Transcription

Firestone Building ProductsPlatinum EPDM Design GuideMarch 2013

TABLE OF CONTENTSTable of Contents . 21.01 General Design Criteria . 41.02 Quality Assurance . 111.03 Vapor Retarders / Air barriers . 121.04 Substrate and Substrate Requirements . 141.05 Fasteners . 171.06 Decks . 191.07 Base Ply Sheet . 221.08 Insulation . 221.09 Roof Membrane . 251.10 Flashings . 251.11 Walkways . 281.12 Roof Coatings . 291.13 Warranty . 29Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20132

LIST OF TABLESTable 1.01-1CHART OF ROOF SYSTEM APPLICABILITY . 5Table 1.01-2Platinum Warranty PHW Puncture-Hail-Wind . 5Table 1.01-3Platinum Warranty PW Puncture-Wind . 6Table 1.01-4Platinum Warranty PH Puncture-Hail . 7Table 1.01-5Platinum Warranty P Puncture or Warranty B Basic . 9Table 1.04-1The Minimum Fastener Pullout Resistances For Platinum EPDM . 16Table 1.04-2Recommended Number Of Pull Out Tests . 17Table 1.05-1Allowable Fasteners By Substrate . 20Table 1.05-2Acceptable Fastener Uses . 21Table 1.06-1Structural Deck Classification . 22Table 1.08-1Insulation Attachement Options - Mechanical Attachment . 26Table 1.08-2Insulation /Cover Board Attachment Adhesive Attachment . 27Table 1.10-1Detail Description For Firestone Platinum EPDM roof system . 30Table 1.13-1Firestone Warranty Summary . 35LIST OF DIAGRAMDiagram1.01.1Typical Roof Assembly Layers . 11 1Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20133

1.01GENERAL DESIGN CRITERIAA. APPLICABILITY:1. Parameters of this manual outline the minimum requirements for a Firestone Platinum warranty. Local codeand insurance requirements may require specific enhancements.2. Statements in this design guide are provided in good faith with the expectation that a design professional beconsulted prior to any job decisions being made.3. All components of the Firestone Platinum roof system must be roofing system materials furnished byFirestone. The Platinum roof system shall consist of Firestone: .090” Platinum EPDM membrane, fullyadhered to HailGard, ISOGARD HD, min.¼” DensDeck, min ¼” SECUROCK Gypsum-Fiber or ISO 95 Polyiso Insulation attached to an acceptable substrate combined with other Firestone roof system accessoriesas indicated in the following text and tables.4. Firestone roof systems may or may not be applicable, without special consideration, if subject to local,regional, or national building code requirements or testing agency restrictions.a) It is the building owner’s or the design professional’s responsibility to consult with the controlling codeagency official(s) to determine the specific requirements of each project and each system.b) The Firestone Roof System Advisors should be contacted when local or controlling codes are in conflictwith Firestone recommendations. Contacts: 800.428.4511 or RoofSolutiions@firestonebp.com .Certain situations may arise where Firestone specifications and/or roofing requirements cannot be applied. It may not bepossible for Firestone to issue the desired warranty for projects that deviate from current Firestone requirements andstandards, unless a written request for approval has been received, reviewed and approved by the Firestone Technical Servicesprior to application of the proposed system.5. The following conditions require special consideration and may not be warrantable. Contact the FirestoneTechnical Services at Firestone Building Products if any of the following conditions are present: Roofs that exceed the maximum slope and height limits for the Firestone Platinum Roof systemassembly see Table 1.01-1Projects that require special wind coverage greater than 55 mphRoofs located where localized wind phenomenon may occur, reference ASCE-7 wind mapsRoofs located down slope or foothills of mountain rangesGeographical areas susceptible to hurricanesRoofs subject to chemical or process byproduct dischargeRoofs with non-linear slopes such as arches, domes and barrels, etcBuildings with large openings in a wall (greater than 10% of the wall surface) that could be leftopen in a stormRoofs subject to heavy trafficRoofs subject to positive pressure situations such as: pressurized buildings, air infiltrating decks,canopies, overhangs, airplane hangars, distribution centers, etcBuildings with high interior humidity such as swimming poolsRoof decks that do not provide adequate fastener pullout resistance6. Cold storage and freezer facilities constitute a special condition. A design professional familiar with coldstorage construction and vapor migration should be consulted in the design of the roof system.Unlimited slope in the following chart only refers to the potential maximum installation slope. When using installationequipment there may be practical limitations to the slope that can be done. Safety is the first order to consider when doing anyjob. Consult with the equipment manufacturer on the performance of the individual items.Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20134

