Transcription

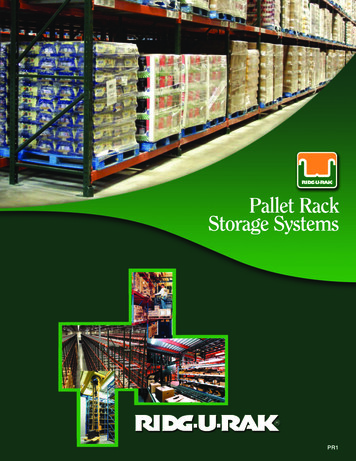

Pallet RackStorage SystemsPR1

Your Single Sourcefor Quality PalletRack Storage SystemsRidg-U-Rak is a world-class manufacturer of qualitypallet rack storage systems as well as a wide varietyof other systems. Since 1942, Ridg-U-Rak has beena pioneer in the development of innovative palletrack storage with more than 400,000 square feetof production and warehouse space. As such,we are able to effectively serve as your singlesource for all your pallet rack storage requirements.For information on how we can help in your palletrack selection, please call. Toll Free 1-866-479-7225.We’re ready when you are.Roll Formed Columnsand BeamsAt the heart of most Ridg-U-Rak structures is ourfamous roll-formed column design. Each upright isfully welded using heavy-duty bracing and base platesto ensure structural integrity and to eliminate installationdelays and costs inherent in bolt-together uprights.In addition to roll formed sections, we offer structuralsteel shapes in a virtually unlimited selection of sizesand capacities to meet your requirements.Ridg-U-Rak offers a wide variety of column and beamprofiles in various gages to provide our customerswith the most efficient solutions possible. All uprights,beams and support components are engineered tomaximum load capacities while minimizing weightto reduce cost.Original Slotted2TeardropHybridStructural FrameRoll-form Beam

Where to find it.Leading the Industryin Pallet RackStorage SystemsRidg-U-Rak is one of the largest pallet rackstorage manufacturers in North America,producing more than 100 million poundsof pallet rack, high density storage rack andspecialized rack systems annually. We offerengineering, design, project managementand installation services that meet yourpallet rack needs on time and on budget.Our customers include distribution centers,manufacturing facilities, large scale retailand home improvement outlets, industrialwarehouses and assembly operations.The Ridg-U-Rak team has the experienceto handle projects ranging from smallselective systems to large complex projectsincorporating a variety of storage solutions.A national network of distributors provideknowledgeable service, and their stockinglocations supply a “quick ship” optionfor standard products.For over 70 years, Ridg-U-Rak has beena pioneer in developing and improvingpallet rack safety, including Column Sentryreinforcements, slant back/offset uprights,beam-to-column locking mechanisms andSeismic Base Isolation technology.Slotted RackFrames & Beams.4-5Teardrop RackFrames & Beams.6-7Structural Steel RackFrames & Beams.8-9Frame Options .10Beam Options.11Column Sentry IIReinforcing forImpact Protection .12-13AccessoriesSlotted & Teardrop Beams .14Structural Steel Beams .15Pallet Rack Storage Systems3

Slotted FramesRidg-U-Rak original slotted pallet rack systemsfeature automatic lock beam-to-column connectionsand are available in a virtually unlimited selection ofsizes and load capacities. Our six-bend, roll-formedcolumns with fully welded bracing set the standard forrigidity, strength and durability in pallet rack systems.Wide massivebracingCurled flangeprovides enhancedstabilitySolid cornersSlotted pallet rack is available in a vast array ofsizes and load capacities and is extremely versatile.The slotted system features long-lasting powdercoated finishes to ensure enduring performance.Features Roll-formed columns 180 return flanges100% welded uprightsSuperior bracing designLarge base platesOffset anchor holes4" vertical adjustabilityOffset anchoring holeLarge base platesFull fillet weldsFrame 58,70055,90053,00046,50039,70033,10026,900Consult with factory for vertical beam-to-beam spacings greater than 108" The Frame Capacity Chart gives allowable loads based on the specified “Unsupported Length” of the columns. Values shown are in full compliance with the current RMI Specifications. The loads on upright frames accumulate from top to bottom, therefore, the unsupported length and the column load beloweach beam level should be checked to determine the worst-case scenario. The capacities shown in this table are for static load conditions only. For other special conditions such as seismic or wind loadings, consult with Ridg-U-Rak sales.REG4Style 32CStyle 33CStyle 43C. #5150

