Transcription

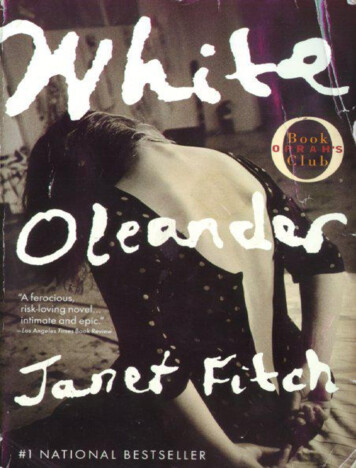

USD2555aPalltronic Flowstar IV Filter Integrity Test Instrument and MUX Extension

The Next Generation Filter IntegrityTest InstrumentThe Palltronic Flowstar IV filter integrity test instrument isThe latest networking capabilities are also incorporated forthe result of Pall's long experience and expert technicaleasy integration within a network, and the optional WLANknowledge in producing successful, top-quality testadaptor, USB connectivity plus an extended range of remoteinstruments. The Flowstar IV instrument introduces manycontrol/automation options enable even greater flexibility.new features, enabling users to test even more filters, reliablyand reproducibly, in less time, saving time and money.Manufacturing Practices) guidelines, and offering fullLightweight, compact and ergonomic, the instrumentcompliance with 21 CFR Part 11, the Palltronic Flowstar IVfeatures an enhanced, touch screen and user-friendlyinstrument is supported by an extensive qualificationinterface, requiring minimal training of operators.documentation package, including guides for InstallationImproved pressure/flow calibration preserves measurementaccuracy while ensuring faster tests.2Developed in accordance with GAMP (Good Automatedand Operational Qualification (IQ/OQ)

Volume-Dosed Flow MeasurementThe Palltronic Flowstar IV integrity test instrument is a highlysensitive measurement instrument for gas pressure and flow.Highly sensitive pressure sensors are available from manysources, but highly accurate gas flow sensors for ameasurement range of 0.01 to 1000 mL/min are not.However, such a range is required for an integrity testin pharmaceutical production.The Palltronic Flowstar IV integrity test instrument utilizesa method that was developed by Pall for use in integritytest instruments and patented as “volume-dosed flowmeasurement technology”. The current version of this flowmeter consists of a valve block with three high precisionpressure sensors, a pressure regulator, three definedvolumes and a specific control algorithm.One pressure sensor constantly measures the gaspressure of the filter system, while the other two sensorsare used to verify the pressure of the internal volumes.As gas diffuses through the wetted filter (as in the ForwardFlow test) the integrity test instrument constantly refills gasinto the filter system. The amount of gas that is dosed inthe defined volumes is accurately determined and equalsThe flow rate does not need to be calculated out ofvolume determination and pressure decay measurementThe Forward Flow and Water Intrusion Tests are runat constant pressure over the complete test timeThe instrument offers full compliance with regulatorydemands on filter integrity testing.the diffusion rate of the filter.In Pall’s standard calibration procedure, the measurementAccuracy and Calibrationpart of the instrument is calibrated as a whole usingThe requirements on calibration are described in 21 CFRaccurate flow references. This confirms that all flow820.72 and the European GMP guide, chapter 4. Pall hasmeasurement components are working correctlyestablished calibration procedures to verify pressure and flowand produce accurate results.measurement which are qualified over the full measurementrange of the instrument. Palltronic Flowstar IV integrity testThe benefits of this technology are:instruments can be calibrated in a Pall-qualified laboratoryIntegrity test is much faster, as upstream volumedoes not have to be measuredallow us to confirm an accuracy of 0.33% for pressureThe flow measurement loop is directly calibratedmeasurement and of 3% for flow measurement, in allor within your manufacturing site. Our traceable referencesparts of the world.www.pall.com/biopharm3

