Transcription

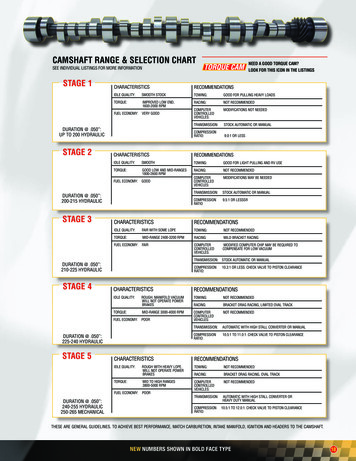

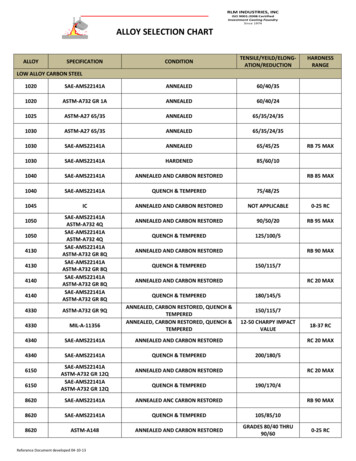

ALLOY SELECTION GATION/REDUCTIONHARDNESSRANGELOW ALLOY CARBON 2 GR 1AANNEALED60/40/241025ASTM-A27 65/35ANNEALED65/35/24/351030ASTM-A27 S22141AANNEALED AND CARBON RESTORED1040SAE-AMS22141AQUENCH & TEMPERED75/48/251045ICANNEALED AND CARBON RESTOREDNOT APPLICABLE0-25 RCANNEALED AND CARBON RESTORED90/50/20RB 95 MAXQUENCH & 141AASTM-A732 4QSAE-AMS22141AASTM-A732 4QSAE-AMS22141AASTM-A732 GR 8QSAE-AMS22141AASTM-A732 GR 8QSAE-AMS22141AASTM-A732 GR 8QSAE-AMS22141AASTM-A732 GR 8QQUENCH & TEMPEREDANNEALED, CARBON RESTORED, QUENCH &TEMPEREDANNEALED, CARBON RESTORED, QUENCH &TEMPEREDASTM-A732 GR 9Q4330MIL-A-113564340SAE-AMS22141AANNEALED AND CARBON RESTORED4340SAE-AMS22141AQUENCH & TEMPERED6150SAE-AMS22141AASTM-A732 GR 12QSAE-AMS22141AASTM-A732 GR 12QRB 90 MAX150/115/7ANNEALED AND CARBON RESTORED43306150RB 85 MAXANNEALED AND CARBON RESTOREDQUENCH & TEMPEREDRC 20 MAX180/145/5150/115/712-50 CHARPY IMPACTVALUE200/180/5RC 20 MAX190/170/48620SAE-AMS22141AANNEALED ANC CARBON RESTORED8620SAE-AMS22141AQUENCH & TEMPERED105/85/108620ASTM-A148ANNEALED AND CARBON RESTOREDGRADES 80/40 THRU90/60Reference Document developed 04-10-1318-37 RCRC 20 MAXANNEALED AND CARBON RESTOREDQUENCH & TEMPEREDRB 75 MAXRB 90 MAX0-25 RC

ALLOY SELECTION GATION/REDUCTIONHARDNESSRANGE8620ASTM-A148QUENCH & TEMPEREDGRADE 105/8526-28 RC8620ASTM-A732 GR 13QANNEALED, CARBON RESTORED, QUENCH &TEMPERED0-25 RC8625/8630SAE-AMS22141AANNEALED AND CARBON RESTOREDRB 90 MAX8625/8630SAE-AMS22141AQUENCH & TEMPERED8625/8630ASTM-A148ANNEALED AND CARBON RESTORED8625/8630ASTM-A148QUENCH & TEMPERED8630ASTM-A732 GR 14QANNEALED AND CARBON RESTORED8630ASTM-A732 GR 14QQUENCH & TEMPERED8640SAE-AMS22141AANNEALED AND CARBON RESTORED8640SAE-AMS22141AQUENCH & AMSJ435SPECIFICATION150/115/7GRADES 80/40 THRU90/60GRADES 105/85 THRU150/1350-25 RC26-36 RC0-25 RC150/115/7RC 20 MAX180/145/5BHN 190-230BHN 170-229ANNEALEDANNEALEDBHN NITIC STAINLESS STEELS303ASTM-A743 GR. CF-16FSOLUTION ANNEALED303MIL-S-81591SOLUTION ANNEALED304ASTM- A743 GR. CF-8SOLUTION ANNEALED304LASTM- A743 GR. CF-3SOLUTION ANNEALED304 (or)304LMIL-S-81591SOLUTION ANNEALED316ASTM A743 GR. CF-8MSOLUTION ANNEALED316LASTM A743 CF-3MSOLUTION ANNEALEDReference Document developed 04-10-13RB 95 quirement70/30/35RB 95 quirement70/30/30

