Transcription

High LightMotors are fully submersiblePumps can handle up to 2” spherical solidsIndoor and outdoor installationEasy installation and removalFor sump and rain waterControl system availableFiberglass and steel basin available

INTRODUCTIONSHOWN AS “QOSP” SERIES PREPACKAGED SYSTEM WITH FRAME,COVER AND BASINSump pumps provide for the lifting and disposalof fluids from retaining basins or concrete pitsand are pumped to city water disposal lineswhere these fluids cannot drain under gravityconditions alone. Typically located below grade,sump pumps provide building owners the abilityto design and locate floor drains or otherfacilities below ground that are serviced bythese lift stations.Compatible with Federal Pump’s OS, FSS, SBS,TCS, and NPC simplex, and duplex controlsystem, the Q series can support 24/7 automaticoperation for standard sump pump service inresidential and small commercial buildings.The “Q” product offering is also convenientlypackaged in the “QOSP” system that providesthe end user with trouble and maintenance freeoperation when designed, installed, andmaintained properly. 2

PRODUCT DETAILSDISCHARGESEAL2” NPT, female vertical104 F (40 C) continuousSingle mechanical seals withcarbon/ceramic/Buna-N faces forextended seal life with stainless steelhardwarePUMP BODYCORD ENTRYCast iron ASTM A-48 class 3020ft of neoprene cord SJO 14/3, sealedagainst moistureLIQUID TEMPERATUREIMPELLER2 vane open cast iron ASTM A-48class 30 impeller, with vanes on backside, balanced.SHAFT416 series stainless steelO-RINGBuna-NHARDWARE300 series stainless steelBEARINGSupper row ball bearing forradial load, and lower rowball bearing for radialand thrust loadMOTORSingle Phase: NEMA L, permanentsplit capacitor, 115, 208, & 230 volts, 60Hz, 4-pole, oil filled, with overloadprotection in motor.Three Phase: NEMA B, 208,230,& 460volts, 60 Hz, 4-pole, oil filled. Overloadprotection should be included in thecontrol panel.Q-2F MODEL SHOWN 3

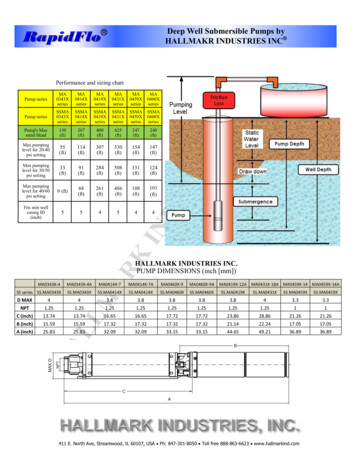

SELECTION TABLE*SYSTEM DESIGN COMPONENTSThe Q series sump pump is available in freestanding and automatic operation option(1Ph/115V models only) and should bereviewed in detail prior to order. Dimensionsmay vary based upon option requested andcustom specification requirements. Everyoption will include a submersible pump andmotor with mechanical seal rated to 104 F.Pump to close coupled to motor. Add “.A” tothe “DISCHARGE SIZE & SUSP. PLATEDESIGN” for 1Phase/115V models to addbuilt-in automatic float switch to the pump.Q-2F.A-½-4-1C†PUMP SERIESDISCHARGE SIZE & SUSP. PLATE DESIGNHORSEPOWERRPMELECTRICAL RATING (PHASE & VOLTAGE)† 1 1PH,3 3PHA 115V, B 208V, C 230V, D 460VDISCH.DISCH.DISCH.DISCH.HEAD MOTORSIZEHEAD MOTORSIZEMODEL NOG.P.M. [FEET] H.P. [INCHES]MODEL NOG.P.M. [FEET] H.P. 12*Table is used for quick sizing only. Refer to pump performance curve for exact pump operation over its range.*Refer to page 9 for amp draw on the each pump and model selectionOnly models running in 1Ph/115V in the Q series sump pump line are available with automatic float switch option.Add 2 pounds to equipment weight for automatic float switch options. 4

