Transcription

HOT RUNNERREFURBISHMENTAND MAINTENANCEPROGRAMSEXTEND CAPACITY& PERFORMANCE

HOT RUNNER REFURBISHMENT AND MAINTENANCE PROGRAMSEXTEND CAPACITY AND PERFORMANCEWhile many molders have strict maintenance programs for their molds, some look at their hot runnersystems as a mystery and better left untouched. Hot runner melt delivery and management is just ascritical to molding productivity as the cavity, cores, and cooling, so why not apply the same disciplineand critical evaluation when it comes to melt delivery?Continually inspecting and maintaining your hot runner system ensures that it constantly operates atpeak performance. In addition to maintenance, system refurbishment can also be done dependingon the condition of the system.Our RefurbishmentProcess Steps Include:Molders can implement a variety of refurbishmentmeasures that deliver a range of benefits including: Discussion of timing requirements Initial review of your hot runner Dismantling and cleaning Modify or rework (as required)Reset of meltdelivery to 100%cavitationAssurance ofhighest partquality andoutputConfidencein increaseduptime andoperating lifeMuch lowercost thanoutrightreplacementOpportunity toimplement newtechnologies orconversionsHot runner refurbishment or maintenance programs can refresh or replace wear items in theassembly with genuine Husky replacement parts. Inspection of key features of the hot runner ensuresthat bore depths and preload are still within tolerance, and tip and stem heights meet criteria neededfor proper mold interface. Upon completion of assembly, the hot runner is heat-tested to confirmall heaters and thermocouples work as required. All work is performed by highly trained Huskytechnicians.Refurbishment ensures that the hot runner operates at maximum performance with the longestpossible operating time, until a process modification is needed to account for performance. Greaterconfidence in the hot runner system helps the entire molding system achieve 100% cavitation withmaximum possible output and quality, while also reapplying Husky’s three-year leakproof guaranteewhen a Platinum rebuild is completed.All refurbishment work is completed by trained Husky Experts Reassembly, testing,and inspection Packaging and shipmentA range of service tiers are available to meet cost and timing requirements. These range from aplatinum-level cleaning with full rebuild including all new components and full inspection, to a basiclevel cleaning where all parts are re-used at reassembly.Open communication throughout the refurbishment program is an important part of the process. Weissue progress reports and provide updates and changes along the way. Upon completion, Huskysupplies a final inspection report of the hot runner. Root cause analysis and troubleshooting isconducted upon request.Refurbishment is not limited to recently-purchased hot runners. Husky has been a leadingmanufacturer of hot runners for more than 50 years, and complements its offering with extensiverebuilding services.Conversions are also an excellent time for refurbishment. In some cases, a single-faced hot runneror mold is reconfigured to operate as a stack mold. In other instances, the nozzles are replacedto accommodate a new “L” dimension or nozzle protrusion spec, preloads are adjusted, manifoldsmodified to accommodate a different resin, or old nozzle tips converted to utilize modern designs.After refurbishment, the hot runner is returned in “as-new” condition with documentation outlining allinspection, work details, and replacements. Molders can have complete confidence that the upgradedmelt delivery system will return the injection molding line to its peak operating level.turn this.into thisSeveral steps are involvedto ensure a hot runneroperates like new

TYPICAL HOT RUNNER MAINTENANCE RECOMMENDATIONSHOT TIP SYSTEMSWhether it is a full refurbishment program or a standard maintenance package, Husky’s expert hotrunner team can recommend the best approach to secure the most value, performance, and servicelife from your system.3110996Item10Clean and visually inspect nozzle tip insert, tipretainer seal-off diameter and tip insulator 2Clean and visually inspect sprue bushing Perform a meter check on all electricalcomponents Verify electrical readings to electrical schematic Visually inspect for plastic leakage Remove water fittings and check for corrosiondeposits within channels Analyze water if necessary 6Clean and visually inspect locating ring 7Inspect manifold heater and heater insulation 5 Clean and inspect melt channels 9Replace center locating insulator, nozzle discsprings and back-up pads 10Replace nozzle tip inserts, tip retainers and tipinsulators Remove sprue bushing Clean melt channel and rework spherical radius Replace sprue heater and thermocouple 127211543–4YearsRemove manifolds and nozzle stacks from plates81151YearRemove manifold backing plate496Months1315Maintenance Task

