Transcription

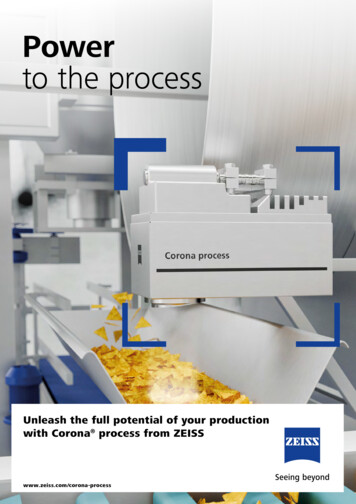

Powerto the processUnleash the full potential of your productionwith Corona process from ZEISSwww.zeiss.com/corona-process

A broad spectrum of qualityZEISS – over 140 years ofexperience in spectroscopy2019The first connected spectrometerwith real time access to data fordefined product quality2015The first portable spectrometerfor convenient quality control andmeasurement out in the field or on the move2013The first process spectrometerwith the highest level ofrobustness and long-term stabilityErnst Abbe developed the world’sFrom the beginning, the name ZEISS has stood for continuity and foresight as well asfirst spectrometer for a companyfor passion and responsibility. Most importantly of all, the name has stood for globallythat Carl Zeiss founded 28 yearsleading optical measurement technology. Our vision is the perfection of spectroscopyearlier in Jena in 1874. Today, oversolutions for process and quality control. We’ve always been the first to bring high-140 years after Abbe’s spectrometer,quality technology to the marketplace. Like in 1924, when we developed a photometerZEISS is one of the world’s leadingthat allowed us to measure colors. Or in 1968, when we created the SPECORD seriestechnology companies in the opticalof two-beam spectral photometers for laboratory analyses. Or in 1999, when we setand optoelectrical industry withnew standards for the agricultural industry with an NIR spectrometer mounted onto aover 30,000 employees in nearly 50harvester.19991997The first process spectrometeron a harvesting machinecountries and approximately 120distribution, service, productionThroughout our history, we have always developed new technology that has madeand development facilities.processes reproducible and minimized production losses. By fulfilling the qualityThe first NIR spectrometerfor the near infrared wavelengthexpectations for products “Made in Germany”, we’ve helped our clients to fulfill theirpromises to their own customers. This has led to the development of a business areaspecializing in material analysis, spectroscopy and process analytics, which now playsa key role in the company’s global success.ZEISS spectrometers are as versatile as they are accurate, providing unparalleledperformance. Regardless of whether they are a permanent fixture in your production,such as Corona extreme / Corona process from ZEISS or whether they are mobile andused in the field, such as AURA handheld NIR from ZEISS, you can obtain the best results in almost any environment and our spectrometers are tailored to your process. This19331968The first SPECORD series two-beamspectral photometerfor analyses in the laboratoryThe first quartz spectrographfor spectral analyses in theultraviolet wavelengthmeans that our solutions are not only sought after in areas such as food production andagriculture, but also beyond our own atmosphere: ZEISS high-performance gratings areused in satellites that monitor the air quality on earth, for example.From food production to harvesting and space, the use of ZEISS equipment providesErnst Abbe1840-1905a technological edge. This is also what drives us every day: maximum efficiency andsustainability as well as long-term success and satisfaction for our customers.1874Carl Zeiß1816-18882The first spectrometerfor the spectral fracture of lightwith a prism system3

Improving measurement withbetter control Corona processfrom ZEISSThe proof is inthe processCorona process provides you with a wide range of advantagesfor the widest variety of different processes and productions.Every process is different.From the environmental conditions ina production facility to the nature andMeasure fat, moisture dry mass,spices, protein, color and more inthe 380 to 1,650 nm wavelengthrangeReact quickly to processvariations, make adjustmentsas necessary and optimizeproduct quality constantly byusing accurate results in yourdecision makingUse standardized and calculatedinstead of predicted color valuesin different color scalesReduce operating costsand increase profit marginsthanks to greater efficiencyRely on consistent and repeatable results, regardless of thedistance to sampleIntegrate Corona processeasily into existingcustomer networksMeasure different parametersat the same time – in real timeUse Corona process directlyat the process line, thanksto IP protection level 67 andhygienic designvariability of the raw materials beingmeasured, there are many factors thatinfluence the quality of the final productyou produce. That’s why you needconsistently accurate measurements tocontrol every step. Corona process isspecifically designed to not just measureand control every aspect of yourproduction, but also to help you optimizethe process to make it more efficient,consistent and sustainable.How does it work?As a full-scale spectrometer system thatcan gather information in the 380 to 1,650nm wavelength range, Corona processis ideally suited to measure a wide rangeof parameters in real time. From fat andmoisture to dry mass, spices and even colorin different color scales, Corona processgives you accurate measurement datawithout having to change devices or filters.That means you can adjust production andoptimize your process almost instantly andtwo automatically switchable lamps ensurethat the process can continue running. Thisallows you to profit from lower productioncosts and greater energy efficiency as well.Even the most effective process can benefitfrom greater control and higher, moreconsistent quality. That’s exactly whatCorona process gives you.Corona process mounted over a conveyor belt using a mounting bracket45

