Transcription

Cleanroom Control and BestPractices13 Aug 2020Beth KroegerTechnical Service Senior Managerbeth kroeger@steris.comSTERIS Life SciencesContamination Control SolutionsCopyright 2018 STERIS Corporation. All Rights Reserved.

Agenda Definition of Cleanroom and how classifiedCleanroom behaviorCleanroom startupCleaning and Disinfection Best Practices Cleaning and disinfection techniques/development of Cleaning SOP Rotation of disinfectants/sporicidal agents RinsingCopyright 2018 STERIS Corporation. All Rights Reserved.

Origin of the Cleanroom Invented in 60’s by WillisWhitfield “Mr. Clean”– Pioneer of Unidirectionalairflow. Invented room 1000 x cleaner “Particle counters broken”Copyright 2018 STERIS Corporation. All Rights Reserved.

Why do we need Cleanrooms? 21 CFR 211.46(b) “Equipment foradequate control over airpressure, micro-organisms, dust,humidity and temperature shallbe provided when appropriate forthe manufacture, processing,packaging or holding of a drugproduct.”Copyright 2018 STERIS Corporation. All Rights Reserved.

Clean-room Classifications Clean-room users concernedwith 2 types of particulates:: lint, soil, skinflakes, etc.: bacteria, viruses,molds and spore formingorganismsCopyright 2018 STERIS Corporation. All Rights Reserved.

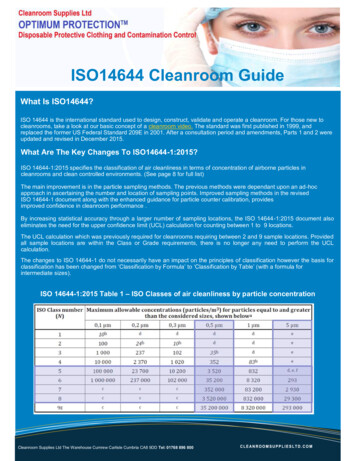

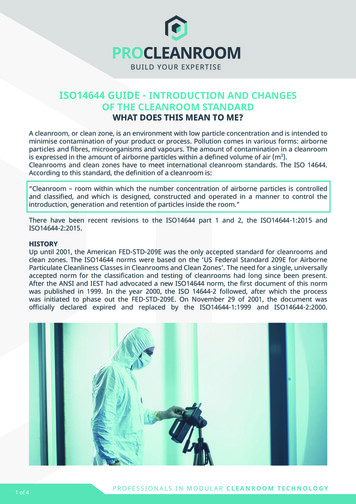

mClassificationISO 14644-1CleanroomClassificationsEU GMP Annex1 Grades 0.5µmparticles/m3ViableMicrobes(cfu/m3)Mean 01005 – 105 – 4810,0007C352,0001010 – 1560 – 901,0006-35,200725 – 40150 – 2401005A & B*3,520140 – 80240 – 480*at rest. Grade B in operation is equivalent to a Grade C at rest.Copyright 2018 STERIS Corporation. All Rights Reserved.

Don’t forget, in case of questions .Copyright 2018 STERIS Corporation. All Rights Reserved.

Contamination SourcesFacilityGenusA/B (6729) C/D (2500)Micrococci (and related)38%40%Staphylococci21%11% Aging facilityBacillus (and related)13%10% MaintenancePseudomonas (and related) 1%8% Cleaning anddisinfectionCorynebacterium (and related)3%5%RhodococciFungi 1%N/AN/A3% Poor designMaterials Pass through sterilizers(autoclaves, dry heat ovens,depyrogenation tunnels, etc.)Decontamination chambers (EO,VHP, UV, etc.)Material handling airlocksPeople Gowning rooms Attire (clothing, shoe covers,hoods, face masks, goggles, etc) Conduct Standard Operating Procedures

Procedures to prevent microbialgrowth Failure to have sanitation program/not following proceduresDisinfectant contact time not specified Poor aseptic techniqueDisinfectant used in ISO 5 area not sterileNo sanitization of items into hoodFailure to consistently sanitize gloved handsFailure to work slow and deliberateCopyright 2018 STERIS Corporation. All Rights Reserved.

