Transcription

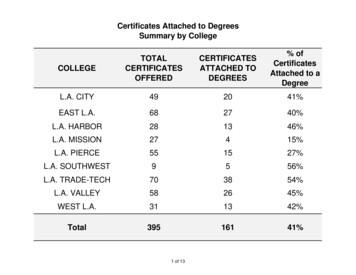

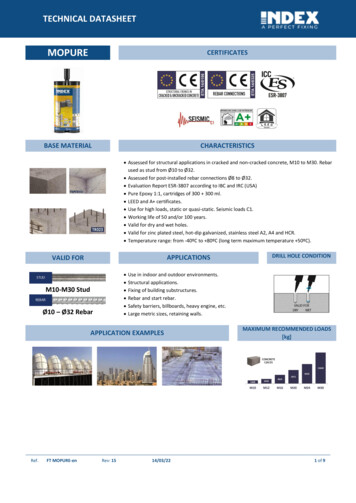

TECHNICAL DATASHEETMOPURECERTIFICATESBASE MATERIALCHARACTERISTICS Assessed for structural applications in cracked and non-cracked concrete, M10 to M30. Rebarused as stud from Ø10 to Ø32. Assessed for post-installed rebar connections Ø8 to Ø32. Evaluation Report ESR-3807 according to IBC and IRC (USA) Pure Epoxy 1:1, cartridges of 300 300 ml. LEED and A certificates. Use for high loads, static or quasi-static. Seismic loads C1. Working life of 50 and/or 100 years. Valid for dry and wet holes. Valid for zinc plated steel, hot-dip galvanized, stainless steel A2, A4 and HCR. Temperature range: from -40ºC to 80ºC (long term maximum temperature 50ºC).APPLICATIONSVALID FOR M10-M30 StudØ10 – Ø32 RebarUse in indoor and outdoor environments.Structural applications.Fixing of building substructures.Rebar and start rebar.Safety barriers, billboards, heavy engine, etc.Large metric sizes, retaining walls.APPLICATION EXAMPLESRef.FT MOPURE-enRev: 15DRILL HOLE CONDITION14/03/22MAXIMUM RECOMMENDED LOADS[kg]1 of 9

TECHNICAL DATASHEET1. RANGEITEMCODESIZE1MOPURE600600 ml.PHOTOCOMPONENTPURE EPOXYMORTARMATERIALPure Epoxy mortar.Format: side by side cartridges of600 ml122. STUD BOLTS3MORCEPKITCLEANING BRUSHES3 Cleaning brushes kit of ø14, ø20 and ø29 mm.4MOBOMBACLEANING PUMPPump for cleaning dust and drill hole fragments5MORCAPUMIXING NOZZLEPlastic. Helix static mixer.Ref.FT MOPURE-enPHOTOCOMPONENTAPPLICATION GUNRev: 1514/03/22MATERIALGun for 600 ml cartridgesThreaded steel stud, class 5.8 ISO 898-1Threaded steel stud, class 8.8 ISO 898-1Threaded stainless steel stud A2-70Threaded stainless steel stud A4-702 of 9

TECHNICAL DATASHEET3. INSTALLATION DATA - CONCRETE FIXING (SET UP PARAMETERS)SIZEd0: nominal diameterdf: fixture hole diameter Tins: torque Circular cleaning brush in 8dh1: drill hole depthscr,N: critical spacingccr,N: critical edge distancecmin: minimum distance to edgesmin: minimum spacinghmin: minimum concrete thicknessStandard studh1: drill hole depthscr,N: critical spacingccr,N: critical edge distancecmin: minimum distance to edgesmin: minimum spacinghmin: minimum concrete thicknesshef,max 20dh1: drill hole depthscr,N: critical spacingccr,N: critical edge distancecmin: minimum distance to edgesmin: minimum spacinghmin: minimum concrete thickness[mm][mm][mm][mm][mm][mm]5.8 / 8.8 Zinc plated stud codeA2 / A4 Stainless steel stud codeRef.FT MOPURE-enRev: 15 The hef depth value may be selected by the user ranging between hef,min 8d andhef,max 20d. Any intermediate values may be interpolated. Critical distances are those where anchors in a group of anchors are not influencedby one another with regard to tension load effects. For smaller distances, down tominimum distances, corresponding reduction coefficients must be applied. Standard studs are available for each measurement, as shown in the table.14/03/223 of 9

