2 x 8 horizontal drilling spindles in X··2 x 2 horizontal drilling spindles in Y··2 x swivelling grooving saw (90 )··2 x 6 kW ETP routing spindle11

12HOMAG DRILLTEQ H-600Connection possibilitiesDiscover the connection possibilities –at least one is for you.LIKE A CHAMELEON THE DRILLTEQ H-600 HARMONICALLY ADJUSTS TO THE ENVIRONMENT. Here is an excerpt ofour most established versions from a range of connection possibilities. All possibilities from manual feeding up to fully-automaticprocesses are provided.

HOMAG DRILLTEQ H-600Example AExample BExample CExample DExample EExample FConnection possibilities13

14HOMAG DRILLTEQ H-600Additional equipment – OptionsAdditional equipment – OptionsWITH THIS ADDITIONAL EQUIPMENT you can further optimise and automate your machine.Pre-positioningHorizontal special buffer system··Fast and easy automation of the process chain··Easy handling by fence guidance··Safe positioning by clamping cylinder··For manual feeding and removal of workpieces··Higher buffer capacity on relatively small base areaBarcode connectionAir-conditioning··Barcodescanner / -software··Supported barcodes: 1D – Barcode 2D – Data Matrix Code··Every workpiece is excactly identified for the further workpiece··Air-conditioned switch cabinet··Provides permanently solid temperatures even under challengingflowclimatic conditions – continuous system protection

Apps thatmake workinglife easier.··Protects machine andconfiguration expertise··Faster service for machinebreakdowns··Saves time when restartingproduction··Saves on maintenance costs··Automatic backups of severalmachines··Create service cases quicklyand easily and send them to thecorrect service partner··Live video diagnostics to solveservice cases with image support··Video reduces the language anddistance barriers··Also works without a machineconnection to tapio (andis therefore ideal for oldermachines)··Push notifications··Machine data and status can beviewed from anywhere in realtime··Lists of errors, warnings,maintenance tasks and actions··Displays the remaining timeuntil the next intervention by themachine operatorFree demo for all tapio apps, no registration required. Simply download and test.tapio is the open wood industry ecosystemThis means that everyone involved in the wood industry can participate.Because together with our business partners, we develop digital solutions for everyone.This means that everyone involved in the wood industry can participate.Because together with our business partners, we develop digital solutions for everyone.

16HOMAG DRILLTEQ H-600powerTouch221341The powerTouch2 screen is clearly structured. You cansee all the important information at a glance, but youstill have all the details.2We have also improved the traffic light dialog further.You can now directly influence the machine‘sproduction readiness by selecting actions via thetraffic light icon.3A functional pop-up keyboard that can be kept open,including automatic word completion for faster entries(when you enter the first letters, frequently usedapplications are proposed and you can select themdirectly).4Enhanced “Start” menu with additional informationdisplayed (e.g. an indication of how many messagesare currently pending or status bars that show theprogress of the application) and direct access toactions (e.g. confirmation of actions without having tojump to the application).

HOMAG DRILLTEQ H-600powerTouch2The next generationof powerTouch:powerTouch2Faster, more comfortable, clearer: Enjoy the benefits ofour further improved powerTouch user interface. We haveoptimized our standardized operating concept and furtheradapted it to our customers‘ requirements.Controlling your HOMAG machines is now even faster andmore intuitive. The new, modern design has a clear structure.The innovative touch operation allows you to achieve thedesired result easily and comfortably.With the new powerTouch generation, you can enterinformation at your machine even more quickly. Comparedto the previous version, you can achieve a time saving ofup to 30%. This is possible thanks to new features, such asautomatic word completion, a pop-up keyboard that can bekept open and Windows-like functions, such as the selectionof common actions directly via the start button.Our successful powerTouch philosophy –standardized, simple, ergonomic, evolutionary – consistently further developedTHE HIGHLIGHTS AT A GLANCE:··Direct and efficient operation, up to 30% faster··Clearer and more informative thanks to additional informationand live illustrations instead of program icons··New applications for operating and controlling machines andsystems (e.g. NCCenter in the PC87 control system on CNCmachines or woodCommander 4 on throughfeed machines)··Fresh, attractive design, based on the new HOMAG machinedesign17

