Transcription

Dk300jElectric ScrewdriversGENERAL CATALOG

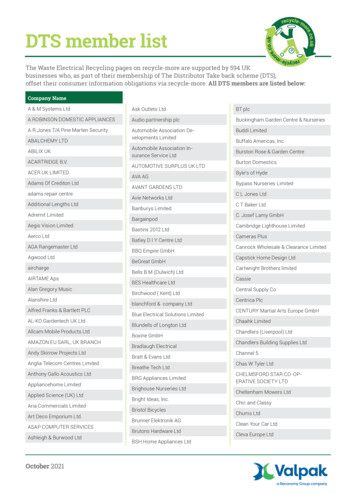

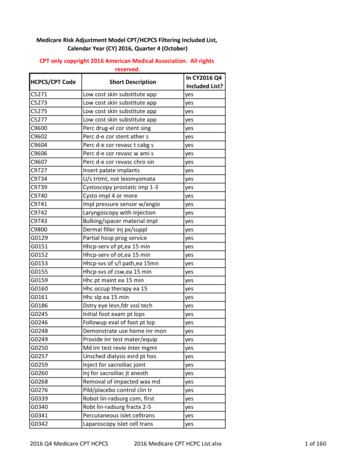

Selection mationFeaturesStarting 0/240 V ACDLV7410A/7410HA/7420ABit GroundingLow ShockESDDLC1110DLV7419A/7419HA/7429ABit GroundingLow ShockESDClean RoomBit GroundingLow 820/5820H/5840Bit GroundingESDDLV7313/7321/7323/7331/7333Low VoltageDLV7325/7335Clean RoomDLV7321-B EDLV7331-B merlessHigh SpeedDLV7530/7540Torque Reach LightDLV7550Torque Reach LightHigh TorqueDLV8530/8540Torque Reach V8150Torque Reach LightHigh TorqueTransformerlessTransformerlessHigh 100/115/230/240 V AC100/220 V AC24 V AC100 V AC100 V ACBLever StartPush to StartLever Start100/115/230/240 V AC100/115 V ACPush to Start230 V ACLever StartDLC4511-GGBDLR1510-JEPush to StartLever StartTransformerlessHigh TorqueTransformerlessTransformerlessHigh TorqueDLV8221DLV8231/8241TransformerlessHigh SpeedDLV8251TransformerlessHigh TorqueDLV02/12/16Brushless /3131/3141/3151DLV30 A -DJNDLV45 A -DKNDLV70LA -DKN100/115/230 V ACDLC1213A-Clean RoomLow ShockESDTransformerlessHigh TorqueDLV8550Lever odel7400A711Electric ScrewdriverSeriesTransformerlessBrushless MotorLow VoltageBrushless Motor115 V ACPush to StartLever StartLever StartPush to StartLever StartPush to StartLever StartPush to StartLever StartPush to StartLever StartPush to StartLever StartPush to StartFor AutomationExternal InputBrushless MotorFor AutomationExternalInput SignalDLC16S-W B100 - 240 V AC230 V ACDLR70S-WGBDLC70S-WGBDLC3310100 - 240 V AC24 V AC100 V AC100 V AC

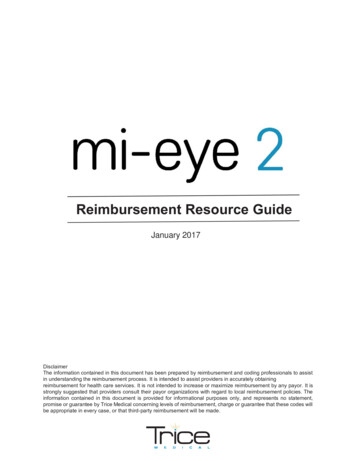

Selection ChartThis chart is for reference only.Torque (Nm)modelDLV-0 0.02 0.03 .0 - 2.37313Up to 2.0020.150.20.250.30.350.40.450.50.550.70.75 0.9511.11.21.51.61.7Torque (Nm)2.00 0.022.70.033.00.053.80.10.157.00.2Torque RangeScrew Size(mm)1.0 - 2.273217323732533211.0 - 2.31.0 - 3.01.0 - 3.07020575080201.0 - 3.07420A/7429A57405740H58401.6 - 2.61.4 - 3.0122.0 - 3.073192.2 - 4.0162.0 - 3.073292.3 - 2.6312171208120712481242.6 - 3.070318031703080302.0 - 3.02.0 - 3.57333733533312.0 - 3.5722072218220822182242.6 - 3.02.6 - 5.0303.0 - 3.573392.6 - 3.531317130723181308231713481348234753085302.6 - 4.03.0 - 3.5734975408540714072418140824171448144824431413.5 - 5.03.5 - 5.07251815082518154755085503151454.5 - 6.05.0 - 8.070Torque (Nm)4.50 0.02 0.03 0.050.10.150.20.250.30.350.40.450.50.550.70.75 0.9511.11.21.51.61.72.02.73.03.84.57.02

