Transcription

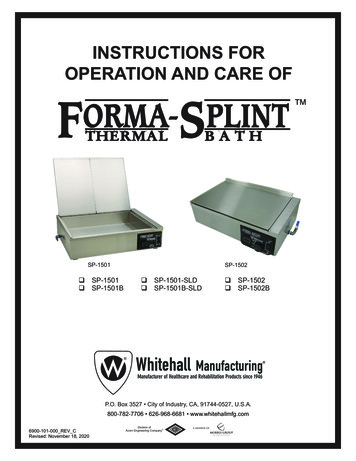

INSTRUCTIONS FOROPERATION AND CARE OF SP-1501qqSP-1502q SP-1501-SLDq SP-1501B-SLDSP-1501SP-1501BqqSP-1502SP-1502B P.O. Box 3527 City of Industry, CA, 91744-0527, U.S.A.800-782-7706 626-968-6681 www.whitehallmfg.com6900-101-000 REV CRevised: November 18, 2020Division ofAcorn Engineering Company

PLEASE READ THIS ENTIREBOOKLET BEFORE OPERATINGYOUR NEW SPLINT PAN!!Failure to follow these instructions could result in damageto your new heating appliance and/or injuryEuropean Union CE MarkThe presence of the CE Mark on Whitehall equipment means that it has been designed, tested and certified as complyingwith all applicable European Union regulations and recommendations.Waste Electrical and Electronic Equipment (WEEE)This symbol on the product or on its packaging indicates that this product must not be disposed of with regular waste. Instead,it is the user's responsibility to dispose of waste equipment according to the local laws. Separate collection and recycling ofthe waste equipment at the time of disposal will help conserve natural resources and ensure it is recycled in a manner thatprotects human health and the environment. For information about where the user can drop off the waste equipment forrecycling, please contact your local waste collection authority. See pages 11 and 12 for instructions on how to disassemblethe equipment for recycling purposes.Electric ShockThe Electric Shock Symbol is used to indicate a hazard arising from dangerous voltage. Any mishandling could result inirreparable damage to the equipment and/or personal injury or death.General Warning or CautionThe Exclamation Symbol appears in Warning and Caution statements. This symbol designates where personal injury ordamage to the equipment is possible.WARNINGTo avoid electric shock, connect the instrument to properly earth-grounded, GFCI protected, 3-prongreceptacles only. Failure to observe this precaution can result in severe injury.ŸDO NOT operate the appliance without properly filling with water. Under no circumstance should the appliance beoperated without water, as operating the appliance without water may result in damage to the heating element. Appliancemust be unplugged while filling or emptying water.ŸCONNECT the appliance into a properly polarized G.F.C.I. (Ground Fault Circuit Interrupter) electrical receptacle forprotection against electrical shock. Have a qualified electrician verify the wall socket is properly polarized and grounded.Use only the power cordset provided with the unit. The Splint Pan appliance must be properly grounded.ŸAVOID skin contact with HOT water at all times! Carefully place splinting material into the Splint Pan appliance to avoidsplashing onto skin or coming into contact with HOT water. DO NOT reach into HOT water with bare hands to removeheated splint material. Use a grasping device, such as tongs, to remove splint material from HOT water.ŸDO NOT use in the presence of flammable liquids or gases, as these may present a fire and/or explosion hazard.ŸALWAYS allow the appliance to cool down before draining water or moving unit.ŸDO NOT use the lid handle to lift or transport appliance.ŸNEVER leave appliance operating unattended for long periods of time. Water can evaporate and cause appliance to overheat which may result in damage to the heating element. Turn "OFF" when not in use.ŸFOLLOW splint material manufacturer instructions for proper material heat-up temperature and duration.aWHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathTABLE OF CONTENTSWhy Forma-Splints? . 2Model Descriptions for SP-1501. 2Model Descriptions for SP-1502.3Set-up Instructions . 4 & 5Using Your Splint Pan . 5Emptying Your Splint Pan .5Care & Cleaning of Your Splint Pan . 5Splint Pans Parts Table . 6Model Diagram for SP-1501 . 7Electrical Diagram for SP-1501 . 8Model Diagram for SP-1502 . 9Electrical Diagram for SP-1502 .10Electrical Parts Disassembly for SP-1501 . 