Slotted BeamsRidg-U-Rak offers many standard beamprofiles in virtually any length with capacitiesto 22,500 lbs. per pair. Beams have a safetyfactor of 1.67 based on minimum yield of steel.All beam capacities are calculated based on therequirements of the current RMI specification.All capacities are based on uniformly distributedloads on a pair of beams. Other loading conditionscan greatly reduce the carrying capacity of abeam. For unusual loading requirements,call your local Ridg-U-Rak distributor.Beam lengthBeam length 3" for 3" columnBeam length 4" for 4" columnBeam CapacitiesBeamProfile250 S300 S355 S410 L410 S465 S500 S550 S600 S650 S650 R Beam 0003,6104,6105,7707,1107,970Capacities marked with * indicate that the column connection capacity may be limited based on the hook option and/or frame model (see table below).Capacities listed are for non-seismic conditions. For seismic conditions consult with Ridg-U-Rak sales or engineering.Capacities are based on uniformly distributed loads per pair of beams.Capacities listed are for a 2-pallet wide condition.All beams over 114" in length should utilize at least one flanged, tek-screwed or lock-in cross bar located at mid length.Beam Profile Dimensions15/8"X/"7 8UprightFrame 55.0021/2"5.506.00REG. #5150Maximum Beam Capacities (per pair)2-Lug Hook #029,000 lbs13,500 lbs12,000 lbs13,000 lbs15,000 lbsHook #02Hook #033-Lug Hook #0313,000 lbs16,000 lbs18,000 lbs19,500 lbs22,500 lbsHook # 02 is standard for beams 2.50", 3.00", 3.55",4.10", 5.00", 5.50", 6.00" tallHook # 03 is standard for beams 6.50" tall6.50Slotted Roll-Formed Pallet Rack5

Teardrop FramesTeardrop systems offer easy assembly with2" vertical beam adjustments. No tools arerequired. The teardrop beam-to-columnconnection is designed to be compatiblewith other widely available teardrop systems.Heavy duty bracingFeatures Offset anchor holesFull array of profiles to optimize the solutionTwo-inch vertical adjustabilityLarge base plate6 bend column100% welded uprightsLarge base platesSolid cornersLarge base platesOffset anchoring holeFull fillet weldsFrame 96"108"31I32I33I43I3 x 1-5/83 x 600Consult with factory for vertical beam-to-beam spacings greater than 108" The Frame Capacity Chart gives allowable loads based on the specified "Unsupported Length" of the columns. Values shown are in full compliance with the current RMI Specifications. The loads on upright frames accumulate from top to bottom, therefore, the unsupported length and the column load below each beamlevel should be checked to determine the worst-case scenario. The capacities shown in this table are for static load conditions only. For other special conditions such as seismic or wind loadings, consult with Ridg-U-Rak sales.REG6Style 31 IStyle 32 IStyle 33 IStyle 43 I. #5150

Teardrop BeamsInterchangeable teardrop beams, as with slottedbeams, are available in many profiles, in virtuallyany length, with capacities to 18,000 lbs. per pair.You can tie into many existing systems both oldand new. Beams have a safety factor of 1.67 basedon minimum yield of steel. All beam capacitiesare calculated based on the requirements ofthe current RMI specification.Our teardrop pallet system provides a robust,patented, automatic lock for improved safety.The Springlock assembly provides positivebeam-to-column engagement, improvinginstallation speed and safety.All capacities are based on uniformly distributedloads on a pair of beams. Other loading conditionscan greatly reduce the carrying capacity ofa beam. For unusual loading requirements,call your local Ridg-U-Rak distributor.Beam lengthBeam length 3" for 3" columnBeam length 4" for 4" columnBeam CapacitiesBeamProfile250 S300 S355 S410 L410 S465 S500 S550 S600 S650 S650 R Beam 1803,0003,6104,6105,7707,1107,970Capacities are based on uniformly distributed loads per pair of beams.Capacities listed are for non-seismic conditions. For seismic conditions consult with Ridg-U-Rak sales or engineering.Capacities listed are for a 2-pallet wide condition.All beams over 114" in length should utilize at least (1) flanged, tek-screwed or lock-in cross bar located at mid length.Maximum shelf load for Teardrop Beams using 6" connectors with 2-pins is 12,000# per pair.Maximum shelf load for Teardrop Beams using 8" connectors with 3-pins is 18,000# per pair.Enhanced robustautomatic lockBeam Profile Dimensions15/8"/"7 8X2.503.0015/8"3.554.10X4.65REG. #51505.0021/2"5.506.006.50Teardrop Roll-Formed Pallet Rack7