NITTO KOHKI's "Delvo" Electric Screwdrivers are high-quality tools for professional use, withspecial emphasis on precise torque control and long life. They always apply just the correctamount of torque with accurate and positive control at your fingertips. They are smooth andshockless in operation, too. NITTO KOHKI's customer-oriented service system through our salesagents ensures that you can use Delvo Electric Screwdrivers with a high degree of reliability.ShocklessSophisticated clutches and motor braking mechanismreduce the shock at the end of the screw tighteningoperation and causes less fatigue.Long LifeMotor brushes stand over a million tightening cycles.They can be replaced easily.Brushless motors are adopted.They are eco-friendly, long life, and cover wide torquerange.High AccuracyHigh repeatable torque accuracy provides moreconsistent screw tightening torque.Models for 16 seriesDLV30/45/70-M G seriesDLV30/45/70-IKE seriesDLC70S/DLR70S-WGBHigh SpeedHigh-speed torque motors cut down screw tighteningtime and enhance productivity.Safety StandardsModels with CE Marking (for the European Union) orCCC (for People’s Republic of China) are available.QuieterCompare Delvo with a conventional pneumaticscrewdriver, and you will hear the difference.3Models for the People’s Republic of 40HC/5750CDLC0350GC/0950GCDLV30/45/70-M C seriesDLV30/45/70-SPC(M C) seriesDLR5040A-WC

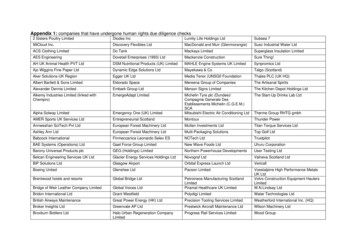

Green ProcurementNITTO KOHKI has made every effort in environmental improvement schemes on a company-wide basisthrough the implementation of ISO14001 to execute environmentally conscious business activities. As a partof our ongoing commitment to improve the environment, we are also committed to exclude or reducerestricted chemical substances in our products, as designated by the RoHS directives and Laws andRegulations of Chemical Substances in Japan. For further details, please see the following:Nitto Kohki group companies’ Green Procurement Guidelines have beenestablished by their environmental committee which consists of membersfrom all the Nitto Kohki group of companies. Nitto Kohki group companiesgive preferential treatment to suppliers that work to an environmentalpolicy framework. Nitto Kohki group companies periodically survey theirsuppliers to ensure their chemical management systems include themonitoring of environmental issues such as the RoHS directives, andJapanese laws and regulations of Chemical Substances to minimizepackaging and waste. We are continuing our goal to ensure that ourmade-to-order items are also covered by our environmental policy.Green Procurement PolicyEach of the Nitto Kohki group companies is clarifying the controlcategories of the environmental management substances included in theparts and auxiliary materials constituting Nitto Kohki products and thoseof the environmental management substances used in the manufacturingprocesses. We will promote prohibition and reduction of use of theenvironmental management substances according to such controlcategories. Through these activities, we will comply with various laws andregulations related to the environmental management substances andreduce the impact to the global environmental conservation and to theecological system.Scope of ApplicationOur Green Procurement Guideline applies to all materials, parts,products, and auxiliary materials which Nitto Kohki Group companiespurchase for production or sales.Our Green Procurement ActivitiesNITTO KOHKI group companies continually aim to comply with RoHSdirectives, and Japanese laws and regulations of Chemical Substances. Standard products have been RoHS compliant. Green procurementactivities on made-to-order products are continuing. NITTO KOHKI group companies are now working to the REACHRegulation. NITTO KOHKI group companies are building a database of the chemicalmanagement substances regulated by the RoHS directives, the REACHRegulation and Japanese laws and regulations of Chemical Substances.CONTENTSSelection ChartDLV7400A seriesDLV5700 seriesDLV5800 seriesDLV7300 seriesDLV7300-BME / BKE seriesDLV7000 / 8000 seriesDLV7104 / 8104 / 8204 seriesDLV7500 / 8500 seriesDLV7100 / 7200 / 8100 / 8200 (115 V) seriesMultiple ControllersDLV02 / 12 / 16 seriesDLV30 / 45 / 70 seriesDLV30 / 45 / 70-IKE seriesDLR70S-WGBDLC70S-WGBDLV3100 / 3300 seriesDLV30 / 45 / 70 automation seriesDLR5040A / 5340-WEDLR5640-WNScrewdrivers designed for DLR5640-WNTorque CheckersAccessoriesAccessories / Optional CordSleeves and Vacuum PickupsNK 4