Personnel Practices:Cleanroom Behaviors Manipulations Keep body/hands out of the path of unidirectional flow Contact sterile materials only with sterile instruments Always walk and move slowly: Prevents turbulence to laminar airflow in the room. Can increase particles in area. No excessive talkingCopyright 2018 STERIS Corporation. All Rights Reserved.

Personnel Practices:Cleanroom behaviors Limit movement Do not lean against walls or equipment. Do not touch floors. If process requires work on floor, put down barrier or leave after task iscomplete. If you drop something, pick it up, spray it off and IPA/EtOH item andhands. May have to exit Do not touch face, masks, or Safety glasses once gowned. NO GUM and NO Reaching for phones inside of gown!Copyright 2018 STERIS Corporation. All Rights Reserved.

Personnel PracticesHealth and Hygiene Personnel transmission: Inspectors are paying attention to operator’s gloves Integrity (packaged and while worn) Frequency of sanitization Compatibility Residue removal Proper gowning Adulteration Expect written procedures to detail methods usedto don Expect micro surface sampling aftermanipulationsCopyright 2018 STERIS Corporation. All Rights Reserved.

Personnel Practices:Re-gown if . Your gown has been compromised/soiled.If gown or inner glove is torn.Your gown contacts the floor due to kneeling, etc.After platingAny doubt your suit is compromised.Copyright 2018 STERIS Corporation. All Rights Reserved.

Inadequate Facility/studies Adequacy of design and qualification studies to ensure facility ismeeting expectations for air balance and air flowFailure to perform filter leak tests PracticesNo control over opening and closing doors to different classificationsIssues with room pressure differentialsCopyright 2018 STERIS Corporation. All Rights Reserved.

New Cleanroom Facility After HEPA’s installation, protect return vents with filter prior toConstruction clean Cleaning of debris, dirt, soiling, particles Removing cardboard, boxes, equipment, hoses Single or Double Cleaning with a formulated cleaner Acidic, Neutral, or Basic Cleaner can be utilized Neutral cleaner is often used to prevent any substrate compatibilityissues Goal: Clean Pristine Surfaces Source: [International Standard 14644-5, Cleanroons and associatedcontrolled environments – Part 5: Operations: 2004]Copyright 2018 STERIS Corporation. All Rights Reserved.

InformationChapter 19, p. 213 - 218Start-up of Cleanrooms, Initially andAfter a Worst-Case EventBy Jim Polarine and Beth KroegerChapter 4, p. 97 – 120How Issues Related to Utilities, Surfaces, andPractices Impact Cleanroom EnvironmentsBy Jim Polarine and Beth Kroeger

Certification After the initial cleaning and large debris removal is complete Clean construction work may still occur (no invasive work) Frequency in ISO 146441-2 every 12 months, not exceeding 366 days in use or 400 days when notin use ISO 5 every 6 months May damage filter or seals w/ install – buy extra The room should meet all the ISO-14644 (including ISO-14644 part 3)specs for particles and air control If Aseptic Manufacturing is taking place, then the requirements for theAseptic Processing Guide (2004) should be met for EMCopyright 2018 STERIS Corporation. All Rights Reserved.

ISO 14644 (part 2 – specs; part 3– test methods) Particle Concentration Test Airflow Test volume of air per unit of time (m3/hr) Determines air exchange rate Air Pressure Differential TestTemperature TestHumidity TestRecovery Test Ability to eliminate airborne particles Evaluates 100:1 recovery time Installed filter system Leak TestCopyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning around the facility Once the cleaning program is established, it is important to follow therecommendations below to maintain the environment during routineoperations. No cleaning should take place in an area during open operations and/orenvironmental monitoring. Rooms divided by lines of demarcation, separating two classes in thesame room, should be cleaned and monitored per the stricterclassification. Solutions and equipment from a less-strict classification should not beused to clean a stricter room classification.Copyright 2018 STERIS Corporation. All Rights Reserved.