ALLOY SELECTION CHARTALLOYSPECIFICATIONCONDITION316 (or)316LMIL-S-81591SOLUTION ANNEALED310310347ASTM A743 GR. CK20ASTM A351 GR. CK20ASTM A743 GR. CF-8CTENSILE/YEILD/ELONGATION/REDUCTIONRB 95 MAXSOLUTION ANNEALEDSupplementaryRequirement65/28/30SOLUTION ANNEALED65/28/30SOLUTION 7AMS 5362SOLUTION ANNEALED347MIL-S-81591SOLUTION ANNEALEDALLOYSPECIFICATIONCONDITIONHARDNESSRANGERB 95 HARDENABLE STAINLESS STEELS410MIL-S-81591ASTM A743 GR. CA-15ANNEALED410ASTM A743 GR. 410MIL-S-81591QUENCH AND TEMPERED95/75/8/20420ASTM A743 GR. CA-40MIL-S-81591ANNEALED420ASTM A743 GR. CA-40TEMPERED431MIL-S-81591ASTM A743 GR. CB-30ANNEALED431MIL-S-81591QUENCH AND TEMPERED17-4ASTM A747 GR. CB7CU-1HOMOGENIZED, SOLUTION ANNEALED,PRECIPITATION HARDENED17-4AMS 5355J17-4AMS 5343D15-5ASTM A747 GR. CB7CU-2Reference Document developed 04-10-13HOMOGENIZED, SOLUTION ANNEALED,PRECIPITATION HARDENEDHOMOGENIZED, SOLUTION ANNEALED,PRECIPITATION HARDENEDHOMOGENIZED, SOLUTION ANNEALED,PRECIPITATION HARDENEDRC 25 MAXRB 94-100RC 25(SupplementaryRequirement)100/70/15/25RC 30 MAX170/130/2(SupplementaryRequirement)CONDITIONS H900H1150CONDITIONS H900H1150RC 38-49BHN 269-375RC ONS H900H1150BHN 269-375

ALLOY SELECTION N/REDUCTION356ASTM B618T-4 AND T-630/20/3A356ASTM B618T-4 AND T-634/24/3.5A356AMS 4218HT-4 AND T-633/27/3A356MIL-A-21180DT-4 AND T-638/28/5355ASTM B618T-4 AND T-636/25/2.5357ICT-4 AND T-633/27/3713ASTM B618T1 AND T532/22/3TYPICAL GATION/REDUCTIONHARDNESSRANGEA-2ICANNEALEDRC 25A-2NAAMSJ435ANNEALEDBHN 201-229A-6ICANNEALED AND CARBON RESTOREDRC 25D-2NAAMSJ435ANNEALEDBHN 217-255D-2ICANNEALEDD-3ICANNEALEDH-13ICANNEALED, CARBON RESTORED, QUENCHAND TEMPEREDM-2ICAS CAST0-1ICANNEAL AND CARBON RESTOREDRC 25L-6ICANNEALEDRB 95S-5ICANNEALEDRB 100S-7ICANNEALEDRC 25S-7NAAMSANNEALEDBHN 187-223CC1ICANNEALEDBHN 190-320NORMALIZED AND TEMPEREDBHN 250-320ALLOYHARDNESSRANGEALUMINUMTYPICAL BHN70TYPICAL BHN80TOOL STEELSCC1ICReference Document developed 04-10-13RC 46-49

ALLOY SELECTION GATION/REDUCTIONHARDNESSRANGECARMOANNEALEDBHN 190-230CARMOPREHARDEN AND SUFACE HARDENEDHB 310-340CALDIEANNEAL, QUENCH AND TEMPEREDRC SSRANGESPECIFICATIONCONDITIONNAAMSAS CASTBHN 163-212STRESS RELIEVEBHN 197-241Gray IronG2500G3500CLASS 40NAAMSSAE J431ASTM A48BMS E115NOMALIZED AND TEMPERED40,000 TensileCLASS 20ASTM A48AS CAST20,000 ONGATION/REDUCTIOND4512NAAMSSTRESS RELIEVEBHN 143-190D6510NAAMSSTRESS RELIEVEBHN 190-248DuctileASTM A536AS CAST88/55/06DuctileASTM A536AS CAST65 45 ION/REDUCTIONBMS K099AS CAST75/30/12HARDNESSRANGEDuctile IronCopper anganeseBronze(C86300)ManganeseBronze(C86200ASTM B22AS CASTASTM B584AS CASTASTM B584AS CASTReference Document developed 04-10-13HARDNESSRANGEBHN 223 MIN110/60/12RB 89-94

ALLOY SELECTION ION/REDUCTIONHARDNESSRANGENickel BaseINCONNEL100INCONNEL600ALLOYAS CASTAS CASTSPECIFICATIONCONDITIONCOBALTCO31Reference Document developed 04-10-13AS CAST

reference document developed 04-10-13 alloy selection chart alloy specification condition tensile/yeild/elong-ation/reduction hardness range