Transcription

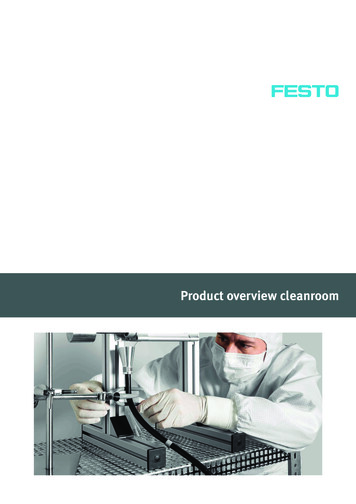

Product overview cleanroom

Product overview cleanroomEdition 2015/01All technical data are correct atthe time of going to print.All texts, representations,illustrations and drawingsincluded in this catalogue arethe intellectual property of FestoAG & Co. KG, and are protectedby copyright law. No part of thispublication may be reproducedor transmitted in any form or byany means, electronic, mechanical, photocopying or otherwise,without the prior writtenpermission of Festo AG & Co. KG.All technical data are subject tochange according to technicalupdates. Festo AG & Co. KGPostfach73726 EsslingenRuiter Straße 8273734 EsslingenGermany

Table of contentsProduction in the clean room 1. A booming trend: production in the clean room.42. Cost-effective standard products for the clean room.5Which Festo products are suitable in clean environments?.53. For sensitive applications: the 2-stage consultation concept.64. The goal for tomorrow: a consistent global qualification method.75. How does Festo qualify its products?.86. Framework of standards.9ISO 14644-1 standard in comparison with US Federal Standard 209 E.97. Passing on expert knowledge: comprehensive consultation and training.10Products Products Pneumatic drives .11Products Electromechanical drives .20Products Grippers .24Products Handling systems .26Products Vacuum technology .27Products Valves .29Products Valve terminals .33Products Sensors .36Products Compressed air preparation .38Products Pneumatic connection technology .43Wide range of industry sectors .45Festo Didactic. 49What must be taken into account when using Festo products?. 502015/01 – Subject to change – Product overview cleanroom www.festo.com/catalogue/.3

Production in the cleanroom 1. A booming trend: production in the cleanroomMore and more industry segments have to manufacture their productsunder clean conditions. Whereas 50 years ago these included only theemerging semiconductor industry, aerospace technology and perhaps thenuclear industry, today there are numerous industry segments in whichclean or at least controlled ambient conditions are required for production.Cleanroom compatibility is now one more important characteristic added tothe long list of features that make a product suitable for a given application.These cleanrooms need to have suitable production equipment, including ofcourse all those components that are built into the machines and systems inthe cleanroom. Ultimately, all suppliers of machine components and partsmust prove that their products are appropriate for use in a cleanroom.4 www.festo.com/catalogue/.Product overview cleanroom – Subject to change – 2015/01

Production in the cleanroom 2. Cost-effective automation for the cleanroomISO class 7Electric cylinder DNCEISO class 5Standard cylinder DSBFISO class 3Specially adapted components:fluidic muscle DMSPWhich Festo products are suitable in clean environments?This catalogue takes a look at this characteristic and classifies products accordingly.Festo has therefore tested a specific selection of its series products to determine their suitability for use in cleanrooms. This cross-section of ourproduct range is designed to allow our customers to solve the majority ofautomation tasks using components that are always available, anywhere inthe world.There is currently no internationally recognised method for testing andcertifying cleanroom suitability. Yet we know that many of our products aresuitable for use in cleanrooms, even without specific certification. Almost allproducts in the Festo portfolio can be used in a cleanroom ISO class 7 orhigher. In this catalogue we will show you which Festo products can also beused in lower cleanroom classes. These components cater to the majority oftoday's application requirements. The parts do not even need to bepackaged specially for the cleanroom – an expensive process that is usuallycompletely unnecessary. However, it is essential to consider where exactlythe components will be used. Every application has different areas withvarying requirements in terms of cleanroom class.We also know from experience that almost any piece of equipment designedfor cleanroom use can be assembled and shipped in a normal environment.The final cleaning procedure takes place at the destination site.All information in this catalogue refers to the suitability of Festo products interms of the airborne particles emitted by the components in question. Noinformation is provided on chemical or biological contamination.Outside of the production cell ISO 7Production cell with separate ventilation (mini-environment)Workflow/conveyorISO 5Above the workpieceISO 4Below the workpieceISO 5 or 6Below the workflow/conveyorISO 7Figure 1: Where a piece of equipment is used is decisive for the required cleanroom classWhat is important for you to know is that the Festo products comply with the specified cleanroom class during operation.This is confirmed by the aforementioned ISO classification.2015/01 – Subject to change – Product overview cleanroom www.festo.com/catalogue/.5