Test CapabilitiesAutomatic Self TestWhen the Palltronic Flowstar IV instrument is switched on,an automatic self test is run. This test can be repeated anytime during operation of the instrument. During the self test,the instrument does a full diagnosis of its functions:Inlet gas pressureThe Palltronic Flowstar IV instrument performs the ForwardFlow test quickly and with extreme accuracy. The volumedosed flow meter can perform a Forward Flow test ina range of 0.1 to 1000 mL/min within minutes and withan accuracy of 0.1 mL/min or 3%.The features of the Forward Flow test function are:Function of the internal valvesThe test is performed at constant pressureFunction and signal of the internal pressure sensorsA volume dosed flow sensor is usedFunction of the internal pressure regulatorCheck on internal leaksProgress of the test is shown on screen while otheroperations can be performed on the instrumentInternal communicationValidated Auto Test Time function to shorten test timesIntegrity of the operating system and the softwareAll relevant data for the test result is stored on the instrumentData integrity of user lists, test programs and test resultsand can be printed or transferred to a network location.The full result of each self test is saved and can be printedat any time. The combination of the self test and a regularcalibration and service guarantee a continuous reliableoperation of the instrument for many years.The benefits provided by these features comparedto other integrity test instruments are:No need for time consuming volume measurementbefore testingNo loss of accuracy due to inexactly determined volumeAuto Test TimeThe Auto Test Time function is available for the Forward FlowFilters with asymmetric membranes can be tested morereliably at constant pressureTest and the Water Intrusion Test. It has been developed andTest times are very short, usually below 10 minutesvalidated to shorten test times while maintaining the reliabilityProgress of the test can be monitored in real timeof the result. The results of a Forward Flow or Water IntrusionUnstable test conditions are detectedtest are interpreted by this algorithm during the test.Accurate and reproducible test results are obtainedIf the measured flow rate is evidently below the limit, and themeasurement is stable, the instrument will interpret this as aWater Intrusion Testpassed test. The filter integrity test times can be shortenedThe Water Intrusion test is widely spread in pharmaceuticalby more than 50% without any risk of false pass results.manufacturing to perform inline integrity testing of sterilizinggrade gas filters with hydrophobic membranes. The PalltronicForward Flow TestFlowstar IV instrument is specially made and validated toThe Forward Flow test is the filter integrity test that isperform this very sensitive water intrusion test. The watermost common in pharmaceutical manufacturing. All majorintrusion test profits from the features and benefits of thefilter suppliers recommend the Forward Flow test as theForward Flow test.method of choice for integrity testing of filter cartridge orcapsule assemblies.4

The additional benefits are:The undefined upstream volume has no influence onthe accuracy of the test resultThe change in water level during the test does notinfluence the accuracy of the resultThe very sensitive volume dosed flow measurementtechnology accurately measures a water flow as lowas 0.03 mL/minBubble Point TestThe Palltronic Flowstar IV integrity test instrument candetermine the Bubble Point of a filter. The gas flow rateis measured at increasing pressure steps, and the BubblePoint is the transition of diffusive gas flow through wettedfilter pores to bulk gas flow through de-wetted filter pores.The features of the Bubble Point test are:A gross leak test is performed at the beginningof the test phaseGas flow is measured very fast in incremental stepsFull Bubble Point curve is determinedAll test parameters are documented with test resultsThe benefits of this are:False pass results due to insufficient filter wettingare avoidedFalse pass results in filters with small defects are avoidedTest result is obtained very quicklyLeak Test and Pressure Decay TestThe leak test can be used to test for leaks in filter systemsor processing systems. It is not an integrity test, since thereis no correlation to bacterial retention. The leak rate can bemeasured either as pressure drop (mbar/min), using thePressure Decay Test or as flow rate (mL/min), using the LeakTest function of the instrument. Possible applications are:Reproducible test results are obtainedAll types of membranes from small disc to cartridgecan be testedCombined Forward Flow andBubble Point TestThe instrument can also determine the Forward Flow andBubble Point value in a single test. The test procedure hasbeen refined to shorten test times of the combined testDiagnosis of filter systems after failed testsInstallation check on filter systems or processing systemsLeak tests on processing equipment during qualificationThe Palltronic Flowstar IV integrity test instrument canperform all kinds of gas pressure tests. It is capable ofperforming those tests reliably and accurately and ofproviding reproducible results.without compromising the accuracy of the result.www.pall.com/biopharm5