TECHNICAL DATASHEET4. PRODUCT SET UP4.1. CONCRETE SET UP1. DRILLCheck the concrete base is compact and porosity is insignificant.Suitable for wet, dry or flooded drill holes.Cartridge installation temperature: 5 ºC.Base material installation temperature: MOPURE 5 ºCUse drill in hammer mode.Drill to the specified diameter and depth values2 - 6. BLOW AND CLEANClear the drill holes completely of dust and fragments by following theprocedure shown in the picture. If the drill hole is flooded, the water must beremoved before mortar is injected.A – B – C. OPEN CARTRIDGERemove the plug from the cartridge and hit the cartridge against a rigidsurface. The mouth must be hit above the thread otherwise, threading won’tbe possible. Once the mouth has been opened, insert the mixing nozzle inthe gun. Pull the trigger repeatedly until the mortar comes out of the nozzlein a uniform grey color. Any iridescence indicates improper mixing. Alwaysdiscard the first two doses of each cartridge: these should never be used forfixing.7. INJECT MORTARInsert the nozzle to the bottom of the drill hole and apply mortar: gradually remove the nozzle, ensuring there are no air bubbles.Fill the hole to ½ and ¾ of its depth.In the event of not fully using the cartridge, leave nozzle attached. Only change if using again and handling time has expired,remembering to discard the first two doses of mortar8. INSTALLATIONIntroduce the stud to be installed by screwing it lightly down to the installation depth value manually; ensuring the mortar covers thestud thread. The introduction of the anchor must take place within the handling time. The mortar must seep from the top of the drillhole to ensure it is completely full and there are no gaps between the stud and the drill hole.TEMPERATURE AND CURING TIMETYPEBase material temperature [ºC]Handling time [min]Curing time [hrs]MOPURE 5 to 102024 10 to 152012 15 to 20158 20 to 25117 25 to 3086 30 to 3565 35 to 4044 40339. APPLY TORQUEOnce the curing time has elapsed, apply torque, never exceeding the values indicated in the table.Ref.FT MOPURE-enRev: 1514/03/224 of 9

TECHNICAL DATASHEET5. STORAGE CONDITIONSKeep the product stored in a cool, dry place, away from direct sunlight and heat sources, at an average temperature between 5 ºCand 25 ºC.Shelf life of unopened cartridge: 24 months from the date of manufacture. The expiration date is indicated on the cartridge.6. RESISTANCES6.1 CONCRETE FIXATIONCharacteristic resistances for C20/25 concrete for an isolated anchor (without considering anchor-to-anchor or anchor-to-edge distanceeffects) and class 5.8 studs or A4-70 stainless steel are shown in tables below.ZINC PLATEDSIZETensionShearSTAINLESSSTEELNON-CRACKED CONCRETECONCRETECLASSCHARACTERISTIC RESISTANCESTensionShearZINC PLATEDShearSTAINLESSSTEELCRACKED CONCRETETensionTensionShearRef.FT MOPURE-enM10M12M16M20M24M30hef,min 8dNRk[kN]27,639,870,799,5130,8182,9Standard studNRk[kN]31,145,669,1109,0149,7230,4hef,max 20d - 5.8NRk[kN]29,042,079,0123,0177,0281,0hef,max 20d - 8.8NRk[kN]46,067,0126,0196,0282,0565,4All depths 5.8VRk[kN]15,021,039,061,088,0140,0All depths 8.8VRk[kN]23,034,063,098,0141,0224,0hef,min 8dNRk[kN]27,639,870,799,5130,8182,9Standard studNRk[kN]31,145,669,1109,0149,7230,4hef,max 20dNRk[kN]41,059,0110,0172,0247,0393,0All depthsVRk[kN]20,030,055,086,0124,0196,0hef,min 8dNRk[kN]21,330,749,855,279,6124,4Standard studNRk[kN]24,035,248,158,787,1145,1hef,max 20d - 5.8NRk[kN]29,042,079,0138,2199,0311,0hef,max 20d - 8.8NRk[kN]53,476,9136,7138,2199,0311,0All depths 5.8VRk[kN]15,021,039,061,088,0140,0hef,min 8d - 8.8VRk[kN]23,034,063,098,0183,2256,0Standard stud 8.8VRk[kN]23,034,063,098,0141,0224,0hef,max 20d - 8.8VRk[kN]23,034,063,098,0141,0224,0hef,min 8dNRk[kN]21,330,749,855,279,6124,4Standard studNRk[kN]24,035,248,158,787,1145,1hef,max 20dNRk[kN]41,059,0110,0138,2199,1311,0All depthsVRk[kN]20,030,055,086,0124,0196,0Rev: 1514/03/225 of 9

