Transcription

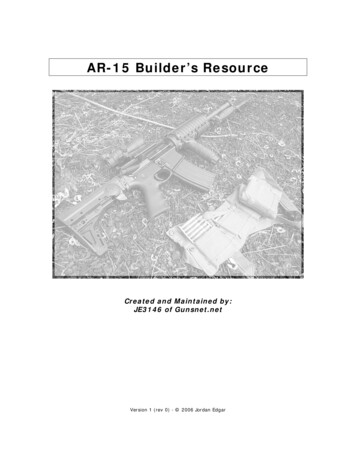

AR-15 Builder’s ResourceCreated and Maintained by:JE3146 of Gunsnet.netVersion 1 (rev 0) - 2006 Jordan Edgar

Table of ContentsChapter 1 – Tools & PiecesChapter 2 – Lower Half AssemblyChapter 3 – Upper Half AssemblyChapter 4 – Collapsible Stock InstallationChapter 5 – Fixed Stock InstallationChapter 6 – Headspacing & Function ChecksChapter 7 – Disassembly & MaintenanceChapter 8 – Build OptionsChapter 9 – Exploded Diagram

Special ThanksM700Police – Photos of Fixed Stock InstallationLegalThis tutorial in no way signifies liability for person or property during assembly orusage. The creator of the AR-15 Builder’s Guide will not be responsible oraccountable for, but not limited to, anything that may arise during purchase,assembly, function checks, or usage of anything in some way related to this guide.Use this guide at your own risk.

Chapter 1 – Tools & PiecesWhat tools do I need?If you’re considering that you might do a complete build in the future, then it’srecommended to just buy the tools now. It will save you from the expense later, andyou’ll have the tools to perform maintenance on the rifle you currently have. Toolssuch as the telescoping stock wrench are integrated within the Armorer’s wrench.Buying both is not necessary.For a Kit Build: Roll Pin Punches (3/32", 1/8", 5/32")A flathead screwdriver and/or allen keyHammerNeedle nose PliersTelescoping stock wrench (if you have a collapsible stock)For a Complete Build: Roll Pin Punch (1/16")A viceAction blockBarrel or Armorer's wrenchRecommended, but not necessary Tools for a Complete Build: Gas tube pusherSnap-Ring pliersPivot Pin Detent tool or razor bladeWhat pieces do I need for a kit build?The following is a list of pieces you will need for a kit build: AR-15 kitAR-15 stripped lower receiver

What pieces do I need for a complete build?The following is a list of pieces you will need for a complete build: Stripped Lower ReceiverUpper ReceiverLower Receiver Parts Kit (*)Bolt AssemblyCharging HandleGas Tube & Gas Tube Roll PinDelta Ring AssemblyBarrel with Barrel NutHandguardStock Assembly with Buffer Spring and BufferSight, Optic, or other aiming device if your upper does not include one(*) Lower Receiver Parts Kit Expanded Trigger GuardDisconnectorTriggerBolt CatchMagazine Catch ButtonMagazine CatchHammerSelectorTrigger and Hammer PinsTakedown and Pivot Detent SpringsSelector SpringBolt Catch SpringBuffer Retaining SpringDisconnector SpringMagazine Catch SpringTrigger SpringHammer SpringPistol Grip Lock Washer & ScrewTakedown PinPivot PinBolt Catch Roll PinTrigger Guard Roll PinBuffer RetainerBolt Catch BufferSelector DetentTakedown and Pivot Detents

Chapter 2 - Lower Half AssemblyLay out the PartsBefore starting any project, be sure to layout the parts and make sure you haveeverything you need. Do the same with your tools. Starting a project and finding outhalfway through it, that you don't have the tool you need could pose a problem. Onone hand, you could wait until you find, locate, or acquire the tool, or on the otherhand you could make due with what you have. Doing the latter poses a great riskand many AR's have been messed up by people being impatient without propertooling. Take this step seriously.Courtesy of AR15.com for this pictureAll parts will be coated with protective grease. Prior to installation, make sure toclean off this protective grease and coat with a lubricant of your choice. I usedBreakFree CLP for this installation. All parts will have very tight tolerances. However,nothing should have to be overly forced into place. If something is not going right,then stop, take another look at the guide, figure out what isn't going right and thenstart again. The key element to any successful build is PATIENCE. The only parts thatneed to be hammered into place are the two roll pins.

1. The Magazine CatchCAREFUL - YOU CAN SCRATCH YOUR RECEIVER ON THIS STEPFirst you insert the Mag CatchSpring into the hole shown. Thenext step is to insert the MagazineCatch into its hole on the oppositeside. Then proceed to stick the MagRelease Button into its proper holeshown and depress it downwarduntil the threads of the MagazineCatch meet the button. Push thebutton into the hole. This willcreate spring tension and push theMagazine Catch out the other side.The goal is to thread the MagazineCatch onto the button.