TABLE 1.01-1CHART OF ROOF SYSTEM APPLICABILITYSystemSlopeBarrel, Arch, etc.Maximum HeightMaximum Warranty TermEPDMAdheredUnlimited(See note below)OK250'(76.2 m)Platinum30 YearTABLE 1.01-2PLATINUM WARRANTY PHWPUNCTURE-HAIL-WIND (100 MPH)Membrane:Insulation:HailGard, min 11/2” (38.1 mm.).090” (2.2 mm) EPDMOnly approved Insulation for Puncture-Hail-Wind WarrantyType of DeckingAttachmentMinimum PenetrationFirestone HailGard Fastener3/4” (19.0 mm) through deckFirestone HailGard Fastener1” (25.4 mm)into deckFirestone Concrete Drive andPlate11/4” (31.7 mm) into deckPlywood or Oriented Strand Board min. 7/16”(12.7mm)Firestone HailGard Fastener1” (25.4 mm) through deckWood Planking –min. 3/4” (19.1mm)Firestone HailGard Fastener1” (25.4 mm)into deckFirestone Polymer Fastener andPlate11/2” (38.1 mm)into deckFirestone HailGard Fastener3/4” (19.0 mm) through the metal panFirestone HailGard Fastener1" (25.4mm) into structural concretedeckFirestone Concrete Drive andPlate11/4" (31.7mm) into structuralconcrete deckSteelmin. 22 Gauge (0.76 mm)Structural Concrete or Pre-cast min. 3000 psi (20684 kPa)Poured or Pre-cast Gypsum and Cementitious Wood Fiber,min. 2” (51 mm)Lightweight Concrete Decksand Fills(see 1.06-I)Notes: All insulation must be fastened at a rate of no less than 20 in the field, 30 in the perimeter and 35in the corners with Firestone HailGard Fasteners per 4’ x 8’ (1.22 m x 4.44 m) board.Contact Firestone Technical Services for the proper fastener attachment pattern for otherextended wind speed warranties or code requirements.If more than one layer of insulation is required, Firestone ISO 95 must be used beneath theFirestone HailGard in multiple, staggered layers.Insulation thickness requirements may vary for code compliance. Consult Firestone TechnicalServices and the local code official.HailGard Insulation must be fastened. (adhesives are not acceptable) AcryliTop, white coating option available Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20135

TABLE 1.01-3PLATINUM WARRANTY PWPUNCTURE-WIND (100 MPH)Membrane:Insulation:HailGard, min 1.5” (38.1 mm.).090” (2.2 mm) EPDMOnly approved Insulation for Puncture-Wind WarrantyType of DeckingAttachmentMinimum PenetrationFirestone HailGard Fastener3/4” (19.0 mm) through deckFirestone HailGard Fastener1” (25.4 mm) into deckFirestone Concrete Drive andPlate11/4” (31.7 mm) into deckPlywood or Oriented Strand Board min. 7/16”(12.7 mm)Firestone HailGard Fastener1” (25.4 mm)through deckWood Planking –min. 3/4” (19.1mm)Firestone HailGard Fastener1” (25.4 mm)into deckFirestone Polymer Fastener andPlate11/2” (38.1 mm) into deckFirestone HailGard Fastener3/4” (19.0 mm) through the metal panFirestone HailGard Fastener1” (25.4mm) into structural concretedeckFirestone Concrete Drive andPlate11/4" (31.7mm) into structuralconcrete deckSteelmin. 22 Gauge (0.76 mm)Structural Concrete or Pre-cast min. 3000 psi(20684 kPa)Poured or Pre-cast Gypsum and Cementitious Wood Fibermin. 2” (51 mm)Lightweight Concrete Decksand Fills(see 1.06-I)Notes: All insulation must be fastened at a rate of no less than 20 in the field, 30 in the perimeter and 35in the corners with Firestone HailGard Fasteners per 4’ x 8’ (1.22 m x 4.44 m) board.Contact Firestone Roof Technical Services for the proper fastener attachment pattern for otherextended wind speed warranties or code requirements.If more than one layer of insulation is required, Firestone ISO 95 must be used beneath theFirestone HailGard in multiple, staggered layers.Insulation thickness requirements may vary for code compliance. Consult Firestone TechnicalServices and the local code official.HailGard Insulation must be fastened. (adhesives are not acceptable) AcryliTop, white coating option available Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20136