11Electrical Parts Disassembly for SP-1502 .121WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathWHY FORMA-SPLINTS?Forma-Splint Pans are made out of durable stainless steel to resist corrosion. The heating element has also been speciallydesigned to insure even heating of the splinting material. Both models feature variable temperature settings and a convenientdrain. Grounded plugs and high heat safety switches are standard.Model SP-1501 has a spacious interior that accommodates splinting sheets up to 24” x 18” (61cm x 46cm).Model SP-1502 has a compact design that makes it universally ideal for clinical use. The unit accommodates sheets up to 19” x11” (48cm x 28cm).INTENDED USEThe Forma-Splint Thermal Bath is a stainless steel water pan capable of heating water within a set of temperature rangeof 60ºC (140º) to 88ºC (190ºF). The unit is intended and designed to heat and soften thermoplastic splitting material at afactory set water temperature. Proper splint material heat-up temperature & duration is based on the splint materialmanufacturer’s requirements and instructions.Environmental ConditionsThis product is to be used under the following environmental conditions:Indoor use only; Altitude up to 2000m; Ambient temperature 5ºC to 40ºC (41ºF to 113ºF); Maximum relative humidity 80%for temperatures up to 31ºC (87ºF) decreasing linearly to 50% relative humidity at 40ºC (104ºF); Mains supply voltagefluctuations up to 10% of the nominal voltage; TRANSIENT OVERVOLTAGES up to the levels of OVERVOLTAGECATEGORY II; Temporary over-voltages occurring on the mains supply; Applicable pollution degree 2 of the intendedenvironment.Double LidsMODEL SP-1501Shown with Double Lids(sliding lid Model SP-1501-SLDalso available)100-120 Volts, 50/60 Hz,13 AmpsMODEL SP-1501B200-240 Volts, 50/60 Hz,7 AmpsStainless SteelWorking BathDrain and Drain ValveHigh or LowTemperatureControlINSIDE DIMENSIONS24-1/2” x 18-1/2” x 5” Deep(622mm x 470mm x 127mm Deep)OperatingIndicator Light28-1/2”21”(720)(530)7”(180)22WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathMODEL SP-1502100-120 Volts, 50/60 Hz,6 AmpsMODEL SP-1502B200-240 Volts, 50/60 Hz,3 AmpsLarge StainlessSteel LidDrain and Drain ValveVariable Temperature ControlINSIDE DIMENSIONS19-1/2” x 11-7/8” x 4-1/2” DeepOperatingIndicator Light(500mm x 300mm x 110mm LL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathOPERATOR SKILLS AND TRAININGSkills:TrainingOperators using the Splint Pan need a workingknowledge of occupational therapy procedures.Operator trainees need to:!Ÿ be trained in occupational therapy protocols.Ÿ read and understand this manual.WARNINGOnly trained personnel should operate the Splint Pan.Untrained operators can cause injury or be injured.Ÿ use precautions when lifting the unit for relocation ortransportation. Lift from bottom on opposite sides.No user serviceable parts in this unit. Refer all service &repair to qualified technicians.INSPECTING THE SPLINT PANThis Whitehall product has been carefully packaged atthe factory to minimize the possibility of damage duringshipping.— Inspect the packaging for external signs ofdamage.— Inspect the contents for damage.If there is visible damage to the instrument upon receipt,inform the shipping company and Whitehall immediately.!Inspection ChecklistŸ Is the Splint Pan free of excessive wear?Ÿ Is a properly-grounded and voltage-matchedreceptacle available?Ÿ Is the outlet equipped with a functioning GFI?WARNINGŸ Does the drain valve open and close properly?Do not attempt to operate this equipment if there isevidence of shipping damage or you suspect the unitis damaged. Damaged equipment may presentadditional hazards to you. Contact Whitehall technicalsupport for advice before attempting to plug in andoperate damaged equipment.SET-UP INSTRUCTIONS1. Your new Splint Pan includes the following:(1) Heating Appliance(1) Power Cordset(1) Operation & Maintenance ManualNOTE: If you are missing any of the above,contact WHITEHALL MANUFACTURINGtoll free telephone no. (800) 782-7706 or (626) 968-66812. Unpacking your Splint PanRemove all shipping & packaging material. Remove allitems from inside of tank such as Power Cordset,Warranty Registration Card, and Operation &Maintenance Manual.3. Location of your Splint PanPlace the Splint Pan at a convenient height & locationsuch as on a table or scratch-resistant counter top.IMPORTANT: Appliance must be placed on a levelsurface! Splint Pan must be positioned so to allow easeof disconnecting Power Cordset if necessary.4. Preparing to Fill your Splint PanMake sure appliance is unplugged and all packaging hasbeen removed from reservoir. Ensure that the inside oftank is thoroughly clean before