Transcription

Easy, efficientand impressive.info@homag.comwww.homag.comYOUR SOLUTIONStatus 02/18 Technical changes, print errors and mistakes reserved. Pictures may show special equipment.HOMAG Group AGOur 3D Design SoftwarewoodCAD CAMYOUR SOLUTION

02HOMAG woodCAD CAMHOMAG woodCAD CAMContentsContentswoodCAD CAM –3D design and production forfurniture and interior fittingEven shorter delivery times? Increasingly individualized requests? Withthe woodCAD CAM 3D software, you can stay flexible and deliver yourcustomers the high quality they demand. Because a software solution canbest support your work when it covers everything: Planning and presentation,design and manufacture. It must allow changes at any time, in order toreact to new requirements during the process. Based on proven CAD/CAMtechnology, you can achieve a work preparation time saving of up to 70% withwoodCAD CAM.YOUR SOLUTIONMORE: HOMAG.COMwoodCAD CAMCONTENTS04design-to-machine06Planning and presentation10Design modules14Connections and fittings16Components and material structure17Calculation18Production documentation20CNC data generation22eBusiness03

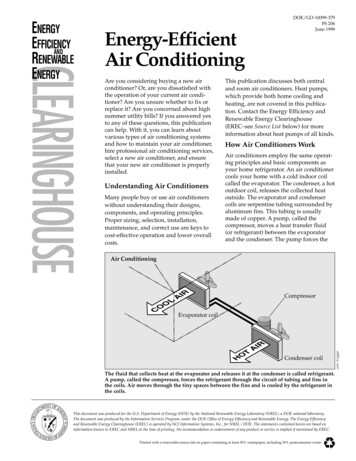

04HOMAG woodCAD CAMHOMAG woodCAD CAMdesign-to-machinedesign-to-machineWhere data and ideas flow. woodCAD CAM, the best3D software for interior fittingInnovative technology has long depended on traditional craft. Most operations would not be competitive if there were noconnection between concept planning and finished product. woodCAD CAM offers you exactly the flexibility you need toimplement customer requirements quickly and individually, at high quality and excellent value. Whether you need to supply asingle part, build an entire house or produce large quantities of parts as a large business, the right software puts you in theposition to make it happen.Perfection can be programmedNo matter how big your company orbusiness is, with woodCAD CAM fromHOMAG, it is easy to optimize yourbusiness processes. From the firstsketches to the final product, from thecalculation to the offer and from thedesign to the CNC data generation: WithwoodCAD CAM, you can optimize yourwork preparation processes. The benefitsfor you: Efficiency and safety in orderprocessing and production. At the click ofa mouse, the parts list data is transferredto the Cut Rite cutting optimization system,and CNC programs are automaticallygenerated for your HOMAG machines.woodCAD CAM especially supports theproduction of furniture designs based onplate materials, including in the filed ofkitchen, bathroom, living, office, interiorfitting and shop fitting.woodCAD CAM understands your craftThe software even supports you inwinning the order. Not only can you designindividual pieces of furniture or entire roomsquickly, you can present and calculatethem at just the same pace. Changes arepossible at any time, including updating theoffer prices. In the design phase, you addmore planning detail, then the design datais automatically prepared for productionand sent to the machines.Ideal for industryDo you produce many different variants?Do a large amount of custom designing?Then woodCAD CAM is perfect for you.The system core is SQL database-oriented.The advantage is that design data andparts lists can easily be transferred todownstream systems. As a result, ERPsystems and production controllers are wellsupplied.Opportunities through productflexibilityThe key functions of woodCAD CAMare parameter-based furniture designand a direct connection to the machinetechnology. Production drawings and partslists are available at the click of a mouseimmediately after design, and designdata is converted into NC programs andsent to HOMAG Group machines in afully automated process. The machinesare perfectly integrated in the processchain. The software turns your machineinvestment into a competitive advantage.Transparency in productionUsing potential for salesWhile woodCAD CAM generatesproduction data, ControllerMES takesover production distribution with the goalof optimizing the production process.The module creates transparency andefficiency, whether it is forming productionbatches, reducing machine downtimeor creating post-processing orders:ControllerMES represents efficient use ofthe installed machine base.woodNET, the internet-based sales andordering system, has been conceived asan integrated B2B and B2C solution forthe sale of furniture and furniture parts.The software has been developed withthe latest internet technology and followsthe innovative approach “directly from saleto machine.” woodNET connects yourproduction potential to the market andopens up new business models.CADDesignIDEACutPlanningEstimatesWOODCAD CAMEdgeCNCCAM@Component drawingPRODUCTCustomerDesign onlineCAD CAM workControllerMESMaschinepreparationAssemblyThe software solutions woodCAD CAM, woodNET and ControllerMES can be used as standalone solutions or in combination. The processchain “directly from the customer to the machine” can thus be closed. The modular structure also allows the software to be introduced into thecompany step by step.05