TYPICAL HOT RUNNER MAINTENANCE RECOMMENDATIONSVALVE GATE SYSTEMSWhether it is a full refurbishment program or a standard maintenance package, Husky’s expert hotrunner team can recommend the best approach to secure the most value, performance, and servicelife from your system.311312568ItemClean and visually inspect nozzle tip retainer, tipinsulator and valve stem 2Clean and visually inspect sprue bushing Perform a meter check on all electricalcomponents Verify electrical readings to electrical schematic Remove manifold backing plate Clean plastic leakage around valve gate back uppad / manifold surface Remove valve gate cylinder and piston assembly Clean and visually inspect air sealing surfaces 4155 Replace valve gate piston seal Remove water fittings and check for corrosiondeposits within channels Analyze water if necessary 8Clean and visually inspect locating ring 9Inspect manifold heater and heater insulation 74 Clean and inspect melt channels 11Replace center locating insulator 12Replace nozzle disc spring and back-up pad 13Replace nozzle tip retainer, tip insulator and valvestem Remove sprue bushing Clean melt channel and rework spherical radius Replace sprue heater and thermocouple 14792143–4YearsRemove manifolds and nozzle stacks from plates1071YearClean and inspect valve gate piston6116Months1310Maintenance Task15

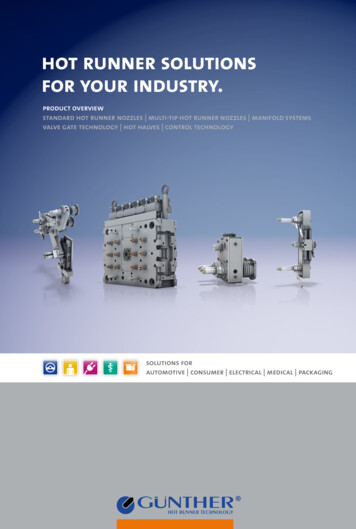

HOT RUNNER REFURBISHMENT SERVICESFOR HOT RUNNER SYSTEMS (INCLUDING PLATES)Husky Hot Runner Refurbishment ServicesServicesHOT RUNNER REFURBISHMENT SERVICESFOR MANIFOLD ONLY SYSTEMSHusky Hot Runner Refurbishment ServicesPlatinum Package RebuildGold Package Cleaing/InspetionSilver PackageCleaning/InspectionBronzeLevel CleaningServicesGold Package Cleaing/InspetionSilver Package ManifoldCleaning/InspectionBronzeLevel CleaningFull disassembly Full disassembly Fluidized bed cleaning (manifold) Fluidized bed cleaning (manifold) Fluidized bed cleaning (parts) Fluidized bed cleaning (parts) Inspection of manifold N/AInspection of manifold N/AInspection of components N/AMelt channel cleaning N/AN/A N/AMelt channel cleaning Melt channel bore scope inspection N/AMelt channel bore scope inspection Melt channel extrude hone & wash Melt channel extrude hone & wash Heat test Heat testN/AN/AN/AAir leakage test Air leakage testInspection of componentsRework Components (if applicable)Silver PackageCleaning/InspectionBronzeLevel Cleaning N/AN/AN/ABacking plate grind & jig boreN/AN/AN/AN/AManifold plate grind & jig boreN/AN/AN/AAll manifolds grind & jig boreN/AN/A All manifolds grind & jig bore N/AN/AN/APlatinum Package RebuildGold Package Cleaing/InspetionSilver PackageCleaning/InspectionBronzeLevel Cleaning N/AN/AN/A3-year Leak-proof WarrantyN/AN/AN/ASilver Package ManifoldCleaning/InspectionBronzeLevel CleaningN/AN/AN/A N/AGold Package Cleaing/InspetionSilver Package ManifoldCleaning/InspectionBronzeLevel CleaningVG piston seal **N/AN/AVG grafoil seal **N/AN/AVG crush ring (if applicable) **N/A N/AN/A Platinum Package RebuildGold Package Cleaing/InspetionSilver PackageCleaning/InspectionBronzeLevel Cleaning N/AVG crush ring (if applicable)Warranty and Coverage3-year Leak-proof Warranty6-months parts workmanshipHot Runner Refurbishment Replacement PartsHot Runner Refurbishment Replacement PartsVG grafoil sealRework Components (if applicable)Gold Package Cleaing/InspetionN/A6-months parts workmanshipVG piston sealN/ABronzeLevel CleaningGold Package Cleaing/InspetionManifold plate grind & jig boreComponentsN/ASilver