Once the Magazine Catch isthreaded onto the Mag ReleaseButton, you can take a punch (oneof the larger ones) and depress thebutton downward. Rotating theMagazine Catch clockwise willthread it into place. Keep doingthis until the threads of theMagazine Catch are flush with thetop of the hole on the button. Thiscan be seen a few photos down.

Finished Mag Catch2. The Bolt CatchCAREFUL - YOU CAN SCRATCH YOUR RECEIVER ON THIS STEPInsert the Bolt Catch Spring intoproper hole on the receiver asshown.Insert the Bolt Catch Buffer onto theBolt Catch Spring.

Insert the Bolt Catch.This step is best done with thereceiver vertical. Place the Bolt CatchRoll pin into its proper spot, and giveit 1 or two taps with the roll pinpunch and a hammer to start it inthe hole.The next part is best done with someform of protection on the receiver.Masking tape, duct tape or a plasticZiploc bag work nicely for protectingthe finish. You will have to line upthe Bolt Catch with one hand whiletapping the roll pin in with the other.This job requires 3 hands to be doneeffectively and is sometimes bestdone with a 2nd person. Once you getthe roll pin going and everything islined up, you can stand it verticalagain to finish it the rest of the way.Don’t push it too far through though.

The finished product will look likethis.3. The Trigger GuardCAREFUL - YOU CAN BREAK YOUR RECEIVER ON THIS STEPThe easiest way to complete thisstep is to position the "ears" of thereceiver onto a book for support.In my example, I've found theONLY use for a DifferentialEquations book. My trigger guardmay look a little different, butthat's nothing to worry about. Findthe roll pin and use the (1/8")punch. Go SLOW on this step.Without the receiver on a support,and going too fast could result inbreaking the ears off your receiver.That would be bad. Give the pinsold hits, but don't take largeswings at it. It will gradually moveinto place. Once the roll pin is inplace, rotate the trigger guardforeword, and the front part willsnap into place with a springloaded pin that comes preinstalledon the trigger guard.

4. The Pivot Pin TIP: Do this step in a 1 gallon Ziploc bag. If parts fly, and they will for a first timer,then they will be isolated in Ziploc bag. This saves time. Otherwise you'd be huntinga very tiny piece that's now located several feet away and buried in the carpet. ARazorblade works well to hold the pin in place during installation, and a Pivot PinDetent Installation Tool works even better.First insert the Detent Spring intothe hole.Next insert the Detent onto theDetent Spring. The goal is to getthe setup looking like the nextphoto down. The easiest way toaccomplish this is using a flat razorblade to hole the detent pin in thehole, while you slide the pivot pininto place over the top of thedetent. Another method is using apair of needle nose pliers. The finalmethod is using a special 4 tool.The tool saves headaches, but isnot necessary.Finished Pivot Pin.

5. The TriggerInsert the disconnector spring asshown below. Make sure the "fat"part of the spring is downward. If itis not downward, the disconnectorwon't sit right and you won't getyour trigger pin in right.Next put your Trigger Spring ontothe Trigger as shown.Next put your Trigger Spring ontothe Trigger as shown.

Finally place the trigger assemblyinto the receiver, and insert thetrigger pin. Push downward ontothe disconnector to get the holes toline up right.And this is the finished product.6. The HammerOnly 3 pieces for this step.

Put the hammer spring onto thehammer as shown below.Then insert the hammercorrectly with the spring legssitting atop the trigger pin thatyou just installed. Then insertthe hammer pin in the samefashion as you did the trigger.Push downward on the hammeruntil the holes line up andshove the Hammer Pin throughthe receiver. This pin usually isa little tight, so a few VERYlight taps from a hammer oncethe pin has been startedthrough is generally not a badidea. Just make sure not tooverly hit it or miss. A veryvery light tap should be morethan enough.A properly installed hammer.

Carefully lock back thehammer to function test, butDO NOT let go of the hammeruntil you are fully sure it locksinto place. If the hammerreleases, it could crack yourreceiver upon impact.7. The Safety Selector and Pistol GripInsert the Selector Switchinto the proper hole, asshown.Flip the receiver over andinsert the Selector Detent,point side down, so that thebase of the pin fits nearlyflush, as shown.

Insert the Selector Spring intothe Grip hole, and wiggle the griponto the receiver lining the springup with the Selector Detent hole.Push the grip down fully.Find the Grip Screw and makesure the washer is in place. TheGrip Screw may either require aflathead screwdriver or an allenkey pending on the make of theLower Parts Kit.