Keeping results andquality constantHardware you can count onCorona process technical specificationsUsable spectral range380 – 1,650 nmMeasuring distance100 – 590 mmMeasuring spot size 30 mmLight source2 Halogen lampsLamp lifetime 20,000 hfor the food industry. As a precision measurement tool that’s as robust and reliable as it is accurate.Protection levelIP67Corona process gives you the data you need to make the right decisions to optimize quality andHousing size (w x h x d)(360 x 160 x 220) mm³Weight15 kgOperating temperature range-10 C to 50 CCorona process is designed to fit seamlessly within a modern production environment and is idealconsistently deliver the best possible products. Regardless of whether it’s mounted at the productionline, over a conveyor belt or in a mixer, the results are precise, reproducible and always dependable.That’s because we understand your needs and have designed all the elements and hardware ofCorona process to function at its best in the widest variety of production environments.Adaptable, accurate and dependableSpecially designed lampsMechanical interfacespecifically for use in spectrometers and in the foodfor easy and convenient mounting aboveproduction industry; a 20,000-hour lifespan andthe samplesautomatic fail-safe function ensure high levels ofprocess stabilityRobust Lemo contacts with IP67protectionFull-scale spectrometer system made by ZEISSPerfectly protected for demandingto cover a wide wavelength range between 380 andapplications in the food industry1,650 nm to accurately measure quality parameterssuch as fat, moisture, sugar, spices and colors in variousstandardized color scalesLED status displayfor constant operational readiness andconvenient monitoring of functional activityInternal referencefor constantly precise measurement results, irrespectiveof external factors such as temperature variationsHygienic designwith a food grade, stainless steel housingMeasuring windowto keep it clear, an optional air purge ring can beDistance Sensormountedensures consistently accurate andreproducible measurement results regardlessof the distance of the measuring window tothe sample67

Software to make senseof hard dataGood software should be as powerful and versatile as it is intuitive and easy to use. Our InProcessMeasurement Historysoftware is designed not just to provide you with all the information you need quickly and easily, butAccess all previous measurements and results asalso to fit around your specific needs, thanks to a range of customization options. InProcess is alsowell as spectrum data exports, measurement valuesready for Industry 4.0 and provides the ideal platform to profit from connected spectroscopy andand sample information.access your measurements from anywhere, at any time, thanks to easy cloud integration.MeasurementResults can be displayed as a spectrum, value, ortrend. For more automation, you can set up automaticResult MonitorEvent logmeasurement starts, alerts for when limit values areControl more than one spectrometer with justSee all the events that have occurred whileexceeded and the elimination of implausible spectra.one piece of software. See measurement resultsInProcess has been in use and access allfrom several device groups or various productsthe relevant information, filtered by textin real time in one view.search, levels and the state of the device.Product SetupInProcess allows you to individually configuremeasurement behavior, calculation results andrepresentation graphs and tailor these to your specificneeds. Calibration can be performed with the supportof common chemometrics software, such asGRAMS IQ , Aspen Unscrambler , SL CalibrationWizard or UCal .System SettingsCreate and manage groups of users with variouslevels of access and use InProcess in many differentlanguages. The software also communicates withcommon fieldbus systems and industry standards,such as OPC UA, DA, Modbus, Profinet, Profibus,DiagnosticsExitEthernet/ IP and more.Spectrometer functionality can be verified with aSoftware can be shut down when performing revisionself-test and important service information is availableor maintenance work as well as during plannedat the touch of a button and can instantly be sent todowntimes to conserve energy and resources.ZEISS Service for evaluation.89

Augmenting abilityAccessories for Corona processCorona process TURNSTEP ST Sample BowlsCorona process is ideal for use in-line,Corona process is designed to provide high levels of measurement performance and robust reliability in the widest variety ofnext to the production line or in theapplications. We have all the accessories and upgrades you need to maintain that performance and give you more application options.lab, especially when combined withTURNSTEP ST. Tailor made to fit snuglyonto Corona process, TURNSTEP STrotates samples during measurement toallow for greater quantities to be analyzedand more representative results.Air purge ringOn top of that, movement can beA clean measurement window is very importantsimulated, allowing for calibrationwhen it comes to precise results. The Air purgedevelopment in the laboratory or nextring keeps the measuring window free of productto the production line without priordebris, steam and grease, providing even betterinstallation of Corona process. A labperformance.stand completes the package, making iteven easier to measure at line.HMIIntegration into existing customer networks and process controlsoftware is one of the keys to unlocking Corona process’full potential. That’s why we have custom HMI systems forMounting bracketIndustrial Power Supply Unitvarious communication interfaces and protocols. In addition toFor optimal and easy mounting above a conveyor beltTo ensure that Corona process is even safer inconnection via Profibus or EtherNet/IP, measurement values andor mixer.demanding environments, we offer an industrialtrends can be displayed directly on site as well. This allows youpower supply unit. With IP67 levels of protection,to monitor, control and optimize your production efficiently andSample Buttonit can be mounted close to the system, like on aeffectively, with seamless integration into your infrastructure.With our sampling probe, samples can be markedwall, for example, meaning that cables don’t getduring measurement, allowing for filtering at a laterin the way.stage. This is ideal for checking calibrationsor creating new ones.1011

