Transcription

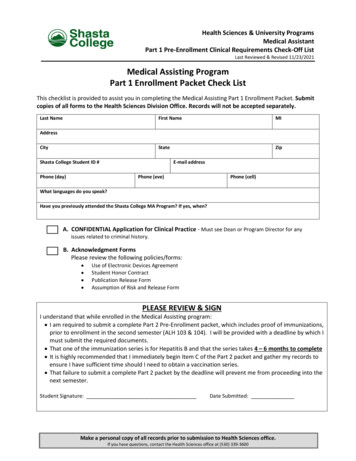

Check ListOPERATING INSTRUCTIONS:Preparation For Installation, Product IdentificationCheckCharging The BatteriesCheckChecking And Adjusting The LiftCheckMounting Head’s BracketsCheckMounting Clamps And Quick-Locking ArmsCheckInstallation Of Accessories On The Control Unit And First StartCheckRegistration Of Heads On The LiftAdjusting The Angle Of The Measurement HeadsCheckAdjusting The Vertical CCD On LiftCheckTargets Assembly And Targets SettingCheckWhat Remains To Be Done? – Last OperationsCheckAll items listed in this table are discussed extensively in the following pages

Quick Start StepsUnpack The Wheel Aligner nitorPrinterMechanicalturn tablesQuick Start StepsCyclops3

Charge The BatteriesRemove the Control Unit from the platform, remove the power cord normallyplaced in the printer compartment, connect the cable to the Control Unit and toa suitable power outlet.Leave the power switch of the ControlUnit in OFF position. Only the charger isenergized at this time.Identify the box containing the measuringheads and open it.Remove the batteries inserted in the heads (push the 2 tabs on each side) andput them in charge - The 2 red LEDs on the charger will light up.TabsChecking And Adjusting The LiftWith the lift all the way down, hanged onthe supports, check and adjust the ramps.Any registration made on a vehicle is doneproperly if the vehicle is on level thenthe lift should be “leveled”. The 3D wheelaligner compensates the lift variationbetween no load condition and to differentloads as per lift variation between theground position and the different heightsto working position (ramps at different heights) but to do this, it is has to startfrom a known condition: LIFT LEVELED AT THE GROUND POSITION ! !Quick Start StepsCyclops4

Mounting Head’s BracketsRemove from theboxes containing themeasuring headsthe 2 supports to bescrewed in the lift.Using the support of figure 1:Place the Turn Table properly as per the position shown inthe manual (in the backward Turn Table place).Take the measures to fix the measuring heads supports asindicated in the service manual.Distance between the center of the Turn Table and the firsthole of the heads support:1135 mm for the left side and1140 mm for the right side with respect to the drive-indirection of the vehicle.Figure 1 - Support headsused up to 31/12/2014Using the heads support as a template, mark the spotwhere drilling, drill with a drill bit for steel diameter of 6.7mm and thread M8.The support of figure 2 must be fixed using the measurements shown belowFigure 2 – New measuring heads supportMeasure for the Left side rampDrive-in DirectionMeasure for the Left side rampDrive-in DirectionUsing the heads support as a template, mark the spot where drilling, drill with adrill bit for steel diameter of 6.7 mm and thread M8.Quick Start StepsCyclops5

Mount Clamps And Quick-Locking ArmsIdentify the package containing the clamps and open it.Remove the clamps and assemblethem. The knobs used to stop the armsshould be pointing towards the groundin order to facilitate the adjustmentof the arm and be sure that the knobturns easily into the groove on the armto ensure a good seal.Please note the mounting position ofthe Quick Locking arms and relativeadjustment knobs. The system isdesigned to have a left and right armwith both knobs mounted as shown,respect this position to have an easyadjustment, see the following figure.Clamp positioned with one arm inthe “12 o’clock” Wheel diameteradjustment knob to the right, QuickLocking arms properly mounted withknobs at “6 o’clock”Arm in the“12 o’clock”WheeldiameteradjustmentknobKnobs at “6o’clock”- OKConnect the quick locking device onthe clampAttach theclawsInsert the clips to lock the pin.Assemble the springs.Attach the claws.Quick Start StepsCyclops6