DLV7400A seriesFor Miniature Screws (1.0 - 2.6 mm)FeaturesThe light and compact body reduces operator fatigue The built-in coreless motor achieves reduced inertia Torque accuracy is within a top-ranked worldwide level(Based on measurements at our laboratory) Compliant with CE standards Use of the Screw Fastening Counter prevents human fasteningerrors and enhances accurate fastening control (No CE markingor CCC applied) Screw Fastening Counter Model DLR5640-WN works in conjunctionwith any dedicated SPC-type electric screwdriversseries Reduces shock applied to workpieces when fastening screws ESD (electrostatic discharge) protection compliant with IEC61340-5-1 Lightweight (Standard type 230 g, Clean room type 275 g) The Clean Room Type complies with Class 3 Clean Room Rating The controller can adjust speed(Screw-fastening speed can be set to suit specific fastening conditions) The controller provides a soft start function The initial speed at screwdriver startup can therefore be sloweddown, effectively preventing screw heads from being ationsDLV7410A-BMEDLV7419A-BMEStandard TypeClean Room TypeStarting MethodInput VoltageTorque Adjustment(Nm)Torque(min-1)Free SpeedPower Consumption(W)Screw SizeMachine Screw(mm)Tapping Screw500 - 750DLV7410HA-BMEDLV7419HA-BMELever Start40 V DCStepless0.02 - 0.21.0 - 2.31.0 - 2.0ø4(mm)(g)Plug ShapeControllerMassModelFeaturesInput VoltageControl FunctionPlug ShapeMassAsiaBit51.6 - 2.61.4 - 2.311Standard type 230 / Clean room type -HEDLC1213A-GGB*1 DLC1213A-HEB*1StandardStandardStandardWith CE MarkWith CE MarkWith CE MarkStandard100 V AC, 50/60 Hz 115 V AC, 50/60 Hz 220 V AC, 50/60 Hz 230 V AC, 50/60 Hz 240 V AC, 50/60 Hz 230 V AC, 50/60 Hz 240 V AC, 50/60 HzSoft Start, Speed Control, ESD ProtectedAsiaAsiaUKEuropeUKEuropeUK(g)2,300900*1: An optional cord is required to connect with this model.EuropeUKNeither DLC1213A-GG nor DLC1213A-HE can be used with the DLV7400A series.Model DLC1213A-GGB or DLC1213A-HEB Cord DLW9072Standard AccessoriesNo.No.0 1.8 44No.0 2.5 44No.1 4 44Connection Cable DLW9070Spring for Low TorqueSuspension BailSleeve for Vacuum DLS21240.15 - 0.4450 - 600700 - 1,000Approx. 103.5Bit TypeDLV7420A-BMEDLV7429A-BME2Electric 20A1111-DLV7419A111111DLV7419HA111111DLV7429A11111

For Miniature Screws (1.0 - 2.6 mm)Torque Diagrams (for reference)0.45High TorqueSpring(black)0.200.150.10Low 9A-BME0.50Bit Torque e Scale23456789Torque ScaleShock Waveform Comparisonbetween the 7400A series andour conventional modelsseries1Shock valueOur conventional modelsPeak shock value : 33 GValue of shock applied to the workpiece asmeasured using acceleration pickup.DLV7400A seriesPeak shock value : 8 GTimeExternal DimensionsOptional AccessoriesDLV7410A/7410HA/7420A-BME165.5Holder clamp7Lever SwitchØ3236SleeveCouplingTorque Adjustment RingThis minimizes tampering or accidental turningof the torque adjustment ring once the torque is 3Ø32* Please see page 32 for details.Torque Adjustment Ring CoverDLW5700 (TD02875)Forward/ReverseChangeover SwitchLock NutVacuum PickupDLP5300 (TD04342)DLV7400ABit Torque LC111013.5Connector for ScrewdriverSpeed Adjustment KnobSoft Start Knob150Power Swich485291Power LampUnit: mm6