Structural Frames & BeamsSlotted ConnectionsUpright framesFrame capacity chart Upright frame capacities vary accordingto vertical beam spacing. See chart. Upright columns are hot-rolled structuralchannel with 50,000 psi minimum yield. Upright frames have a safety factor of1.92 based on minimum yield of steel. Slotted beams are vertically adjustableon 4" centers. Standard colors:Uprights – forest greenBeams – safety orangeOther colors available on special order. Front column foot protector is optional. Heavy duty lower horizontal brace is optional.Vertical 0030,00024,00018,40014,20011,300Beam lengthcolumn center linedeterminationBeam lengthBeam length 3" for 335 columnBeam capacities - Slotted ,010Note: Beams must be secured by beam locks against accidental upward forces.All capacities are per pair of beams based on uniformly distributed loads.Capacities are based on current RMI specifications.8567

Structural Frames & BeamsBolted ConnectionsUpright framesFrame capacity chart Upright frame capacities vary accordingto vertical beam spacing. See chart. Upright columns are hot-rolled structuralchannel with 50,000 psi minimum yield. Upright frames have a safety factor of1.92 based on minimum yield of steel. Bolted beams are vertically adjustableon 2" centers. Standard colors:Uprights – forest greenBeams – safety orangeOther colors available on special order. Front column foot protector is optional. Heavy duty lower horizontalbrace is optional.Vertical BeamSpacingSBF-335 SBF-341 6,800Beam lengthcolumn center linedeterminationBeam lengthBeam length 3" for 335 columnBeam length 4" for 445 columnBeam capacities - Bolted r18,960Note: All capacities are per pair of beams based on uniformlydistributed loads. Capacities are based on currentRMI specifications.Structural Pallet Rack9

Frame OptionsFull DepthBase ChannelWelded AngleDeflectorFloor PadOptionsWeldedWrap-AroundDeflectorSingle HeavyDuty BottomHorizontalWeldedWrap-AroundDeflectorFront AnchorDoubleHeavy roundDeflector FrontAnchor & HeavyHorizontalOffsetFrames

Beam OptionsBolted BeamConnectionBeam StepPunchingFor “Tabbed” and“Drop-in” Cross BarsTeardropBeamConnectionPallet StopsFactory Weldedto Beam2 Pin3 PinUprightFramePallet StopsBeamSlant-back Frame OptionFrames & Beam Options11

Column Sentry IIRack AbuseAccidental lift truck impact damage is inevitable,but unique Column Sentry II reinforcing keepsit to an absolute minimum.IncreasesImpact Strengthby 240%!Ridg-U-Rak’s Column Sentry II reinforcing isa double-thick, double-strength box section thatprovides exceptional resistance to impact damageof frame columns.Column Sentry II reinforcing helps guard against rackfailure, collapse, and local buckling; and, at the sametime, it increases column load carrying strength.And that’s not all. Column Sentry II reinforcing iscompact, thereby, saving critical aisle space. Nomore space is required than our standard column,and it need be applied only in critical areas suchas floor to first beam level on front columns(aisle side).No other reinforcing method offers the protection,strength, and economy of Column Sentry II.Column Sentry II32C 3 x 2-1/412Column Sentry II33C 33 I43C 43 IColumn Sentry II reinforcing can beapplied cost-effectively where it’s neededmost – such as lower leg of front uprightcolumn. No need for heavy, inflexible,expensive structural components in areaswhere damage is unlikely to occur.