Quality is measured by service.And vice versa.We’re there for you –for the lifetime of a deviceGood quality goes beyond productperformance – it’s about the levelof service you receive as well. We’remore than just a provider to ourclients, we’re partners, which is whythe service we offer is as importantto us as the product we manufacture.We’re with you every step of theThe measure ofyour successway, from first consultation to finalpurchase and then for the entire lifecycle of the product.Multinational food company is renowned forWe also understand that every client isconsistently providing the highest quality for theirdifferent, which is why we can developcustomers day in, day out. But to satisfy the highestindividual service packages that arerequirements on a regular basis, they need a reliable,tailored to your company, facility, process,accurate and consistent measurement solution.or specific project. That’s what we meanby partnership and service quality: aCorona process is the ideal solution to measurerelationship based on trust and a detailedguarantee optimal performance, increaseOur expert serviceat a glance:understanding of individual needs andcircumstances.service life and provide many years of Installation of equipment and softwareFurthermore, you can rely on ourreliable and precise results. You can Application support for the wholeglobal distribution and service network.also profit from our digital maintenanceRegardless of whether it’s gratings,services, which provide you with user- Preventive maintenancemodules, spectrometers or solutions,friendly, location-independent solutions Customer-specific maintenance contractshardware, software, or calibration, we’rewith no waiting times. And if something On-site and in-house repairsthe only ones who develop and offerdoes need to be repaired on site, then our Remote diagnostics, maintenanceall spectrometer components from aservice technicians can be with you in nextsingle source. Exclusive service packagesto no time.several quality parameters such as fat, moisture andcolor simultaneously during production.product lifetime»» Constant ZEISS innovation hasenabled us to pursue informationat a greater accuracy, reliability,and with consistent support.Since our lines run continuously,reliability and robustness ofequipment is critical. ZEISShas always provided top notchservice for both our researchand manufacturing teams. Thissupport has ensured we meet ourtechnology goals to advance ourbusiness strategy, and achievehigher overall consistent quality. «Major Food Manufacturerand repairScan now to find outmore about Corona processfrom ZEISS1213

When the going gets tough,Corona extreme gets goingPerformance in the palmof your hand withAURA handheld NIRFrom operating temperatures of -15 C to 50 C and shocks of up to 50 times the force of gravity,As a portable, agile and convenient spectroscopyCorona extreme from ZEISS is at home in difficult conditions. All the while providing accurate, repeatablesolution, AURA handheld NIR from ZEISS allowsand dependable real-time measurements results. From applications where the device needs to be in directyou to get up close to samples in just about anycontact with samples, such as in closed transport systems for agricultural produce or food production linesweather conditions. And its long-lasting battery, and laboratories, Corona extreme is designed for full flexibility and durability. Regardless of whether youintegrated computer, intuitive software and largeneed measurements in the lab or in-line and under constantly variable conditions, Corona extreme allowstouch-screen display means it’s easy to use andyou to optimize your processes and maximize efficiency, no matter how tough the going gets.completely portable, regardless of whether you need to measure out in the field, in stables or justabout anywhere else you’d need a spectrometer.Your benefits:When it comes to ultimate flexibility in gettingaccurate measurements, the power is in your hands. Full-scale spectrometer for the measurement of fat, dry mass, protein and more inthe 950 to 1,650 nm wavelength range. Measures in direct contact with the samplewithout damaging it Measures various parametersat the same time – in real time Easily integrated into the widest varietyof spaces, from pipelines to trough chainYour benefits: Completely portable and easy to use Take measurements up close and indirect contact with samples Includes complete softwarefor comprehensive measurementresults on the moveconveyors Ideal for use directly at the process line,thanks to IP protection level 66 Rugged and reliable in almostall conditions Available with a range of convenientaccessories Practical carrying case includedfor ideal portabilityScan now to find outmore about Corona extremefrom ZEISS14Scan now to find out moreabout AURA handheld NIRfrom ZEISS15

Office: 49 3641 64-2838Fax: 49 3641 ectroscopyprogress subject to change without notice. Carl Zeiss Spectroscopy GmbHEN 40 010 0004II 2021-11 Design, scope of delivery and technicalCarl Zeiss Spectroscopy GmbHCarl-Zeiss-Promenade 1007745 Jena, Germany

6 7 Corona process is designed to fit seamlessly within a modern production environment and is ideal for the food industry. As a precision measurement tool that's as robust and reliable as it is accurate. Corona process gives you the data you need to make the right decisions to optimize quality and consistently deliver the best possible products.