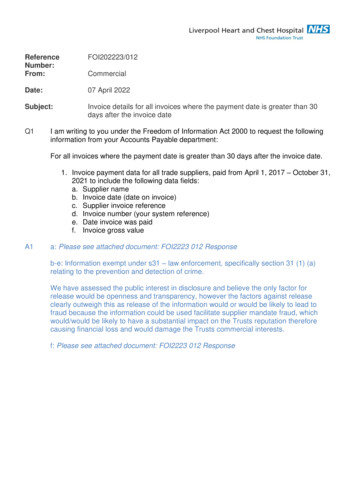

DLV5700 seriesFor Miniature Screws (1.0 - 3.0 mm)FeaturesFor quality improvement and productivity enhancement Grounded bit installation mechanism Electro-static discharge (ESD) control Low-shock for tightening(30 % less of standard models) Low swing bit mechanism Ergonomic design High-performance DC motor New clutch 0950ModelStarting MethodInput VoltageTorque Adjustment(Nm)Torque(min-1)Free SpeedPower Consumption (W)Screw Size Machine Screw(mm)Tapping ScrewBit TypeDLV5720HDLV5740Lever Start40 V DCDLV5740H0.02 - 0.2700 - 1,000Approx. 10500 - 7500.15 - 0.4450 - 6001.0 - 2.31.0 - 2.0DLV575036 V DCStepless1,200 - 1,800Approx. 3521.0 - 3.01.0 - 2.6ø411230DLC0350E100 V AC, 50/60 Hz0.1 - 0.55670 - 1,0001.6 - 2.61.4 - 2.33.5(g)ModelInput Voltage300DLC0350F115 V AC, 50/60 HzAsia Grounding wire U.S.A.UKDLC0350G230 V AC, 50/60 HzDLC0950E100 V AC, 50/60 HzDLC0950G230 V AC, 50/60 HzAsia Grounding wirePlug Shape(g)DLV5720Bit Torque (Nm)0.25DLV5720H11-BitNo.No.0 1.8 44No.0 2.5 44No.1 4 44Connection Cable(1.5 m)DLW9081Suspension BailSpring for Low Torque1111-0.150.101External Dimensions34567Torque ue Adjustment Ring CoverDLW5700 (TD02875)234567Torque Scale8Holder clamp36Forward/ReverseChangeover SwitchCouplingDLC035091Lock NutCouplingDLC095099150Power lampExternal output terminal6.5Forward/ReverseChangeover Switch172External output terminal52486965Power lamp188.5Lever switchTorque Adjustment Ringø32Lock NutThis minimizes tampering or accidental turningof the torque adjustment ring once the torque is set.9DLV5740H/5750165.5Lever switchHolder clampVacuum PickupDLP5300 (TD04342)* Please see page 33 for details.0.250.20DLV5720/5720H/5740Torque Adjustment RingSleeve0.100.05Spring forLow Torque (silver)20.550.500.45DLV5750Optional AccessoriesDLV5740/5740H/57500.60Spring forHigh Torque 574038Standard AccessoriesTorque Diagrams(for reference)1,800900ø32MassBit Torque (Nm)ControllerDLV5720(mm)MassDLV5700seriesElectric ScrewdriverSpecificationsSoft-Start Adjustment KnobSpeed Adjustment KnobConnector for screwdriver7Power SwitchSoft-Start Adjustment KnobSpeed Adjustment KnobConnector for screwdriverPower SwitchUnit: mm

DLV5800 seriesFor Miniature Screws (1.0 - 2.6 mm)FeaturesIn response to the needs of cell production systemspace-saving DELVO screwdrivers are released.Controller is designed for emphasis on space-saving size and lightness. Clear disengagement of clutch (low-shock mechanism unavailable) Grounded bit installation mechanism ESD (electrostatic discharge) protection New lever is adopted Low swing bit mechanism Low voltage transless controllerDLC0250EDLV5820/5820H/5840DLC03501.0 - 2.31.0 - 2.00.15 - 0.46001,000Approx. 101.6 - 2.61.4 - 2.33.5(mm)(g)Mass(m)Cord LengthGrounding Bit Feature(g)U.S.A.Plug ShapeAntistatic materialCase Material* Electric screwdrivers DLV5800 series can be also used withDLC0350.2301.5 (with connector)Equipped as standardTorque Diagrams (for reference)No.DLV5820 DLV5820HNo.0 1.8 441No.0 2.5 441No.1 4 44Suspension Bail1Connection Cable (1.5 m)1Spring for Low Torque (Silver)1BitDLV58401111-Optional AccessoriesDLV5820/5820H0.250.20Vacuum PickupDLP5300 (TD04342)0.150.1012Torque Adjustment Ring CoverDLW5700 (TD02875)34567Torque Scale80.300.200.150.10Spring forLow Torque (silver)0.040.02* Please see page 33 for details.0.40Spring for High Torque(black)0.05DLV58400.50Bit Torque (Nm)Standard AccessoriesSleeve11Bit Torque (Nm)Bit TypeDLC0250E100 V AC, 50/60 HzGrounded Bit Installation Mechanism30091234567Torque Scale89series750ModelInput VoltageFunctionMassDLV5840DLV58000.02 - 0.2DLV5820HLever Start40 V DCSteplessControllerDLV58202ModelStarting MethodInput VoltageTorque Adjustment(Nm)Torque(min-1)Free Speed(W)Power ConsumptionScrew Size Machine Screw(mm)Tapping Screwø4Electric ScrewdriverSpecificationsThis minimizes tampering or accidental turning of thetorque adjustment ring once the torque is set.External DimensionsDLV5820/5820H/5840Connection cable1.5 m165.568Lever switchø3236DLC0250ETorque AdjustmentRingHolder verseChangeover Switch40Lock NutUnit: mm8