Production in the cleanroom 3. For sensitive applications: the 2-stage consultation conceptOf course, highly sensitive applications come with stricter requirements. Weare happy to analyse these together with our customers in order to deter mine the correct solution. This is where the 2-stage consultation conceptfrom Festo comes in.In the first stage, our specialists work with you to assess the task at hand.During these discussions, it often turns out that a component from ourstandard product range with ISO class 5 or 6 fulfils the requirements of theapplication perfectly.Whether you use our standard components in a cleanroom or make use ofour extensive expertise in cleanroom applications, Festo has more than15 years of experience in providing cleanroom solutions.All that knowledge is at your disposal.If the required functionality can only be achieved with an ISO class 4component, we will look into making design modifications to our standardproducts. You will receive an offer from the Customer Solutions division atFesto straightaway.Our many years of experience and optimised process sequences make allthe difference and make this type of solution usually economically feasible,even in small quantities.Consultation concept6 www.festo.com/catalogue/.Product overview cleanroom – Subject to change – 2015/01

Production in the cleanroom 4. The goal for tomorrow: a consistent global qualification methodThere is currently no internationally recognised test or qualification methodfor ensuring that products are suitable for cleanroom use. Each manufac turer can use its own test method for classifying equipment and publish thedata obtained with that method.As long as the manufacturers describe and explain their individual methods,there is nothing wrong with this – with one exception: it is very difficult tocompare cleanroom compatibil ity between products as a result.This supplement to ISO 14644 is likely to closely follow the German direc tive VDI 2083-9.Festo contributed to the development of VDI 2083-9, and has already beenapplying the procedure it describes ever since its publication. It is now onlya matter of time before a standardised global qualification method will beavailable.In order to counteract the lack of consistency in the tests and ensure greatertransparency, technical committee ISO 209 has been developing a universal,internationally valid procedure since 2012. This method is scheduled to bedefined within the next two years in ISO 14644-14, "Assessment of suitability for use of equi pment by airborne particle concentration".Visual particle counterIThe following section classifies Festo components in accordance with thevarious ISO-14644-1 cleanroom classes, thus confirming their suitability fora particular cleanroom class . This means that the component in questionwill not contaminate the listed cleanroom class if it is used there.2015/01 – Subject to change – Product overview cleanroomThere are several other factors to consider when using production equipment. For example, an active, moving component influences the cleanroomdifferently than a passive, inactive component. The experts at Festo havebuilt up the necessary level of specialist knowledge over a period of morethan 15 years – knowledge that is at your disposal whenever you need it www.festo.com/catalogue/.7

Production in the cleanroom 5. How does Festo qualify its products?Festo follows the test procedure defined in the VDI 2083-9 directive.Laminar air flowAir supplyTestspecimenLoadCritical rangeMeasuring volume: 28.3 l/minVisual particlecounterFigure 2: The direct measuring procedure in accordance with VDI 2083-9With the direct measuring procedure, the test object is first of all scanned bya particle detector in a "mini-environment" which complies with ISO14644-1 class 3. This procedure is used to pinpoint the critical areas. Theseare the places where most of the particles are generated, for example thearea immediately around the piston rod seal on pneumatic cylinders. Theadvancing and retracting motion results in particles being discharged intothe atmosphere. The average particle concentration at this point is thenmeasured for a period of 100 minutes. During measurement, the cylinder isoperated at 80% of its maximum permissible load.The test setupAdjusting the test setupParticle detector on the test setup8 www.festo.com/catalogue/.Product overview cleanroom – Subject to change – 2015/01

