Transcription

TYIALECSPELSTE

CONTENTS1.ALLOY STEELSAISI 3312AISI 4130AISI 4140AISI 4145AISI 4340AISI 86202.1-23-45-789 - 1011 - 12COLD FINISHED STEELSAISI 1018AISI 12L14AISI 1045 T&GCHROMED SHAFTINGINDUCTION HARDENED SHAFTINGAISI 4140 PRECISION3.HOT ROLLED STEELSAISI 1020AISI 1040 / 10504.2122 - 23TOOL STEELSAISI O-1AISI A-2AISI D-2AISI H-13AISI S-75.2425262728DRILL RODSAISI W-1 / O-16.13 - 141516 - 1718192029FLAT GROUND STOCKAISI 0-1 / A-27.MACHINING ALLOWANCES8.THEORETICAL WEIGHTSESTIMATING PURPOSESWEIGHT EIGHT-OCTAGONWEIGHT-FLATS30313233 - 3435 - 3738394041 - 45VANGUARD STEEL LTD.

CONTENTS9.ALLOYING ELEMENTS IN STEEL10.CHEMICAL COMPOSITIONINDEXING SYSTEMCARBON STEELSALLOY STEELSTOOL STEELS11.46 - 4849 - 5051 - 5354 - 5657 - 60CONVERSIONSCONVERSION TABLESHARDNESS TABLEDECIMAL EQUIVALENTS61626312.GLOSSARY OF TERMS13.COLOUR CODESAPPENDIX A14.MATERIAL SAFETY DATA SHEETSAPPENDIX B64 - 87VANGUARD STEEL LTD.

ALLOY STEEL - 3312AISI / SAE 3312 (UNS G 33106)3-1/2% NICKEL-CHROMIUM CASE HARDENING STEELTYPICAL ANALYSISCMnPSSiNiCr0.08 / 0.130.045 / 0.60.025 Max0.025 Max0.2 / 0.353.25 / 3.751.40 / 1.75A high alloy carburizing steel possessing supreme toughness and fatigue resistance in both carburized andnon-carburized condition. Its alloy content provides extremely high core strength, allowing this steel to be used fortougher applications than the widely used AISI 8620. It can be air hardened for minimal distortion when heattreating intricate shapes. It retains excellent low-temperature properties, and as such is useful for shock resistantmachine parts in areas subject to intense cold. It may be used in the heat-treated non-carburized condition forapplications requiring extra strength and toughness. Normally, this grade is supplied in the annealed condition.TYPICAL APPLICATIONSHeavy duty gears, transmission components, pinions, piston pins, spline shafts, rock drilling bit bodies, plasticmould, etc.MECHANICAL PROPERTIESAnnealed(The following are average values and may be considered as representative.)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL HARDNESS105.00078,0002464212MECHANICAL PROPERTIESHardened and tempered - uncarburized tempering temperature - 540º degrees Celsius(The following are average values And may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL 1757.5285112,00097,0002070235VANGUARD STEEL LTD.

ALLOY STEEL - 3312AISI / SAE 3312 (UNS G 33106)3-1/2% NICKEL-CHROMIUM CASE HARDENING STEELMECHANICAL PROPERTIESHardened and tempered-carburized single refining tempering temperature - 200º degrees Celsius(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL 2.563.5311148,500100,00018.563.5293THERMAL TREATMENTSDEGREES IN CELSIUSForgingAnnealingNormalizingHardening & TemperingCommence at 1175º / 1230º Finish at 870º / 925º Bury in MICA830º / 855º Cool in Furnace870º / 925º Air Cool(Uncarburized) - 815º / 840º Oil Quench, or 840º / 870º Air Quench.Temper immediately according to strength level required at 200º / 600º.(Single Refining Treatment) - After carburizing at 898º / 929º cool toroom temperature. Reheat to 770º / 800º Oil Quench and temper at 200º.Case HardeningMACHINABILITY3312 in the annealed condition has a machinability rating of 40% of AISI B-1112. Average surface cutting speed is65 feet per minute.SHEAR STRENGTHThe ultimate shear strength is approximately 62% of the ultimate tensile strength.2VANGUARD STEEL LTD.