Unique DesignThe Palltronic Flowstar IV instrument is a highly sensitivemeasurement instrument which is designed for use in alllocations including the laboratory or inside the processsuite or cleanroom.Splash and Dust ProofThe use of powder or liquid chemicals in close proximity toCleanroom EnvironmentThe instrument has been specifically designed to be usedin any kind of cleanroom. There is no cooling fan thatwould disturb the air in a cleanroom. The internal printeris a thermal printer, generating almost no particles duringprinting. All external components are compatible withcommon cleaning liquids to reduce surface bioburden.an instrument is very common in a laboratory. The PalltronicFlowstar IV integrity test instrument has been tested to besplash and dust proof (IP54 rated). The outside of theinstrument can be easily cleaned.User InterfaceThe user interface is one of the major benefits of thePalltronic Flowstar IV integrity test instrument. The 10.4 in.(264 mm) color touch screen displays all functions thatare needed for routine use of the instrument. Use of theinstrument is straightforward and intuitive, and all the mostcommon language options are available.The menu has been optimized for routine use of theinstrument, and all relevant parameters are displayed onthe screen at all times. This allows the operator to easilyaccess the required functions and to avoid mistakes thatcan occur if relevant data is spread over too many screens.Operators who are trained users of existing PalltronicFlowstar instruments can use the Palltronic Flowstar IVintegrity test instrument without further training.6

Electronic Data Handling and Remote ControlThe Palltronic Flowstar IV integrity test instrument has beenbe electronically signed. Configuration, test programs, userdesigned to be used in a facility that complies with 21 CFRdata and test results can be easily exported to a computerPart 11 for electronic storage of data.network or an external flash drive.There are three levels of access - Operator, Supervisor andInterface ConnectionsAdministrator. Operators have access to the test functionsonly, Supervisors can also modify test programs, andAdministrators have full access to all functions and canalso perform changes to the system configuration or tothe access management.A number of connections at the back of the instrument allowinterfacing with different systems. The USB port can be usedto connect an external printer, barcode reader or a flashdrive. The serial ports can be used to interface with otherPalltronic instruments or a PLC. An ethernet port and aThe instrument can be used in two different modes to limitwireless network adapter can be used to link to a computeraccess to the protected functions. When the passwordnetwork. There are also additional ports for an externalcontrolled access is activated, the supervisor level and thepressure sensor and an external vent valve on the sideadministrator level are each protected by a password. In theof the instrument.login-controlled access mode, each user needs to login tothe instrument before having access to its functions. TheRemote Operationlevel of access can be defined for each person separately.The Palltronic Flowstar IV integrity test instrument is equippedwith a number of interface connections, and it can beAll the changes that are performed on the system or theprograms are recorded in the audit trail. The test results canconnected to a PLC using the internal adapters. The integritytest instruments can then be fully controlled by the PLC, andadapters are available for all common communication protocols.The instrument can also be connected to a computernetwork using the on-board ethernet port or the on-boardwireless LAN adapter. Data can be transferred to thenetwork in a controlled manner. The instrument can alsobe fully controlled from a SCADA system using theavailable OPC server protocols.Remote PrintingInstead of using the internal printer, the print data can bedirected to an external printer. Either a printer that isconnected directly to the instrument via the USB port or anetwork printer can be used. The instrument is also capableof generating the printout as a file, using common dataformats, such as PDF or XML or both.www.pall.com/biopharm7