SERIES PERFORMANCE RANGE1750 RPMSERIESDISCH. SZQ2”MODELMOTOR HPDISCH. SIZE[INCHES]RPMIMPELLERWEIGHT [lb.]Q-2F-½-4- ½21750QP05195Q-2F-¾-4- ¾21750QP05596Q-2F-1-4- 121750QP072106RECOMMENDED MINIMUM PIT & BASIN SIZESQPumpSeriesRoundPump mplexDuplex24” dia.36” dia.24” X 24”36” X 36”24” dia.36” dia.24” X 24”36” X 36”24” dia.36” dia.24” X 24”36” X 36” 5

SUGGESTED CONTROLS – DUPLEXFLOAT DETAIL12”OS Control Panel & Floats(Standard Items)NEMA Type 1,4 & 12Disconnect SwitchAcross-the-line Magnetic StarterH-O-A Switch with integral Pilot LightControl Circuit Transformer (24V)HWA Light & Adjustable BuzzerHWA Silencing Push ButtonPump Auxiliary Float SwitchesDedicated HWA Float Switch 6

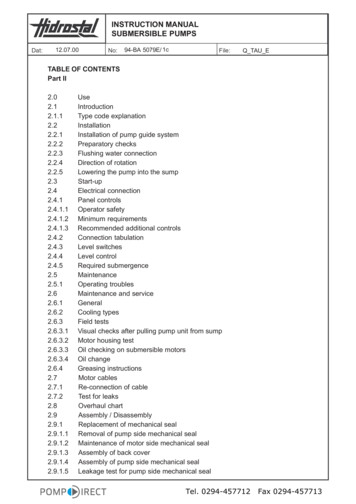

SUGGESTED SPECIFICATIONS – SIMPLEX (PLUG-IN)General Product Overview: Furnish and install where shown in the plans a Federal Pump Series Q simplex submersible sump pump with each pump ratedas shown in the pump schedule. Each pump shall include submersible motor, cast iron casing, standard fitted construction with stainless steel shaft andwater proof power cable and automatic float switch. Motor shall be NEMA L, single phase, permanent split capacitor, 115 volts, 60Hz, 1750RPM, oil filledand have overload protection.Sequence of Operation: Plug the factory provided control plug into a GFI receptacle, then plug the pump into the piggy-back plug. In the event of liquidlevel reaching above the set point, the pump float switch will signal the pump to turn “ON”. Upon lowering the liquid level to meet the “OFF” set point,the pump will terminate operation and standby for the next cycle.Warranty: The pump manufacturer will provide a (1) year limited warranty for material and workmanship and take unit responsibility of the systemcomponents.SUGGESTED SPECIFICATIONS – SIMPLEX (CONTROL PANEL)General Product Overview: Furnish and install where shown in the plans a Federal Pump Series QOSP simplex submersible sump pump with each pumprated as shown in the pump schedule. Each pump shall include submersible motor, cast iron casing, standard fitted construction with stainless steel shaftand water proof power cable and automatic float switch. Motor shall be NEMA L, single phase, permanent split capacitor, 115/230 volts, 60Hz, 1750RPM,oil filled and have overload protection OR three phase, 208/230/460volts, 60Hz, 1750RPM, oil filled.Controls: Pump manufacturer shall provide a Federal Pump series OS simplex level control system including simplex Control Panel (for wall mounting) andaccessory alarms as detailed in this specification. simplex Pump Controller shall include: disconnect switch with thru-the-door handles, across-the-linetype magnetic starters, (overload protection for 3 phase pumps), high water alarm light and horn with silencing push button, (control circuit transformerfor non-115V power), programmable logic controller, oil detection relay, numbered terminal strip, and Form-C circuits for BMS. The controls shall beprovided in a NEMA 1 enclosure built to UL-580A standard. The QOSP package will include a float switch for ON/OFF & high water alarm conditions.Sequence of Operation: In the event of liquid level reaching above the set point, the pump float switch will signal the pump to turn “ON”. In the event ofwhere the pump is not non-functional or cannot keep up with system demand, the liquid level would continue to rise and signal the High Water Alarm.Upon lowering the liquid level to meet the “OFF” set point, the pump will terminate operation and standby for the next cycle. In the event of presence