filling with water.DO NOT use any medium except water.Check drain valve and make sure handle is in the"closed position" by turning clockwise to make certain nowater in tank will drain out of appliance while being filled.5. Filling your Splint PanAppliance must be unplugged. Fill reservoir withwater to at least 3” (76mm) deep.Note: We recommend the use ofdistilled water to reduce the buildup of mineral deposits and dirt.Ball valve closed244WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathSET-UP INSTRUCTIONS (continued)6. Preparing to turn "ON" your Splint PanClose lid.Caution! Lid can pinch fingers.Locate the Power Switch at front of the appliance andmake sure it is set to "OFF". Insert connector end ofpower cordset into power inlet at back of appliance.Connect plug end of power cordset into a G.F.C.I.protected AC electrical receptacle.7. Turning "ON" your Splint PanYou are now ready to turn "ON" the appliance. Locatethe Power Switch at the front of the unit and press to"ON" position.8. Adjusting/Setting the Heat-Up TemperatureCarefully insert splinting material into tank and avoidsplashing HOT water. Avoid direct skin contact with HOTwater at all times. While splint material is immersed inwater, the lid should remain closed to help retain heatinside tank. Remove splint material from tank only after ithas reached the manufacturer’s specified duration. Usecaution when removing splint material from tank. Applysplint material as specified by splint manufacturer’sinstructions.Keep the lid closed when appliance is not in use.Maintain proper water level at all times. Immediately fillthe appliance with water to 3” (76mm) deep. Avoidallowing water to reach a "very low water" level. A "verylow water" level would be any water level 3/4" (20 mm)or less water depth as measured from the tank bottom.Never operate appliance without water! Theseprecautions will prevent the appliance from over-heatingand prevent potential damage to the heating element.To change the set temperature on the model SP-1501,drain the water and unplug the unit. Carefully remove thefour screws holding the nameplate and locate the twothermostat knurled knobs. The top knob is thethermostat for the high temperature limit setting and thebottom knob is the thermostat for the low temperaturelimit setting. Insert a small screwdriver into the slottedhead of the thermostat knob turning clockwise to raisethe temperature limit and counterclockwise to lower thetemperature limit. Please note that 1/8 of a turn isapproximately equal to 5ºF (-2.8ºC).EMPTYING YOUR SPLINT PANDO NOT turn the thermostat more than one full turn ineither direction. Reinstall the nameplate and fill the unitwith 3” (76mm) of water. During manufacturing the lowtemperature is preset at 160ºF (71ºC) and the hightemperature at 175ºF (79ºC).CARE & CLEANINGOF YOUR SPLINT PANOn the standard SP-1502 model, the temperature is variedby turning the thermostat knob clockwise for an increaseand counterclockwise for a decrease in temperature. Thetemperature on low setting should approximate 140ºF(60ºC) and on high 190ºF (88ºC).!WARNINGUse the Splint Pan only as directed in this manual.Any other use can cause injury.USING YOUR SPLINT PANOnce the digital display indicates the desiredtemperature, the appliance will be ready for use. Allow /- 3ºF (1.7ºC) temperature variance.Always refer to the correct temperature & durationspecified by the splinting material manufacturer.Be certain to heed all warnings as outlined in theWARNING section (inside front cover of this manual).Keep lid closed while water is heating up.Before emptying (draining) your appliance, be sure thatthe power switch is set to "OFF". Allow the appliance tocool down before emptying. Lifting the lid will acceleratethis cooling. The Splint Pan must beunplugged when emptying thereservior. The appliance has beenprovided with a Drain Valve that hasa 1/4” (6.35mm) barbed nipple toattach a hose.Turn power switch "OFF" and unplug the unit from theelectrical receptacle. If necessary, drain the appliance byfollowing instructions as outlined in the "EMPTYINGYOUR SPLINT PAN" section.When cleaning, rinsing, and/or drying your appliancealways rub in the direction of the stainless steel grainlines to minimize marring or scratching the surfaces.Use mild soaps, gentle non-abrasive detergents, or mildmixtures