Environmental Control:Buildings and Facilities HVAC function Temperature and RH control is vital References: FDA Guidance for Industry, Sterile Drug ProductsProduced by Aseptic Manufacturing –Current GoodManufacturing Practice. Sep. 2004. p 4 Parenteral Drug Association (2015) PDA Points toConsider for Aseptic Processing, Part 1, January 2015,Parenteral Drug Association. ISO 14644-4 Design, Construction, and Start-up30 – 60% RH16 - 24 CMaintain 24 hours a dayA velocity of 0.45 m/s has generally been established,with a range of 20% around the set point, whenmeasured 15 – 30 cm from the filter face Airflow: AC/HR depends on room and system Class 100,000: of 20 airchanges/hr Class 10,000: of 50 airchanges/hr Class 100: of 100 airchanges/hr Blockage and placement of feed and return ventsCopyright 2018 STERIS Corporation. All Rights Reserved.

Environmental Control:Buildings and Facilities HVAC function HVAC systems maintain pressure between spaces Dependent on nature of operation Pressure differential: 0.04 – 0.06” WC (10 – 15 Pascals)“Close the door policy”Monitor continuously, alarms documented, and deviations investigated.Procedures in place for excursions CONFIRMCopyright 2018 STERIS Corporation. All Rights Reserved.

Environmental Control:Buildings and Facilities Airlocks, Passthroughs & Gowning rooms Restricted access. Doors should be interlocked. Locked, alarmed (audible/visual) or procedures DRAFT Annex 1 now requires interlocks, also describes a time delay Divided into “Dirty” and “Clean” sides. Room cleaned to the higher level of ISO level Cart with wipes and disinfectants available. Cleaning often referred to as 2-step cleaning. Disinfectant/Sterilant followed by IPA or EtOH as a rinse agent or where residue is aconcernCopyright 2018 STERIS Corporation. All Rights Reserved.

Disinfectant regulation Federal Insecticide, Fungicide and Rodenticide Act (FIFRA) All germicidal products fall under the FIFRA as amended (1988) andadministered by EPA FDA regulation as medical device per Food Quality Protection Act of1996 if used to reprocess other medical devices or if used as a sterilantfor medical devicesCopyright 2018 STERIS Corporation. All Rights Reserved.

EPA classifications Sanitizer Disinfectant SterilantCopyright 2018 STERIS Corporation. All Rights Reserved.

Sanitizer defined Proper use results in bacteria reduction of 99.9% Used on precleaned surfaces How many bacteria can be found on the head of a pin? Log reduction 1,000,000 1-Log Reduction would reduce the number of bacteria 90% Example: 100 bacteria would be reduced to 10, or 10 reduced to 1Copyright 2018 STERIS Corporation. All Rights Reserved.

Disinfectant defined Proper use results in 100% kill of vegetative bacteria, targetviruses and target fungi May or may not require precleaning Serum efficacyStaphylococcus aureusSalmonella entericaPseudomonas aeruginosaCopyright 2018 STERIS Corporation. All Rights Reserved.

Sterilant defined Proper use results in 100% kill of all microorganisms, including bacterialspores Demonstrated 6-7 Log reduction Always requires precleaningCopyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning and Disinfection:Techniques Grid Overlapping strokes Pull and lift Figure 8 for floors orunidirectional mopping strokes Modified Figure 8 for wallsAnne MarieDixon,Ch.STERIS11, Cleaningof AllNon-ProductContact Surfaces, p 226, in Cleaning and Cleaning Validation for the Pharmaceutical and Medical DeviceCopyright 2018Corporation.Rights Reserved.Industries, Vol. 1 Basics, Expectations, and Principles. Paul L. Pluta, Ed., PDA, Bethesda, MD, and DHI Publishing, LLC, River Grove, IL. 2009.

Cleaning and Disinfection:TechniquesLink to the YouTube video for the 3 bucket mop technique:http://youtu.be/ajZ5 QHErqU Two Bucket routine:– Disinfectant in front or both– Bucket under wringer is rinse & waste Three Bucket routine:– Third bucket used for catching wrungout solutions Changing out the use dilutions– Every 600 ft2/ 55.74 m2 (ISO 5,6)– Every 1000 ft2/ 92.90 m2 (ISO 7,8)Bucket #1containsdisinfectantsolutionBucket #2contains rinsesolutionCopyright 2018 STERIS Corporation. All Rights Reserved.Bucket #3contains wrungout waste

Visible Particulateon Surfacesexcessive soil iseasy to seeCopyright 2018 STERIS Corporation. All Rights Reserved.

Result of typicaltechnique usingwetted wipersCopyright 2018 STERIS Corporation. All Rights Reserved.

Single pass stroketo removeparticulateCopyright 2018 STERIS Corporation. All Rights Reserved.

Importance ofoverlappingstrokesCopyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning and Disinfection: Techniques Cleanest to dirtiest areaTop to bottom and back to frontMost critical to least critical surfaceClean the farthest corner of the roomtowards the exit that will be used to leavethe room. Rooms divided by demarcation with two“classifications” Clean to the stricter classification Mops and buckets: ISO level dedication Different Mop for Walls, Floors, and Ceilings Double glove when cleaning floor drainsCopyright 2018 STERIS Corporation. All Rights Reserved.34

Cleaning SOP development Don’t complicate procedures. Give yourself some leeway when starting up a cleaning program. Define daily, weekly, monthly, etc. Consider weekends and holidays. Daily can mean “business day” Weekly – 7 3 days Monthly – 30 days 10 days Triple clean definition Different for everyone Satisfies monthly, weekly and daily requirements.Copyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning SOP development Draft procedures to handle unplanned events Non-routine cleaning – spills, excursions, disturbances Address room pressure excursion cleaning If excursion occurs: “room will be two-stepped .if lessthan 5 min. with traffic or less than one-hour without.” If excursion exceeds above: “room will be two stepped .taggedOOS, Management and Quality notified .” Room is monitored and placed back into service.Copyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning SOP developmentCopyright 2018 STERIS Corporation. All Rights Reserved.

Key issue - Rotation Alternation of antimicrobial actives Two disinfectants in sequence,regular rotation, with sporicidal agentas needed One disinfectant daily, with sporicidalweekly or monthlyCopyright 2018 STERIS Corporation. All Rights Reserved.

Key issue - Rotation Why do facilities rotate? Good practice to ensure all microorganisms eliminated Inspectors from FDA, MHRA, etc. expect it Recommended by USP 37 1072 , Aseptic Processing Guide, Annex 1,Orange Guide etc. Why is it important to rotate like or compatible chemicals? Some disinfectants contain incompatible ingredients For example, cationic (Quats) and anionic (Phenolics) surfactants cannot be mixedCopyright 2018 STERIS Corporation. All Rights Reserved.

Key issue - Rotation Recent scientific discussion on need forrotating disinfectants– Bacteria resistance? Chemical disinfectants– have a higher biocidal activity and bacterialpopulations are generally very low incleanrooms. Persistent bacterial populations due to:– Ineffective cleaning methods– Disinfectant cannot reach the bacteria– Misuse of disinfectantCopyright 2018 STERIS Corporation. All Rights Reserved.

Antibiotic Action SitesCopyright 2018 STERIS Corporation. All Rights Reserved.

How Disinfectants Work Disinfectants have three mechanisms of action or ways that theyaffect or kill an organism Cross-linking, coagulating, clumping Structure and function disruption Oxidation Chlorine – Oxidizing proteins, lipids, and carbohydrates Peroxide compounds – Oxidizes cell membrane and protein coat on sporecausing them to collapse exposing core to lethal disinfectant Phenols – penetrates and disrupts proper functioning of the cell wallCopyright 2018 STERIS Corporation. All Rights Reserved.

Alcohol Alcohols cause cell proteins to clump and lose their functionBacteria’s lipid membrane is held together because thehydrophobic part of the lipid sticks closely in the coreReference: https://www.youtube.com/watch?v j5jaHwuSuzoCopyright 2018 STERIS Corporation. All Rights Reserved.

Quaternary Ammonium Compounds Quaternary Ammonium Compounds denatures proteins of the bacterial orfungal cell, causes substances to leak out of cell causing deathImages reference: opyright 2018 STERIS Corporation. All Rights Reserved.