Palltronic Flowstar IV MUX ExtensionAvailable separately, the Palltronic Flowstar IV MUX extensionThe volume-dosed flow measurement technology utilized byis an innovative, time-saving companion to the Palltronicthe Palltronic Flowstar IV instrument enables filter test timesFlowstar IV instrument. Up to four filters can be attached toto be reduced by half or even more, without compromisingeach Palltronic Flowstar IV MUX extension and up to ninethe very high accuracy of results. Real-time sensing of flowextensions can be ‘chained’ together, allowing for thestability and automatic control of test times ensures safe,automatic, sequential testing of multiple filters at once.*accurate test results for every test in the shortest possibleThe operator simply connects the filters to the PalltronicFlowstar IV MUX extension(s) and programs the testparameters - any combination of integrity-testable filter sizesand test types can be used. The first Palltronic Flowstar IVMUX extension attached to a Palltronic Flowstar IVtime. Automated testing of up to thirty-six filters at onceminimizes operator involvement, and filters can also bedisconnected from the Palltronic Flowstar IV MUX extensionimmediately after each test is completed, allowing formaximum flexibility.instrument becomes the master (Pall Part numberThe Palltronic Flowstar IV MUX extension is an ideal solutionFFS04MUXM) and all subsequent systems attached tofor production areas and facilities where large amounts ofthe master are slaves (Pall Part Number FFS04MUXS).filters are tested offline. With up to thirty-six channels able tobe programmed and activated independently, this evenKey AdvantagesEach Palltronic Flowstar IV MUX extension provides afour-channel extension to the Palltronic Flowstar IV integritytest instrument – saving operator timeSystem software and hardware enables multiple tasksto be performed at once – improving test efficiencyAny combination of filter size and type can be connected –offering total flexibility8allows the user to exchange filters and select new testprograms while existing channels are undergoing integritytests. These features combine to provide a simple, reliableyet highly-efficient method for high-throughput filter testing.*The Palltronic Flowstar IV instrument must be running software version2.0c or later to support the Palltronic Flowstar IV MUX extensionfunctionality.

Service and SupportQualificationThe instrument has been designed following the GAMPguidelines. The Palltronic Flowstar IV integrity test instrumentis classified as a software category 3 and hardware category1 instrument in accordance to GAMP 5. The componentshave been carefully selected for long term availability andThere are Pall-qualified service centers throughout the world.Please contact your local representative to find the mostsuitable way to calibrate and service your instruments.All components used in the Palltronic Flowstar IV integrity testinstrument have been carefully selected and tested for quality.Trainingreliable functionality. All relevant functions have beenthoroughly validated. A description of the main functionsand an operational qualification (OQ) are usually sufficient toqualify the instrument. An extensive documentation packagewith all the relevant documents is available.On-site training is also available for the Palltronic Flowstar IVintegrity test instrument. Training is also available oninstrument validation, filter validation, integrity testing basicsand regulatory requirements. We are happy to assist youwith a custom-designed training program.Calibration and ServiceThe Palltronic Flowstar IV integrity test instrument can becalibrated at any Pall-certified service center or directly onsite. Calibration equipment, procedures and training areavailable. Pall recommends calibration of the instrumentat least once a year, with a full service after three years.www.pall.com/biopharm9

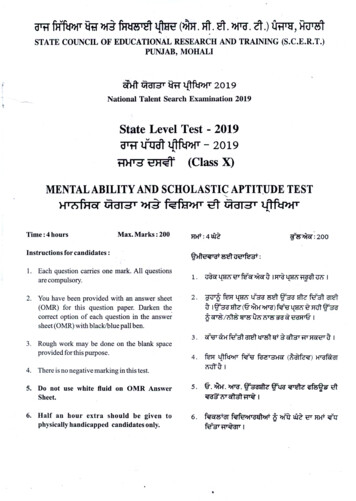

OptionsThe Palltronic Flowstar IV integrity test instrument is availablein three different versions. The basic version is designed asa standalone integrity test instrument. The standard versionoffers all the networking options and can be fully automated.The wireless version includes an internal WLAN adaptor.Features of the Palltronic Flowstar IV InstrumentsPart NumberOptimized user interfaceMultitasking menuDesigned for use in highlydemanding pharmaceuticalproductionSuitable for use in cleanroomSplash and dust proof (IP54)Self testVolume dosed flow measurementCalibration for flow and pressureBasic integrity test capability(FF, BP, combined FF/BP, WIT,Leak Test, Pressure Decay Test)Password access controlUSB port ((printer, barcode reader,flash drive)Printing to USB printerPDF printing to USB flash memorySerial port*Login-based access controlElectronic signatures in compliancewith 21 CFR part 11Configuration of parameter namesConfiguration of main menuFieldbus adapter* for automationOPC server for automationEthernet portPrinting to network printerPDF printing to network driveWLAN adapterBasicStandardWirelessFFS04B FFS04S FFS04R *must be specified at time of ordering10

Technical SpecificationsPalltronic Flowstar IV InstrumentPhysical DimensionsCommunication Ports(nominal) