Transcription

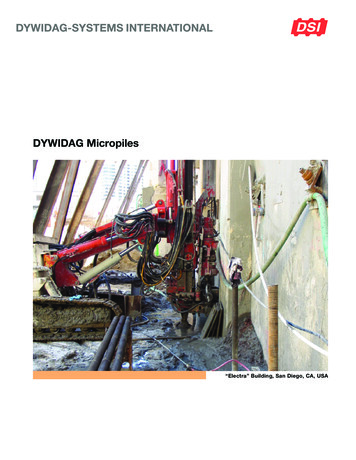

DYWIDAG Micropiles“Electra” Building, San Diego, CA, USA

DYWI Drill Hollow Bar Anchorssecure “Electra” Building in San DiegoConversion of the former “Old SDGE Station B” in downtown San Diego, CAin December 2007, the new nostalgiccomplex will bear the name of “Electra”— in reference to the former o wners ofthe site — and offer about 250 modern,luxurious apartments with a magnificentview of the harbour and the city of SanDiego.Condon-Johnson & Associates Inc.,San Diego, was awarded the contractfor the excavation, sheeting and shoring work. To increase the load capacityof the f oundation soil nchors wereDYWI Drill Hollow Bar Aused.The historic “Old SDGE Station B”building is located in downtownSan Diego. The building was originally built in 1911 to accommodatethe boilers and turbines of the SanDiego Electrical Railway Company.Later it became the property of the SanDiego Gas & Electric Company underwhose name it is still k nown. A builderapplied for the permit to build a new43-storey high-rise building on thatsite. However, the historically deemedfacade with its neo-classical and ArtDeco stylistic elements was to be maintained. Therefore, it was decidedto build the new high-rise building within the old facade and to integratethe facade into the new project.For this purpose, the SDGE buildingwas entirely gutted inside, andthe facade was elaborately stabilized during the construction. In addition, theload capacity of the foundation soil hadto be improved in a s ustainable manner for the anticipated loads of the newskyscraper. Following its completioniDYWI Drill Hollow Bar Anchors can easily be installed on the constructionsite under confined space conditionsusing simple and small dimensioneddrilling equipment.The DYWI Drill Hollow Bar Anchor System offers the following advantages:n useof small dimensioned drilling equipment.n Nopredrilling need under limitedspace conditions.n Simultaneousdrilling and groutingin a single operation.For this landmark project that will exceed any other buildings in SanDiego a fter its completion DSI LongBeach s upplied a total of10,000 ft. DYWI Drill Hollow BarAnchors type T76S i ncluding hardware a ccessories such as drill bits and couplers.Owner Bosa Development California II, Inc, British Columbia, Canada Main Contractor Bosa Development California II, Inc,British Columbia, Canada Execution Condon-Johnson & Assoc. Inc., San Diego, CA, USADSI Unit DSI-LANG, Geotechnical Systems Business Unit, Toughkenamon, PA, USADSI-Services Supply of about 10,000 ft /3.048 m DYWI Drill Hollow Bar Anchors type T76S including hardware accessoriessuch as drill bits and couplers

ContentsHistory. 4General Notes. 4Applications. 4Advantages. 5Design Methodology. 6Corrosion Protection. 7Installation of a GEWI Pile. 8Bar Properties. 10Multibar Properties. 11Hardware and Accessories. 12Testing. 13References. 14Drilling in confined spaceTesting GEWI PilesDetails, dimensions and system designsare subject to change without notice.www.dsiamerica.com3

HistoryUse of micropile (mini pile, reticulatedpile, etc.) started in early 1950s in Italyfor underpinning applications of historicbuildings damaged during World War II.Micropile technology is a reliablepile system that can withstand large capacity axial or lateral loads with minimal disturbance to the existingstructures. They became very populardue to their ability to transfer loads efficiently through skin friction and dueto their many installation advantagesover conventional pile systems.General NotesA GEWI Pile is a drilled and groutedmicropile, less than 12 inches in diameter that is centrally reinforcedwith either one or a group of two orthree high tensile strength DYWIDAGThreadbar . GEWI Pile can carryloads up to 300 tons in compressionor tension in relatively small boreholes.GEWI Pile is also a friction pile. Theload is transferred by bond from thethreadbar to a cement grout body andfrom there by friction to the surroundingground. The friction value betweengrout-ground can be increased by useof post grouting techniques.Soil TypesThe GEWI Pile is a foundation elementfor any ground condition:—C ohesive Soils:For example, clays, silts(up to an untrained shear strengthof Cu 1.45psi) do not requireadditional lateral support.ApplicationsGEWI Pile applications are influencedby the existing environment and soilconditions and methods of construction. There are two major applicationsthat can be classified.—N oncohesive Soils:For example, sand and gravel— Rock:Ranging from hard clays togranite, with open or closedjoints and f issures.1. Structural support, directly loadedpile (used most often)— Underpinning of existing structures(repair or replacement)— Seismic retrofitting— New foundations— Permafrost:Easy to transport and to install.Ask for DSI grouting instructions.2. Insitu reinforcement— Slope stabilization and earth retension— Settlement reduction.Uplift and CompressionBridge FoundationsReinforcement of Soils4Foundaions of the Communicationsand Transmission TowersConveyer BeltFoundationsSeismic Retrofit and Upgradingin Confined Areas

Advantages and Characteristics1. Offer a practical and cost-effectivesolution to costly alternative pilesystems as well as a solution to jobsites with different access.2. Continuous Thread— DYWIDAG THREADBAR has acontinuous rolled-on pattern ofthread-like deformations that allowfull load couplers and anchoragesto be easily positioned along thepile.—T he pile length can be segmentallyincreased allowing access insidelow head rooms areas.—C oarse thread remains threadableeven if dirty or damaged.3. Easy Installation— Compact, lightweight drilling andinstallation equipment makesGEWI piles ideal for remote orconfined areas such as: steepslopes, wetlands, river pier foundations, basements, beneathoverpasses— Drill small holes very close to existing walls.6. Foundation Element for any groundCondition—C ohesive soils (clay, silt, sand),non-cohesive soil (sandy gravel,cobbles, boulders), rock—C ompression and tensile loads,also alternating loads, can betransferred into the undergroundby skin friction along the groutbody.4. Vibration-Free Drilling Method— Boreholes can be drilled withoutdamage to adjacent structures.7. Environmentally Friendly—D o not require large access roador drilling platforms—M aterials are environmentally safe5. Preloading Capacity— Piles can be easily pre-loaded, virtually eliminating long-term settlement of structuresAnchorageCouplerPile Installation in l imited head roomThe plate anchorage with atorqued anchor plateDSI’s solution for a micropile is the GEWI Pile5

Design Methodology2. Review geotechnical data for soilproperties, design parameters,corrosion protection requirements,grout-to-ground parameters, bondlength, pile spacing for group effects1. Review project information inregards to pile layout, loadingrequirements, access andoverhead clearance3. Structural design should includes:— Anticipated settlement/requiredstiffness analysis— Lateral load pile capacity/Anticipated lateral d isplacement— Buckling of the pile/soil lateral support40GEWI Pile35305. Load testing program and qualitycontrol requirements700600GEWI Bar500Ductile Iron GGG 50400U 4F D25U Pile diameterF Pile area4. Additional structural details such as:case and uncased length,strain/ductility of the steel, transitionbetween case and uncase section,reinforcement splice connections,pile to footing connection, corrosionprotection,Stress [N/mm2]GEWI Pile design follows currentlyavailable methods for micropile, standard pile and earth anchors. Asper FHWA-SA-97-070 Manual, minimumrecommended design steps 12Range forminipiles6345Pile diameter6DYWIDAG Threadbar stress-strain diagram45Strain [%]

Corrosion ProtectionSingle Corrosion ProtectionThe DYWIDAG THREADBAR at thecore of the pile is surrounded by acement grout layer of various thickness.In addition to sealing the bar frommoisture, the high ph-value of thecement grout passivates the steel surface of the bar, providing furthercorrosion protection. Under compressive loads, the grout remainsfirmly bonded to the bar (without cracking), providing good corrosionprotection.Under tensile loads, the bar’s threaddeformations create a uniform distribution of fine cracks in the cementgrout, the width of which are minimizedby the low elongation of the threadbaritself. However, for permanent piles andwhere the crack width exceeds acceptable levels, double corrosionprotection should be used.AdditionalReinforcementTorquedHexnutBearing PlateTorquedHexnutConcreteStructureDouble corrosion protection is recommended for permanent tensionpiles and piles installed in aggressivemedia.GEWI BarBearing PlateTorqued HexnutAdditionalReinforcementShop groutedplasticCorrugatedsheathingDrilled holeCement grout(Field ugatedSheathingOuter CementGroutDouble Corrosion ProtectionDouble corrosion protection is providedby placing the threadbar within a corrugated PVC sleeve and by fillingthe annulus between the bar and thesleeve with a non-shrink cement grout,preferably in a qualified shop. This pregrouted threadbar is then assembled,installed and grouted in the same wayas the single corrosion protected bar.Torqued HexnutFull loadCoupler(if required)DYWIDAGTHREADBAR Inner CementGroutDrill HoleCement Grout(Field installed)DYWIDAGTHREADBAR GEWI Pile with SimpleCorrosion ProtectionGEWI Pile with Double CorrosionProtectionCement GroutCross section ofDCP GEWI PileCorrugatedSheath7

Installation of GEWI PileDrilling and Grouting with CasingDrillinga casedholeIn granular soils, the GEWI Pile isalways installed in cased bore holes.Due to the small diameter, these holescan be made using the advanced drillprocedures of the anchor technology.The bore holes can be advanced quickly, without vibrations and relativelyquiet. Drilling obstacles, such as hardstrata, blocks or foundations, can bepenetrated without problems. The boreholes can be inclined to any degree,from horizontal to vertical. The rigidcasing not only permits straight holes inwhich the GEWI Piles can be installedwithout bending, but also pressuregrouting of the bond length and theshaft of the pile. The figure shows thevarious phases in the installation of theGEWI Pile.Installationof theGEWI Pilein sectionsPrimaryPostLoadgrou grouting in testing ofting andcohesive GEWI Pile retractionsoilsof thecasingPost-groutingPost-grouting improves the loadcarrying capacity in cohesive soils byincreasing the skin friction. The samepost-grouting system, as developed forthe DYWIDAG bar anchor, is used forthe GEWI Pile. Through a ring line,with grout valves in the bond length,Post grouting is done once or repeatedly. The limits for the load transfer capacity is not only determinedby the maximum obtainable skin friction, but also by the ability of thesoil itself to carry the load.Note: Post grouting can be performed in multi-stages.1-stage per 18 hour interval. Post-grout injection pressure should be notexceed 6MPa.Failed piles can often be recovered to safe design loadby additional p ost-grouting.Corrugated PVC Sheath outerLayer of corrosion protectionGEWI BarGEWI BarPVCGravity Grout(all pieces)Gravity GroutPost-groutPost Grout LinesCementGrout Bodyafter PostGrouting(EnlargedGrout Body)Post-groutLineGravity Grouted Cement Grout Body (before Post-Grouting)8Cement Grout Body (after Post-Grouting)

Installation ReferencesLion Gate HospitalMini-track mounted drill rigInstaller: Kani FoundationTechnologyKerrisdale Elementary SchoolPile InstallationContractor: Southwest Contracting9

Bar PropertiesDYWIDAG THREADBAR Reinforcing Steel ASTM A615 (Grade 75)THREADBAR DesignationMaximumTHREADBAR DiameterYield StressCross Section AreaYield Load(fy)(As)(fy x As)Nominal 797.9011.3820.2425.1635.8548.79Note: Maximum test load 90% of the yield load; Mill length 60'-0" for #6 through #24 bars and 48'-0" for #28 barsDYWI Drill Hollow Bar PropertiesBarNominal e YieldStress(fy)Average UltimateTensile Stress(fu)Average CrossSection Area(As)Yield LoadUltimate Load(fy x As)(fu x As)Nominal 6.708.1016.8019.70Note: Maximum allowable, temporary test load is 100% of the yield load. Average cross section area is based on average internal diameterof the bar. The ultimate and yield load capacity are measured values. The ultimate tensile and yield stress are calculated average values.Mill length is 9‘-10“ (3m). Longer lengths can be special order.DYWIDAG THREADBAR Prestressing Steel ASTM A722 (Grade 150)THREADBAR Designation1-1/4"1-3/8"* 1-3/4"* 2-1/2"* 3"MaximumTHREADBAR DiameterUltimate StressCross Section AreaUltimate Load(fu)(As)(fu x As)Nominal 8.2024.096.538.2713.7226.3635.85* Meets the strength requirements of the A 722.Note: Maximum test load 80% of the ultimate load; Mill length 60'-0" for 1", 1¼" and 1 " Threadbars and 45'-0" for 1¾", 2½" and 3" barsProperties of Multibar GEWI PilesBar quantity/size[No.][mm]Yield stress( f y)[MPa][KSI]3ea #143x435173ea #183x575173ea #203x63552All combinations of sizes up to 3 GEWI 10Cross Section Area(Aps)[in²]756.757512.008014.73Bars are possible.Ultimate Load(Aps x fu)Yield Load(Aps x fy)Nominal 792,2534,0055,24422.9540.8050.1034.1460.7274.55

Bar Hardware PropertiesDYWIDAG THREADBAR Reinforcing Steel ASTM A615 (Grade 75)Hex NutLengthTHREADBAR DesignationCoupler LengthCouplerOuter 2332702.252.653.503.864.755.3857678998121137DYWI Drill Hollow Bar Hardware PropertiesCouplerLengthBar SizeR51LT40NR51NT76NT76SCouplerDiameterHex Nut .683.543.153.159068908080DYWIDAG THREADBAR Prestressing Steel ASTM A722 (Grade 150)Hex NutLengthTHREADBAR Designation[in][mm][in][mm]Coupler Length[in][mm]CouplerOuter 3Coupler and hexnut develop the full load of the bar ultimate load. Bearing plates are available inany size and are made from steel material conforming to ASTM A36 or ASTM A572 grade 50.Multibar AssemblyAt the AnchorageBearing Platewith Hex NutIn the DBAR (Tot. 3)CementGroutPrimary Grout TubePost Grout Tube11

Hardware and AccessoriesThe GEWI Splice Coupler,allowing splicing at any point,offers the following advantages:of GEWI Piles under restricted headroom such as forfoun dation rehabilitations in basements and underneath bridges.n I nstallationn S horttransport lengths, if needed,in case of container or helicopter transport.n U nlimitedextension of the nchorGEWI Bar, for example, to athe cross beam for pile tests.Bearing Plate-Hexnut AnchorageCoupler with HexnutsGEWI Pile assembly with double corrosion protection (DCP) and highpressure post-grout lines/ values.Post-grouting can be performed in oneor more stages. Post-grouting willincrease bond values between grout body and soil by up to 3 timesover conventional gravity grouting.DCP Threadbar with Centralizerand postgrout Line12Threadbar with postgrout Line

GEWI Pile TestingThe safety of a foundation, particularlyin low resistance soils, depends largelyto what extent the foundation can betested.Testing of GEWI Piles in compressioncan be facilitated by using adjacentpiles as reaction piles. Testing intension is usually sufficient since thecompression capacity of the pile isalways slightly higher than the tensioncapacity.Settlement or creep of GEWI Pilesunder service loads is generally verylow — usually less than 5mm. In granular soils, settlements of less than2mm are common.Tested piles are not affected by thetesting process and can be used as anintegral part of the foundation sytem.Testing of GEWI Piles is a simple procedure since the jack is axiallypulling the centre bar or group of n PileTension PilePile length: 43 ft. (13 mm)Ground:0-26 ft. (0 -8 m) fill (gravel)26-43 ft. (8 -13 m) natural ground (dense gravel)13

ReferencesIrving Tissue Weston road plant upgrade; CanadaiOwner Irving Tissue Corporation, Toronto, Canada Consulting Engineers AMEC Earth & Environmental Limited, S carborough, Canada Piling Contractor Geo-Foundations Contractors Inc., Bolton, CanadaDSI Unit DSI Canada, Eastern Division, Gormley, Ontario, Canada ccessories,DSI Services Supply of 40 GEWI Piles, 92 ft/28m long, x 57 mm grade 75 bar with double corrosion protection, aexpertise and equipmentReferencesDYWIDAG Technology provides a dditional seismic event stability for T erminal Buildingi14Owner Vancouver International Airport Authority, BC, Canada General Contractor Ledcor Industries Ltd., Vancouver, BC, Canada Structural Design Read Jones Christoffersen Ltd., Vancouver, BC, Canada Geotechnical Engineers Macleod Geotechnical Ltd., NorthVancouver, BC, Canada Piling Contractor Kani Foundation Technologies, Richmond, BC, CanadaDSI Services Supply of 330 GEWI Piles with double corrosion protection, total length 59 ft/18 m; Technical support; Rental oftesting equipment