Microbial Resistance?Eudralex annex 1 (2008)“61. The sanitation of clean areas is particularly important. Theyshould be cleaned thoroughly in accordance with a writtenprogramme. Where disinfectants are used, more than onetype should be employed. Monitoring should be undertakenregularly in order to detect the development of resistant strains.»JP guidance on aseptic manufacturing (2006)PIC/SWHOFDA guidance on aseptic manufacturing (2004)“ . Routinely used disinfectants should be effective against thenormal microbial vegetative flora recovered from thefacility. .” and “ Therefore, a sound disinfectant programalso includes a sporicidal agent, used according to a writtenschedule and when environmental data suggest the presence ofsporeforming organisms.”PDA TR70 cleaning and disinfection (2015)“The antimicrobial agents typically employed in cleanrooms continue to beeffective because they have numerous effects on a number of aspects ofcellular physiology. That means multiple mutations would be required in ashort period of time (ex. 5 minutes) with exposure to low numbers of cellstypically found in a cleanroom to overcome their detrimental effects. Assuch, resistance of a cell to agents used in a disinfection process would behighly unlikely given the environmental conditions and low cell number.”Copyright 2018 STERIS Corporation. All Rights Reserved.(3)If selecteddisinfectants ofmighthave andinferior“Cleaningand disinfectionfacilitiesefficacy against microorganisms isolated from theequipment A program for cleaning andenvironment, the efficacy should be reevaluated anddisinfecting facilities and equipment should bethe replacement with or alternate use of differentestablished taking into account the potentialdisinfectants should be considered and implemented, asdevelopment of drug-resistant microorganisms.appropriate.The program should contain procedures for(4)If environmentaldata inindicateorscreeningand classifyingmonitoringbacterial isolateseachsuggestthe presenceof spore-formingbacteria ormanufacturingenvironment.»fungi, suitable sporicides or fungicides should beselected for disinfection.”Given this knowledge, the pharmaceutical and biotechnology industrieshave moved away from the rotation of two disinfecting agents. Thisformerly common practice led to high residue levels and subordinateefficacy performance. Today most firms use a system whereby adisinfectant is rotated with a sporicide to more effectively reduce thebioburden levels. The rotation of a disinfectant with a sporicide issuperior to the use of rotations of multiple disinfectants.”

Key issue - Rotation CURRENT USP 1072 DISINFECTANTS AND ANTISEPTICS “The development of microbial resistance to disinfectants is lesslikely to occur , as disinfectants are more powerful biocidal agentsthan antibiotics”. “ they are normally applied in high concentrations against lowpopulations of microorganisms usually not growing actively, so theselective pressure for the development of resistance is lessprofound”. “ frequently isolated microorganisms .may be periodicallysubjected to use-dilution testing with the agents used in thedisinfection program to confirm their susceptibility, as there are realdifferences among different species in resistance to the lethaleffects of different sanitizers”.Copyright 2018 STERIS Corporation. All Rights Reserved.

RotationUPIP VAPI Working group on the Annex 1 revisionCopyright 2018 STERIS Corporation. All Rights Reserved.

Draft Annex 1: Disinfection – 2007 versus 20XXCopyright 2018 STERIS Corporation. All Rights Reserved.

Future Requirements for Disinfectant Rotation More than one type of disinfecting agent should be employed (if Regs require) andshould include the periodic use of a sporicidal agent Disinfectants should be shown to be effective for the duration of their in-use shelflife taking into consideration appropriate contact time and the manner in andsurfaces in which they are utilized Monitoring should be undertaken regularly in order to show the effectiveness ofthe disinfection program and to detect the development of resistant and/or sporeforming strains. Cleaning programs should be effective in the removal of disinfectant residues.

Cleaning and Disinfection:Rinsing Do I need to rinse? 483 observations Your firm does not always keep laminar flow hoods visually clean ofresidue on HEPA filter surfaces and covering grates I observed whiteand yellow residue on the HEPA filters .and in areas up to approx. eightinches square on the filter . I observed white particles on the floor of the clean room approximatelytwo to three millimeters square.Copyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning and Disinfection:Rinsing Efficacy concerns: Residues inhibiting Biocides Do residues support harbor microbial growth? Do residues inhibit preceding actives (rotational chemistries)? Functional Issues: Sticky or opaque surfaces due to residues Aesthetic Issues: Surfaces do not look “clean” Safety Issues: Transfer (direct and indirect) from surfaces to manufactured drugproducts or medical devices Personnel safety (slippery, tacky, sticky, etc.)Copyright 2018 STERIS Corporation. All Rights Reserved.