Installation Of Accessories On The Control Unit And First StartOpen the rear panel of the console. Open the Computer door on the front of theconsole. Make sure your computer is free from items used for packagingand is well ventilated.Remove the packaging of the monitorfrom the compartment of the printer. Takethe monitor and tighten the brackets tothe support on the consoleConnect the signal cable and the powercable to the monitorMake sure they are connected to thecomputer and to the power outletRemove the printer from the box andconnect it to the power outlet and the USBcable from the computer.Remove the SMART CARD from the plasticbag and place it correctly in the readerQuick Start StepsCyclops7

You can now switch to the ON position the powerswitch on the back of the console. The computerwill automatically turn on, check that the monitorturns on otherwise turn it on. Also turn on theprinter and Insert the Ink cartridges.Take the two batteries placed previously under charge, insert them into themeasuring heads and press the central gray button for more than a second inorder to Turn on both heads.If all goes well you got to this point thecomputer has finished starting. In themonitor appears the logo page of WheelAligner program. In the lower right sideof the monitor, spent about one minute,you have to see the two Bluetooth icons inBlue color which tells us that the heads areconnected with the Computer.Now mount the heads of their respectivesupports. Make sure that the arrow stuck onthe cover is facing the driving direction ofthe vehicle.Quick Start StepsCyclops8

Registration Of Heads On The LiftADJUSTING THE ANGLE OF THE MEASUREMENT HEADSGo in front of the monitor and from the logo pagedisplayed on the right, proceed as follows:Press the F2 function key, you see the followingpage; Press F3 to select the “AdditionalFeatures”; confirm by pressing F4 to access thenext page.The cursor is now positioned on the “TestApplication”, if it does not, press the F2 or F3 keyto move the cursor to this selection. Confirm bypressing F4 to access the next page.By pressing the F2 or F3 move the cursor toselect “Measure Head: onboard sensor”. Confirmby pressing F4 to access the next page. Themeasuring heads must be switched on.Quick Start StepsCyclops9

If you do not read any values as in this screen, itcan be caused by:1) The heads are off - turn them on.2) The heads are on but there is no Bluetoothconnection, Bluetooth icons appear on the screenare gray - perform the procedure “Searching forBluetooth”3) The heads are on, the Bluetooth icons areblue colored (connection established), check thatthere are no obstructions between the CCDUnder normal conditions, this page displays thevalues. Read the values “ICL X” and “ ICL Y “of the 2 heads; these are the values of theinclinometers. ICL Y depends on the accuracywith which you have been carried out the fixingholes of the heads support to the lift, the optimalvalue is 0:00 degrees but a tolerance of /- 1degree is acceptableThe “ICL X” is adjustable, see picture below.Acting on the Allen screws (size 3) shown in thefigure, bring the values ICL X to 0.00 degrees.THESE ADJUSTMENTS SHOULD BE MADEWITH LIFT COMPLETELY DOWN.After the adjustment of the ICL X values close tozero (tolerance /- 0,05 degrees) it is suggestedto lock the adjustment screws by using a specialglue (thread braker).ADJUSTING THE VERTICAL CCD ON LIFTThis adjustment is used to compensate different heights between the left andright ramps of the lift. Installations on the floor (in the pit) and lifts who haveramps at the same height do NOT require this adjustment.To perform this procedure: Read the service manual.Quick Start StepsCyclops10