of ammonia to routinely clean the surfaces ofthe appliance. Be sure to always rinse with clean, warmwater and wipe dry. Use stainless steel cleaners such as3M Stainless Steel Cleaner/Polish, Sheila Shine ,Twinkle Stainless Steel Cleaner/Polish, Penny Brite,Cameo Stainless Steel Cleaner/Polish, and EZ Brite, onstainless steel surfaces. Strictly follow brand namemanufacturer’s instructions on proper use of thestainless steel cleaner. NOTE: The use of brand namesis intended only to indicate a type of cleaner.DO NOT use bleach, chlorinated solvents, or other harshchemicals to clean your appliance. DO NOT use steelwool to clean the stainless steel surfaces. For scaly,hard-water spots use a strong solution of vinegar &water and let it stand for approximately 5 minutes. Rinsewith clean, warm water and wipe dry.5WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathWHITEHALL SPLINT PANSWhitehall Part #DescriptionSP-1501x16903-112-199Bottom Panel26903-212-199Bottom Panel36903-152-000Drain Ball Valve (Stainless Steel) 1/4-18 NPT x 1/4x46903-160-000Drain Barb (Stainless Steel) 1/4-18 NPT x 1/4xSP-1501B SP-1502 SP-1502BxxxxxxxxxDrain Elbow (Stainless Steel) 1/4-18 NPT x 1/4xxxxxx56903-166-00066903-162-000Drain Threaded Pipe (Stainless Steel) 1/4-18 x 3” NPT76903-262-000Drain Threaded Pipe (Stainless Steel) 1/4-18 x 5” NPTxx86903-256-000Element, Heating 120Vxx96903-257-000Element, Heating 220Vxxxx106903-156-000Element, Heating 120Vx116903-157-000Element, Heating 220Vxx126903-168-199Face Plate (Plastic) for Control Panelxx136903-268-199Face Plate (Plastic) for Control Panel140710-230-001Fuse Holder Assembly, 5mm x 20mm150710-232-000Fuse Holder Assembly, 1/4 x 1-1/4 lgx166900-136-000Fuse, 15 Amp, 120V, Time Delay, 1/4 x 1-1/4 lgx170710-226-000Fuse, 8 Amp, 220V, Time Delay, 5mm x 20mm180710-233-000Fuse, 6 Amp, 120V, Time Delay, 1/4 x 1-1/4 lg190710-203-000Fuse, 4 Amp, 220V, Time Delay, 5mm x 20mmxxxxxxx206504-605-000Cabinet footxxx217000-415-000J Nut, Self Retainingxxxxxx226900-130-000Knob for Thermostat236900-135-000Light, Rectangular (Green) 125VAC246903-137-000Light, Rectangular (Green) 250VAC256505-540-000Light, Round (Amber) 125VAC266505-541-000Light, Round (Amber) 250VACxxxxxx276900-134-000Light, Round (Green) 125VAC286900-134-001Light, Round (Green) 125VAC296505-542-000Light, Round (Green) 250VAC306900-108-000Power Switch316900-109-000Power Switch (3 Way)x326505-056-000Powercord Assembly 120Vx33Call for part #Powercord Assembly 220Vxxxxxxxxxx346903-138-001Rim and Lid Assembly (Stainless Steel)356903-238-001Rim and Lid Assembly (Stainless Steel)366903-338-001Rim, Stainless Steel (Lid not included) SP-1501-SLDxx376900-128-000Rubber Grommetxx386903-195-001Sliding Lid Assembly, Stainless Steel SP-1501- SLDxx396903-142-000Thermometer, Digital (Fahrenheit) 120V Onlyx406903-143-000Thermometer, Digital (Celsius) 220V Only416903-150-000Thermostat, Capillary (Operating)xxxxxxxxxxxx426903-146-000Thermostat, L-145xx436903-147-0003/4” Thermostat, Manual Resetxxxx446502-100-000#8-32 x 3/8” Phil Pan Head Screwxxxx450116-013-000#10-32 x 3/4” SST Phil Round Head Screwxxxx466900-144-0001/4” Clear Plastic Drain Hose (Not Shown)xxxx662WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathMODEL SP-1501MODEL SP-1501B38363410114354234143214 1533FUSE 1637FUSE 21612172829394023 24312021444517WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathTHERMOSTATDPDTSWITCHSP-1501POWER INLETLBLKBLKHI LIMITSENSORFUSE 1BLKBLKTHERMOMETERPROBEBLKMOUNTTO TANKBLKLOWERLED LIGHTGRN/YELHI LIMITSENSORFUSE 2WHTNBLKBLKUPPERLED GTHERMOSTATALWAYS disconnect power cord fromthe mains before changing the fuses.Use only Time Delay Fuse.See Parts List, Page 6, Item 16GNDTHERMOSTATDPDTSWITCHSP-1501BPOWER INLETLBRNBRNHI LIMITSENSORFUSE 1BRNBRNTHERMOMETERPROBEBRNMOUNTTO TANKBRNLOWERLED LIGHTGRN/YELHI LIMITSENSORFUSE 2NBLUBRNBRNUPPERLED ALWAYS disconnect power cord fromthe mains before changing the fuses.Use only Time Delay Fuse.See Parts List, Page 6, Item 17Protective Conductor TerminalThe protective conductor terminal symbol in the above figureidentifies the location of the bonding terminal, which is bonded toconductive accessible parts of the enclosure for safety purposes.Symbols on labels:Alternating Voltage or CurrentFuse Location28WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.comHEATINGELEMENT

