Transcription

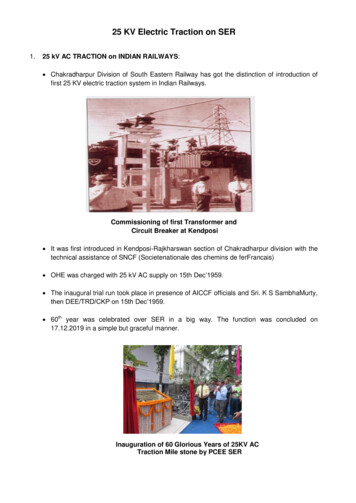

25 KV Electric Traction on SER1.25 kV AC TRACTION on INDIAN RAILWAYS: Chakradharpur Division of South Eastern Railway has got the distinction of introduction offirst 25 KV electric traction system in Indian Railways.Commissioning of first Transformer andCircuit Breaker at Kendposi It was first introduced in Kendposi-Rajkharswan section of Chakradharpur division with thetechnical assistance of SNCF (Societenationale des chemins de ferFrancais) OHE was charged with 25 kV AC supply on 15th Dec‟1959. The inaugural trial run took place in presence of AICCF officials and Sri. K S SambhaMurty,then DEE/TRD/CKP on 15th Dec‟1959. 60th year was celebrated over SER in a big way. The function was concluded on17.12.2019 in a simple but graceful manner.Inauguration of 60 Glorious Years of 25KV ACTraction Mile stone by PCEE SER

2. GROWTH OF ELECTRIC LOCOMOTIVES OVER SERYEAR12001000800600400TOTAL2002021-22 upto 41962-630SER is having highest holding of Electric locomotives (also 3 Phase locos) over Indian Railway.3. Milestones of Electric Loco:3.1ELS/TATA: It is the 2nd Electric Loco shed of Indian Railways. It was established in the year 1962with 69 locomotives under the supervision of SNCF Railway.Present holding (as on 01.07.2021): 201 (WAG9:174, WAP7:27)Future Plan: 250. It was established in the year 1964.

3.2 ELS/BNDM: 3.3Established: 07 January‟1983 with an initial holding of 6 WAM4 locomotives.Present holding (as on 01.07.2021): 191 (WAG7: 89, WAG9: 86, WAP7: 15 & WAGC3:1).Silver Jubilee was celebrated on 25.10.2008.Future Plan: 250 locos.ELS/BKSC: Established: 18th May 2012 with holding of 54 WAG5 locomotives(Inaugurated byShriKulbhushan, Member Electrical on 18.05.2012) Present holding (as on 01.07.2021): 150 (WAG7: 66, WAG9: 84) Future Plan: 200 locos.

3.4 ELS/SRC: Established: 26th January‟1999 with a holding of 6 WAP4 locomotives. Present holding (as on 01.07.2021): Electric: 88 (WAP4: 35, WAP7: 53). Diesel: 18 (WDS6: 10, WDM3A: 8). Future Plan: 1253.5 ELS/ROU:Established:8th Jan 2019 with holding of 01(Inauguration byShriP.S.Mishra,G.M/S.E.Railwayon 08.01.2019) Present holding (as on 01.07.2021): WAG9: 121 Future Plan: 200

3.6ELS/KGP (Earlier known as DLS/KGP): Electric loco allotment of 5 WAG5 on 01.02.2018. Complete evacuation: 01.09.2020. Present holding (as on 01.07.2021):150 (WAG7:125 & WAP4: 25). Future Plan:200 locos.3.73.8ELS/IPTN (Earlier known as DLS/BKSC): Electric loco allotment of 5 WAG5 on 01.02.2018. Complete evacuation: 01.08.2020. Present holding (as on 01.07.2021): 75 (WAG7). Future Plan: 100 locos.CTRC/TATA: Established on 6th February 1976. Wheel repair / manufacture of electric locomotives. Capacity: 750 wheelset per year. TM rewinding of conventional loco. Capacity: 150 armatures per year.

3.9CENTRE OF EXCELLENCE AT ELS/ROU:Established: 31st July 2019(Inauguration by Smt. Manju Gupta, Addl. Member (Elect.) /Railway Board on 31.07.2019) OBJECTIVES:To develop centralized support for Pneumatics and ElectronicsInfrastructures: Smart class capacity : 25Auditorium capacity : 56Conference hall capacity : 51Pneumatics LabPower Electronics LabElectronics LabComputer Based Testing cum Training LabMechanical Lab4.0Infrastructure of Electrical (OP):4.1Running Rooms: There are 29 Running Rooms in SER. Out of which, 28 Running Rooms are airconditioned. Running Rooms in ADA Division are at Adra, Anara, Bokaro and Bhojudih. Running Rooms in CKP Division are at Tatanagar, Chakradharpur, Bondamunda, Rourkela,Dumitra, Karampada, Barsuan, Bimalgarh, Jharsuguda, Sardega, Dangoaposi, Noamundi,Banspani, Joda Mines, Joruli. Running Rooms in KGP Division are at Santragachi, Andul, Kharagpur, Nimpura, Tikiapara,Mecheda, Panskura, Haldia. Running Rooms in RNC Division are at Hatia, Muri.

Running Room HTE won MR Shield of Best Running Room of I.R for the year 2020-21.4.2CREW LOBBIES:There are 21 Combined Crew and Guard Lobbies in SER. All the crew lobbies are airconditioned and integrated with CMS: Crew Lobbies in ADA Division at Adra, Anara, Bokaro and Bhojudih, Bankura. Running Rooms in CKP Division at Tatanagar, Adityapur, Sini, Chakradharpur,Manoharpur, Bondamunda, Rourkela, Jharsuguda, Dangoaposi, Joruli. Running Rooms in KGP Division at Santragachi, Andul, Kharagpur, Nimpura. Running Rooms in RNC Division at Hatia, Muri.In addition, there are another 20 smaller crew booking points integrated with CMS functioning inSER: ADA Division: Mohuda CKP Division: NOMD, BJMD, BBN, BYX, BSPX, DMF, BXF, GUA, KMPD. KGP Division: BPO, HLZ, TPKR, HWH, MCA, PKU, MDN, HLZ (Freight), DGHA, AMTA.4.3TRIP SHEDS & POOLING POINTS: 4.4There are five Trip Sheds with facility of Pit in SER to facilitate Trip inspection and otherattention of loco:ADA Division: BKSCCKP Division: TATA, DPSKGP Division: SRC, KGPRNC Division: HTEIn addition, there are another four Pooling Points (without Pit) in SER to facilitate road sidemaintenance of loco:ADA division: ADA, ANRCKP Division: CKP, ROU.ELTC/TATA: Established in December 1964. Provides initial, refresher and special trainings to crew (CLI/ LP/ALP). Trainee capacity: 4440.

5.0Achievements of SER during 2020-21:5.1 During 2020-21, 132 (SRC - 2, TATA - 24, BNDM - 46, BKSC - 30 & ROU - 30) newlocomotives have been commissioned at SER. With this, total holding of electric loco in SERhas become 952 (534 - three-phase) which is highest on Indian Railway.5.2 Diesel loco shed/Bokaro and Diesel loco shed/KGP have become fully operational 6th and 7thElectric loco sheds of South Eastern Railway with present holding of 75 and 150 Electriclocomotives respectively. As these sheds no more hold any Diesel locomotives so their nameshave been changed to Electric loco shed/Ispatnagar (ELIN) and Electric loco shed/KGP (ELKP)respectively from 05.01.2021 with the approval of GM/SER.Infrastructure of ELS/Ispatnagar for Maintaining Electric Locomotives:MVMT Test StandMVSL / MVSI Test StandTM Test MachineEPC Test StandPressure switch Test StandFlasher Light Test BenchSMGR Test StandPHGR Test StandPantograph Test StandTraction Motor carbon brushholder pressure test standVCD test standMV drop test-stand for line contactorsand drumcontactors

Major Infrastructure of ELS/KGP for Maintaining Electric LocomotivesSuction Arrangement for DustRemovalEMC Test BenchAuxiliary Motors Light Run TestStandLine Contactor Test StandPHGR Test BenchPantograph Test StandAuxiliary compressor TestStandFixture for handling of VCBMPH Test StandHigh Vacuum Type Transformer OilPurification PlantCPA Test StandPure Air Brake System (IRAB-1) TestStand

5.3 During 2020-21 ELS/ROU has become fully operational with inspection and lifting bays, storescomplex.Major Infrastructure of ELS/ROU for Maintaining Electric LocomotivesEOT carne (65/10,35/6,15/6)T65/10T EOT crane with Lifting tackleBAKING OVENVVVF drive Testing MachineDGA MachineInduction heaterTFP Oil filterElectronics Test equipmentPIT WHEEL LATHEEquipment handling stackerHot & cold high pressure jet cleanerPipe brazing machinePipebending machineStacking arrangement inside storeStacking arrangement in heavy lifting bay

5.4 Centre of Excellence has been setup at ELS/ROU for giving maintenance support to variousElectric loco sheds of SER and imparting both training to running and maintenance staff. Total5254 (SER – 594 & FR – 4660) trainees have been imparted training during 2020-21.Major Infrastructure at “CENTRE OF EXCELLENCE “/ROUCENTRE OFEXCELLENCESmart Class RoomHeavy Repairing Lab(GTO Valve SetRepairingsetup)Electronic Labwith TestEquipmentsConferenceHallwithVIideoConferencing System56 Seated AuditoriumMechanical Model RoomComputer based TestingandTrainingPneumaticLabwith CCB and E70Test Bench

5.5 ELS/TATA has become the first shed of SER to home 100% three-phase locomotives.5.6 On Load Testing Facility for Hotel Load Converter developed by ELS/SRC & TATA:ELS/Santragachi& TATA have developed an “Onload testing facility for Hotel Load Converter”during 20-21. It helps in identifying defect, if any, inthe hotel load converter of the loco in shed itself. Thissetup has been built up completely in-house by thesheds using a released 60 KVA TFP of LHB coach.5.7 Commissioning of High-end Electronics Testing Setup for M/S Medha& M/S BHEL makePropulsion Systems at ELS/TATA:Unique testing facilities have been commissioned at ELS/TATA for Medhamake (Version-II) &M/S BHEL make Propulsion Systems of three-phase locos. These are the first of their typeon Indian Railways. The systems are capable of carrying out functional tests of various cardsof Propulsion Systems. It would be very useful in testing problematic / doubtful cards inElectronics lab and will avoid troubleshooting by trial and error on locomotives.Medha Make Test Rig (Version II)BHEL Make Test Rig

5.8 Conversion of WAG9 Bogie to Conventional Brake Rigging by KGP Workshop:At KGP Workshop TBU/PBU to conventional brake rigging modification was carried out byBogie Repairs Shop & fitment of brake riggings, pneumatic pipelines, conventional handbrakeand footsteps by ERS-POH shop. Total 8 bogies were modified in 2020-21.Unmodified bogie of WAG9Modified bogie of WAG95.9 Modification of Pneumatic Pipe Line in FB Cubical:A number of three phase locomotives have failed due to “Harmonic Filter Contactor” stuck up“Harmonic Filter” isolated. It was found that in FB Panel ferrule of thermoplastic air tube getdislocated due to improper griping.To get rid of this problem, SER carried out an in-house modification by providing copper pipe(10 mm dia) in place of thermoplastic type flexible pneumatic pipe. This said modification hasbeen carried out in 281 locos so far.5.10 Modification in Pneumatic Circuit of VCB:Ingress of moisture in VCB through its pneumatic circuit has beena troublesome area. It hampered the functioning of VCB. SER hascarried out in-house modification in 46 Locos by providing an AirDryer in the pneumatic circuit of VCB so that moisture-free air maybe fed to VCB.5.11 E70 Electronic Card Test Facility at ELS/TATA:Brake system of three phase loco has pneumatics as well as electronics. So far sheds had testsetup for pneumatics only, so the electronic cards were being troubleshooted by trial and error.ELS/TATA has developed a unique test set up for testing of various cards of E70 brake systemby in house efforts. The power supply cards are tested on load on this bench andmeasurements are carried out at critical test points to ascertain health of the electronics.

Test KitPSU beingtestTest KitedTest KitPSU beingtestTest KitLoadResistorComplete Setup of PSU CardLoadResistorLoadResistor5.12 Consist Operation of WAP4 Locomotives by ELS/SRC:edELS/SRC is entirely a coaching loco shed, maintaining 85 coaching electric locomotives(WAP4: 35 and WAP7: 50) and 18 DieselsLoadlocomotives. Due to COVID-19 pandemic situation;service of many Mail/Express and Passenger trains was suspended as a result some of theResistorcoachinglocomotives had become idle.PSU beingtestELS/SRC has made 4 CONSISTs (12 WAP4 locomotives) which are under trial usage overSER. Those are being used to haul fully loaded Goods traffic over graded sections of SER.ed5.13 ELS/TATA converted condemned WAM4loco no. 21393 to battery operated dual modePSU beingshuntingloco for shunting within shed attestrestricted speed of 10 kmph only.ed5.14 A e-help desk have been commissioned incounselling rooms of important Lobbies ofCKP Division. This contains various itemsincludingGyanKunj.Crewcantestthemselves on both safety and technicalsubjects. This is available in both onlineand offline mode.5.15 By better coordination and monitoring, Divisions controlled accrual of overtime of crew to34,932 hours during 20-21 compared to 9,60,309 hours in 19-20. It would not be out of placeto mention that on an average 971.3 T.O.s per fortnight were served per day in 20-21compared to 898.1 in 19-20 i.e NIL O.T despite higher T.O.5.16 During 20-21, “Trip Schedule” of record 3532 (SER - 2480, FR - 1052) Coachingand 1925(SER - 699, FR - 1226) Goods locos was carried out by SER.

5.17 ELTC/TATA:4273 have been trained and released by ELTC in the Financial Year 2020-21 compared to3842 in 2019-20.5.18CTRC/TATA:650 wheelsets were repaired by CTRC during Financial year 2020-21 compared to 633 in19-20.5.19 Following new M&P were commissioned during 2020-21 at various Electric Loco shedto increase outturn and improve reliability: Induction Heater with demagnetising facility at ELS/BKSC, ELKP & ELIN. Portable Pressure Sensor Tester at ELS/BKSC. SMGR Test Bench at ELS/BKSC & ELKP. Universal Test Bench for Master Controller of Conventional Locomotives at ELS/SRC. Spheriblock Fitment / Removal Machine at ELS/BKSC. Opening-Closing Time Checking Instrument for EM/EP Contactor at ELS/BKSC & TATA. Provision of Additional Support in Compressor of 3-Phase Locomotives at ELS/BNDM. Hydraulic Double Acting Jack for Mounting and Dismounting of Racer of WAG9Locomotives at ELS/BKSC & TATA. Commissioning of Universal Multipurpose Armature Machine (UMA) at ELS/BKSC.VVVF (Variable Voltage Variable Frequency) 3 Phase AC Drives for Light Load Run Test ofTraction Motors of WAG9 Locomotive at ELS/BKSC & ELS/ROU.5.20 Energy Regeneration by 3 Phase Loco: 74161146 kWh energy has been regenerated by three phase electric loco on territorialbasis during 2020-21.5.21 Right Powering of Freight Trains: During 2020-21, SER has offered 296 MU loco (WAG7: 155.8 WAG9: 140.2) per day toensure right powering of freight trains against a target of 280.3 (WAG7: 143 WAG9: 137.3)which is about 16% more than the MU offered during 2019-20. In addition, 22 pairs of RRC & Push Pull loco are also utilized per day during 2020-21 toensure right powering of freight trains.5.22 Use of HOG to save Diesel: Total 56 HOG equipped WAP-7 locos are being utilized to work 38 pairs (50 rakes) ofHOG trains to reduce consumption of diesel fuel during 2020-21.

5.23 Safety Drives, Seminars & Quiz: 132 numbers of safety drives have been conducted during 2020-21. 232 numbers of safety seminars have been conducted during 2020-21. 29 numbers of quiz have been conducted during 2020-21. 15 numbers of Text-To-Speech instructions on safety issues in mp3 version have beencirculated during 2020-21.6. Achievements in 1st Quarter of 2021-22 (Apr'21 to Jun'21):6.1 During 1st quarter of 2021-22, 26 (SRC: 3, TATA: 10, BNDM: 3, BKSC: 6 & ROU: 4)new electric locomotives have been commissioned at SER. Total holding of electricloco has become 978 (560 - three-phase) in SER, which is highest on Indian Railway.6.2 During 1st quarter of 2021-22 a special cable checking drive has been undertaken byElectric Sheds in which 535 electric Locos were checked and 232 locos werecorrected.6.3 Test arrangement for cross travel checking of overhauled Pantograph and a test plantfor checking capacity of overhauled MPH have been made by ELS/IPTN with in-houseefforts. It will help in improving reliability of overhauled Pantograph and MPH.6.4 ELS/TATA took a drive to check all electrical panel boxesinstalled within ELS/TATA shed premises by ThermoVision Camera for any unusual heating of cables andjoints.

6.5 Sand Heating facility at ELS/ROU:A sand heating facility has been fabricated with in-housefacilities at ELS/ROU. Proper testing of sanders is beingensured by all the Sheds of SER using dry sand.6.6 New Running Room has been commissioned at JMTC of CKP Division. It wasinaugurated by DRM/CKP on 10.04.2021.6.7 e-Help Desk (Kiosk) have been installed at ROU, CKP, TATA, DPS,JHS, RNC, KGP & ADA lobbies. It helps crew to enhance theirtechnical and SWR knowledge. It provides technical and safetyinformation that are accessible through a touch screen. It also hasfacility for self test.6.8 During Jun ‟21, “Trip Schedule” of 573 (SER – 365 & FR - 208) Coaching and 300(SER -107, FR - 193) Goods locos were carried out by SER compared to 428 &92respectively in corresponding period of 2020-21.The cumulative figure has become1,679 Coaching and 955 Goods locomotives in 2021-22 compared to 891 &225respectively in corresponding period of 2020-21.6.9 By better coordination and monitoring, Divisions have controlled accrual of overtime ofcrew to 3,441 hours during Jun ‟21 compared to 1,520 hours in Jun ‟20 (lockdownperiod) and 89,337 hours in Jun ‟19. It would not be out of place to mention that on an

average 1101.5 T.O.s were served per day in Jun ‟21 compared to 852.5 in Jun ‟20and 897.6 in Jun‟19. The cumulative figures (till Jun)of accrual of OT hours were2,32,009, 1,550 (lockdown period) & 26,669 in 2019-20, 2020-21 & 2021-22respectively.6.10 ELTC/TATA: 456 staff (Refresher: 144, Promotional: 41, Diesel to Electric conversion training toLoco maintenance staff / supervisor: 143 and others: 128) havebeen trained andreleased by ELTC during Jun‟21 compared to 197 in Jun ‟20 and 264 in Jun‟19.On a cumulative basis, 1,296 staff (Initial: 180, Refresher: 376, Promotional: 218,Diesel to Electric conversion training to Loco Pilot: 28, Diesel to Electric conversiontraining to Loco maintenance staff / supervisor: 340 and others: 154) have beentrained and released by ELTC during 2021-22 (till Jun ‟21) as compared to393&833 staff trained during similar period of 2020-21 and 2019-20 respectively. Model of actual motorized Bogie of threephase loco has been kept on raised platformnear model room of ELTC/TATA for trainingpurpose. It helps in improving fault detectionskills of crew. CCTV has been installed in Loco model room of conventional (relay type)locomotive. Activities being carried out by trainee crew are visible to other traineeswaiting for their turn. Such facility was earlier available in MPCS type loco modelroom only.Due to condemnation of old hostel building, the microprocessor based modelbenches had become nonfunctional. These trainers have been repaired and re commissioned in new model room developed in ELTC main training block.CCTV camera with sound system for old WAG-5Model carMPCS based Trainer

A reading room has been commissioned near Library located at phase- I Hostel. Online Yoga, Meditation, Soft Skill & CBWE (Central Board of WorkerEducation) classes have been started by ELTC. During 1st quarter of 2021-22:313, 255, 71& 72 trainees have made use of these classes respectively.MPCS based Trainer No. 1 & 2Shifting of Library from Academic Building toPhase-I hostel.Front view of Library and Reading Room6.11 Reading RoomCoE/ROU:CBC online training, on three phase locomotives, has been imparted to 929 (SER:53& FR: 876) during 1st quarter of 2021-22.Investigation/testing of 17 electronic cards were carried out by CoE during 1 stquarter of 2021-22.Repairing of 13 DC-DC Converter and one Flasher light unit were carried out byCoE during 1st quarter of 2021-22.CoE/ROU added 62 printed documents in its Library during 1st quarter of 2021-22.Stator and Rotor Model of TM have been kept at Mechanical Lab for training.

6.12 CTRC/TATA: 12 & Nil Hitachi & TAO armatures were repaired by CTRC during Jun'21 comparedto 7 & 1 during Jun „20. Cumulative figure (till Jun) has become 23 & 7 in 2021-22compared to 12 & 1 respectively in corresponding period of 2020-21. 68 wheelsets were repaired by CTRC during Jun'21compared to 61 during Jun‟20.Cumulative figure (till Jun) has become 186 in 2021-22 compared to 99 incorresponding period of 2020-21. Surface wheel lathe has beencommissioned at CTRC. It willenable CTRC to send wheelaftercarryingoutfinalmachining.6.13 Revised gradient chart has been made by CKP. It was inaugurated by Sh. VijayKumar Sahu DRM/CKP on 28.06.2021.*****************

Complete Setup of PSU Card test 5.12 Consist Operation of WAP4 Locomotives by ELS/SRC: ELS/SRC is entirely a coaching loco shed, maintaining 85 coaching electric locomotives (WAP4: 35 and WAP7: 50) and 18 Diesels locomotives. Due to COVID-19 pandemic situation;