Transcription

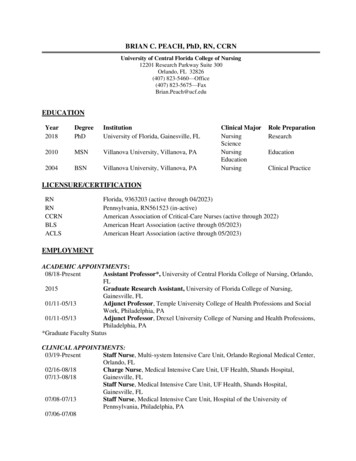

March 18,Docket Nos. 50-277and 50-278-DISTRIBUTION w/enclosures:Docket Fil eACRS (10)NRC & Local PDRGPA/PAPDI-2 Rdg.OC/LFMBSVargaRBlough, RGN-IFGreenmanLDoerflein, RGN-IWButlerSLWu, 8E-23MO'Brien(2)GSuh/RClarkDHagan 3206GHill(4)Wanda JonesJCalvoMr. George J. BeckDirector-Licensing, MC 5-2A-5Philadelphia Electric CompanyNuclear Group HeadquartersCorrespondence Control DeskP.O. Box No. 195Wayne, Pennsylvania 1.9087-0195Dear Mr. BeckSUBJECT:1991MINIMUM CRITICAL POWER RATIO SAFETY LIMITS, PEACH BOTTOM ATOMICPOWER STATION, UNITS 2 AND 3 (TAC NOS. 79325 AND 79326)The Commission has issued the enclosed Amendment Nos. 157 and 159 to FacilityOperating License Nos. DPR-44 and DPR-56 for the Peach Bottom Atomic PowerStation, Unit Nos. 2 and 3. These amendments consist of changes to theTechnical Specifications in response to your application dated December 17,1990 as supplemented on January 22, 1991.These amendments would revise the Technical Specifications to revise MinimumCritical Power Ratio Safety Limits since the cores will be reloaded with a newfuel type, GE 8X8 NB, for Cycle 9 operation. The proposed amendments alsoinvolve miscellaneous administrative changes.A copy of the Safety Evaluation is also enclosed. Notice of Issuance will beincluded in the Commission's Bi-Weekly Federal Register Notice.Sincerely,/S/Gene Y. Suh, Project ManagerProject Directorate 1-2Division of Reactor Projects - I/IIOffice of Nuclear Reactor RegulationEnclosures:1. Amendment No. 157 to DPR-442. Amendment No. 159 to DPR-563.Safety EvaluationNRC ALE CENTER COPYcc w/enclosures:See next pageOFC:P INAME:MDATE:PDI-2/PMn--------- -:GSuh:rb,4'/\/917/j?/91OFFICIAL RECORD COPYDocument Name::PDI-2/D:0G,: /yej:---- 4 -:WButler---.--.-1. / :i//9/91/9LTAC NOS 79325/6]I,

REGU(10 UNITEDSTATESNUCLEAR REGULATORY COMMISSIONWASHINGTON, D. C. 20555March 18,1991Docket Nos. 50-277and 50-278Mr. George J. BeckDirector-Licensing, MC 5-2A-5Philadelphia Electric CompanyNuclear Group HeadquartersCorrespondence Control DeskP.O. Box No. 195Wayne, Pennsylvania 19087-0195Dear Mr.SUBJECT:Beck:MINIMUM CRITICAL POWER RATIO SAFETY LIMITS, PEACH BOTTOM ATOMICPOWER STATION, UNITS 2 AND 3 (TAC NOS. 79325 AND 79326)The Commission has issued the enclosed Amendment Nos. 157 and 159 to FacilityOperating License Nos. DPR-44 and DPR-56 for the Peach Bottom Atomic PowerStation, Unit Nos. 2 and 3.These amendments consist of changes to theTechnical Specifications in response to your application dated December 17,1990 as supplemented on January 22, 1991.These amendments would revise the Technical Specifications to revise MinimumCritical Power Ratio Safety Limits since the cores will be reloaded with a newfuel type, GE 8X8 NB, for Cycle 9 operation.The proposed amendments alsoinvolve miscellaneous administrative changes.A copy of the Safety Evaluation is also enclosed.Notice of Issuance will beincluded in the Commission's Bi-Weekly Federal Register Notice.Sincerely,Gene Y. Suh, Project ManagerProject Directorate 1-2Division of Reactor Projects - I/IlOffice of Nuclear Reactor RegulationEnclosures:1. Amendment No. 157 to DPR-442. Amendment No. 159 to DPR-563.Safety Evaluationcc w/enclosures:See next page