DLV7300seriesFor Miniature Screws (1.0 - 3.5 mm)Features The dedicated controller realizes high-accuracy screwtightening High repeatable torque accuracy The controller provides a soft start function. The initialspeed at screwdriver startup can therefore be sloweddown, effectively preventing screw heads from beingscratched. Variable speed adjustment enables to select optimumscrew tightening speed. DLV7325, DLV7335 meet Class 5*1 Clean Roomstandards*1: Based on Nitto's standard of 7321-CMEDLV7323-CKEDLV7321-CKE0.03 - 0.150.05 - 0.51.0 - 3.01.2 - 2.63502For 05 - 0.5700 - 1,0000.3 - 1.2500 - 7001.0 - 3.01.2 - 2.62.0 - 3.52.0 - 3.0400EuropeOptional AccessoriesTorque AdjustmentRing Cover for DLV7303DLW5500 (TD00333)Mass(kg)ControllerPlug ShapeDLV7325-CME*2Vacuum pump for suction of screw is*2 : availableas option. See page 31 for detailsof the vacuum pump.ModelFeaturesInput Voltage Control FunctionPlug ShapeDLC1213A-ENStandard100 V AC, 50/60 HzAsiaDLC1213A-FE*3Standard115 V AC, 50/60 HzUKStandard220 V AC, 50/60 HzDLC1213A-GESoft start,EuropeWith CE Mark230 V AC, 50/60 Hz Speed controlDLC1213A-GGUKWith CE Mark230 V AC, 50/60 HzDLC1213A-GG UWithout PlugStandard240 V AC, 50/60 HzDLC1213A-HE2 Screwdrivers for 1 Controller 100 V AC, 50/60 HzDLC1215-EN*4Asia2 Screwdrivers for 1 Controller 220 V AC, 50/60 HzDLC1215-GE*44Multiple Controller24 V AC, 50/60 HzDLC2310-CE*AsiaDLE3610A-EN*4 Power Supply for DLC2310-CE 100 V AC, 50/60 Hz*3 : This model is made to order. *4 : See page 16 for details of the models other than DLC1213A series.AsiaDLC1213AClean Room er Start36 V DCStepless0.3 - 1.2500 - 700Approx. 352.0 - 3.52.0 - 3.0700 - 1,000Up to 2.0Up to 1.7DLV7325/7335This minimizes tampering or accidental turningof the torque adjustment ring once the torque is set.Torque Diagram (for reference)2.31.2UKStandard AccessoriesSleeveBitNo.0 1.8 44No.0 2.5 44No.1 3 44No.1 4 44No.1 7 50No.2 4 44No.2 4.5 50No.2 7 50DLS2124DLS2127DLS2130DLS2134DLS2135Suspension BailDLV7321 / 23 DLV7331 / 33 DLV7321 / 23 /-CME-CME31 / 7325 / 35-CKE11DLV7313/7323/7333DLV7321/7331DLV7323 / 7333 : 22536Lever Switch923456145PilotLampReceptacleCord 2 mPower SwitchPlugSoft-Start Adjustment KnobLever SwitchNozzle for ConnectionVacuum PumpCord1.5 mTorqueAdjustment Ring7Torque Scale247Lever Switchø32Cord 1.5 m1DLV7325/7335/7319/7329/7339Forward / ReverseChangeover Switchø40Plug5TorqueAdjustment RingDLV7313143ø32Forward / ReverseChangeover Switch0.4DLC1213A21540ø30ø34DLV7313 : 215DLV7321/7323/73250.60.050Speed Adjustment KnobExternal 33/73351.00.369Cord1.5 mSleeveForward / ReverseChangeover Switchø40DLV7313-CME11ø4DLV7321/7331Bit Torque (Nm)Electric ScrewdriverBit Type (mm)Bit Shank:ø4 mmModelBit Shank:Hex.6.35 mmStarting MethodInput VoltageTorque Adjustment(Nm)Torque(min-1)Free SpeedPower Consumption (W)Screw Size Machine Screw(mm)Tapping Screw(g)MassFor CME3.5DLV7300seriesSpecificationsUnit: mm