ofoil, the oil sensing element will terminate pump operation and sound the alarm horn and light alerting the presence of oil in the sump.Warranty: The pump manufacturer will provide a (1) year limited warranty for material and workmanship and take unit responsibility of the systemcomponents.SUGGESTED SPECIFICATIONS – DUPLEX (CONTROL PANEL)General Product Overview: Furnish and install where shown in the plans a Federal Pump Series QOSP duplex submersible sump pump with each pumprated as shown in the pump schedule. Each pump shall include submersible motor, cast iron casing, standard fitted construction with stainless steel shaftand water proof power cable and automatic float switch. Motor shall be NEMA L, single phase, permanent split capacitor, 115/230 volts, 60Hz, 1750RPM,oil filled and have overload protection OR three phase, 208/230/460volts, 60Hz, 1750RPM, oil filled.Controls: Pump manufacturer shall provide a Federal Pump series OS duplex level control system including Duplex Control Panel (for wall mounting) andaccessory alarms as detailed in this specification. Duplex Pump Controller shall include: individual disconnect switches with thru-the-door handles, singlefeed power input terminal block, across-the-line type magnetic starters, (overload protection for 3 phase pumps), H-O-A selector switches with integralpilot run lights, (control circuit transformer for non-115V power), high water alarm light and horn with silencing push button, power relays, control relays,oil detection relay, numbered terminal strip, and Form-C circuits for BMS. The controls shall be provided in a NEMA 1 enclosure built to UL-580A standard.The QOSP package will include a float switch for high water alarm conditions. Each of the (2) pumps have dedicated automatic float switch.Sequence of Operation: In the event of liquid level reaching above the set point, the pump float switch will signal the lead pump to turn “ON”. If theliquid level rise above a certain rate where the lead pump along cannot satisfy demand, the lag pump will start at a predetermined set point and work inparallel with the lead pump to satisfy system conditions. Upon lowering the liquid level to meet the “OFF” set point, the lag pump will terminateoperation first, then the lead pump, and the two would standby for the next cycle. The system will automatically alternate lead and lag pumps – thepump’s level set point will dictate the lead and lag orientation. In the event of where the pumps are not non-functional or cannot keep up with systemdemand, the liquid level would continue to rise and signal the High Water Alarm. In the event of presence of oil, the oil sensing element will terminatepump operation and sound the alarm horn and light alerting the presence of oil in the sump.Warranty: The pump manufacturer will provide a (1) year limited warranty for material and workmanship and take unit responsibility of the systemcomponents. 7

SYSTEM SCHEMATICFully automatic sump pump system designed for ease in installation and future pump maintenanceAvailable to shipped loose for field assembly with fiberglass basins and “gas-tight” covers. The Qseries effluent pump provides a formidable sump system by combining the ease of installation with asmall form factorComplete set of “QOSP” packaged system includes:Submersible “Q” series sump sumpsDuplex control panelAutomatic float switchHigh Water Alarm float switchBAccessories that be modified:Frame & CoverBasinEDABCDEFITEMSubmersible PumpDuplex PanelFloat SwitchesHigh Water Alarm Float SwitchFrame & CoverBasinACF 8