Mr. George J. BeckPhiladelphia Electric CompanyPeach Bottom Atomic Power Station,Units 2 and 3cc:J. W. Durham, Sr., EsquireSr. V.P. & General CounselPhiladelphia Electric Company2301 Market StreetPhiladelphia, Pennsylvania 19101Single Point of ContactP. 0. Box 11880Harrisburg, PennsylvaniaPhiladelphia Electric CompanyATTN: Mr. D. B. Miller, Vice PresidentPeach Bottom Atomic Power StationRoute 1, Box 20PDelta, Pennsylvania 17314Mr. Thomas MI.Gerusky, DirectorBureau of Radiation ProtectionPennsylvania Department ofEnvironmental ResourcesP. 0. Box 2063Harrisburg, Pennsylvania 17120Philadelphia Electric CompanyATTN: Regulatory Engineer, A1-2SPeach Bottom Atomic Power StationRoute 1, Box 208Delta, Pennsylvania 17314Resident InspectorU.S. Nuclear Regulatory CommissionPeach Bottom Atomic Power StationP.O. Box 399Delta, Pennsylvania 17314Regional Administrator, Region IU.S. Nuclear Regulatory Commission475 Allendale RoadKing of Prussia, Pennsylvania 19406Mr. Roland FletcherDepartment of Environment201 West Preston StreetBaltimore, Maryland 21201BoardPeachR. D.Delta,17108-1880of SupervisorsBottom Township#1Pennsylvania 17314Public Service Commission of MarylandEngineering DivisionATTN: Chief Engineer231 E. Baltimore StreetBaltimore, MD 21202-3486Mr. Richard McLeanPower Plant and EnvironmentalReview DivisionDepartment of Natural ResourcesB-3, Tawes State Office BuildingAnnapolis, Maryland 21401

UNITED STATESNUCLEAR REGULATORY COMMISSIONWASHINGTON, D.C. 20555PHILADELPHIA ELECTRIC COMPANYPUBLIC SERVICE ELECTRIC AND GAS COMPANYDELMARVA POWER AND LIGHT COMPANYATLANTIC CITY ELECTRIC COMPANYDOCKET NO.50-277PEACH BOTTOM ATOMIC POWER STATION,UNIT NO. 2AMENDMENT TO FACILITY OPERATING LICENSEAmendment No. 157License No. DPR-441. The Nuclear Regulatory Commission (the Commission) has found that:2.A.The application for amendment by Philadelphia Electric Company, et.al. (the licensee) dated December 17, 1990 as supplemented onJanuary 22, 1991, complies with the standards and requirements of theAtomic Energy Act of 1954, as amended (the Act), and the Commission'srules and regulations set forth in 10 CFR Chapter I.B.The facility will operate in conformity with the application, theprovisions of the Act, and the rules and regulations of theCommission;C.There is reasonable assurance (i) that the activities authorized bythis amendment can be conducted without endangering the health andsafety of the public, and (ii) that such activities will be conductedin compliance with the Commission's regulations;D.The issuance of this amendment will not be inimical to the commondefense and security or to the health or safety of the public; andE.The issuance of this amendment is in accordance with 10 CFR Part 51 ofthe Commission's regulations and all applicable requirements have beensatisfied.Accordingly, the license is amended by changes to the TechnicalSpecifications as indicated in the attachment to this license amendment,and paragraph 2.C(2) of Facility Operating License No. DPR-44 is herebyamended to read as follows:

-2(2)Technical SpecificationsThe Technical Specifications contained in Appendices A and B, asrevised through Amendment No. 157 , are hereby incorporated in thelicense. PECO shall operate the facility in accordance with theTechnical Specifications.3.This license amendment is effective as of the date of startup in Cycle 9.FOR THE NUCLEAR REGULATORY COMMISSIONWalter R. Butler, DirectorProject Directorate 1-2Division of Reactor ProjectsAttachment:Changes to the TechnicalSpecificationsDate of Issuance:March 18,1991-I/II

ATTACHMENT TO LICENSE AMENDMENT NO. 157FACILITY OPERATING LICENSE NO. DPR-44DOCKET NO. 50-277Replace the following pages of the Appendix A Technical Specifications withthe enclosed pages.The revised areas are indicated by marginal 0c256a256a

Unit 2PBAPSSAFETY LIMIT1.1 FUEL CLADDING INTEGRITYApplicability:LIMITING SAFETY SYSTEM SETTING2.1 FUEL CLADDING INTEGRITYApplicability:The Safety Limits establishedto preserve the fuel claddingintegrity apply to thosevariables which monitor thefuel thermal behavior.The Limiting Safety System Settingsapply to trip settings of theinstruments and devices which areprovided to prevent the fuelcladding integrity Safety Limitsfrom being exceeded.Objectives:Objectives:The objective of the SafetyLimits is to establish limitswhich assure the integrity ofthe fuel cladding.The objective of the Limiting SafetySystem Settings is to define thelevel of the process variables atwhich automatic protective action isinitiated to prevent the fuel claddingintegrity Safety Limits from beingexceeded.Specification:Specification:A. Reactor Pressure 800 psiaand Core Flow -10% of RatedThe limiting safety system settingsshall be as specified below:A. Neutron Flux ScramiiThe existence of a minimumcritical power ratio (MCPR)less than 1.06 for tworecirculation loop operation,or 1.07 for single loopoperation, shall constituteviolation of the fuel claddingintegrity safety limit.1. APRM Flux Scram Trip Setting(Run Mode)When the Mode Switch is in theRUN position, the APRM fluxscram trip setting shall be:S 0.58W 62% - 0.58 AWTo ensure that this safetylimit is not exceeded, neutronflux shall not be above thescram setting established inspecification 2.1.A for longerthan 1.15 seconds as indicatedby the process computer. Whenthe process computer is out ofservice this safety limit shallbe assumed to be exceeded ifthe neutron flux exceeds itsscram setting and a controlrod scram does not occur.Amendment No.%,,where:S Setting in percent of ratedthermal power (3293 MWt)W Loop recirculating flow ratein percent of design. W is100 for core flow of 102.5million lb/hr or greater.-9-19- I

Unit 2PBAPS2.1BASES:FUEL CLADDING INTEGRITYThe abnormal operational transients applicable to operation of the Peach BottomAtomic Power Station Units have been analyzed throughout the spectrum of plannedoperating conditions up to or above the thermal power condition required byRegulatory Guide 1.49. The analyses were based upon plant operation in accordance with the operating map given in Figure 3.7.1 of the FSAR.In addition,3293 MWt is the licensed maximum power level of each Peach Bottom Atomic PowerStation Unit, and this represents the maximum steady state power which shallnot knowingly be exceeded.Conservatism is incorporated in the transient analyses in estimating thecontrolling factors, such as void reactivity coefficient, control rod scramworth, scram delay time, peaking factors, and axial power shapes.These factors are selected conservatively with respect to their effect on the applicabletransient results as determined by the current analysis model.Conservatismincorporated into the transient analyses is documented in References 2 and 3.Amendment No. n, "K, 124 157-17-