Targets Assembly And Targets SettingPlace one car on the lift stopped with the frontwheels on the turn table.Fix the clamps on the wheels.Take care of the vertical arm of the clamp to beplaced to “12 o’clock” as shown in the figure.In the rear part of the Target, there is a labelwhich identifies the working position.There must be at Target FL; FR; RL and RR tobe fixed on their respective wheels (Front Left,Front Right, Rear Left and Rear Right).Mount the targets on their clamps.The filter of the target should be facing thecamera mounted in the measuring head.For now, do not stop the Target because theyhave to be adjusted in accordance to a correctangle Clamp / Target / Camera.The settings are made as follows:FilterTurn on the measuring heads.Go in front of the monitor and from the logopage displayed on the right, proceed as follows:Press the “F2” key (blue)Press “F2” or “F3” key (blue or yellow) to movethe cursor to “System Configuration”.Press “F4” to continue.Quick Start StepsCyclops11

Press “F2” or “F3” key (blue or yellow) to move thecursor to “Equipment Configuration”.Press “F4” to continue.Press “F2” or “F3” key (blue or yellow) to move thecursor to “Equipment Configuration”.Press “F4” to continue.WE CHECK THAT THE TARGET CODE (ONBAR CODE STACKED ON THE REAR OF THEEACH TARGET) MATCHES WITH THE FILESENTERED IN THE WHEEL ALIGNMENT PROGRAMCONFIGURATION.Press “F2” or “F3” key (blue or yellow) to move thecursor to the “Target File” Press “F4” to continue.Check that the names of the Target written on thispage match with the code on the label stacked oneach target, see photo below. The name written hereshould match with the file characterization/calibrationof the target and this file is used to correctly read theangles of the wheels. If the file name is wrong alsofile stored on your computer is not correct. Entercorrect code and the right file normally stored onthe USB memory key will be automatically copied onthe wheel aligner program.The Target files are located in the memory stick thatcame with the PC. Check on the memory key, in the“TARGET” folder, the files stored have the same nameof the target mounted on Clamps. Connect the USBto the PC.Referring to the previous image, write the correctcode in each box of the Target if wrong or notpresent. When you press the “F1” key to exit thispage, the program will automatically copy the filesfrom USB to PC, if not already done.Quick Start StepsCyclops12

This is an example of a “Recovery” key thatcame with the wheel alignment containingthe TARGET folder with files.After pressing “F1” from the target codepage, the program goes back to show thepage here displayed; move the cursor to“Equipment Configuration” and press “F4”.Press “F2” or “F3” (blue or yellow) to movethe cursor to “Target Mounting”.Press “F4” to continue.We are ready to record and lock the targets inthe clamps in their normal operating position.Make sure that measuring heads areturned on.Check the Targets are fully inserted inclamps.Target far from the rightposition, please continueto rotate the targetTarget out ofposition or absentTarget close to thecorrect position, rotateslowly and lockTarget in rightposition – lockWith the pin slightly braked, turn the targetuntil you find the correct position.Quick Start StepsCyclopsTHE TARGET WHEN REACHED THERIGHT POSITION MUST BE LOCKED13

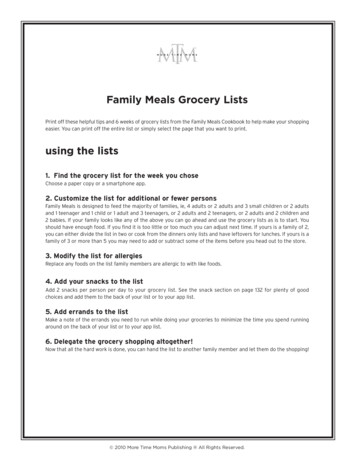

What Remains To Be Done? – Last OperationsAt this point the wheel aligner is ready for operation.It remains to choose: The measure unit by which you want to display the measurements(mm, degrees minutes or degrees decimal), The resolution of the measured values, How you want to display the vehicles database You have to write the heading of the client, the address, the phone, to besaved and printed in the report.Please consult your service manual and user manual for this information.Quick Start StepsCyclops14

ICL Y depends on the accuracy with which you have been carried out the fi xing holes of the heads support to the lift, the optimal value is 0:00 degrees but a tolerance of /- 1 degree is acceptable The "ICL X" is adjustable, see picture below. Acting on the Allen screws (size 3) shown in the fi gure, bring the values ICL X to 0.00 degrees.