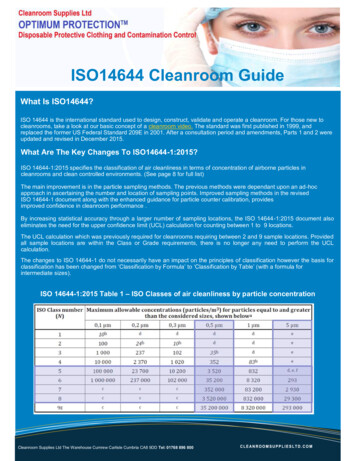

Production in the cleanroom 6. Framework of standardsThe concentration of airborne particles in cleanrooms is kept below aspecified limit through the use of ingenious ventilation technology. Theselimits are defined in the ISO 14644 series of standards.Even today, the “old” classifications in accordance with US Federal Standard209 are still quoted regularly. This standard was the definitive guide foralmost two decades. It was characterised by its clear presentation ofparticle concentrations using the reference size of 0.5 µm.ISO 14644-1:1999 was the first and fundamental standard of this series. Itwas originally based on US Federal Standard 209 E issued in 1988, and hasbeen continuously revised and supplemented since its initial publication.Technical committee ISO 209, “Cleanrooms and associated controlledenvironments”, is responsible for the standardisation.In 2001, US Federal Standard 209 was withdrawn in order to make way forthe new ISO 14644-1.ISO 14644-1 standard in comparison with US Federal Standard 209 EISO classification number Maximum value for particle concentration (particles per cubic metre of air)(N)0.1 μm0.2 μm0.3 μm0.5 μm1 μmISO class 1102–5 μm–ISO class 210024104ISO class 31,00023710235US FederalStandard 209 E–––––8––ISO class 410,0002,3701,02035283ISO class 510,000023,70010,2003,520832ISO class ISO class 7–––352,00083,2002,93010,000ISO class 8–––35,20,000832,00029,300100,000ISO class 9–––35,200,0008,320,000293,0002015/01 – Subject to change – Product overview cleanroom www.festo.com/catalogue/.–9

Production in the cleanroom 7. Passing on expert knowledge: comprehensive consultation and trainingWe are happy to provide our customers with detailed, expert advice in orderto help you to choose the right product for your cleanroom application.If you require additional information and have more extensive questions inthis area, Festo Didactic offers in-depth training courses about cleanroomsthat address the subject in more detail.Festo offers training on cleanroom topics10 www.festo.com/catalogue/.Product overview cleanroom – Subject to change – 2015/01

Products Pneumatic drives Pneumatic drives Software toolPneumatic simulationFesto Design Tool 3DFDT 3D2015/01 – SubjectSubject toto changechange – ProductClean roomproductoverview2015/01overviewcleanroomPerfect simulations replace expensiveThis tool can be foundactual tests. either in the electronic catalogue byThe tool is an expert system that supportsclicking on the blue buttonyou in the selection and configuration of"Engineering"the entire pneumatic control chain. If or on the DVD under Engineering Tools.one parameter is changed, the programautomatically adapts all the others.The Festo Design Tool 3D is a 3D productconfigurator for generating specific CADproduct combinations from Festo. Thisconfigurator makes your search for theright accessory easier, more reliable andfaster.You can then order the module thathas been created with a single ordercode either completely pre-assembledor as individual parts in a single box.As a result, your bill of materials isconsiderably shortened and downstreamprocesses such as product ordering, orderpicking and assembly are significantlysimplified.All ordering options are available in thefollowing countries: IT, IE, TR, DK, SE, NO,NL, FI, FR, DE, BE, CH, ES, GB, ZA, AT, SK,PL, CZ, HU, SI, RU.This tool can be found either via the address:www.festo.com/FDT-3D in thecountries listed above, or on the CD "FDT 3D" (part no.135595 for countries listed above) or on the DVD.www.festo.com/catalogue/. www.festo.com/catalogue/.131111