06HOMAG woodCAD CAMHOMAG woodCAD CAMPlanning and PresentationPlanning and PresentationIndividual. Optimal. Automated.CONVENIENT SALES WITH PRACTICAL EQUIPMENT PLANNING ANDQUOTATIONS. Designing individual home environments? Create compellingoffer documents automatically? Simply use the integrated planning module.woodCAD CAM also provides you with many visualization options for excitingpresentations. These range from colored view drawings, to 3D perspectives inshade mode, to photo-realistic renderings. And the correct sale price is alwaysdisplayed during the planning phase. The advantage is that alternative offers can becreated quickly and efficiently with different materials or fronts.3D spatial planningPhotorealismQuotation··With guided 3D architecture module··Use the architect’s 2D layoutswoodCAD CAM has an integrated modulefor photorealistic illustrations. This usesthe materials and colours specified in theplanning or design phase.The shopping cart remains flexible:Change prices, add or delete products —everything is possible until the offer isprinted.07

08HOMAG woodCAD CAMHOMAG woodCAD CAMPlanning and PresentationPlanning and PresentationPlanning: faithful to detailsPresentation: easy to understandTHE RIGHT MODULE FOR COMPLEX PLANNING. Whenand doors can easily be planned in and individually adapted.the interior layout throws up a new challenge and detailedOf course, the module also offers many modificationplans are needed, it helps when you know you can present tofunctions. Especially helpful is the internal dimension module.your customer clearly and thoroughly. In woodCAD CAM, youA wide variety of requirements can be met by enteringare supported by a special architecture module. This allowsparameters, plus manual dimensions and notes can addquick and easy transfer of building dimensions into the CADextra information to the drawing. Sectional drawings can besystem. Required information such as wall thickness, wallgenerated automatically and thus help in manufacturing andlength and room height are requested in the dialog. Windowsassembly.Interior designItem libraries and selectionPhotorealismDrawing proposalExploded-view drawingProduction drawings3D walls can be created from thearchitect’s 2D drawing by simplyselecting the drawn elements. The spatialenvironment is completed with the insertionof components such as steps, supportsand pillars. Very quickly, the user has adetailed architectural basis for the desiredplan. Decoration blocks such as lights,plants, sanitary objects, devices, etc. areavailable to give the customer presentationa natural appearance.woodCAD CAM centrally manages alllibrary elements such as standard anspecial items, purchased parts and variableelements. The structure of the library canbe freely defined, the contents are easy tobuild and expand upon during the planningprocess.woodCAD CAM has built-in photorealisticrepresentation, which uses materials andcolors defined in the planning or designphase. In this way, the customer can createa clear picture of the product or interiorlayout as early as the planning phase.The remarkable effect of photorealisticrepresentation is achieved through:woodCAD CAM supports you in thepreparation of genuinely convincingpresentation and drawing proposals.Because with our software you havethe choice of many presentation andvisualization options.An exploded-view drawing of every itemcan also be created as an assemblyaid and for design documentation.woodCAD CAM shows the items andcomponent structures stored in thedatabase.Component measurements mean the fullydimensioned production drawings can beproduced for all components. Parametersallow you to adjust the information thatappears on the drawing.woodCAD CAM also creates associatecross-selection drawings which can beautomatically updated in the case of designchanges.Individual furniture types includingpermitted machine deigns can be puttogether in a catalogue and configuredusing a convenient selection interface. Assoon as it is fully determined, the item canthen be added into the 3D room plan anpositioned precisely. A powerful insertionand connection function is available.··Assignment of materials for surfaces,veneers and profiles··Setting different light sources such assunlight, spotlight, etc.··Shadow and mirror calculation··Alternatively, the data can be transferredto common rendering and animationprograms via a special interface··Automatically generate layout and viewdrawings including dimensions··Visible textures of components can berepresented easily with the coloringfunction··Shaded? Realistic? X-ray? In the 3Dvisualization, you can choose.09