TABLE 1.01-4PLATINUM WARRANTY PHPUNCTURE-HAILMembrane:Insulation:HailGard, min 1.5” (38.1 mm.).090” (2.2 mm) EPDMEach are approved for Puncture-HailWarrantyType of Decking(I.S.O.TwinPack I.S.O. FIX or I.S.O. SPRAY Smay require pull tests, consult Table 1.08-2ORMin ¼” (6.4 mm) DensDeck Prime orSECUROCK Gypsum-Fiber,Over ISO 95 min. 1.0” (25.4 mm)AttachmentFirestone HailGard Fastener(Must use on HailGard Insulation)Steel, min. 22 Gauge (0.76 mm)Structural Concrete or Pre-cast min. 3000psi (20684 kPa)Plywood or Oriented Strand Board min.7/16” (12.7 mm)Wood Planking – min. 3/4” (19.1mm)Firestone Heavy Duty Fastener and PlateFirestone I.S.O. SPRAY SMinimum Penetration3/4” (19.0 mm) through deckFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackFirestone HailGard Fastener(Must use on HailGard Insulation)Firestone Heavy Duty Fastener and PlateBead spacing: 12” field, 6” perimeter,4” corners, MinimumFirestone Concrete Drive and Plate11/4” (31.7 mm) into deckFirestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackBead spacing: 12” field, 6” perimeter,4” corners, MinimumFirestone HailGard Fastener(Must use on HailGard Insulation)1” (25.4 mm) through deck1” (25.4 mm) into deckFirestone Heavy Duty Fastener and PlateFirestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackFirestone HailGard Fastener(Must use on HailGard Insulation)Bead spacing: 12” field, 6” perimeter,4” corners, Minimum1” (25.4 mm) into deckFirestone Heavy Duty Fastener and PlatePoured or Pre-cast Gypsum andCementitious Wood Fiber, min. 2” (51 mm)Firestone Polymer Fastener and Plate(Predrilling may be required)Firestone HailGard Fastener(Must use on HailGard Insulation)Lightweight Concrete Decksand FillsFirestone Heavy Duty Fastener and PlateFirestone HailGard Fastener(Must use on HailGard Insulation)(see 1.06-I)Firestone Heavy Duty Fastener and PlateFirestone Concrete Drive and Plate1.5” (38.1 mm) into deck3/4” (19.0 mm) through the metal pan.11/4"(31.7mm) into structural concretedeck11/4" (31.7mm) into structural concretedeckNotes: Table 1.01-4 All insulation must be fastened in the field of the roof at a rate of no less than 16 FirestoneHailGard Fasteners for HailGard Insulation and Firestone Heavy Duty fasteners and insulationplates per 4’ x8’ (1.22 m x 4.44 m) ISO 95 , DensDeck or SECUROCK Gypsum-Fiber board.I.S.O. SPRAY S, I.S.O. TwinPack, and I.S.O. Fix must use 4’ x 4’ (1.2m x 1.2m) boards.Contact Firestone Technical Services for the proper fastener attachment pattern for otherextended wind speed, greater than 55 mph but less than 100 mph, warranties.If more than one layer of insulation is required, Firestone ISO 95 must be used beneath theFirestone HailGard in multiple, staggered layers.Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20137