Products PneumaticPneumaticdrives drives Standard cylinders11Compact cylinderStandard cylinderStandard cylinder, Clean DesignStandard cylinderTypeADNDSBCDSBFDNCMode of uble-actingPiston diameter12mm, 16mm, 20mm, 25mm,32mm, 40mm, 50mm32mm, 40mm, 50mm, 63mm,80mm32mm, 40mm, 50mm, 63mm,80mm32mm, 40mmTheoretical force at 6 bar,advancing51 . 1178 N415 . 3016 N415 . 3016 N415 . 754 NStroke1 . 400 mm1 . 2800 mm1 . 2800 mm2 . 2000 mmCushioningP: elastic cushioning rings/padsat both ends, PPS: self-adjustingpneumatic end-position cushioningPPS: self-adjusting pneumaticend-position cushioning, PPV:pneumatic cushioning, adjustable at both endsPPS: self-adjusting pneumaticend-position cushioning, PPV:pneumatic cushioning, adjustable at both endsPPV: pneumatic cushioning,adjustable at both endsDescription Piston diameter 12 . 50 mmin accordance with ISO 21287 Up to 50% less installationspace than comparablestandard cylinders to ISO15552 For position sensing Piston rod with male or femalethread Wide range of variants ISO 15552 (ISO 6431, VDMA24562) With the self-adjustingpneumatic end-positioncushioning PPS adaptsperfectly to changes in loadand speed For position sensing High flexibility thanks to thewide range of variants An extensive range of accessories makes it possible to installthe cylinder virtually anywhere ISO 15552 with increasedcorrosion protection Resistant to conventionalcleaning agents FDA-approved lubrication andsealing on the standard design Long service life thanks tooptional dry-running seal Hygienic mounting of thesensors possible Comprehensive range ofmounting accessories for justabout every type of installation ISO 15552 (ISO 6431, VDMA24562) For position sensing Saves up to 11% on fittingspace compared with ordinarystandard cylinders Wide range of variants Profile slot for proximitysensors on three sides No protruding proximitysensorsClassification number to4556101001001000adndsbcdsbf-cdncISO 14644-1Classification number toUS Federal Standard 209 Eonline:1412www.festo.com/catalogue/. overview – Subject2015/01ProductoverviewSubject toto changechange – 2015/01

Products Pneumatic drives Pneumatic drives Standard cylinders11Standard cylinderTypeDSNUMode of operationDouble-actingPiston diameter8mm, 10mm, 12mm, 16mm, 20mm, 25mmTheoretical force at 6 bar,advancing23 . 295 NStroke1 . 500 mmCushioningP: elastic cushioning rings/pads at both ends, PPS: self-adjusting pneumatic end-position cushioning, PPV: pneumatic cushioning, adjustable atboth endsDescription Classification number to6ISO 6432For position sensingWide range of variantsGood running performance and long service lifePiston rod with male or female threadISO 14644-1Classification number to1000US Federal Standard 209 Eonline:dsnuCompact, short-stroke and flat cylindersShort-stroke cylinderCompact cylinderTypeADVCADVUMode of operationDouble-actingDouble-actingPiston diameter6mm, 10mm, 12mm, 16mm, 20mm, 25mm12mm, 16mm, 20mm, 25mm, 32mm, 40mmTheoretical force at 6 bar,advancing4.9 . 295 N42 . 754 NStroke2.5 . 25 mm1 . 300 mmCushioningP: elastic cushioning rings/pads at both endsP: elastic cushioning rings/pads at both endsDescription 50% less installation space than comparable standard cylinders toISO 15552 For position sensing Wide range of variants Piston rod with male or female threadClassification number to561001000advcadvuMinimal space requiredHigh clamping forces in a compact sizeFor position sensing with proximity sensor for T-slot and for C-slotPiston rod with male or female threadISO 14644-1Classification number toUS Federal Standard 209 Eonline:2015/01 – SubjectSubject toto changechange – ProductClean to.com/catalogue/. www.festo.com/catalogue/.1513