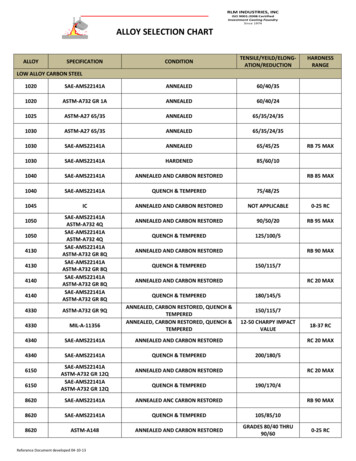

ALLOY STEEL - 4130AISI / SAE 4130 (UNS G 41300)CHROMIUM MOLYBDENUM STEELTYPICAL ANALYSISCMnPSSiMoCr0.28 / 0.330.4 / 0.60.035 Max0.04 Max0.15 / 0.350.15 / 0.250.8 / 1.10A through-hardening alloy of great versatility. The chromium and molybdenum content suffices to provide throughhardness penetration in fairly light sections. Good mechanical properties may be obtained by normalizing where therequired strength is not too high. This grade responds to nitriding for wear and abrasion resistance. The carboncontent causes this alloy to be considered as an oil or water hardening grade.TYPICAL APPLICATIONSShafting, wellhead components, axles, gears, sprockets, tool joints, piston rods, etc.MECHANICAL PROPERTIESAnnealed(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL HARDNESSTHERMAL TREATMENTSDEGREES IN e at 1200º Max. Finish at 950º830º / 855º Cool Slowly in Furnace870º / 930º Cool in Air840º / 870º Water Quench855º / 885º Oil Quench430º / 700º According to Properties RequiredTempering380,00056,0002557149VANGUARD STEEL LTD.

ALLOY STEEL - 4130AISI / SAE 4130 (UNS G 41300)CHROMIUM MOLYBDENUM STEELMACHINABILITY4130 in the annealed condition has a machinability rating of 72% of AISI B-1112. Average surface cutting speed is120 feet per minute.WELDABILITYThis grade may be welded by any of the common welding processes. Preheating and post-heating are recommendedfor difficult segments. The grade of welding rod to be used depends upon the thickness of section, design andservice requirements, etc.4VANGUARD STEEL LTD.

ALLOY STEEL - 4140AISI / SAE 4140 (UNS G 41400)CHROMIUM-MOLYBDENUM STEELTYPICAL ANALYSISCMnPSSiMoCr0.38 / 0.430.75 / 1.000.035 Max0.04 Max0.15 / 0.350.15 / 0.250.8 / 1.10This chromium-molybdenum alloy steel is oil-hardening steel of relatively high harding ability, and is among themost widely used and versatile machinery steel. The chromium content provides good hardness penetration and themolybdenum imparts uniformity of hardness and high strength. This grade is especially suitable for forging as it hasself-scaling characteristics it responds readily to heat treatment and is comparatively easy to machine in the heattreated condition. In the heat treated condition tensile strengths of 170,000 PSI. For small sections and 140,000 PSI.For larger sections are attainable, all combined with good ductility and resistance to shock. This steel resists creep intemperatures up to 540º degrees Celsius and maintains its properties even after long exposure at these relatively highworking temperatures. In the hardened and tempered condition, this steel possesses good wear resistance. The wearresistance can be considerably increased by flame or induction hardening, or alternatively, may be nitride.TYPICAL APPLICATIONSShafts, gears, bolts, couplings, spindles, tool holders, sprockets, hydraulic machinery shafts. for the oil industry-drillcollars, kelly bars, tool joints, subs, etc.MECHANICAL PROPERTIESAnnealed(The following are average values And may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL 02159197VANGUARD STEEL LTD.

ALLOY STEEL - 4140AISI / SAE 4140 (UNS G 41400)CHROMIUM-MOLYBDENUM STEELMECHANICAL PROPERTIESHeat treated and stress relieved.(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL 1139,780114,69515.546.9321MECHANICAL PROPERTIESHeat treated RC 22 Max. for sour gas.(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)HARDNESS - 66.418MECHANICAL PROPERTIESHeat treated to ASTM A.193 GRADE B7(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (%)REDUCTION IN AREA, (%)BRINELL 1922277VANGUARD STEEL LTD.

ALLOY STEEL - 4140AISI / SAE 4140 (UNS G 41400)CHROMIUM-MOLYBDENUM STEELTHERMAL TREATMENTSDEGREES IN ngCommence at 1200º Max. Finish at 950º815º / 950º Cool Slowly in Furnace870º / 900º Cool in Air820º / 870º Oil Quench430º / 700º According to Properties RequiredMACHINABILITY4140 in the annealed condition has a machinability rating of 66% of AISI B-1112. Average surface cutting speed is110 feet per minute.SHEAR STRENGTHThe ultimate shear strength is approximately 63% of the ultimate tensile strength.WELDABILITY4140 is on the border line of weldability because of its relatively high carbon content. It can be welded by any ofthe common welding processes providing the section is preheated and stress relieved after welding. The grade ofwelding rod to be used depends upon the thickness of section, design, and service requirements, etc.7VANGUARD STEEL LTD.