Insulation thickness requirements may vary for code compliance. Consult Firestone TechnicalServices and the local code official.HailGard Insulation must be fastened. (adhesives are not acceptable) AcryliTop, white coating option availableTABLE 1.01-5Membrane:PLATINUM WARRANTY P / PLATINUM WARRANTY BPUNCTURE/BASICInsulation:HailGard, min 1.5” (38.1 mm.)ORISOGARD HD, min 1/2” (12.7 mm) overISO 95 min. 1.0” (25.4 mm).090” (2.2 mm) EPDMAll Three are approved for Puncture WarrantyORMin ¼”(6.4 mm) DensDeck Prime or SECUROCKGypsum-Fiber over ISO 95 min. 1.0” (25.4 mm)ORISO 95 min. 1.0” (25.4 mm)Type of DeckingSteelmin. 22 Gauge (0.76 mm)Structural Concrete or Pre-castmin. 3000 psi (20684 kPa)Plywood or Oriented Strand Boardmin. 7/16” (12.7 mm)AttachmentMinimum PenetrationFirestone HailGard FastenerFirestone Heavy Duty Fastener and Plate3/4” (19.0 mm) through deckFirestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackFirestone HailGard Fastener(Must use on HailGard Insulation)Bead spacing: 12” field, 6” perimeter, 4” cornersFirestone Concrete Drive and Plate11/4” (31.7 mm) into deckFirestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackFirestone HailGard Fastener(Must use on HailGard Insulation)Bead spacing: 12” field, 6” perimeter, 4” cornersPoured or Pre-cast Gypsum andCementitious Wood Fibermin. 2” (51 mm)Firestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackBead spacing: 12” field, 6” perimeter, 4” corners(see 1.06-I)1” (25.4 mm) into deckFirestone Heavy Duty Fastener and PlateFirestone I.S.O. SPRAY SFull coverageFirestone I.S.O. FixFirestone I.S.O. Twin PackBead spacing: 12” field, 6” perimeter, 4” cornersFirestone Polymer Fastener and Plate(Predrilling may be required)Firestone I.S.O. SPRAY SFirestone I.S.O. FixFirestone I.S.O. Twin Pack1.5” (38.1 mm) into deckFirestone HailGard Fastener(Must use on HailGard Insulation)Lightweight Concrete Decksand Fills1” (25.4 mm) into deckFirestone Heavy Duty Fastener and PlateFirestone HailGard Fastener(Must use on HailGard Insulation)Wood Plankingmin. 3/4” (19.1mm)1” (25.4 mm) into deckFirestone Heavy Duty Fastener and PlateFirestone Heavy Duty Fastener and PlateFirestone HailGard Fastener(Must use on HailGard Insulation)Firestone Heavy Duty Fastener and PlateFirestone Concrete Drive and PlateFirestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/2013Full coverageBead spacing: 12” field, 6” perimeter, 4” corners3/4” (19.0 mm) through the metal pan.1" (24.5mm) into structural concrete deck11/4" (31.7mm) into structural concrete deck8

Notes: For table 1.01-5 All insulation must be fastened in the field at a rate of no less than 16 Firestone HailGardFasteners for HailGard Insulation and Firestone Heavy Duty fasteners and insulation plates per4’ x8’ (1.22 m x 4.44 m) ISO 95 , SECUROCK Gypsum-Fiber or DensDeck board.I.S.O. SPRAY S, I.S.O. TwinPack, and I.S.O. Fix must us 4’ x 4’ (1.2m x 1.2m) boards.Contact Firestone Technical Services for the proper fastener attachment pattern for otherextended wind speed, greater than 55 mph but less than 100 mph, warranties.If more than one layer of insulation is required, Firestone ISO 95 must be used beneath theFirestone HailGard in multiple, staggered layers.Insulation thickness requirements may vary for code compliance. Consult Firestone TechnicalServices and the local code official.HailGard Insulation must be fastened. (adhesives are not acceptable) AcryliTop, white coating option available B. CONSULTATION:1. Firestone recommends that a design professional be involved in the design process. For additional assistance,Firestone Technical Services is available for consultation with respect to any necessary deviations fromcurrent Firestone requirements and standards.2. For recommendations on any specific project, about the applicability, or appropriateness, of any material'ssuitability for use or use of products in conjunction with any other specific material, follow these steps:a) Consult Firestone Building Products Website: www.firestonebpco.comb) Consult this Technical Database, the Firestone EPDM Application Guide and the specific TechnicalInformation Sheet (T.I.S.).c) Consult with the building owner or his design professional.d) Consult with the Firestone Technical Services at Firestone Building Products.3. Statements in this design guide are provided in good faith with the expectation that a design professional beconsulted prior to any job decisions being made.C. DESIGN:1. Firestone does not perform engineering or design functions and does not approve or make commentsregarding them.2. Firestone recommends that a design professional be consulted to assure proper design, (i.e. roof systemselection) installation, and conformance to building codes, insurance requirements, etc.The following are just a few of the conditions, which may influence the need for a design professional:Structural conditions that might not be sufficient to support the anticipated load of the completed roofinstallation.Structural conditions to support the dynamic loading of the roof systemThe need to review the proposed system assembly for its applicability on specific projectsThe requirements of local building codes for the need of a thermal barrierThe requirements of local building codes for the need of a vapor retarderThe requirements of local building codes for the need of an air barrierWhen considering the effect of loads on the structure/decking due to the loading/staging of materials as apart of system installation. The building owner or his design professional should specify the load limitationsto be observed by the Firestone licensed applicatorFirestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/20139