HOMAG woodCAD CAMDesign modulesYour new assistant: fast, safe andreliableSPECIALIZING IN FURNITURE CONSTRUCTION AND INTERIOR FITTING.Work with software that is designed to perfectly meet your furniture design needsas well as the steps necessary for interior fitting. Sides, floors, frames and fills canbe selected from all available materials, coatings, edges and profiles. Once created,the furniture is then designed in 3D, and no further manual steps are necessary formachine-controlled production.Whether for cabinet construction, commercial construction orcomponent production, woodCAD CAM has tailor-made functions forall carpenters from small trade operations to large-scale production.This means that even complex furniture building tasks are highlymanageable with the design tools available.Article DesignerObject DesignerPart DesignerThe article designer is there for thosedesigns which vary, including in theirdimensions. This module meets therequirements of cabinet and commercialconstruction, where similar items offurniture are required with variations insize or front divisions. The article designeraccesses parametric components toachieve this.The object designer builds on thetrained engineer’s traditional 2D thinking.Component generation is based on oneor more vertical sections as well as thetop-down view of the design. 2D geometrydata can be created with simple 2D CADfunctions such as polyline. From thevarious 2D views, woodCAD CAM thenautomatically generates the entire counterelement in 3D and in full detail. If elementsof the 2D drawing are changed, the 3Dmodel can be adjusted at the click of amouse.The part designer provides even moreflexibility and individuality in 3D modeling.Individual parts are freely put togetheron the screen in 3D. The procedure issimilar to the final assembly of a piece offurniture. Each element receives captureand identification points. Components,edges, connectors, processes, etc. canbe customized interactively on the screen.Profiles, materials and fixtures will only beapplied when the shape is established.11

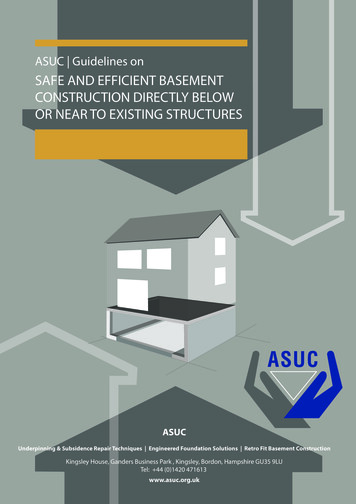

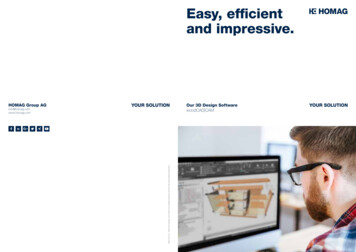

12HOMAG woodCAD CAMHOMAG woodCAD CAMDesign modulesDesign modules1Body design: Article designer2Object designer for counters3Drawer Manager4Frames and profiles5Long parts/countertops6Sliding door fittings541632Change requests? No problem!THE INTEGRATED CHANGE AND DESIGN FUNCTIONS MEAN THATADJUSTMENTS CAN BE MADE TO A CUSTOMER’S ORDER EVEN WHENTHE PLANS ARE ACTUALLY READY FOR PRODUCTION. woodCAD CAM hasbeen programmed so that the drawings, part list data and CNC programs for allexisting production documents can be checked and changed if necessary. Quicklycreate new articles from existing components and make use of the numerouscustomization and modification functions in order to change the properties of itemsand components. If anything is changed, the modifications are saved along withthe item. This means you can carry out modifications once and apply them to itemswith altered dimensions.Strips and countertopsProfiles and frame componentsFor kitchen, interior and laboratory work, assistants are used toproduce lighting strips, skirting boards and cornices as well ascountertops. In this process, elements are automatically created,taken through the application-specific design principles andconnectors are attached where necessary.Using the “stretchable purchased parts” wizard, designs can becreated with profiles, pipe elements or connecting pieces, and eitherwood, metal or plastic parts used. Modules comprising severalcomponents, such as door frames, can be created quickly andeasily with the “multiple components” wizard. Design is graphicaland can be checked in the 3D view at any time.13

14HOMAG woodCAD CAMHOMAG woodCAD CAMConnctions and fixturesConnections and fixturesLeave connections andfixtures to usWOODCAD CAM TAKES ON THE CHOICE OF CONNECTIONS ANDCOMPONENT-OPTIMIZED FIXTURES FOR YOU. All common connectionsfor furniture and interior design are saved in the library. That means you can savetime and be confident in the design process. At the same time, the necessaryinformation is prepared in order to appear in all further drawings and parts lists. Youwill also save valuable time when searching for fittings. Not only does the softwarefind the correct fittings for you automatically, but it

Based on proven CAD/CAM technology, you can achieve a work preparation time saving of up to 70% with woodCAD CAM. YOUR SOLUTION MORE: HOMAG.COM woodCAD CAM CONTENTS 04 design-to-machine 06 Planning and presentation 10 Design modules 14 Connections and fittings 16 Components and material structure 17 Calculation 18 Production documentation 20 CNC data generation 22