Unit 22.1BASES: (Cont'd)L.References1.Linford, R. B., "Analytical Methods of Plant Transient Evaluationsfor the General Electric Boiling Water Reactor", NEDO 10802,February 1973.2."General Electric Standard Application for Reactor Fuel",NEDE-24011-P-A (as amended).3."Methods for Performing BWR Reload Safety Evaluations,"PECo-FMS-0006-A (as amended).Amendment No.157-24-II

Unit 2PBAPS3.5.BASES (Cont'd)J.Local LHGRThis specification assures that the linear heat generation rate in any 8X8 fuelrod is less than the design linear heat generation. The maximum LHGR shall bechecked daily during reactor operation at 25% power to determine if fuelburnup, or control rod movement has caused changes in power distribution.ForLHGR to be at the design LHGR below 25% rated thermal power, the peak localLHGR must be a factor of approximately ten (10) greater than the average LHGRwhich is precluded by a considerable margin when employing any permissiblecontrol rod pattern.K.Minimum Critical Power Ratio (MCPR)Operating Limit MCPRThe required operating limit MCPR's at steady state operating conditions are derived from the established fuel cladding integrity Safety Limit MCPR andanalyses of the abnormal operational transients presented in Supplemental ReloadLicensing Analysis and References 7 and 10.For any abnormal operating transient analysis evaluation with the initial condition of the reactor being atthe steady state operating limit it is required that the resulting MCPR doesnot decrease below the Safety Limit MCPR at any time during the transientassuming instrument trip setting given in Specification 2.1.To assure that the fuel cladding integrity Safety Limit is not violated duringany anticipated abnormal operational transient, the most limiting transientshave been analyzed to determine which result in the largest reduction incritical power ratio (CPR).The transients evaluated are as described inReferences 7 and 10.Amendment No.'81&,I"115a,-140a-

Unit 2PBAPS3.5. K.BASES (Cont'd)The largest reduction in critical power ratio is then added to the fuel claddingintegrity safety limit MCPR to establish the MCPR Operating Limit for each fueltype.Analysis of the abnormal operational transients is presented in References 7and 10.Input data and operating conditions used in this analysis are shownin References 7 and 10 and in the Supplemental Reload Licensing Analysis.3.5.L.Average Planar LHGR (APLHGR),Ratio (MCPR)Local LHGR and Minimum Critical PowerIn the event that the calculated value of APLHGR, LHGR or MCPR exceeds itslimiting value, a determination is made to ascertain the cause and initiatecorrective actions to restore the value to within prescribed limits. Thestatus of all indicated limiting fuel bundles is reviewed as well as inputdata associated with the limiting values such as power distribution, instrumentation data (Traversing In-Core Probe - TIP, Local Power Range MonitorLPRM, and reactor heat balance instrumentation), control rod configuration,etc., in order to determine whether the calculated values are valid.In the event that the review indicates that the calculated value exceedinglimits is valid, corrective action is immediately undertaken to restore thevalue to within prescribed limits. Following corrective action, which mayinvolve alterations to the control rod configuration and consequently changesto the core power distribution, revised instrumentation data, including changesto the relative neutron flux distribution, for up to 43 in-core locations isobtained and the power distribution, APLHGR, LHGR and MCPR calculated.Corrective action is initiated within one hour of an indicated value exceeding limitsand verification that the indicated value is within prescribed limits isobtained within five hours of the initial indication.In the event that the calculated value of APLHGR, LHGR or MCPR exceeding itslimiting value is not valid, i.e., due to an erroneous instrumentation indication, etc., corrective action is initiated within one hour of an indicatedvalue exceeding limits. Verification that the indicated value is within prescribed limits is obtained within five hours of the initial indication. Suchan invalid indication would not be a violation of the limiting condition foroperation and therefore would not constitute a reportable occurrence.Amendment No.tM, Ik,,X,"'S,4%,157S,-140b