DLV7300-BME/BKEseriesFor Miniature Screws (1.0 - 3.5 mm)FeaturesWorkpiece-conscious electric screwdriversseries Statistic electricity buildup is prevented to protect workpiecesfrom electrostatic discharge Minimal impact in screw tightening protects workpieces fromdamaging and enables stable screw tightening ESD (electrostatic discharge) protection compliant withIEC61340-5-1 Meet Class 5*1 or more Clean Room standards*1: Based on Nitto’s standard of measurementESD / Low ShockDLV7329-BME*2 DLV7339-BMEDLV7319-BME*2ø7For BKE(g)MassTorque DiagramDLV7349-BME*2(for reference)3.0 - 3.52.6 - 3190.40.30.2923DLV73491.00.45 - 0.950.55 - 1.2500 - 70023.5For BMEB1.2Lever Start36 V DCStepless0.2 - 0.40.25 - 0.55700 - 1,000Approx. 352.0 - 3.02.0 - 2.6Bit Type(mm)DLC1213A-Bit Torque (Nm)ESDBit Shank:ø4 mm DLV7321-BME*2 DLV7331-BME*2ModelDLV7321-BKEDLV7331-BKEBit Shank:Hex. 6.35 mmStarting MethodInput VoltageTorque Adjustment0.3 - 1.20.05 - 0.5(Nm)Torque(min-1)500 - 700700 - 1,000Free SpeedPower Consumption (W)2.0 - 3.51.0 - 3.0Screw Size Machine Screw(mm)Tapping Screw2.0 - 3.01.2 - 2.6ø4Electric que Scale7ControllerMeasurement PointPower CableBitSleeveNo.0 2.5 44No.1 3 44No.1 4 44No.1 7 50No.2 4 44No.2 7 50DLS2124DLS2127DLS2130DLS2134Suspension BailPartMaterialSynthetic resin with carbon fiberStatic Electricity(V)3505Handle Lever SwitchSurface Resistance( )more than 1013104(V)Power CableStatic Electricity3502Surface Resistance( )more than 1013104Static Electricity(V)252Static Electricity(V)110Surface Resistance( )more than 105101310DLV7319/29 DLV7339/49-BME-BME1* Measurement conditions (Temperature:22 Humidity:66 %)(1) Static electricity Earth the measurement equipment and measuring person.Grip the screwdriver five times using Ansel Edmont electronic control glove.Turn on the switch of the screwdriver. Measure each part of the screwdriverusing electronic measurement equipment manufactured by Shishido electrostatic Ltd.(2) Surface resistance Measure using Simco Japan surface resistivity measurementequipment. ----19DLV73 1-B E : 215DLV73 9-BME : 247Lever Switch-- 1-Anti-static materialExternal DimensionsStandard AccessoriesNo.EScrew Suction PumpConnection NozzleConnect with Suction PumpDLP2500(Option)ø40Forward / Reverse SwitchDLV7300-BU.S.A.ø32Lever SwitchUKEuropeScrew Suction Sleeve-102HandleConventional ProductPlug Shape*2 : These models are made to order.Input VoltagePlug ShapeControlMass(kg)Model100 V AC, 50/60 HzUSADLC1213A-ENBGrounding,USADLC1213A-FEB*3 115 V AC, 50/60 Hz2.3Soft Start,230VAC,50/60HzEuropeDLC1213A-GGBSpeed Control240 V AC, 50/60 HzUKDLC1213A-HEB*3 : This model is made to order.DLV7300-BME/BKEDLV73Power Cable1.5 mForward/Reverse Changeover SwitchB145PilotLampReceptaclePower SwitchSpeed Control Volume Soft Start Adjustment VolumePower Cable 2 mUnit: mm10