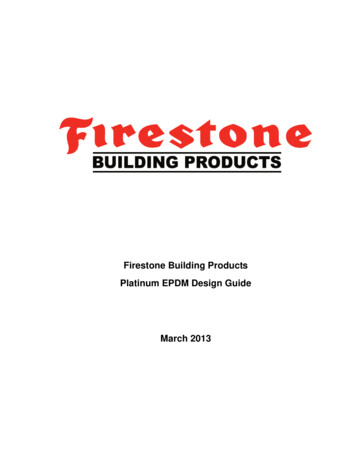

WARRANTY:3. Where a Firestone Platinum EPDM warranty is required:a) Submit an Electronic Pre-Installation Notice (P.I.N.) along with an approved roof drawing, 14 days prior toproject start and receive an acknowledgement of acceptance or required enhancements to meet Firestonerequirements to receive a warranty.b) The roof must be installed according to the current Firestone requirements appropriate to the projectconditions and design requirements.c) The Firestone roof system must be installed by a current Firestone Red Shield licensed applicator.d) The Firestone roof system must be inspected by a Firestone Technical Representative.e) Upon inspection and acceptance of the installed roof system by a Firestone Technical Representative, thewarranty will be issued and dated based on the completion date of the roof by the roofing contractor.4. Firestone’s inspection is not intended as an inspection for benefit of the building owner or the designprofessional with respect to contract, building codes or compliance with specifications other than Firestone’s.Firestone roof systems cannot receive a Platinum EPDM warranty if any of the following conditions exist:Non-roofing applications such as plaza deck construction, waterproofing, pond liners, etc.Roofing applications for single-family residencesCertain situations may arise where Firestone specifications and/or roofing requirements cannot be applied. It may not bepossible for Firestone to issue the desired warranty for projects that deviate from current Firestone requirements andstandards, unless a written request for approval has been received, reviewed and approved by the Firestone Roof SystemSolutions Group prior to application of the proposed system.5. At a minimum, the Platinum EPDM roof system shall consist of a .090 inch (2.2 mm) Platinum EPDMmembrane, fully adhered to one of the following Firestone Insulations, which has been installed over anacceptable substrate: HailGard, min. 1.5” (38.1 mm) ISOGARD HD min. ½” (12.7mm ) DensDeck, min. 1/4” (6.4 mm) ISO 95 Polyiso Insulation, min. 1.0” (25.4 mm) SECUROCK Gypsum-Fiber, min ¼” (6.4 mm)Consult the appropriate warranty table of the Platinum systems for the needed assembly.6. An air barrier is required for projects with large wall openings that are greater than 10% of the total wall areathat can be left open in a storm. Criteria to be determined based upon Firestone’s Review.Diagram 1.01.1Typical Roof Assembly LayersNot all inter layer attachment methods are shownfor clarity.See the Firestone Glossary for terms commonlyused in this manual.Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/201310

1.02QUALITY ASSURANCEA. JOB SITE CONSIDERATIONS:1. During the construction process, the roofing contractor is responsible for ensuring that all components of theFirestone roof system are protected from damage, including the finished areas of the Firestone roof system.This includes: Damage that may result from the continued construction processDischarges from such as petroleum products, greases, oils (mineral and vegetable), animal fatsand other byproductsDirect contact with continuous steam or heat sources when the in-service temperature is inexcess of 180F (82C)Asphalt, coal tar, oil base or plastic roof cements, and re-saturated roof products are not to beused in direct contact with the waterproofing components of the Firestone Platinum EPDM roofsystem2. All safety regulations required by OSHA and other agencies having jurisdiction must be followed.3. Refer to the Firestone Technical Information Sheet (T. I. S.) “Recommended Guidelines for Working on anOccupied Building” for specific guidelines when installing adhesives or asphalt products on an occupiedbuilding.4. Cold weather application considerations.:a) When the outside temperature is below 40 F (4.4C), installation of Firestone roof system may requireadditional application precautions: For a minimum of 24 hours before installation, adhesives and sealants should remain in anenvironment between 60F and 80F (15.5C and 26.6C)Materials should be used within four hours of removal from a heated storage area. If materialsare not used within that time period, they should be returned to the heated storage area until thetemperature of the material returns to the temperature of the heated storage area. Typically, thisis 24 hours. Check product for quality prior to continued as the cold may affect the integrity ofmaterials.b) For additional information and guidelines, see the Firestone EPDM Application Guide and the NRCARoofing and Waterproofing Manual.B. PHASED CONSTRUCTION is not allowed when constructing a Firestone Platinum EPDM roof system.C. TEMPORARY ROOFING:1. If installation of the roof system is required during unsuitable weather, or before completion of wood blocking,curbs, penetrations, or the erection of walls, a temporary roof may need to be installed.2. If a temporary roof is needed due to construction requirements, Firestone recommends installing a modifiedasphalt base sheet or two fiberglass roofing plies in an appropriate adhesive over an approved substrate, to beused as the temporary roof. This temporary roof can serve to protect the interior of the building during theearly stages of construction. It may then be removed or repaired, if necessary, and can be left as a vaporretarder prior to the installation of the finished Firestone roof system.3. If roof insulation is installed under the temporary roof, the insulation shall be inspected for wet or damagedareas, so that such areas may be removed and replaced prior to installation of the Firestone roof system.4. When a temporary roof is specified as a vapor retarder, precaution shall be exercised in protecting thetemporary roof from other construction tradesmen. Damage to the temporary roof may impair its effectivenessas a vapor retarder. If the vapor retarder is installed as a temporary roof during construction, the vapor retardershall be examined, and if necessary, repaired to ensure watertight integrity prior to installation of the remainderof the roof system.5. For additional information regarding temporary roofs, refer to the NRCA’s Roofing and Waterproofing Manualor contact Firestone Roof System Solutions Group.Firestone RoofingPlatinum EPDM Design GuideInterim Updates at www.firestonebpco.com3/27/201311