Unit 2PBAPS3.5.L.BASES (Cont'd)Operating experience has demonstrated that a calculated value of APLHGR, LHGRor MCPR exceeding its limits value predominantely occurs due to this lattercause.This experience coupled with the extremely unlikely occurrence of concurrent operation exceeding APLHGR, LHGR or MCPR and a Loss-of-Coolant Accidentor applicable Abnormal Operational Transients demonstrates that the timesrequired to initiate corrective action (1 hour) and restore the calculatedvalue of APLHGR, LHGR or MCPR to within prescribed limits (5 hours) areadequate.3.5.M.References1."Fuel Densification Effects on General Electric Boiling Water ReactorFuel", Supplements 6, 7 and 8, NEDM-10735, August 1973.2.Supplement 1 to Technical Report on Densifications of General ElectricReactor Fuels, December 14, 1974 (Regulatory Staff).3.Communication:Densification",4.General Electric Company Analytical Model for Loss-of-Coolant Analysis inAccordance with 10 CFR 50, Appendix K, NEDE 20566 (Draft), August 1974.5.General Electric Refill Reflood Calculation (Supplement to SAFE CodeDescription) transmitted to the USAEC by letter, G. L. Gyorey to VictorStello, Jr., dated December 20, 1974.6.DELETED.7."General Electric Standard Application for Reactor Fuel",(as amended).8.Loss-of-Coolant Accident Analysis for Peach Bottom Atomic Power StationUnit 2, NEDO-24081, December 1977, and for Unit 3, NEDO-24082, December1977.9.Loss-of-Coolant Accident Analysis for Peach Bottom Atomic Power StationUnit 2, Supplement 1, NEDE-24081-P, November 1986.10."Methods for Performing BWR Reload Safety Evaluations," PECo-FMS-0006-A(as amended).Amendment No. N,X,V. A. Moore to I. S. Mitchell, "Modified GE Model for FuelDocket 50-321, March 27, 1974.1X,X,sAq, 15 7X,-140cNEDE-24011-P-A

Unit 2PBAPS6.9.1Routine Reports (Cont'd)(2)PECo-FMS-0002-A, "Method for Calculating TransientCritical Power Ratios for Boiling Water s Report"(4)PECo-FMS-0004-A, "Methods for Performing BWR SystemsTransient Analysis"(5)PECo-FMS-0005-A, "Methods for Performing BWR SteadyState Reactor Physics Analysis"(6)PECo-FMS-0006-A, "Methods for Performing BWR ReloadSafety Evaluations"'"Steady-State Fuel Performance(3)The core operating limits shall be determined such that allapplicable limits (e.g., fuel thermal-mechanical limits, corethermal-hydraulic limits, ECCS limits, nuclear limits such asshutdown margin, transient analysis limits, and accidentanalysis limits) of the safety analysis are met.(4)The CORE OPERATING LIMITS REPORT, including any mid-cyclerevisions or supplements, shall be submitted upon issuance foreach Operating Cycle to the NRC Document Control Desk withcopies to the Regional Administrator and Resident Inspector.Amendment No., 157-256a-

UNITED STATESNUCLEAR REGULATORY COMMISSIONWASHINGTON, D.C. 2066PHILADELPHIA ELECTRIC COMPANYPUBLIC SERVICE ELECTRIC AND GAS COMPANYDELMARVA POWER AND LIGHT COMPANYATLANTIC CITY ELECTRIC COMPANYDOCKET NO. 50-278PEACH BOTTOM ATOMIC POWER STATION, UNIT NO. 3AMENDMENT TO FACILITY OPERATING LICENSEAmendment No. 159License No. DPR-561.2.The Nuclear Regulatory Commission (the Commission) has found that:A.The application for amendment by Philadelphia Electric Company, et.al. (the licensee) dated December 17, 1990 as supplemented onJanuary 22, 1991, complies with the standards and requirements of theAtomic Energy Act of 1954, as amended (the Act), and the Commission'srules and regulations set forth in 10 CFR Chapter I.B.The facility will operate in conformity with the application, theprovisions of the Act, and the rules and regulations of theCommission;C.There is reasonable assurance (i) that the activities authorized bythis amendment can be conducted without endangering the health andsafety of the public, and (ii) that such activities will be conductedin compliance with the Commission's regulations;D.The issuance of this amendment will not be inimical to the commondefense and security or to the health or safety of the public; andE.The issuance of this amendment is in accordance with 10 CFR Part 51 ofthe Commission's regulations and all applicable requirements have beensatisfied.Accordingly, the license is amended by changes to the TechnicalSpecifications as indicated in the attachment to this license amendment,and paragraph 2.C(2) of Facility Operating License No. DPR-56 is herebyamended to read as follows:

-2(2)Technical SpecificationsThe Technical Specifications contained in Appendices A and B, asrevised through Amendment No. 159, are hereby incorporated in thelicense. PECO shall operate the facility in accordance with theTechnical Specifications.3.This license amendment is effective as of the date of startup in Cycle 9.FOR THE NUCLEAR REGULATORY COMMISSIONWalter R. Butler, DirectorProject Directorate 1-2Division of Reactor Projects - I/IIAttachment:Changes to the TechnicalSpecificationsDate of Issuance:March 18,1991

ATTACHMENT TO LICENSE AMENDMENT NO. 159FACILITY OPERATING LICENSE NO.DOCKET NO.DPR-5650-278Replace the following pages of the Appendix A Technical Specifications withthe enclosed pages.The revised areas are indicated by marginal 0c256a256a

Unit 3PBAPSSAFETY LIMIT1.1 FUEL CLADDING INTEGRITYApplicability:LIMIl ING SAFETY SYSTEM SETTING2.1FUEL CLADDING INTEGRITYAppli cability:The Safety Limits establishedto preserve the fuel claddingintegrity apply to thosevariables which monitor thefuel thermal behavior.The L.imiting Safety System Settingsapply to trip settings of theinstyruments and devices which areprovi ded to prevent the fuelcladdling integrity Safety Limitsfrom being exceeded.Objectives:Objec:tives:The objective of the SafetyLimits is to establish limitswhich assure the integrity ofthe fuel cladding.The o)bjective of the Limiting SafetySyste)m Settings is to define thelevel of the process variables atwhichI automatic protective action isiniti ated to prevent the fuel claddinginteg)rity Safety Limits from beingexcee ded.Specification:Speci fication:A. Reactor Pressure -800 psiaand Core Flow 10% of RatedThe 1imiting safety system settingsshall be as specified below:A. Neutron Flux ScramThe existence of a minimumcritical power ratio (MCPR)less than 1.06 for tworecirculation loop operation,or 1.07 for single loopoperation, shall constituteviolation of the fuel claddingintegrity safety limit.1. APRM Flux Scram Trip Setting(Run Mode)When the Mode Switch is in theRUN position, the APRM fluxscram trip setting shall be:S 0.58W 62% - 0.58 AWTo ensure that this safetylimit is not exceeded, neutronflux shall not be above thescram setting established inspecification 2.1.A for longerthan 1.15 seconds as indicatedby the process computer. Whenthe process computer is out ofservice this safety limit shallbe assumed to be exceeded ifthe neutron flux exceeds itsscram setting and a controlrod scram does not occur.Amendment No.1X,, \, ,where:S Setting in percent of ratedthermal power (3293 MWt)W Loop recirculating flow ratein percent of design. W is100 for core flow of 102.5million lb/hr or greater.-9-I

Unit 3PBAPS2.1BASES:FUEL CLADDING INTEGRITYThe abnormal operational transients applicable to operation of the Peach BottomAtomic Power Station Units have been analyzed throughout the spectrum of plannedoperating conditions up to or above the thermal power condition required byRegulatory Guide 1.49. The analyses were based upon plant operation in accordance with the operating map given in Figure 3.7.1 of the FSAR.In addition,3293 MWt is the licensed maximum power level of each Peach Bottom Atomic PowerStation Unit, and this represents the maximum steady state power which shallnot knowingly be exceeded.Conservatism is incorporated in the transient analyses in estimating thecontrolling factors, such as void reactivity coefficient, control rod scramworth, scram delay time, peaking factors, and axial power shapes.These factors are selected conservatively with respect to their effect on the applicabletransient results as determined by the current analysis model.Conservatismincorporated into the transient analyses is documented in References 4 and 5.Amendment No. N,X'INQ, 159-17-