DLV7000/8000 seriesFor Miniature Screws (1.0 - 3.5 mm)Features100 / 115 V AC Direct Transformerless Precision Miniature Screw Typeseries A built-in controller model saves space and facilitates layout change High repetitive torque accuracy Available with lever type (DLV7000 series) for each screw alignmentand push to start type (DLV8000 series) for rapid screw tightening The high-speed type (DLV7031/8031) available at 1,200 min-1 forimproving work efficiency (100 V AC only)DLV7000 V8020-FME*1DLV8030-FME*1Lever StartPush to StartStepless0.3 - 1.10.1 - 0.550.3 - 1.10.05 - 0.55650900650900Approx. 252.0 - 3.51.0 - 3.02.0 - 3.51.0 - 3.02.0 - 3.01.2 - 2.62.0 - 3.01.2 - 2.6100 V AC Input115 V AC InputStarting MethodTorque Adjustment(Nm)Torque(min-1)Free SpeedPower Consumption (W)Screw Size Machine Screw(mm)Tapping ScrewModel(g)Mass400High SpeedDLV8031-EMNDLV7031-EMNLever StartPush to Start0.3 - 1.01,200Approx. 302.0 - 3.02.0 - 3.023.5(mm)Bit Typeø4Electric ScrewdriverDLV7000/8000DLV8000 series11410400410AsiaPlug Shape(EMN/FME type)*1 : These models are made to order.No.No.0 2.5 44No.1 3 44No.1 4 44No.2 4 44Torque Diagram (for reference)DLV7020 / 80201DLV7030 / 8030 / 7031 / 80311.5--11-DLV7030/80301-1Suspension BailBit Torque (Nm)Optional AccessoriesTorque Adjustment Ring CoverDLW5300 (TD00332)1.0DLV7031/8031DLV80200.5This minimizes tampering or accidental turningof the torque adjustment ring once the torque is set.DLV702001External Dimensions345Torque Scale76DLV8020/8030/8031Cord 3 m3244Forward/Reverse Changeover SwitchForward/Reverse Changeover Switch32DLV7020/7030/70312Cord 3 m44BitStandard AccessoriesLever Switch240236Torque Adjustment Ring11Torque Adjustment RingUnit: mm

DLV7104/8104/8204 seriesFor Machine Screws (2.6 - 6.0 mm)FeaturesThe most popular models have been redesignedDLV7104 arting MethodLever StartInput VoltageTorque Adjustment(Nm) 0.25 - 0.75 0.5 - 1.7Torque(min-1)Free Speed900Power Consumption (W)Screw Size Machine Screw 2.6 - 3.02.6 - 4.0(mm)Tapping Screw 2.3 - 3.02.3 - MKHDLV8144MJEDLV8144MJHDLV8144MKEDLV8144MKHHigh 44MKEDLV8244MKH2.0 - 4.54000.35 - 0.72,0000.5 - 1.71,8001.2 - 3.01,1004.5 - 6.04.5 - 5.09102.6 - 3.02.3 - 3.02.6 - 4.02.3 - 3.57103.5 - 5.03.0 - 4.0Push to Start230 V AC, 50/60 HzStepless0.25 - 0.75 0.5 - 1.71.2 - 3.09006001.2 - 3.0600353.5 - 5.03.0 - 4.0For MJE/MJHBit TypeDLV8154High 6 - 3.02.3 - 3.02.6 - 4.02.3 - 3.57103.5 - 5.03.0 - 4.0For MKE/MKH524ø6ø71496.35unit : mmFor MJE/MKEU.S.A.23UKTorque Diagram (for reference)For MJH/MKHBit Torque (Nm)Electric ScrewdriverModelPlug ShapeDLV8104/8204seriesStandard AccessoriesFor MJE/MJH Bit No.1 6 70: 1 pc. Bit No.2 6 70: 1 pc. Spare Carbon Brush: 2 pcs. Suspension Bail: 1 pc.For MKE/MKH Bit No.1 7 75: 1 pc. Bit No.2 7 75: 1 pc. Spare Carbon Brush: 2 pcs. Suspension Bail: 1 pc.For 8154-MKE/MKH Bit No.2 7 75: 1 pc. Bit No.3 7 50: 1 pc. Spare Carbon Brush: 2 pcs. Suspension Bail: 1 134/8DLV7124DLV7124/81.504.0154V8DL3.512Torque Scale3456789External Dimensions48ChangeoverSwitchCord 3 m134264Brush HolderBit51ChangeoverSwitchCord 3 m134DLV815426413451Torque Scaleø50ø39.5ø50ø39.5Lever24140Torque Scale73Torque AdjustmentRing CoverTorque AdjustmentRingTorque AdjustmentRing Cover951Torque AdjustmentRingø50BitDLV8124 / 8134 / 8144 / 8224 / 8234 / 8244263Brush Holderø39.5DLV7124 / 7134 / 7144DLV7104/8104/8204series Equipped with bit grounding mechanism Long-life cam is utilized The clear plastic torque adjustment ring cover minimizesunintentional tampering of the preset torque The changeover switch enables operators to change forward/reverserotation with a single hand The ergonomically designed grip can be held tightly to resistagainst tightening reaction force, resulting in reduced operatorfatigue40unit: mm12

DLV7500/8500 seriesFor Machine Screws (2.6 - 6.0 mm)FeaturesLow vibration, low noise, and easy gripping in a compact designseries The easily visible torque reach light goes on when the set torque is reached The combination of an advanced clutch design and the auto-stop circuit assures torque accuracy The long life motor with a yoke made of advanced materials further assures a long service life Compliant with CE standard ESD (electrostatic discharge) protection compliant with IEC61340-5-1 (BKE ModelESDStarting MethodInput VoltageTorque Adjustment(Nm)Torque(min-1)Free SpeedScrew Size Machine Screw(mm)Tapping ScrewBit TypeDLV7530-MKEDLV7530-BKE0.5 - 1.71,1002.6 - 4.02.3 - 3.5(g)Lever SwitchForward / Reverse SwitchConnection CableDLV8540-MKEDLV8540-BKEPush to Start0.5 - 1.71,1002.6 - 4.02.3 - 3.51.2 - 2.77003.5 - 5.03.0 - 4.02.0 - 4.55004.5 - 6.04.0 - 5.01.2 - 2.77003.5 - 5.03.0 - 4.0239High TorqueDLV8550-MKEDLV8550-BKEConventional product750650PartDLV7500/8500-BKEStatic Electricity(V)3505Surface Resistance( )more than 1013104Static Electricity(V)3502Surface Resistance( )more than 1013104Static Electricity(V)252Static Electricity(V)110Surface Resistance( )more than 105132.0 - 4.55004.5 - 6.04.0 - 5.06.35750650Measurement pointHandleDLV8530-MKEDLV8530-BKE59 V DCStepless(mm)MassStandardHigh Lever Startø7Electric ScrewdriverSpecifications1010External DimensionsMaterialHandle Lever SwitchSynthetic resin with carbon fiberConnection CableAnti-static material* Measurement conditions (Temperature:22 Humidity:66 %)(1) Static electricity Earth the measurement equipment and measuring person.Grip the screwdriver five times using Ansel Edmont electronic control glove.Turn on the switch of the screwdriver. Measure each part of the screwdriverusing electronic measurement equipment manufactured by Shishido electrostatic Ltd.(2) Surface resistance Measure using Simco Japan surface resistivity measurementequipment. Standard AccessoriesBitDLV7500 seriesLever SwitchCord 3 mNo.DLV7530 / 7540 /8530 / 8540DLV7550 / 8550No.1 7 75No.2 7 75No.3 7 5011-11Spare Carbon BrushConnection CableSuspension Bail211Torque Reach LightDLV8500 seriesø5055ø39.5257Forward/Reverse Changeover SwitchReceptacle M20Unit: mm13

For Machine Screws (2.6 - 6.0 mm)Torque Diagram (for esBit Torque (N m )4.0DLV7530/8530123Torque LC4511-GGBStepless speed adjustment 80 - 100 %Soft start: adjustable time setting of slow speed (max. 3 sec.)External output signals: start and torque upElectro-static discharge(ESD) controlScrew counting: OK lamp and buzzer for notificationVariable non-operation timeSetting protection by key lock switchSetting by touch switch for easy operationExternal output signals: Start, Torque up, Count up & Cycle OKDLV7500/8500Model230 V AC, 50/60 HzInput Voltage(kg)Mass3.55.1EuropePlug ShapeExternal ing,Time Setting Display139140Touch SwichNUMBER SETTING/COUNTINGTIME SETTING(sec)ROKSPEEDHIGH126Soft DE SELECTION77.581.5LOWSOFT STARTSLOWQUICK( )UP(-)DOWNRESETSETÇRLOCKÇT3 5-ReceptacleReceptaclePower S

NITTO KOHKI's "Delvo" Electric Screwdrivers are high-quality tools for professional use, with special emphasis on precise torque control and long life. They always apply just the correct amount of torque with accurate and positive control at your fingertips. They are smooth and shockless in operation, too.