Transcription

Gray Balance Control in Offset Printingwith the ECI/bvdm Gray Control StripInstructions for UseJune 2012

2 ECI / bvdm Gray Control Strip Introduction1 Gray Balance Process Control –Easy, Practical, EffectiveThe aim of process control at press side is to quickly achieve the desiredcolor results. When the more important press parameters, such as standardized plate production, dot gain, paper and ink have been determined, then it won’t take very long to balance the inking for the best possible outcome.The ECI/bvdm Gray Control Strip has been developed for printers as anaid to help balance the press process in the best way possible by utilizinga standardized proof. That’s why the ECI/bvdm Gray Control Strip isbased on the same color characterization data that are used in industrystandard ICC profiles (for example, the ECI profiles) and the Ugra/FograCMYK Media Wedge in prepress. ECI offset profiles are based on colorcharacterization data from Fogra.

ECI / bvdm Gray Control Strip Explanation 32 The ECI/bvdm Gray Control StripGray balance patches that allow a quick and convenient visual control aregood aids for accurate inking. That’s why the “ECI/bvdm Gray ControlStrip” relies on this one simple rule: “Chromatic gray (CMY) has to lookexactly like true gray (K)”.The aim is therefore, to match the ECI/bvdm Gray Control Strip chromaticgray patches to the true gray patches by controlled inking. That is, thetechnical tone consisting of defined cyan, magenta and yellow (chromaticgray) values is compared to a tone value that consists of pure black (truegray). By “balancing out” the colors at the press, two patches that consistof two different sets of values ideally end up looking the same.The Human Eye as “Metering Device”Because the human eye is well suited in comparing colors that aredirectly adjacent to each other, and in particular are very sensitive indetecting color differences within the gray zone, they serve as a “visualmetering device” when using the ECI/bvdm Gray Control Strip for assessment. By visually controlling the gray balance patches, deviations in inking can be recognized and corrected in due time press side, before thesehave a chance to show up on the printed image. Yet visually controllingthe gray balance in no way replaces a metered evaluation of full tonecolor coordinates and the tone value increase or using an automatic colorcontrol that may be on hand.Why Gray Balance?Standard process offset printing states that the correct dot gain for eachdifferent printing ink is one of the most important preconditions for balancing printing and proof. It has also been determined that the differencebetween the colors is not to be too great (key word: spread), or a deviation, for instance in the gray balance, may occur.Usually the dot gain of each single process color is measured to verify thisstipulation. Even before a measurement is made, a color shift (e.g. a redcast) in the chromatic gray patch when compared to the true gray patchcan be detected by simply inspecting it with the naked eye. Fundamentally, it is very useful to make an assessment based on screened mixedcolors (in this case the chromatic gray patch), since most images consistof those tertiary colors. Print control elements that contain only screenedprimary color values (no mixed colors) are not suitable for this type of initial evaluation.

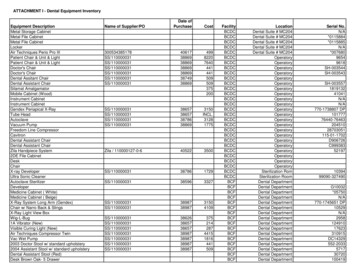

4 ECI / bvdm Gray Control Strip Explanation“How Gray is Gray?” or “Which Gray Balance is the Right One?”One approach in defining the most suitable chromatic gray patchesinvolves establishing exactly those CMY color value combinations fromout of respective color characterization data that match comparable values of pure black (true gray), and/or that arrive at exactly the sameCIELAB color values when metering the color.The chromatic gray patches on the ECI/bvdm Gray Control Strip weredetermined using this method. These correspond with the definition forchromatic gray in compliance with the international press process standard ISO 12647-2: “A colour having the same a* and b* CIELAB values asa half-tone tint of similar L* value printed with black ink.”.true gray 70chromatic gray 70true gray 50chromatic gray 50true gray 30chromatic gray 30ECI/bvdm Gray Control Strip (S) FOGRA39 v2CMY 70K 70CMY 50K 50CMY 30K 30CIE L*45,5345,5361,8261,8276,1276,12CIE a*0,00,00,00,00,00,0CIE e 1: CIELAB color coordinates and CMYK values of true gray (K) andchromatic gray patches (CMY) for offset printing on coated paper(FOGRA39).Respective characterization data for all printing conditions may be takenfrom the CIELAB values for black. Characterization data are determinedby means of test targets (e.g. ECI2002 test table) that were printed onspecific papers under controlled conditions. These data also serve as abasis for the creation of ICC profiles, which may be applied for data preparation and proofing.Table 1 illustrates the CIELAB color coordinates and CMYK color valuesof the three chromatic gray (CMY 70, CMY 50, CMY 30) and true gray (K70, K50, K 30) patches for standardized offset printing on coated paper(characterization data FOGRA39).

ECI / bvdm Gray Control Strip Explanation 5In printing, each chromatic gray and true gray pair look the same to thehuman eye and ideally the color measurements show the CIELAB colorvalues from the characterizations file of the respective printing condition(here: FOGRA39).It is also important to make sure that the respective ECI/bvdm Gray Control Strip is applied according to the type of paper used, since differentCIELAB values of the black patches and different CMY values resultdepending on the printing process and printing condition.Definitions of the ECI/bvdm Gray Control Strip gray patches for offsetprinting are each based on the Fogra characterization data for standardized offset printing in compliance with ISO 12647-2. The ECI producesICC profiles by means of these characterization data, which can be downloaded from the ECI website. They also constitute a part of the AltonaTest Suite Application Kit.Fogra published new characterization data sets in June 2009: FOGRA45for heatset web offset printing on improved LWC paper (light weight coating), FOGRA46 for heatset web offset printing on standard LWC paperand for offset printing on uncoated white paper (FOGRA47). In January2012 another characterization data set for web offset printing on INPpaper (improved news print) was added (FOGRA48).A list of current versions and their classification according to paper typecan be seen in Table 2 on page 14.

6 ECI / bvdm Gray Control Strip ExplanationIs Process Control of Other Printing Parameters Still Necessary?The ECI/bvdm Gray Control Strip serves as an “early warning system” or“quick test”. When a visual balance of true gray and chromatic gray onthe press is impossible to arrive at the conventional way, such as by achange in the inking, this is an indication that some basic printing process parameters need adjustment. As a rule, deviations may be correctedby changing influencing factors (i.e.: another ink, adjustment of CtPcurves). In order to locate and remedy the fault, it is required to reviewthe dot gain and full tone color coordinates of the inks and make anassessment of additional areas (e.g. slur / doubling), which are typicallyincluded in machine control bars. The ECI/bvdm Gray Control Strip istherefore not a substitute for printing control elements, but rather a supplement to these.Gray Balance – An ECI or bvdm Invention?No! Gray balance is a known issue in the printing industry since decades.Fogra covered the topic in many studies – the first was issued in the year1953. In fact in printing the control of the gray balance has been in practice for many years, for example it is utilized in the “Ugra/Fogra Minitarget” (www.ugra.ch and www.fogra.org) and the density-based color control systems from System Brunner (www.systembrunner.ch). Simplechromatic gray patches are still in common use in Scandinavian newspapers.

ECI / bvdm Gray Control Strip Structure 72.1 ECI/bvdm Gray Control Strip VersionsThe ECI/bvdm Gray Control Strip is available in three different layouts.Depending on intended purpose and available space they can either beapplied singularly or in combination.The Basic “S” VersionThe ECI/bvdm Gray Control Strip “S” version consists of three true gray /chromatic gray pairs. The true gray patches are arranged in 70%, 50%and 30% tone values of the black ink. The tone values for cyan, magentaand yellow in the respective chromatic gray patches were determinedfrom absolute colorimetric color conversions of CIELAB values (of therespective black ink value).ECI/bvdm Gray Control Strip (S) FOGRA39 v2Illustration 1: The Basic ECI /bvdm Gray Control Strip “S” VersionTwo items are to be noted. Firstly, the CIELAB value of the true graypatches originate from the corresponding characterizations file. Secondly, when determining the chromatic gray patches the black generation setting was “none” (without black ink).The control element is 36 x 8 mm. Each patch is 6 x 6 mm. The identification line of the wedge allows you to verify the utilized printing conditions.In this respect it is recommended to show the Identification line on theprinting forme.The Expanded Versions “L”, “M” and “M i1”The ECI/bvdm Gray Control Strip versions “L” and “M” are based on thebasic “S” version and contain additional patches for the measurement ofother process parameters.ECI/bvdmGrayCon L v2FOGRA39Version “M”ECI/bvdmGrayCon M v2FOGRA39cmy 70Version “L”cmy 50k 50cmy 30k 100102030405060708090100102030405060708090100cmy 70k 70cmy 50k 50cmy 30k 80100ECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgECI/bvdmGrayCon M i1 v2FOGRA39Version “M i1”k 70ECI/bvdm Gray Control Strip (L) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgcmy 70k 70cmy 50k 50cmy 30k 30Stopcmy 70Paperk 70mycmy 50cmk 50cycmy 30cmyk 3010020804060604080201001002080406060408020100 StartECI/bvdm Gray Control Strip (M i1) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgIllustration 2: Expanded versions “L” and “M” with their density valuesabove each patch, identification lines below and an abbreviated versionon the left side of the wedge.Layout “L”The “L” layout is 291 mm wide and has a height of 10 mm, whereas eachpatch (with exception of the last patch) is 5.5 mm wide. When necessary,patch density values and the identification line below may be cut off sothat its height may be reduced to 6 mm.

8 ECI / bvdm Gray Control Strip StructureThis layout consists of 51 control patches in all, which may be grouped asfollows:Solid color overprint patches (trapping patches)Paper-whitecmy 70k 70cmy 50k 50cmy 30k 30cmycmcymy10203040506070809010010203040Start 0708090100ECI/bvdmGrayCon L v2FOGRA39ECI/bvdm Gray Control Strip (L) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgEnd patchGray balance patchesHalftone step wedges with primary color solid-tone patchesIllustration 3: ECI /bvdm Gray Control Strip patches divided into groups– Start and end patch, required for positioning hand-held scanningdevices in front of the first measurable patch and for their phase outafter the last patch.– Paper-white patch used as a reference value for densitometers and todetermine the paper color coordinate.– Three gray balance patch pairs, consisting each of one chromatic grayand one true gray patch for visual gray balance control. The true graypatches are laid out in the tone values of 70%, 50% and 30%. The chromatic gray patches are created from out of the primary colors cyan,magenta and yellow so that each printing condition indicated in the ECI/bvdm Gray Control Strip identification line can ideally be visuallymatched to the true gray patches.– Solid color overprint patches (trapping patches), for the visual andtechnical evaluation of secondary colors (M Y, C Y, C M), also forthe tertiary color black (C M Y). This allows the detection of ink trapping problems.– Halftone step wedges in the four primary colors: black, yellow,magenta and cyan. Each halftone step wedge contains the tone valuesfrom 10% to 100% in 10% increments. It serves for the visual (by way ofinking standards) and technical control of solid color inking and todetermine characteristic curves of printing.Since it is often very hard to distinguish between neighboring controlpatches, small white or solid-tone guide lines that border each patch andthat have no affect on the automatic measurement of scanning deviceswere added to aid the positioning of the sensing head.

ECI / bvdm Gray Control Strip Structure 9Printing ConditionsThe identification line below the patches contains the name of the controlwedge and the layout version (L). Following that are the printing conditions, a reference to the respective characterization file standard and thegray condition in compliance with ISO 12647-2. The Internet addresses ofthe project partners are also listed including those addresses where theECI/bvdm Gray Control Strip may be downloaded. Because the large version may be shortened to save space you will find at the left of the endpatch another three short lines with the abbreviated names and the reference name of the layout version, the wedge version (“v1”) and the characterization file name This information allows the easy identification ofeach wedge.Layout “M”Layout “M” at a width of 197.5 mm is the abbreviated version of Layout“L”. This version should only be applied when there is not enough available space on the paper format for the application of version “L”. Thiscan be the case for instance when short grain pages are to be processedin A4 format.Of course the 10 mm height of layout “M” may also be reduced to 6 mmby cutting off the patch density values on the top and the identificationline underneath. The width of each control patch is 6 mm. Layout “M”also differs from Layout “L” only by the number of the primary color halftone steps, where instead of 10% increments, 20% increments from 20%to 100% tone values have been indicated.Layout “M i1”Between the patches marked “Start” and ”Stop“ the layout “M i1” contains patches for the fast measurement of CIELAB values and tone valueincrease curves with scanning devices. Six gray balance patches for thevisual assessment have been added to the lower end of the control strip.ECI/bvdmGrayCon M i1 v2FOGRA39cmy 70k 70cmy 50k 50cmy 30Stopk 30cmy 70Paperk 70mycmy 50cmk 50cycmy 30cmyk 3010020804060604080201001002080406060408020100 StartECI/bvdm Gray Control Strip (M i1) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgIllustration 4: “ECI/bvdm Gray Control Strip (M i1)”Layout “tvi 10”The purpose of this control strip is the assessment of production printswith regard to the specifications defined by the standard ISO 12647-2.For that reason the strip contains solid-tone and overprint patches aswell as halftone steps in 10% increments. The “ECI/bvdm tvi 10” can beused for all printing conditions as it does not contain graybalancepatches. The color sequence of the control patches is optimized for fastmeasurments with scanning 04070308020ECI/bvdmtvi 10 v2ECI/bvdm tvi 10 (i1) 6 mm Control strip with tone values in 10 percent steps for print process control in accordance with ISO 12647 www.bvdm.org www.eci.orgIllustration 5: “ECI/bvdm tvi 0100Start

10 ECI / bvdm Gray Control Strip ApplicationImportant Note Regarding Measurement with Scanning DevicesThe space for control strips on printing sheets is very limited. For thatreason the control patches of the layouts “M i1” and “tvi 10” are smallerthan specified by the manufacturer X-Rite for the manual measurementin scan mode using the ruler. Devices marked “Rev A” at the bottom sideare not suited for the measurement of these strips in scan mode. Usingi1Pro devices marked “Rev B”, “C” or “D”, in some cases errors in scanmode measurements may occure – in particular on uncoated paper typeswith an uneven surface or coarse screening. All revisions (Rev A-D) willwork properly if mounted on the iO scanning table. In order to achievereliable measurement results it is recommended to measure the samecontrol strip in the modes “strip” and “patch” and to compare the tworesults. In the case of significant differences choose the reliable “patch”mode and do not use the ruler.3 Implementation of the ECI/bvdm Gray ControlStripWhich ECI/bvdm Gray Control Strip Version Should I Use?In order to make the right selection for the correct wedge to use, you haveto consider the printing conditions (see also Table 2 on page 14). Asidefrom this, there are three different layout versions available per printingcondition. This allows you to choose the most suitable version accordingto the amount of space available.Example: A matt-coated paper (paper type 2) is intended for the finalprinted product. The matching Fogra characterization data is identifiedas FOGRA39. If there is enough room available on the paper, the “L” or“M” expanded version should be utilized. This will allow a visual check ofthe gray patches as well as a technical measurement of the characteristicprinting curves. In this case use the “ECI GrayConL FOGRA39.pdf”wedge. If there is only very little available space, the basic “S” versionidentified as “ECI GrayConS FOGRA39.pdf” should be used. The basic“S” version is key for the visual control of a press run.How is the ECI /bvdm Gray Control Strip Positioned?All the different versions of the ECI/bvdm Gray Control Strip are availableas PDF files. Choose the version that best suits the printing conditions andposition the ECI/bvdm Gray Control Strip for instance in your impositionprogram as a supplement to your usual control aids. In work environments that do not allow PDF files, the EPS version of the wedge, for example “ECI GrayConL FOGRA39.eps”, may be applied. Make sure that theprinting condition in the identification line that this wedge represents isstill discernable.

cmy 70k 70cmy 50k 50cmy 30k 30cmycmcymy20406080ECI/bvdmGrayCon M v2FOGRA39cmy 70k 70cmy 50k 50cmy 30k dm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.org20406080100cmy 70k 70cmy 50k 50cmy 30k dm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgcmy 50k 50cmy 30k 4060608080100100mdvb/ICE2v L noCyarG93ARGOF03 k 03 ymc 05 k 05 ymc 07 k 07 ymck 70ymccmy 70mcECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgyc03 k 03 ymc 05 k 05 ymc 07 k 07 10011000502018006030960070402400805082009060303 k 03 ymc 05 k 05 ymc 07 k 07 ymc10020406080100204060801002040608003 k 03 ymc 05 k 05 ymc 07 k 07 05ymym2004010501gro.ice.www gro.mdvb.www 74621 OSI htiw ecnadrocca ni lortnoc ssecorp tnirp rof spets tnecrep 01 ni seulav enot htiw pirts lortnoC mm 6 )1i( 01 ivt mdvb/ICE0201100050206030280060304ymgro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG ww ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG 100108cm03010010109cmy04020102001k 300503090301cmy 300604020402k 500705080503cmy 500806030604gro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG mdvb/ICE0705k 700907070806gro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG mdvb/ICE07cmy 7000108040908ECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, 0010010100180tratS020160potS030240ymc04032003 k 03 ymc 05 k 05 ymc 07 k 07 3 k 03 ymc 05 k 05 ymc 07 k 07 ymc0109082001ymc0900109my02mc0203 k 03 ymc 05 k 05 ymc 07 k 07 ymc001cy03ycymc03 k 03 ymc 05 k 05 ymc 07 k 07 ymccm04ym08mcymccmy050103ycmck 30060207ymyccmy 3007030401ymk 500804060201cmy 500905050302k 70001060504gro.ice.www gro.mdvb.www 74621 OSI htiw ecnadrocca ni lortnoc ssecorp tnirp rof spets tnecrep 01 ni seulav enot htiw pirts lortnoC mm 6 )1i( 01 ivt mdvb/ICE0503cmy 700107060604ECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, 010300108400602080109mcgro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG 1gro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG mdvb/ICE0705036001080010604gro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG mdvb/ICE054002090010706gro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG 1050909cy050206001001cm0603040101cmy07040202k 300805070303cmy 300906030404k 5000107080505ECI/bvdmGrayCon M v2FOGRA39ECI/bvdmGrayCon M v2FOGRA39ECI/bvdmGrayCon M v2FOGRA39ECI/bvdmGrayCon M v2FOGRA39ECI/bvdmGrayCon M v2FOGRA39ECI/bvdmGrayCon M v2FOGRA3908020606cmy 5009090707k 70001010808MECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2S03 k 03 ymc 05 k 05 ymc 07 k 07 ymcymcmcycym010203040506070809001010203mdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L noCyarG93ARGOFmdvb/ICE2v L 010203040506070809001ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2tvi 10LECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v2SECI/bvdm Gray Control Strip (S) FOGRA39 v2ECI/bvdm Gray Control Strip (S) FOGRA39 v20010909cmy 70tratS001001ECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.orgECI / bvdm Gray Control Strip Application 11The basic version “S” should be at right angles to the printing direction,for example placed below the color bar you normally use. A repeatedplacement enables a color balance assessment.The two expanded versions “M” and “L” as well as the “ECI/bvdm tvi 10”must be positioned between the pages at right angles to the gripper edge;wedges positioned parallel to the gripper edge would distort the dot gaincalculation of unavoidable inking deviations between the ink zones.Under some circumstances the analysis of the wedge may be distorted onaccount of atypical inking behavior when it is placed at the edge of thepaper.mdvb/ICE2v 01 ivtmdvb/ICE2v 01 ivtgro.mdvb.www ,gro.ice.www )gro.argof.www( txt.93ARGOF ecnerefeR 1 dmA/4002:2-74621 OSI )2 1 TP( repap detaoc ttam ro ssolg no tesffO ’kni kcalb BALEIC‘ noitidnoc ecnalab yarg 2-74621 OSI 93ARGOF )L( pirtS lortnoC yarG mdvb/ICEIllustration 6: Placement of the “S”, “L” and “tvi 10”version on sheets withlong cut-off pages. The red X marks unsuitable positioning.Illustration 7: Placement of the “S” and “M” version on sheets with shortcut-off pages. The red X marks unsuitable positioning.ECI/bvdm Gray Control Strip (M) FOGRA39 ISO 12647-2 gray balance condition ‘CIELAB black ink’ Offset on gloss or matt coated paper (PT 1 2) ISO 12647-2:2004/Amd 1 Reference FOGRA39.txt (www.fogra.org) www.eci.org, www.bvdm.org100

12 ECI / bvdm Gray Control Strip ApplicationWhat Can be Done when K-Gray and CMY-Gray Patches do not Match?In principle, the standardized offset printing process in compliance withISO 12647-2 and/or “ProzessStandard Offsetdruck” (bvdm 2001, 2003)guidelines is to be instituted. Target values and tolerances are itemized inthe “MedienStandard Druck 2004” (download of current version at www.bvdm.org).When however the chromatic gray and true gray patches do not correspond, try adjusting the inking and damping control of one or more of theprocess colors to arrive at a good match.Example: a) When the chromatic gray patch has a red cast when compared to the true gray patch, decrease the magenta and yellow inking orincrease cyan.b) When the chromatic gray patch is too light when compared to the truegray patch, increase the CMY primary inks or reduce true gray.It is to be noted that the gray balance patches only illustrate a bias. Inorder to find out whether the primary color inking is to be reduced orincreased you must make an additional assessment of other control bars,for example check the halftone wedge of the “L” or “M” version of theECI/bvdm Gray Control Strip.In some circumstances deviations arise that do not allow themselves to becorrected by adjusting the inking. Let us take for example the followingcase: The 50% patch is acceptable, but the 30% is not chromatic. Thecharacteristic printing curve of the entire tonal gradation is not balanced.Initially you have to rule out any printing faults (for example slur / doubling, gradual fading, etc,).Then it is absolutely essential that a characteristic printing curve with asufficient increase in tone value is created throughout (for example bymeans of the expanded ECI/bvdm Gray Control Strip “L” version). A calculated correction of the CtP system may become necessary as a result ofthe findings.It should also be noted that there are a multitude of possible causes forprinting problems, for instance in connection with the materials beingused (paper, ink, blanket, additives, etc.). The bvdm ProzessStandard Offsetdruck extensively describes possible causes and gives trouble-shootinginstructions. The Altona Test Suite Application Kit documentationdescribes pre-tests to determine the most optimal inking and the correcttone value increase.

ECI / bvdm Gray Control Strip Remarks 13Gray Balance RemarksIt is well known that with process inks in offset printing, inking anddampin

2.1 ECI/bvdm Gray Control Strip Versions The ECI/bvdm Gray Control Strip is available in three different layouts. Depending on intended purpose and available space they can either be applied singularly or in combination. The Basic "S" Version The ECI/bvdm Gray Control Strip "S" version consists of three true gray / chromatic gray pairs.