Unit 32.1BASES: (Cont'd)L.References1.Linford, R. B., "Analytical Methods of Plant Transient Evaluationsfor the General Electric Boiling Water Reactor", NEDO 10802,February 1973.2."Qualification of the One-Dimensional Core Transient Model forBoiling Water Reactors", NEDO 24154 and NEDE 24154-P, Volumes I,II, and III.3."Safety Evaluation for the General Electric Topical ReportQualification of the One-Dimensional Core Transient Model forBoiling Water Reactors NEDO-24154 and NEDE 24154-P, Volumes I,II, and III.4."General Electric Standard Application for Reactor Fuel",NEDE-24011-P-A (as amended).5."Methods for Performing BWR Reload Safety Evaluations,"PECo-FMS-0006-A (as amended).Amendment No. X,X159-24-

Unit 3PBAPS3.5.BASES (Cont'd)J.Local LHGRThis specification assures that the linear heat generation rate in any 8X8 fuelrod is less than the design linear heat generation. The maximum LHGR shall bechecked daily during reactor operation at 25% power to determine if fuelburnup, or control rod movement has caused-changes in power distribution.ForLHGR to be at the design LHGR below 25% rated thermal power, the peak localLHGR must be a factor of approximately ten (10) greater than the average LHGRwhich is precluded by a considerable margin when employing any permissiblecontrol rod pattern.K.Minimum Critical Power Ratio (MCPR)Operating Limit MCPRThe required operating limit MCPR's at steady state operating conditions are derived from the established fuel cladding integrity Safety Limit MCPR andanalyses of the abnormal operational transients presented in Supplemental ReloadLicensing Analysis and References 7 and 10.For any abnormal operating transient analysis evaluation with the initial condition of the reactor being atthe steady state operating limit it is required that the resulting MCPR doesnot decrease below the Safety Limit MCPR at any time during the transientassuming instrument trip setting given in Specification 2.1.To assure that the fuel cladding integrity Safety Limit is not violated duringany anticipated abnormal operational transient, the most limiting transientshave been analyzed to determine which result in the largest reduction incritical power ratio (CPR).The transients evaluated are as described inReferences 7 and 10.Amentment No.-140a-

"-iiUnit 3PBAPS3.5.K.BASES (Cont'd)The largest reduction in critical power ratio is then added to the fuelcladdingintegrity safety limit MCPR to establish the MCPR Operating Limit foreach fueltype.Analysis of the abnormal operational transients is presented in References7and 10. Input data and operating conditions used in this analysis areshownin References 7 and 10 and in the Supplemental Reload Licensing Analysis.3.5.L.Average Planar LHGR (APLHGR),Ratio (MCPR)Local LHGR and Minimum Critical PowerIn the event that the calculated value of APLHGR, LHGR or MCPR exceedsitslimiting value, a determination is made to ascertain the cause andinitiatecorrective action- to restore the value to within prescribed limits.status of all indicated limiting fuel bundles is reviewed as well as Thedata associated with the limiting values such as power distribution, inputinstrumentation data (Traversing In-Core Probe - TIP, Local Power Range MonitorLPRM, and reactor heat balance instrumentation), control rod configuration,etc., in order to determine whether the calculated values are valid.In the event that the review indicates that the calculated value exceedinglimits is valid, corrective action is immediately undertaken to restorevalue to within prescribed limits. Following corrective action, which theinvolve alterations to the control rod configuration and consequently mayto the core power distribution, revised instrumentation data, includingchangeschangesto the relative neutron flux distribution, for up to 43 in-core locationsisobtained and the power distribution, APLHGR, LHGR and MCPR calculated.Corrective action is initiated within one hour of an indicated value exceedinglimitsand verification that the indicated value is within prescribed limitsisobtained within five hours of the initial indication.In the event that the calculated value of APLHGR, LHGR or MCPR exceedingitslimiting value is not valid, i.e., due to an erroneous instrumentationindication, etc., corrective action is initiated within one hour of an indicationvalue exceeding limits. Verification that the indicated value is withinscribed limits is obtained within five hours of the initial indication. prean invalid indication would not be a violation of the limiting condition Suchforoperation and therefore would not constitute a reportable occurrence.Amendment No. '5 ,,tSq, 159',.,-140b