Products PneumaticPneumaticdrives drives Cartridge cylinders and multimount cylinders11Multimount cylinderTypeDMMMode of operationDouble-actingPiston diameter10mm, 16mmTheoretical force at 6 bar,advancing37 . 121 NStroke1 . 40 mmCushioningP: elastic cushioning rings/pads at both endsDescription Classification number to6Wide range of mounting optionsWide selection of piston rod variantsFor position sensingPiston rod with male threadISO 14644-1Classification number to1000US Federal Standard 209 Eonline:dmmRodless cylindersLinear driveLinear driveTypeSLGDGOPiston diameter8mm, 12mm12mm, 16mm, 20mm, 25mmTheoretical force at 6 bar,advancing30 . 68 N68 . 295 NStroke100 . 700 mm10 . 3500 mmCushioningP: elastic cushioning rings/pads at both ends, YSR: shock absorber,hard characteristic curveP: elastic cushioning rings/pads at both ends, PPV: pneumatic cushioning, adjustable at both endsPosition sensingFor proximity sensorFor proximity sensorDescription Magnetic force transmission Pressure-tight and zero leakage Dirt-proof and dust-proofExtremely flat designIntegrated precision guideAdjustable end stopsChoice of supply portsAvailable with intermediate position moduleClassClassification number to6610001000slgdgoISO 14644-1Classification number toUS Federal Standard 209 Eonline:1614www.festo.com/catalogue/. overview – Subject2015/01ProductoverviewSubject toto changechange – 2015/01

Products Pneumatic drives Pneumatic drives Software toolJuggling pencils and pocket calculators This tool can be foundis now a thing of the past. No matter either in the electronic catalogue bywhether you have discs, blocks, push-onclicking on the blue buttonflanges, grippers, etc., this tool does the"Engineering"job of calculating all the mass moments of or on the DVD under Engineering Tools.inertia. Just save, send or print and you'refinished.Mass moment of inertiaSemi-rotary drivesSwivel moduleSwivel moduleSwivel moduleTypeDSM, DSM-BDRQD, DRQD-BDRRDSize6, 8, 10, 12, 16, 25, 32, 406, 8, 12, 16, 20, 25, 328, 10, 12, 16, 20, 25, 32, 35, 40Torque at 6 bar0.15 . 40 Nm0.16 . 12.5 Nm0.2 . 24.1 NmSwivel angle0 . 270 0 . 360 180 Permissible mass momentof inertia6.5 . 5000 kgcm²0.075 . 4000 kgcm²15 . 6700 kgcm²Position sensingFor proximity sensor, noneFor proximity sensorFor proximity sensorDescription Force transmitted directly to the drive shaftvia a rotary vane With spigot shaft, hollow flanged shaft,tandem rotary vane and spigot shaft,tandem rotary vane and flanged shaft With twin pistons based on the rack andpinion principle High accuracy Extremely good rigidity Wide range of variants With spigot or flanged shaft With twin pistons based on the rack andpinion principle Very high accuracy in the end positions Very high load bearing capacity Very good axial run-out at the flanged shaftClassification number to6551000100100dsmdrqddrrdISO 14644-1Classification number toUS Federal Standard 209 Eonline:2015/01 – SubjectSubject toto changechange – ProductClean to.com/catalogue/. www.festo.com/catalogue/.171511