References20 Windmills reinforced with Micropiles, TexasiOwner General Electric Co., Greenville, South Carolina, USA Execution Nicholson Construction and Hayward Baker, USADSI Unit DSI USA, Business Unit Geotechnical Systems, Toughkenamon, PA, USADSI Services Supply of 240 micropiles using 3 GEWI Bars in lengths of 45 ft /13,7 m each, x 63.5 grade 80 (St 555/700),supply of slotted spacer plates and bar spacers15

DYWIDAG-SystemsInternational USA Inc.DYWIDAG-SystemsInternational Canada Ltd.320 Marmon DriveBolingbrook, IL 60440Phone: (630) 739-1100Fax:(630) 739-5517E-Mail: dsiamerica@dsiamerica.comEastern Division37 Cardico DriveGormley, ON L0H 1G0Phone: (905) 888-8988Fax:(905) 888-8987E-Mail: ecd@dsiamerica.com1591 E. Atlantic Blvd #200Pompano Beach, FL 33060Phone: (954) 532-1326Fax:(954) 532-1330E-Mail: dsiamerica@dsiamerica.com5139 South Royal Atlanta DriveTucker, GA 30084Phone: (770) 491-3790Fax:(770) 938-1219E-Mail: dsiamerica@dsiamerica.com2400 Hwy 287 N.Suite 106Mansfield, TX 76063Phone: (817) 473-6161Fax:(817) 473-1453E-Mail: dsiamerica@dsiamerica.com2154 South StreetLong Beach, CA 90805Phone: (562) 531-6161Fax:(562) 531-3266E-Mail: dsiamerica@dsiamerica.com1314 Central Ave SouthSuite 100Kent, WA 98032Phone: (253) 859-9995Fax:(253) 859-9119E-Mail: dsiamerica@dsiamerica.com1263 Newark RoadToughkenamon, PA 19374Phone: (610) 268-2221Fax:(610) 268-3053E-Mail: dsiamerica@dsiamerica.comQuebec OfficeC.P. 412St. Bruno,Quebec, QC, J3V 5G8Phone: (450) 653-0935Fax:(450) 653-0977E-Mail: ecd@dsiamerica.comWestern Division19433 96th AvenueSuite 103Surrey, BC V4N 4C4Phone: (604) 888-8818Fax:(604) 888-5008E-Mail: wcd@dsiamerica.comCalgary Office2816 - 21st Street NE., #204Calgary, Alberta T2E 6Z2Phone: (403) 291-4414Fax:(403) 250-5221E-Mail: wcd@dsiamerica.comArgentinaA u s t r al i aAustriabelgiumBosnia and herzegovinaBrazilCanadaChileC HIN AColombiaC o s ta R i caC r o at i aCzech republicD e n ma r kEgyptestoniaF i n la n dFranceG e r ma n yGreeceGU A T E M A L AHONDUR A SHong KongIndonesiaItal yJapanKoreaLebanonLuxembourgM ala y s i aMexicoN e t h e r la n d sNorwayOma nPa n amaPa r a g u a yPeruPO L A NDP o r t u g alQ ata rRUSSI ASa u d i A r a b i asingaporeS o u t h A f r i caSpainSwedenS w i t z e r la n dTaiwanT h a i la n dTurkeyU n i t e d A r a b Em i r at e sUnited kingdomUruguayUS AV e n e z u e lawww.dsiamer ica.comwww.dsican ada. ca04180-1US/10.12-web udPlease note:This brochure serves basic informationpurposes only. Technical data and informationprovided herein shall be considerednon-binding and may be subject to changewithout notice. We do not assume any liabilityfor losses or damages attributed to the useof this technical data and any improperuse of our products. Should you requirefurther information on particular products,please do not hesitate to contact us.

Use of micropile (mini pile, reticulated pile, etc.) started in early 1950s in Italy for underpinning applications of historic buildings damaged during World War II. Micropile technology is a reliable pile system that can withstand large capacity axial or lateral loads with minimal disturbance to the existing structures. They became very popular