Typical Components in Disinfectantsand what they look likeComponentResidue AppearanceWaterWater spotsSurfactantVery faint yellow to clear, gelatinous and stickyWhite solid beads.ChelantsWhite or pinkish grey solidSolventNo residue visibleBasesWhite to tan crystalsAcidsClear glaze with points of precipitatesBuildersWhite powderAntimicrobialsWhite to yellowBrown, pinkish tanClear, gelatinous, sticky glazeOxidantWater spotsNo residue visible to white to tan powder or crystals fromadditivesDyesRed, yellow, blue, color residuesCopyright 2018 STERIS Corporation. All Rights Reserved.

Where does the residue come from? Compatibility issues Different agents in rotation program Surface substrates Corrosion – attack of the impurities in themetal by chemical agent Deterioration by melting, softening,discoloration Drying – soft substrates such as Plexiglas,Kydex, Mipolam, epoxy. Staining Poor cleaning practices Drug product/process spills

Residue on SubstratesCopyright 2018 STERIS Corporation. All Rights Reserved.

Residues on Substrates:Desco Quartz Epoxy flooring system, 1.5years, floors daily with phenolicsand 1/month application of sporicidalagentCopyright 2018 STERIS Corporation. All Rights Reserved.

Residue removal trialDesco Quartz Epoxy flooring system in an ISO 8 gowningroom marked off in a grid pattern for in-situ testing.Two-year-old floors are disinfected daily with phenolicsand once per month application of sporicidal agent onetime per month without rinsing.Copyright 2018 STERIS Corporation. All Rights Reserved.Desco flooring after residue removal trial using: WFI (lane 1), Sterile oxidative detergent (lane 2) Sterile neutral detergent (lane 3)

Residue removal trialUp-close beforeimageUp-close after imageafter cleaning with sterileneutral detergentApplication of sterile detergentCopyright 2018 STERIS Corporation. All Rights Reserved.Desco flooring after residue removaltrial using sterile neutral detergentand rinse

Residue removal – Microbial removalCopyright 2018 STERIS Corporation. All Rights Reserved.

Cleaning and Disinfection BestPractices How often to clean? Environmental cleaning frequency determined by: ISO Classification of areaActivity level in area or useEnvironmental monitoring feedbackType of process being performed & equipment usedSubstratesVisual Observations Incorporate rinse/cleaning into cleaning anddisinfection program Nondestructive mechanical action to removecontaminants and residue In addition to sanitizers, disinfectants or sporicidesCopyright 2018 STERIS Corporation. All Rights Reserved.

Contamination Control ProgramRecommendation For clean rooms we still recommend Disinfectant Rotation Phenols or Quats on monthly basis(never a phenol and a quat) Sterilant use routinely based onenvironmental data Rinsing on a routine basis Not necessarily daily, but SOPs shouldinclude weekly/monthly rinsing withIPA or water Evaluate cleanability of heavyresidueCopyright 2018 STERIS Corporation. All Rights Reserved.ContaminationControl icacyDisinfectant

Cleanroom Control and BestPractices13 Aug 2020Beth KroegerTechnical Service Senior Managerbeth kroeger@steris.comSTERIS Life SciencesContamination Control SolutionsCopyright 2018 STERIS Corporation. All Rights Reserved.

Cleanroom Classification ISO 14644-1 Cleanroom Classifications EU GMP Annex 1 Grades 0.5µm particles/m3 Viable Microbes (cfu/m3) Mean Airflow Velocity (fpm) Air-changes/hr 100,000 8 D 3,520,000 100 5 -10 5 -48 10,000 7 C 352,000 10 10 -15 60 -90 1,000 6 - 35,200 7 25 -40 150 -240 100 5 A & B* 3,520 1 40 -80 240 -480 *at rest.