PERFORMANCE DATAMOTOR OPERATING PERFORMANCE [AMPS AVG.]ITEMDESCRIPTIONDISCHARGE SIZE2”MODELHP1PH/115V1PH/208V1PH/230VHORSEPOWER RANGE½ 1 hpQ-2F-½ ½11.66.55.9PERFORMANCE RANGE25 150 GPMQ-2F-¾ ¾-11.610.5MAX. WATER TEMPERATURE104 FCASINGQ-2F-1 1-11.610.5ASTM A48 CLASS 30 CAST IRONIMPELLER2 VANE OPEN CAST IRON ASTM A-48CLASS 30 IMPELLER, WITH VANES ON BACK 16 SERIES STAINLESS STEELQ-2F-½ ½4.64.22.2MOTOR HOUSINGASTM A48 CLASS 30 CAST IRONQ-2F-¾ ¾6.15.52.2CORD ENTRY20FT NEOPRENEQ-2F-1 16.15.52.2FASTENERS300 SERIES STAINLESS STEELMECHANICAL SEALSSINGLE MECHANICAL SEALS WITHCARBON/CERAMIC/BUNA-N FACESBEARINGSUPPER ROW: BALL, SINGLE ROW, OIL LUBRICATED,FOR RADIAL LOADLOWER ROW: BALL, SINGLE ROW, OIL LUBRICATED,FOR RADIAL & THRUST LOADSINGLE PHASEOIL FILLED NEMA-L PERMANENTSPLIT CAPACITOR WITHOVERLOAD PROTECTIONMOTOR TYPETHREE PHASEOIL FILLED NEMA-B WITHOUTOVERLOAD PROTECTIONNOTES:1.2.3.4.Motors are designed for 20 starts per hour. Level devices and pit depths should be designed to maintain 10 12starts per hours at maximum 104 F for typical sump pump applicationsFloat devices require 8 12” of water level differential from low float(OFF) to high float(ON) position. Basins shouldbe designed to accommodate float level differentialHigh water alarm float(ON level) should be designed to activate at 6” below the bottom of invert to prevent anyfluids backing into the supply lines. Float switch tilt travel of 12” should be consideredMost fiberglass basins limit temperature to less than 120 F. For temperature in excess of 120 F where fiberglassbasins are required, contact the factory for special assistance 9

DIMENSIONAL DATABFE2” NPTADCGDisch.ModelHPRPMABCDEFGLb.2Q-2F-½ ½175018.6612.649.766.696.54.882.16952Q-2F-¾ & imensions in inches 10

NOTES 11

Since 1927 Federal Pump has been aleading provider of reliable and innovativefluid handling solutions for supply watermanagement and dewatering pumpservices.Variable Speed BoosterModel VSPV(up to 300 PSI)Its recent introduction of the VSPV &VSPM variable speed domestic watersupply system combines innovativetechnological advancements in premiumefficient motors and variable speed drivesupport programs that reduce energydemand, lower operating costs, andprovide more finely tuned supply controls.Vertical Sewage/Sump PumpModel VSA/VSP(up to 1400GPM)Its VSA/VSP vertical pump rated to 210Fprovidessolutionsindewateringapplications where condensate or boilerfeed water are collected and then cooledand pumped to city sewer connectionsproviding continuous service wheresubmersible pumps do not provide asustainable solution.The SOSP Oil Shield sump pumps alertingbuilding management to potential oil leaksin the elevator areas provide additionalbuilding support.Variable Speed BoosterModel VSPM(up to 600 PSI)Oil Shield Elevator Sump SystemModel SOSP(up to 125GPM)High rise roof fill applications, water makeup systems for mechanical equipmentutilizing rain water systems and energyefficient condensate, boiler feed, andvacuum condensate units continue in thefocus of energy efficiency and buildingsupport.In the tradition of leadership throughproduct innovation, quality designs, andreliable customer service, Federal Pumpcontinues to be a supplier to those watermanagement and dewatering marketswhere it first started that tradition ofleadership in Brooklyn, N.Y. Submersible Sewage/Sump PumpModel MSC-QD/J(up to 500GPM)1144 Utica AvenueBrooklyn, N.Y. 11203Tel: 718-451-2000www.Federalpumps.com

Sump pumps provide for the lifting and disposal of fluids from retaining basins or concrete pits and are pumped to city water disposal lines where these fluids cannot drain under gravity conditions alone. Typically located below grade, sump pumps provide building owners the ability to design and locate floor drains or other .