Products PneumaticPneumaticdrives drives Drives with slides11Mini slideMini slideMini slideMini slideTypeDGSLSLFSLSSLTPiston diameter6mm, 8mm, 10mm, 12mm,16mm, 20mm, 25mm6mm, 10mm6mm, 10mm6mm, 10mm, 16mm, 20mm,25mmTheoretical force at 6 bar,advancing17 . 295 N17 . 47 N17 . 47 N34 . 590 NStroke10 . 200 mm10 . 50 mm5 . 30 mm10 . 200 mmCushioningP: elastic cushioning rings/padsat both ends, Y3: progressiveshock absorber at both endsP: elastic cushioning rings/padsat both endsP: elastic cushioning rings/padsat both endsCC: shock absorber at both ends,P: elastic cushioning rings/padsat both endsPosition sensingFor proximity sensorFor proximity sensorFor proximity sensorFor proximity sensorDescription High load capacity andpositioning accuracy Maximum movement precisionthanks to ground-in ballbearing cage guide Reliable in the event ofpressure drop thanks toclamping cartridge or endposition locking Versatile mounting optionsthanks to piggy-back Compact Slim design Ball bearing guide Versatile mounting options Classification number to5666100100010001000dgslslfslssltFlat designBall bearing guideVersatile mounting optionsEasy adjustment of endpositionsPowerful twin piston driveBall bearing guideVersatile mounting optionsEasy adjustment of endpositionsISO 14644-1Classification number toUS Federal Standard 209 Eonline:1816www.festo.com/catalogue/. overview – Subject2015/01ProductoverviewSubject toto changechange – 2015/01

Products Pneumatic drives Pneumatic drives Drives with guide rods11Mini guided driveGuided driveTypeDFCDFM, DFM-BPiston diameter4mm, 6mm12mm, 16mm, 20mm, 25mm, 32mmTheoretical force at 6 bar,advancing7.5 . 17 N51 . 482 NStroke5 . 30 mm10 . 200 mmCushioningP: elastic cushioning rings/pads at both endsP: elastic cushioning rings/pads at both ends, PPV: pneumatic cushioning, adjustable at both ends, YSRW: shock absorber, soft characteristiccurvePosition sensingFor proximity sensor, noneFor proximity sensorDescription Classification number to6610001000dfcdfmSmallest guided driveHigh precision and load capacityMinimal space requirementDrive and guide unit in a single housingPlain or recirculating ball bearing guideDrive and guide unit in a single housingPlain or recirculating ball bearing guideHigh resistance to torques and lateral forcesWide range of mounting optionsWide range of variantsISO 14644-1Classification number toUS Federal Standard 209 Eonline:Clamping cylindersClamping moduleTypeEVClamping area10x30, 15x40, 15x63, 20x120, 20x180, 20x75, Ø 12, Ø 16, Ø 20, Ø 25, Ø 32, Ø 40, Ø 50, Ø 63Stroke3 . 5 mmDescription Classification number to5Single-acting, with reset functionClamping force 55 . 1690 NCompact cylinders without piston rod, with diaphragmFlat, space-saving designHermetically sealedPressure plates and foot mounting as accessoriesISO 14644-1Classification number to100US Federal Standard 209 Eonline:ev2015/01 – SubjectSubject toto changechange – ProductClean to.com/catalogue/. www.festo.com/catalogue/.1917

Products PneumaticPneumaticdrives drives Fluidic muscle11Fluidic muscleTypeDMSPSize10, 20, 40Theoretical force at 6 bar480 . 6000 NNominal length40 . 9000 mmMax. contraction25% of nominal lengthDescription Classification number to3With press-fitted connectionUp to 30% less weight: a superb force/weight ratioSingle-acting, pulling3 integrated adapter variants10 times the initial force of a comparable pneumatic cylinderStick-slip-free movementsHermetically sealed design offers protection against dust, dirt and moistureISO 14644-1Classification number to1US Federal Standard 209 Eonline:dmspSoftware toolThis tool helps you to select the rightThis tool can be foundrotary indexing table of the type DHTG either in the electronic catalogue byfrom Festo for your application. Letclicking on the blue buttonyourself be guided by the program and"Engineering"enter your general parameters and you or on the DVD under Engineering Tools.will receive at least one suggestion for theproduct best suited to your application.Rotary indexing tableRotary indexing tablesRotary indexing tableTypeDHTGSize65, 90, 140, 220Torque at 6 bar2.1 . 58.9 NmPitch2 . 24Description Classification number to6Sturdy mechanical systemSimple planning and commissioningRotary table diameters: 65, 90, 140, 220 mmVarious directions of rotation possibleISO 14644-1Classification number to1000US Federal Standard 209 Eonline:2018dhtgwww.festo.com/catalogue/. overview – Subject2015/01ProductoverviewSubject toto changechange – 2015/01