Screw the grip down tightly.Finished Lower ReceiverThis is what your finished receiver will look like. The remaining parts will be installedlater when you attach your buttstock. Be sure not to lose them as there is no way toinstall them on the lower receiver without a buttstock.

Chapter 3 - Upper Half AssemblyLay out the PartsBefore starting any project, be sure to layout the parts and make sure you haveeverything you need. Do the same with your tools. Starting a project and finding outhalfway through it, that you don't have the tool you need could pose a problem. Onone hand, you could wait until you find, locate, or acquire the tool, or on the otherhand you could make due with what you have. Doing the latter poses a great riskand many AR's have been messed up by people being impatient without propertooling. Take this step seriously.

Begin AssemblyThe next step is to assemble the Delta ring assembly onto the barrel nut of yourbarrel. The delta ring is compromised of the ring, a spring, and a snap ring. I HIGHLYrecommend a set of snap-ring pliers for this job.Insert the spring into the Deltaring.Set the Delta ring onto the barrelnut, and fit the snap ring in placewith the pliers.

With the delta ring on. Place yourreceiver in the action block.Place the block in a vice.Insert your barrel into thereceiver. If there is extremeresistance, then remove thebarrel and rub steel wool on theoutside of the barrel, where it willslip into the receiver.Sometimes the parkerization canbe a little thick.

Coat the threads with a form ofmoly based grease (*) to preventany form of seizing fromoccurring. Screw the barrel nutonto the receiver threads untilhand tight.(*) NOTHING WITH A GRAPHITEADDITIVE!Now take the wrench and tightenthe nut just a LITTLE bit. Enoughfor it to grab hold. The next stepis to index the slots on the snapring and delta ring spring. Makesure they align on the top mostpart of the receiver. A smallpunch works best for twistingthem around.Next push the gas tube from therear and push it through theindexed snap ring and spring, butNO further than that. This willkeep your snap ring and spring inalignment while you do your finaltorquing.

Finish AssemblyUsing the barrel wrench, torque the nut to 30 ft lbs. A rule of thumb is to tightenthe barrel till it's hand tight, then tighten the nut until the next slot on the barrel nutaligns with the indexed snap ring and spring holes. A torque wrench can be used, butit's not necessary.After torquing the nut, align the hole on the delta ring to see completely through theindexed snap ring, spring, delta ring, and barrel nut. When everything is aligned withthe hole on the receiver, remove the gas tube. Feed the gas tube from the muzzleend through the barrel nut, and through the receiver. Wiggle it around the front sightpost. It will be a tight fit, but the kink in the gas tube will provide enough clearance.Push it foreword and make sure the gas port on the tube is downward. Feed it intothe front sight post, and push it foreword until it is completely in. Using a smallpunch, you can index the hole of the front sight post with the hole in the gas tube.Insert the roll pin, and using a 1/16" punch, tap in the roll pin.

Chapter 4 - Collapsible Stock InstallationLay out the PartsParts Needed: Complete Lower Receiver minus Stockset AssemblyStock BodyBuffer TubeBuffer SpringBufferCastle NutRetainer PlateRear Takedown PinRear Takedown DetentRear Takedown Detent SpringBuffer RetainerBuffer Retaining Spring

Begin InstallationThread the castle nut on with thenotches outward, and place theretainer plate on the buffer tubewith the dimple inward towards thereceiver.Thread the buffer tube onto thereceiver. Screw it on for a coupleturns, but nothing more.Insert the Buffer Retaining Springinto the Buffer Retainer.

Insert the Buffer RetainingAssembly into the receiver asshown. (Spring side down)Depress the Buffer RetainingAssembly into the receiver whilecontinuing to screw the BufferTube onto the receiver. Continue todo this until you can no longer doso.The next step is to place the RearTakedown Pin into its hole. Makesure the side with the internalgroove is facing rearward.

On the rearward portion of thereceiver you’ll find a small hole.Insert the Takedown Detent intothe hole (pointed end first). Theninsert the Takedown Detent Springinto the hole.Make sure the Castlenut is asunscrewed as it possibly can be,then proceed to pull the retainerplate towards it. Unscrew thebuffer tube slightly untileverything’s alignment resemblesthe picture on the right. Push theretainer plate towards the receiverand then finger tighten theCastlenut. Take your Stock Wrenchand fully tighten the

Special Thanks M700Police – Photos of Fixed Stock Installation Legal This tutorial in no way signifies liability for person or property during assembly or usage. The creator of the AR-15 Builder’s Guide will not be responsible or accountable for, but not