ALLOY STEEL - 4145 H MODIFIED HTSRAISI / SAE 4145 (UNS G 41450) MODIFIED HTSRCHROMIUM-MOLYBDENUM STEEL TO ASTM A 29, A 370, A 434 CLASS BD E 112TYPICAL ANALYSISCMnPSSiMoNiCr0.42 / 0.490.75 / 1.300.035 Max0.04 Max0.15 / 0.350.15 / 0.451.00 Max0.75 / 1.20This alloy steel is used primarily for the manufacture of tools in the oil industry. supplied with a straightnesstolerance of 1/8" in any 5 foot length, with a grain size of 6 or finer, as per ASTM E 112. This steel is heat treatedand hardened by water quench, tempered, stress relieved and supplied in a rough turned condition. All bars areultrasonic tested, with charpy v impact @ 57º degrees Celsius ft. lbs. with minimum average value of 3 readings.No more than one single value shall be lower than 5 ft. Lbs. Below stated average value. Can be supplied to complyto API SPEC. 7 In the manufacture of drill collars in 31 to 31-1/2 foot bars.MECHANICAL PROPERTIESLongitudinal, 1" below surface.(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION,(%)REDUCTION IN AREA, (%)HARDNESS - SURFACE BHNHARDNESS - 1" BELOW SURFACECHARPY V-NOTCH FT. LB.Under 5"5" to 7"7" & Over145,000125,0001440 - 50285 - 34128545140,000110,0001440 - 54285 - 34128545135,000100,0001440 - 54285 - 34128545(All tests are performed to ASTM A 370.)WELDABILITY4145 is on the border line of weldability because of its relatively high carbon content. It can be welded by any ofthe common welding processes providing the section is preheated and stress relieved after welding. The grade ofwelding rod to be used depends upon the thickness of section, design, and service requirements, etc.8VANGUARD STEEL LTD.

ALLOY STEEL - 4340AISI / SAE 4340 (UNS G 43400)NICKEL-CHROMIUM-MOLYBDENUM STEELTYPICAL ANALYSISCMnPSSiMoNiCr0.38 / 0.430.6 / 0.80.035 Max0.04 Max0.15 / 0.350.2 / 0.31.65 / 20.7 / 0.9The "king" of the hardening grades of constructional alloy steels. A rich alloy content, thisnickel-chromium-molybdenum steel, possesses much deeper harding ability than the 4100 series. This is the mostextensively used machinery steel with an exceptional range of strength, toughness and ductility. The advantage isrealized principally where high strength is required in heavy sections. The high fatigue-tensile ratio of 4340 makesit ideal For highly stressed parts operating under the most severe conditions, and may be used in both elevated andlow temperature environment. It has remarkable non-distorting properties for an alloy steel. It has good wearresistance and should be used where the greatest margin of safety is desired.TYPICAL APPLICATIONSCouplings, heavy duty shafting, gears, dies, high strength machine parts, crankshafts, arbors, high tensile bolts andstuds, mine-drilling parts, boring bars, down hole drilling components etc.MECHANICAL PROPERTIESAnnealed(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (% in 2")REDUCTION IN AREA, (%)BRINELL ANICAL PROPERTIESHeat treated and stress relieved ASTM A 434 / BD(The following are average values and may be considered as representative)TENSILE STRENGTH, (PSI)YIELD STRENGTH, (PSI)ELONGATION, (% in 2")REDUCTION IN AREA, 40.2VANGUARD STEEL LTD.

BRINELL HARDNESS285321285 / 311302 / 311ALLOY STEEL - 4340AISI / SAE 4340 (UNS G 43400)NICKEL-CHROMIUM-MOLYBDENUM STEELTHERMAL TREATMENTSDEGREES IN CELSIUSForgingAnnealingNormalizingCommence at 1200º Max. Finish at 950º835º / 900º Cool Slowly in Furnace855º / 900º (Due to the air hardening properties of 4340, normalizing isnot recommended except when followed by tempering)815º / 855º Oil QuenchAccording to Properties RequiredHardeningTemperingMACHINABILITY4340 in the annealed condition has a machinability rating of 57% of AISI B-1112 average surface cutting speed is95 feet per minute.SHEAR STRENGTHThe ultimate shear strength is approximately 66% of the ultimate tensile strength.WELDABILITY4340 is on the border line of weldability because of its relatively high carbon contents. It can be welded by any ofthe common welding processes providing the section is preheated and stress relieved after welding. The grade ofwelding rod to be used depends upon the thickness of section, design, and service requirements, etc.10VANGUARD STEEL LTD.

ALLOY STEEL - 8620AISI / SAE 8620 (UNS G 86200)NICKEL-CHROMIUM-MOLYBDENUM CASE HARDENING STEELTYPICAL ANALYSISCMnPSSiMoNiCr0.18 / 0.230.7 / 0.90.035 Max0.04 Max0.15 / 0.350.15 / 0.250.4 / 0.70.4 / 0.7An alloy steel designed for case hardening applications. The nickel imp

aisi 4140 5 - 7 aisi 4145 8 aisi 4340 9 - 10 aisi 8620 11 - 12 2. cold finished steels aisi 1018 13 - 14 aisi 12l14 15 aisi 1045 t&g 16 - 17 chromed shafting 18 induction hardened shafting 19 aisi 4140 precision 20 3. hot rolled steels aisi 1020 21 aisi 1040 / 1050 22 - 23 4. tool steels aisi o-1 24 aisi a-2 25 aisi d-2 26 aisi h-13 27 aisi s-7 28 5. drill rods aisi w-1 / o-1 29 6. flat ground .