Instructions for Operation and Care of Forma-Splint Thermal BathMODEL SP-1502MODEL SP-1502B358329334314 1518 19FUSE 12FUSE 2133727294393402225 26304120214445759WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathSP-1502POWER INLETFUSE 1BLKLDPSTSWITCHBLKOVER TEMPSENSOROPERATINGTHERMOSTATBLKBLKGREENLED LIGHTYEL/GRNBLKHEATINGELEMENTAMBERLED LIGHTFUSE 2WHTWHTWHTNTHERMOMETERPROBEMOUNT TO TANKGNDALWAYS disconnect power cord fromthe mains before changing the fuses.Use only Time Delay Fuse.See Parts List, Page 6, Item 18SP-1502BPOWER INLETLDPSTSWITCHFUSE 1BRNBRNOVER TEMPSENSORBRNOPERATINGTHERMOSTATBRNGREENLED LIGHTYEL/GRNBRNHEATINGELEMENTAMBERLED LIGHTFUSE 2BLUBLUBLUNTHERMOMETERPROBEMOUNT TO TANKGNDALWAYS disconnect power cord fromthe mains before changing the fuses.Use only Time Delay Fuse.See Parts List, Page 6, Item 19Protective Conductor TerminalThe protective conductor terminal symbol in the above figureidentifies the location of the bonding terminal, which is bonded toconductive accessible parts of the enclosure for safety purposes.Symbols on labels:Alternating Voltage or CurrentFuse Location210WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathELECTRICAL PARTS DISASSEMBLYMODEL SP-1501MODEL SP-1501BHigh LimitSensorThermostatOperatingThermostatFuseFuse HolderHeating ElementDigitalThermometerLightsSwitch11WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Instructions for Operation and Care of Forma-Splint Thermal BathELECTRICAL PARTS DISASSEMBLYMODEL SP-1502MODEL SP-1502BHeating ElementFuseFuse HolderHigh Thermostat21012WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.APhone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com

Mailing Address:P.O. Box 3527 City of Industry, CA 91744-0527 U.S.APhysical Address:15125 Proctor Avenue City of Industry, CA 91746 U.S.APhone 800-782-7706 626-968-6681Fax 626-855-4862Web: www.whitehallmfg.comE-mail: info@whitehallmfg.comAny questions regarding servicing of products in Europe or the Middle East should be directed to:Acorn Thorn, Limited 5 Brearley Court, Baird Road Quedgeley, Gloucester GL2 2AF, United KingdomPhone (44) 01452 721211 Fax (44) 01452 721231Web URER'S WARRANTYGo to www.whitehallmfg.com to fill out eWarranty Registration, keyword search: WARRANTY.Whitehall Manufacturing Company warrants that its products are free from defects in material or workmanship undernormal use and service for a period of one year from date of shipment. Whitehall's liability under this warranty shall bedischarged solely by replacement or repair of defective material, provided Whitehall is notified in writing within oneyear from date of shipment, F.O.B. Industry, California.This warranty does not cover installation or labor charges, and does not apply to materials which have beendamaged by other causes such as mishandling or improper care or abnormal use. The repair or replacement ofthe defective materials shall constitute the sole remedy of the Buyer and the sole remedy of Whitehall under thiswarranty. Whitehall shall not be liable under any circumstances for incidental, consequential or direct charges causedby defects in the materials, or any delay in the repair or replacement thereof. This warranty is in lieu of all otherwarranties expressed or implied. Product maintenance instructions are issued with each fixture, and disregard or noncompliance with these instructions will constitute an abnormal use condition and void the warranty. Stainless steelmust be properly maintained after the water has been introduced into the fixture, or Whitehall's limited warranty is void.If you have any questions or require technical assistance, please call 800-743-8219.NOTICE TO KEEP ORIGINAL PACKAGING- Regarding warranty claims: customer must retain original packagingfor one year upon receipt of product. If packaging is discarded, it is the customer's responsibility to provide adequatepackaging. Any shipping claims that are a direct result of customer-provided packaging materials will be handled bythe shipper.Member of

WHITEHALL MANUFACTURING P.O. BOX 3527 City of Industry, CA 91744-0527 U.S.A Phone (800) 782-7706 (626) 968-6681 Fax (626) 855-4862 Web: www.whitehallmfg.com . 855-4862 Web: www.whitehallmfg.com a Failure to follow these instructions could result in damage to your new heating appliance and/or injury! BOOKLET BEFORE .