Products Pneumatic drives Pneumatic drives Software toolWhether diagonal or vertical, curvedor straight, lever or disc, all types ofcushioned movements are taken intoaccount. The software tool alwaysrecommends the best shock absorber.Shock absorber selectionThis tool can be found either in the electronic catalogue byclicking on the blue button"Engineering" or on the DVD under Engineering Tools.Shock absorbersShock absorberTypeYSR-CStroke4 . 12 mmMax. energy absorptionper stroke0.6 . 10 JCushioningSelf-adjustingDescription Classification number to5Hydraulic shock absorber with path-controlled flow control functionRapidly increasing cushioning force curveShort cushioning strokeSuitable for rotary drivesISO 14644-1Classification number to100US Federal Standard 209 Eonline:ysr-cCustomised components for your specific requirementsDrives with customised designsCan't find the pneumatic drive you need in ourcatalogue?We can offer you customised components thatare tailored to your specific requirements from minor product modifications to completenew product developments.Common product modifications: Materials for special ambient conditions Customised dimensions Special strokes Customised mounting options Implementation of special cylinder functions(cylinder/valve combinations, single-actingprinciple, etc.)Many additional variants are possible. Ask your Festosales engineer, who will be happy to help.Further information on customised components can be found on your local website atwww.festo.com2015/01 – SubjectSubject toto changechange – ProductClean to.com/catalogue/. www.festo.com/catalogue/.211911

Products ElectromechanicalElectromechanicaldrives drives Software toolWhich electromechanical linear drive best This tool can be foundmeets your needs? Enter the data for either in the electronic catalogue byyour application, such as position values,clicking on the blue buttoneffective loads and mounting position,"Engineering"and the software suggests a number of or on the DVD under Engineering Tools.solutions.PositioningDrives22Linear drives and slide unitsElectric cylinderElectric cylinderElectric cylinderSpindle axisTypeEPCOESBFDNCEEGC-BS-KFSize166332, 4070, 80, 120Max. feed force Fx50 . 125 N6000 . 7000 N300 . 800 N300 . 1300 NRepetition accuracy / 0.02 mm / 0.01 mm, / 0.015 mm / 0.02 mm, / 0.07 mm / 0.02 mmWorking stroke50 . 200 mm1 . 1200 mm100 . 600 mm50 . 2500 mmDescription Linear drive with permanentlyattached motor With ball screw Available with female thread Available with holding brake Protection class IP40 Compact dimensions Extensive mounting accessories for various installationsituations Suitable for simple applications in factory automationthat in the past were mostlycarried out using pneumaticsolutions With spindle drive Optional: high corrosionprotection, protection classIP65, suitable for the foodindustry, piston rod extension Wide range of accessories Lead screw or ball screw Standard hole pattern to ISO15552 Available with high corrosionprotection Available with lubricationapproved for food use Axial or parallel motormounting Integrated reference switch Freely positionable Non-rotating piston rod Larger strokes available onrequest Recirculating ball bearingguide for high loa

a particular cleanroom class . This means that the component in question will not contaminate the listed cleanroom class if it is used there. There are several other factors to consider when using production equip-ment. For example, an active, moving component influences the cleanroom differently than a passive, inactive component.