TECHNICAL DATASHEETZINC PLATEDSIZETensionShearSTAINLESSSTEELNON-CRACKED CONCRETECONCRETECLASSDESIGN RESISTANCESTensionShearZINC PLATEDShearSTAINLESSSTEELCRACKED CONCRETETensionTensionShearRef.FT MOPURE-enM10M12M16M20M24M3062,387,1hef,min 8dNRd[kN]15,318,933,747,4Standard studNRd[kN]17,221,732,951,971,2109,7hef,max 20d - 5.8NRd[kN]19,328,052,682,0118,0187,3hef,max 20d - 8.8NRd[kN]30,644,684,0130,6188,0269,2All depths 5.8VRd[kN]12,016,831,248,870,4112,0All depths 8.8VRd[kN]18,427,250,478,4112,8179,2hef,min 8dNRd[kN]15,318,933,747,462,387,1Standard studNRd[kN]17,221,732,951,971,2109,7hef,max 20dNRd[kN]21,531,057,890,5130,0206,4All depthsVRd[kN]12,819,235,255,179,4125,4hef,min 8dNRd[kN]11,814,623,726,337,959,2Standard studNRd[kN]13,316,722,927,941,469,1hef,max 20d - 5.8NRd[kN]19,328,052,665,894,7148,1hef,max 20d - 8.8NRd[kN]29,636,665,165,894,7148,1All depths 5.8VRd[kN]12,016,831,248,870,4112,0hef,min 8d - 8.8VRd[kN]18,427,250,478,4112,8170,7Standard stud 8.8VRd[kN]18,427,250,478,4112,8179,2hef,max 20d - 8.8VRd[kN]18,427,250,478,4112,8179,2hef,min 8dNRd[kN]11,814,623,726,337,959,2Standard studNRd[kN]13,316,722,927,941,469,1hef,max 20dNRd[kN]21,531,057,865,894,7148,1All depthsVRk[kN]12,819,235,255,179,4125,4Rev: 1514/03/226 of 9

TECHNICAL DATASHEETZINC PLATEDSIZETensionShearSTAINLESSSTEELNON-CRACKED CONCRETECONCRETECLASSMAXIMUM LOADS RECOMMENDED (when γF 1.4)TensionShearZINC PLATEDShearSTAINLESSSTEELCRACKED ef,min 8dNrec[kN]10,913,524,033,844,5Standard studNrec[kN]12,315,523,537,150,978,4hef,max 20d - 5.8Nrec[kN]13,820,037,658,584,2133,8hef,max 20d - 8.8Nrec[kN]21,931,960,093,3134,2192,3All depths 5.8Vrec[kN]8,512,022,234,850,280,0All depths 8.8Vrec[kN]13,119,436,056,080,5128,0hef,min 8dNrec[kN]10,913,524,033,844,562,2Standard studNrec[kN]12,315,523,537,150,978,4hef,max 20dNrec[kN]15,422,141,364,692,8147,7All depthsVrec[kN]9,113,725,139,356,789,7hef,min 8dNrec[kN]8,410,416,918,827,042,3Standard studNrec[kN]9,511,916,319,929,649,3hef,max 20d - 5.8Nrec[kN]13,820,037,647,067,7105,7hef,max 20d - 8.8Nrec[kN]21,126,146,547,067,7105,7All depths 5.8Vrec[kN]8,512,022,234,850,280,0hef,min 8d - 8.8Vrec[kN]13,119,436,056,080,5121,9Standard stud 8.8Vrec[kN]13,119,436,056,080,5128,0hef,max 20d - 8.8Vrec[kN]13,119,436,056,080,5128,0hef,min 8dNrec[kN]8,410,416,918,827,042,3Standard studNrec[kN]9,511,916,319,929,649,3hef,max 20dNrec[kN]15,422,141,347,067,7105,7All depthsVrec[kN]9,113,725,139,356,789,71 KN 100 kgThe italic font underlined values indicate steel failure; bold values indicate concrete failure, rest indicates pull-out failure.COEFFICIENTS FOR TENSION LOADSIN PULL-OUT FAILURE IN HIGH-RESISTANCE CONCRETE TYPESRef.CONCRETE COEFFICIENTC30/37C40/50C50/60Ψc (Non-cracked)1,031,061,07Ψc (Cracked)1,121,231,30FT MOPURE-enRev: 1514/03/227 of 9