Package ManifoldCleaning/InspectionPlatinum Package RebuildBacking plate grind & jig boreWarranty and CoverageN/AGold Package Cleaing/Inspetion ComponentsVG cylinder N/AN/AVG cylinderNozzle tip insulator N/ANozzle tip insulator **N/A N/AN/ANozzle tip N/AN/ANozzle tipValve stem N/AN/AValve stemN/ANozzle housingNozzle housing N/AN/ANozzle heater N/AN/ANozzle thermocouple *N/ANozzle heater front ringNozzle disc spring/ spring pack N/AN/ANozzle locating insulator (Ultra) N/AN/AN/AAnti-rotation ring (Ultra) N/AN/AN/AHT back up insulator padVG back up InsulatorVG piston * *N/A * *N/AN/AN/AN/AN/AN/AN/A N/AN/AN/A N/AN/AN/AVG piston spacer Manifold bushingManifold heaterManifold thermocouple N/AN/AManifold compression disc N/AN/AManifold spring pack N/AN/ACenter locating insulator N/AN/ASprue heater N/AN/AN/ASprue thermocouple *N/AN/ASprue bushing N/AN/AN/ALocating ring N/AN/AN/AGuide pin N/AN/AN/AElectrical base N/AN/AN/AElectrical connector N/AN/AN/A* Only replaced if damaged** Only supplied if full nozzle stack is returned with systemPlatinum refurb requires plates to be sent in N/AN/AN/AN/AN/ANozzle heater N/AN/ANozzle thermocouple N/AN/ANozzle heater front ring N/AN/ANozzle disc spring/ spring pack N/ANozzle locating insulator (Ultra)N/AN/AN/AAnti-rotation ring (Ultra)N/AN/AN/AHT back up insulator pad * *N/AVG back up Insulator * *N/AVG pistonN/AN/AN/AVG piston spacerN/AN/AN/AManifold bushingN/AN/AN/AManifold heaterN/AN/AN/AManifold thermocouple N/AN/AManifold compression disc N/AN/AManifold spring pack N/AN/A N/AN/AN/AN/AN/A *N/AN/ASprue bushingN/AN/AN/ALocating ringN/AN/AN/AGuide pinN/AN/AN/AElectrical baseN/AN/AN/AElectrical connectorN/AN/AN/ACenter locating insulatorSprue heaterSprue thermocouple* Only replaced if damaged** Only supplied if full nozzle stack is returned with systemPlatinum refurb requires plates to be sent in

Husky Technologies husky.coHead OfficeAsia PacificEuropeCanada Tel (905) 951 5000 Fax (905) 951 5384China Tel (86) 21 2033 1000 Fax (86) 21 5048 4900Luxembourg Tel (352) 52 11 51 Fax (352) 52 60 10Please recycle. 21-133-11-2021Husky Technologies is the owner of registered trademark “Husky” as well as trademarks“Commitment Made, Delivered and Maintained”, “Schöttli” and “Husky Advantage Elite” in theUnited States and other countries, and these trademarks may be used by certain of its affiliatedcompanies under license. All Husky products or service names or logos referenced in thesematerials are trademarks of Husky Technologies and may be used by certain of its affiliatedcompanies under License. 2022 Husky Technologies . All rights are reserved.Disclaimer: Information is made available in this flyer “as is” and no warranties are given or liabilitiesof any kind are assumed with respect to the quality of such Information, including, but not limitedto, its fitness for a purpose, non-infringement of third party rights, accuracy, completeness or itscorrectness. Except as set forth in Husky’s written warranty, Husky makes no additional warranties,whether express, implied or statutory. Certain conditions may apply. For more details please requesta copy of Husky’s written warranty and Standard Terms and Conditions.”

TYPICAL HOT RUNNER MAINTENANCE RECOMMENDATIONS HOT TIP SYSTEMS Whether it is a full refurbishment program or a standard maintenance package, Husky's expert hot runner team can recommend the best approach to secure the most value, performance, and service life from your system. Item Maintenance Task 6 Months 1 Year 3 - 4 Years 1