Unit 3PBAPS3.5. L.BASES (Cont'd)Operating experience has demonstrated that a calculated value of APLHGR, LHGRor MCPR exceeding its limiting value predominantely occurs due to this lattercause.This experience coupled with the extremely unlikely occurrence of concurrent operation exceeding APLHGR, LHGR or MCPR and a Loss-of-Coolant Accidentor applicable Abnormal Operational Transients demonstrates that the timesrequired to initiate corrective action (1 hour) and restore the calculatedvalue of APLHGR, LHGR or MCPR to within prescribed limits (5 hours) areadequate.3.5.M.References1."Fuel Densification Effects on General Electric Boiling Water ReactorFuel", Supplements 6, 7 and 8, NEDM-10735, August 1973.2.Supplement 1 to Technical Report on Densifications of General ElectricReactor Fuels, December 14, 1974 (Regulatory Staff).3.Communication:Densification",4.General Electric Company Analytical Model for Loss-of-Coolant Analysis inAccordance with 10 CFR 50, Appendix K, NEDE 20566 (Draft), August 1974.5.General Electric Refill Reflood Calculation (Supplement to SAFE CodeDescription) transmitted to the USAEC by letter, G. L. Gyorey to VictorStello, Jr., dated December 20, 1974.6.DELETED.7."General Electric Standard Application for Reactor Fuel",(as amended).8.Loss-of-Coolant Accident Analysis for Peach Bottom Atomic Power StationUnit 2, NEDO-24081, December 1977, and for Unit 3, NEDO-24082, December1977.9.Loss-of-Coolant Accident Analysis for Peach Bottom Atomic Power StationUnit 2, Supplement 1, NEDE-24081-P, November 1986, and for Unit 3, NEDE24082-P, December 1987.10."Methods for Performing BWR Reload Safety Evaluations," PECo-FMS-0006-A(as amended).Amendment No. 5k, 5V. A. Moore to I. S. Mitchell,Docket 50-321, March 27, 1974.)R1,*6,-140c-"Modified GE Model for FuelNEDE-24011-P-A

Unit 3PBAPS6.9.1Routine Reports (Cont'd)(2)PECo-FMS-0002-A, "Method for Calculating TransientCritical Power Ratios for Boiling Water s Report"(4)PECo-FMS-0004-A, "Methods for Performing BWR SystemsTransient Analysis"(5)PECo-FMS-0005-A, "Methods for Performing BWR SteadyState Reactor Physics Analysis"(6)PECo-FMS-0006-A, "Methods for Performing BWR ReloadSafety Evaluations"'"Steady-State Fuel Performance(3)The core operating limits shall be determined such that allapplicable limits (e.g., fuel thermal-mechanical limits, corethermal-hydraulic limits, ECCS limits, nuclear limits such asshutdown margin, transient analysis limits, and accidentanalysis limits) of the safety analysis are met.(4)The CORE OPERATING LIMITS REPORT, including any mid-cyclerevisions or supplements, shall be submitted upon issuance

fuel type, GE 8X8 NB, for Cycle 9 operation. The proposed amendments also involve miscellaneous administrative changes. A copy of the Safety Evaluation is also enclosed. Notice of Issuance will be included in the Commission's Bi-Weekly Federal Register Notice. Sincerely, Gene Y. Suh, Project Manager