TECHNICAL DATASHEET6.2 CHEMICAL RESISTANCEChemical resistance of the product for different kind of chemical environments and for a specific concentration.Chemical EnvironmentConcentrationResultAqueous Solution Acetic Acid10%CAcetoneAqueous Solution AluminiumChlorideAqueous Solution Aluminium Nitrate100%XSaturated 10%Chemical EnvironmentHexaneHydrochloric AcidConcentrationResult100%C10% 15% 25%C5% Hydrogen Sulphide Gas100% Jet Fuel100%CIsoproyl Alcohol100%XBenzene100%CLinseed Oil100%Saturated Lubricating Oil100%100%XMineral Oil100% 5 - 15% Paraffin / Kerosene (Domestic)100%C100%CPhenol Aqueous Solution1%CSaturated50%Gas Phosphoric Acid10% / pH13 Ammonia SolutionBenzoic AcidBenzyl AlcoholSodium Hypochlorite SolutionButyl AlcoholCalcium Sulphate Aqueous SolutionCarbon MonoxideCarbon TetrachloridePotassium Hydroxide100%CSea Water100%CChlorine WaterSaturatedXStyrene100%CChloro Benzene100%XSulphur Dioxide Solution10%SaturatedSulphur Dioxide (40 C)50% Cyclohexanol100% Diesel Fuel100%CDiethylene Glycol100% Turpentine100%CEthanol95%XWhite Spirit100% Ethanol Aqueous Solution20%CXylene100%CHeptane100%Resistant to 75 C with at least 80% of physicalproperties retained.CContact only to a maximum of 25 C.C Not ResistantXCitric Acid Aqueous SolutionRef.FT MOPURE-enRev: 1514/03/22Sulphuric Acid5%10%8 of 9

TECHNICAL DATASHEET7. OFFICIAL DOCUMENTATIONThe following documents are available through our Sales Department or on our official website: www.indexfix.com: MOPURE Safety Data Sheet. European Technical Assessment ETA 14/0156 for use on cracked and non-cracked concrete according to EAD 330232-00-0601Guide, option 1, for M10 to M30. Assessment for seismic loads C1. European Technical Approval ETA 14/0325 for the installation of post-installed concrete reinforcements with diameters from 8to 32 mm according to technical report EAD 330087-01-0601. ICC-ES Evaluation Report ESR-3807 according to International Building Code (IBC 2003, 2006, 2009, 2012 and 205) andInternational Residential Code (IRC 2003, 2006, 2009, 2012 and 205). Classified A according to French Regulation DEVL11044875A relative to the emission of volatile pollutants for indoor use. LEED MOPURE Certification of sustainability. Declaration of Performance DoP MOPURE. INDEXcal anchor calculation software. INDEXmor cartridge calculation needs software.Ref.FT MOPURE-enRev: 1514/03/229 of 9

Pure Epoxy mortar. Format: side by side cartridges of 600 ml 12 2. ACCESORIES . SIZE M10 M12 M16 M20 M24 M30 d 0: nominal diameter [mm] 12 14 18 22 26 35 d f . STORAGE CONDITIONS Keep the product stored in a cool, dry place, away from direct sunlight and heat sources, at an average temperature between 5 ºC .