Resistance to ImpactTest of Unreinforced ColumnsGuillotine Impact Testing best simulatesthe impact of a lift-truck fork.Measuring Impact Resistance offers the most accurateassessment of how a column will respond when subjectedto “typical abuse” in warehousing environments. Other tests,such as Load Tests, only measure the ability of a columnas it relates to capacities.Adding Ridg-U-Rak’s Column Sentry IIreinforcing results in a compositecolumn section that increases columnstrength by as much as 240%; aswell as increasing torsional resistanceseveral hundred times. This resultsin an upright frame that is extremelyresilient, impact resistant, economicaland most importantly, providestremendous residual carryingcapacity after an impact occurs!Column Sentry IIColumn Sentry II providesmaximum protectionagainst lift truck impactdamage.Upright column strength comparisonafter equal impactLaboratory tests were conducted to determine the axialload carrying capability of different column sectionsafter an equal impact load was applied. After impact,each column section was placed in a testing machinewhere controlled compressive force was applied. Thedeflection was measured and recorded at increasingload increments and then plotted logically.Load (KIPS)Note: See the Poor Impact Performance of the Tube Columns.StructuralChannelC4 x 5.4Ridg-U-Rak withColumn Sentry IIH32 with CS IIStructuralChannelC3 x 4.1Roll-formedTube Column3 x 3 x 11 ga.4 x 2 x 11 ga.3 x 2 x 11 ga.Deflection (in.)Column Sentry II13

AccessoriesSlotted & TeardropRowSpacerLow wDeckingUprightFrameSquareHole forTear DropForkEntryRoundHole er SquareHole forTear DropSkidRailsRoundHole forSlottedFlangedCrossbar(CBF)Heavy DutyFloorShimsLight DutyMetalDeckBolted d Load StopLoad BeamColumn GuardsTabbedCrossbar(CBU)Manual Locking DevicesNotchedColumnGuardFloor MountedLow ProfileDrop mn Mounted14t

AccessoriesStructuralFront-to-backbeam tieSlottedrow spacerSlotted beamlockSlottedbeamsBoltedbeamsStandardStandard beam position(Use part number designation - B)Structural channelpallet supportAlternateAlternate beam position(Use part number designation - A)Structural anglepallet supportRoll-formedRoll-formed beam also availablefor either connection style.ReinforceduprightcolumnAccessories15

QualityManufacturingRoll Form ManufacturingState-of-the-Art high volumeroll form operation usinginduction welding processfor closed tube beams.AWS Certified WeldersThe quality of the workmanship performed on a racksystem directly relates to that rack’s durability andsafe usage. Ridg-U-Rak uses AWS certified weldersto ensure the manufacturing of reliable products.State-of-the-Art Powder Coat Paint SystemsRacks built to last require a durable finish. Our powdercoated paint finish has superior impact resistance andis applied by our state-of-the-art automated paint linefor uniform quality. Additionally, hard-to-access areasare hand sprayed to ensure coverage. Ridg-U-Raksystems resist chips and scratches, providing along-lasting finish for better appearance andreduced maintenance.Certified FabricationThrough an audit and approval process of ourquality system, Ridg-U-Rak is a licensed and certifiedmanufacturer in a number of municipalities aroundthe United States.For more information,RIDG-U-RAK is a founding member in good standingof RMI. The Storage Rack covered by this manualis in full compliance with the latest designspecification approved by the members of theRACK MANUFACTURERS INSTITUTE. We believethat it is important to you that your supplierbe committed to the principles of continuousimprovement in both product design/application,and in the highest professional and ethicalstandards of performance as embodied inthe mission and work conducted within RMI.please contact us:120 South Lake StreetNorth East, PA 16428Toll Free: ww.ridgurak.com. #5150Proud member of these organizations:RDIB/2.5M 2012 RIDG-U-RAKAHA

for Quality Pallet Rack Storage Systems Ridg-U-Rak is a world-class manufacturer of quality pallet rack storage systems as well as a wide variety of other systems. Since 1942, Ridg-U-Rak has been a pioneer in the development of innovative pallet rack storage with more than 400,000 square feet of production and warehouse space. As such,