Transcription

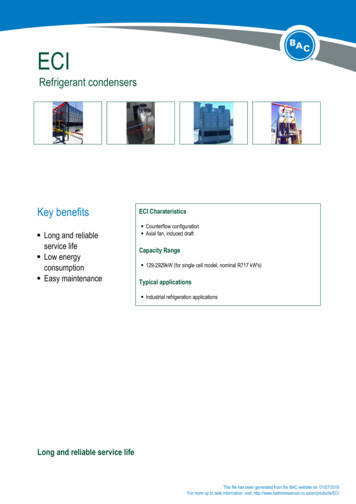

ECIRefrigerant condensersKey benefitsLong and reliableservice lifeLow energyconsumptionEasy maintenanceECI CharateristicsCounterflow configurationAxial fan, induced draftCapacity Range129-2929kW (for single cell model, nominal R717 kW's)Typical applicationsIndustrial refrigeration applicationsLong and reliable service lifeThis file has been generated from the BAC website on: 01/07/2019For more up to date information, visit: http://www.baltimoreaircoil.co.za/en/products/ECI

Standard Baltiplus 800TM construction with corrosion resistant fibreglass side panels will provide along service life.Direct drive fans for most models, reducing regularity of service and component replacement.Low energy consumptionEvaporative cooling for system-wide energy saving at lower operating temperatures.Axial fan uses half the energy of similar centrifugal fan units.Factory tested high efficiency coil.High efficiency/VFD duty fan motorsEasy maintenanceFull cold water basin access when removing the combined inlet shields.Easy no-tool removal of casing side panels gives access to heat transfer coil for easy inspection andcleaning.Easy removable spray branch arms, eliminators and combined inlet shields.Easy access to motor and drives from above the cooling tower.Upgrade the unit with motor removal davit arm for quick and safe service of motors and fans.Removable suction strainer with anti-vortex hood.Low installation costReduce rigging time with the fan plenum section self-aligning with the coil casing section. Motors anddrives are factory installed and aligned.All models can mount directly on parallel I-beams.Use smaller, less costly cranes by shipping in multiple sections to minimize the size and weight of theheaviest lift.Operational safetyClosed loop, no airborne contaminants enter and foul the system.Easy-clean and easy-inspect ECI towers reduce hygiene risks from bacteria (e.g. Legionella) or biofilminside.Combined inlet shields block sunlight to prevent biological growth in the tower, filter the air and stop watersplashing outside.Interested in the ECI evaporative condenser for cooling your industrial refrigerationapplication? Contact your local BAC representative for more information.This file has been generated from the BAC website on: 01/07/2019For more up to date information, visit: http://www.baltimoreaircoil.co.za/en/products/ECI

DownloadsECI refrigerant condenserOperating and maintenance ECI-FCIRigging and Installation ECI - FCIThis file has been generated from the BAC website on: 01/07/2019For more up to date information, visit: owered by TCPDF (www.tcpdf.org)

ECIRefrigerant condensersECI (WIP)The vapour (1) circulates through a condensing coil (2), which iswetted by a spray system (3). An axial fan (4) draws air (5) over thecoil. The evaporation process condenses the vapour into liquid (6) . Thespray water falls into the sloping water basin (7) or sump. The spraypump (8) recirculates the water to the top of the unit. The warmsaturated air (9) leaves the condenser through the drift eliminators(10) which remove water droplets from the air.Interested in the ECI evaporative condenser? Contact your local BACrepresentative for more information.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -principle-of-operationPowered by TCPDF (www.tcpdf.org)

ECIRefrigerant condensersConstruction details1. Material optionsHeavy guage steel is used for the external steel panels and structuralelements, featuring the Baltiplus 800TM material option.The casing sides panels are made of FRP (Fibreglass ReinforcedPolyester) are light and can be easily slid upwards to access the heatexchange coil.Optional stainless steel panels and structural elements with type304L or 316L construction is available for additional corrossionresistance.Or the economical alternative: a water-contact stainless steel coldwater basin. Its key components and the basin itself are stainlesssteel.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -construction-details

2. Heat transfer mediaOur heat transfer media is a cooling coil. In comprehensive labthermal performance tests, it showed proved thermal coolerperformance and offers you unrivalled system efficiency.The coil is constructed of continuous length of prime surface steel, hotdip galvanized after fabrication. Designed for maximum 18 baroperating pressure according to PER. Pneumatically tested at 26.5bar.Sloped tubes for free drainage of the coil.Optional stainless steel coils are in type 304L or 316L.Try our ECI coil options:Multiple circuit coils (split coils) for your halocarbon refrigerants,maintaining individual compressor systems. Or use it for compressorjacket water or glycol cooling.High pressure coils are designed for 28 bar operating pressure andpneumatically tested for 40 bar. Hot-dip galvanized after fabrication.All coils are designed for low pressure drop with sloping tubes for freedrainage of fluid.3. Air movement systemECI fan system features low kW and noise axial fan(s) in corrosionresistant aluminum, with polypropelyne blades encased within thefan cylinder with removable fan guard.All ECI models use multiple independently driven fans, providingthe user with additional capacity control.Our drift eliminators come in UV-resistant plastic, which will not rot,decay or decompose. They are assembled in easily handled andremovable sections, for optimal internal access.Easy removable UV-resistant plastic combined inlet shields at airinlet, block sunlight block to prevent biological growth in tower, filter airand stop water splashing outside.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -construction-details

4. Water distribution systemThese consist of:Spray branches with non-clog plastic nozzles secured by rubbergrommets.Easy accessible sloped cold water basin, includinganti-vortexing steel strainer, make up and overflow connection.Close coupled, bronze fitted centrifugal spray pump with totallyenclosed fan cooled (TEFC) motor.Bleed line with metering valve is installed from pump discharge tooverflow.Interested in the ECI evaporative condenser? Contact your local BACrepresentative.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -construction-detailsPowered by TCPDF (www.tcpdf.org)

ECIRefrigerant condensersOptions and accessoriesBelow is a listing of the main ECI options and accessories. If your required option or accessory is not listed,look no further than your local BAC representative.Platforms, ladders, safety cage andhandrailTo inspect and maintain from the top of the unit moreeasily and safely, platforms, a ladder, safety cageand handrails can be installed.Sump sweeper pipingSump sweeper piping prevents sediment collectingin the cold water basin of the unit. A completepiping system, including nozzles, is installed in thebasin of the condenser for connection to sidestream filtration equipment.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -option-accessories

Standby pumpInstall a standby reserve spray pump as failurebackup!Electric water level control packageFor perfectly precise water level control, replacethe standard mechanical valve with our electricalwater level controller.Basin heater packageThanks to our factory-installed heaters, the waterstays at 4 C and never freezes , even duringequipments downtime and however cold it getsoutside.Nitrogen filling of coilCharge the cooling coil with nitrogenfor anti-corrosion protection during long shipmentperiods (ocean freight) or on-site storage.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -option-accessories

FilterSeparators and media filters efficiently removesuspended solids in the recirculating water,reducing system cleaning costs and optimizing watertreatment results. Filtration helps you keep therecirculating water clean.Water treatment equipmentDevices to control water treatment are needed toensure proper cooling tower water care. Not onlydoes this help protect the components and fill pack,controlling corrosion, scaling and fouling, it alsoavoids the proliferation of harmful bacteria,including legionella, in the recirculating water.This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -option-accessoriesPowered by TCPDF (www.tcpdf.org)

ECIRefrigerant condensersEngineering dataREMARK: Do not use for construction. Refer to factory certified dimensions & weights. This page includesdata current at time of publication, which should be reconfirmed at the time of purchase. In the interest ofproduct improvement, specifications, weights and dimensions are subject to change without notice.Last update: 23/07/2019ECI 30-680This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -30-680

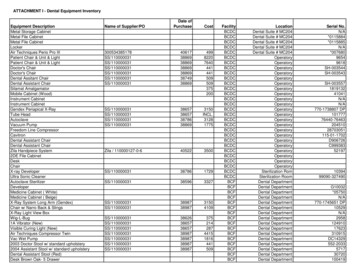

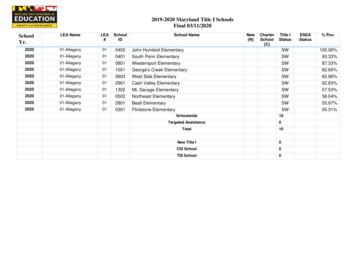

ModelOper.Weight(kg)Weights (kg)Ship.Weight(kg)HeaviestSection(kg)LDimensions (mm)WHAir Flow(m³/s)Fan Motor(kW)WaterFlow (l/s)PumpMotor(kW)R717charge(kg)ECI 154.2ECI 46160010809001890109028554.0ECI 52160010809001890109028554.8ECI 581670119010401890109030754.6ECI 651700122010401890109030755.5ECI 722380160013852880109030355.8ECI 802400162013852880109030356.8ECI 1x)4.0(1x)4.0(1x)4.0(1x)2.2(1x)2.2(1x)16.0ECI .0164.0164.0196.0This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -30-680

.0390.0390.0This file has been generated from the BAC website on: 23/07/2019For more up to date information, visit: -30-680Powered by TCPDF (www.tcpdf.org)

ECI Refrigerant condensers Key benefits Long and reliable service life Low energy consumption Easy maintenance ECI Charateristics Counterflow configuration Axial fan, induced draft Capacity Range 129-2929kW (for single cell model, nominal R717 kW's) Typical applications