For you more than.181,350service employees worldwide90 %less on-site service thanks tosuccessful remote diagnosis5,000customer training sessions per / year150,000machines, all electronically documentedin 28 different languages – in ePartsOptimal service and individual consultations are included inand fast customer solutions, we can guarantee excellentthe purchase of our machines. We provide support throughavailability and cost-effective production for the entire lifeservice innovations and products that are tailored exactly tocycle of your machine.your company’s requirements. With short response timesREMOTE SERVICESPARE PARTS SERVICEFIELD SERVICE··Hotline support via remote diagnosis by··High spare parts availability and fast··Increased machine availability and··Ensuring quality by predefined spare··Regular checks through maintanance /··Identify and inquire for spare parts online··We offer you the highest availability ofour trained experts regarding control,mechanics and process technology.Thus, more than 90 % less on-siteservice required and consequently afaster solution for you!··The ServiceBoard App helps to solvetasks in a fast, simple and concreteway. This is achieved by mobile livevideo diagnosis, automatic sending ofservice requests or the online spare partscatalog eParts.delivery.parts and wear parts kits, comprisingoriginal spare parts.under www.eParts.de 24/7, or buy evenfaster and more comfortably in the newHOMAG Webshop eCommerce.product quality by certified service staff.inspection guarantee the highest qualityof your products.technicians in order to reduce downtimesin case of unpredictable troubles.

HOMAG DRILLTEQ H-600Technical dataTechnical dataL*990H1H2970S065W*Position of switch cabinet freely selectable*Dimensions in mmSETTING UP DIMENSIONSDRILLTEQ H-600DRILLTEQ H-600 FUNCTION DOWELINGDRILLTEQ H-600 FUNCTION 6TH SIDEDRILLTEQ H-600 FUNCTION 6TH SIDE FUNCTION DOWELINGLmm / inch7,350 / 289.48,060 / 317.39,300 / 366.19,390 / 369.7Wmm / inch3,850 / 151.64,750 / 1873,850 / 151.64,750 / 187H1mm / inch2,120 / 83.52,120 / 83.52,120 / 83.52,120 / 83.5H2mm / inch2,800 / 110.22,800 / 110.22,800 / 110.22,800 / 110.2Smm / inch1,000 x 800 / 39.4 x 31.51,000 x 800 / 39.4 x 31.52,000 x 600 / 78.7 x 23.62,000 x 600 / 78.7 x 23.6DRILLTEQ H-600DRILLTEQ H-600 FUNCTION DOWELINGDRILLTEQ H-600 FUNCTION 6TH SIDEDRILLTEQ H-600 FUNCTION 6TH SIDE FUNCTION DOWELINGTECHNICAL DATAWorkpiece feeding dimensionsmm2,500 x 1,3002,500 x 1,3002,500 x 1,3002,500 x 1,300Workpiece dimensionsmm2,500 x 1,0002,500 x 1,0002,500 x 1,0002,500 x 1,000Travel range of theX - Y - Z-axism/min138 - 80 - 50138 - 80 - 50138 - 80 - 50138 - 80 - 50Compressed air connectioninch11x1 1x½11x1 1x½Compressed air requiredbar7777Dust extraction portmm2x Ø 2802x Ø 2802x Ø 280 1x Ø 1602x Ø 280 1x Ø 160Dust extraction volumem³/hmin. 2x 4,450min. 2x 4,450min. 2x 4,450min. 2x 4,450Electrical power –total connection ox. 5,500

extreme flexibility. The result: CNC-Xtreme. Finest coordinated technology which can be combined. YOUR SOLUTION MORE: HOMAG.COM DRILLTEQ H-600 CONTENTS 04 DRILLTEQ H-600 – There’s no limit to flexibility 06 DRILLTEQ H-600 – 3D-model 08 All inclusive – Hardware 10 Configuration 12 Connection possibilities 14 Additional equipment – Options 15 tapio 16 powerTouch2 18 Life Cycle