1.03VAPOR RETARDERS / AIR BARRIERSThe determination of the necessity and location for a vapor retarder or an air barrier are project specific requirements, which isthe responsibility building owner or his design professional. The proper assessment of the building, the need for and the properdesign of the air barrier and vapor retarder are critical to the long-term operation of the roof system.Firestone does not review or calculate dew point analyses and therefore, does not accept responsibility for damage due torecurrence rate or location of the dew point. Although not all projects require a vapor retarder, a design review should beconsidered for all projects.The inclusion of an air barrier or vapor retarder may affect the Underwriter Laboratories or Factory Mutual rating of the roofsystem.The inclusion of an air barrier or vapor retarder may affect the Firestone system requirements and consequently the Firestonewarranty. Contact the Roof System Solutions Group at Firestone Building Products prior to application of the proposed system.A.VAPOR RETARDER:1. To control moisture, a vapor retarder may be necessary to protect certain roofing components when highinterior humidity is of concern. Some examples are: High interior relative humidity is presentWhen a vapor drive may be expected to form a dew point under the roof membrane or in theinsulation. (Building usages with high humidity interiors where vapor drive may occur) such asswimming pools, laundry facilities, paper mills, and bottling plantsa) In these types of environments, there is substantial upward vapor drive, and the potential exists forextreme amounts of moisture accumulation within the roof assembly. If an effective vapor retarder is notincluded at the proper location in the roof assembly, so that the retarder is warmer than the dew point,condensation will cause damage from the moisture retained in the roof assembly.b) This movement is reversed in some air-conditioned buildings in humid summer conditions. This isespecially true in southern states.2. Vapor retarders are installed because water vapor causes several types of roof assembly failures such as: Reduced R-value, since wet insulation becomes a conductor of heat rather than an insulatorDeterioration of the roof membrane, insulation, structural decks, and associated buildingcomponentsDelamination of roof components from trapped moisture, which freezes and thaws, eventuallyevaporating under solar heat with the resulting vapor pressure causing blisters and delaminationof the roof assembly components3. The following is a partial listing which might influence the need for a vapor retarder: Building usage as related to vapor driveExternal temperature in relation to internal temperatureThe humidity of the interior and/or exterior airBuilding code requirementsConstruction moisture, particularly during winter when temporary propane heat is required4. A vapor retarder's effectiveness generally depends upon the following factors: The vapor retarder's perm (permeance) rating shall be as close to zero as possibleThe adequacy design of the vapor retarder membraneThe integrity of the vapor retarder's seals at perimeters and penetrationsThe integrity of the vapor retarder's membran

Platinum EPDM Design Guide Interim Updates at www.firestonebpco.com 3/27/2013 6 TABLE 1.01-3 PLATINUM WARRANTY PW PUNCTURE-WIND (100 MPH) Membrane: Insulation: .090" (2.2 mm) EPDM HailGard, min 1.5" (38.1 mm.) Only approved Insulation for Puncture-Wind Warranty Type of Decking Attachment Minimum Penetration Steel min. 22 Gauge (0.76 mm)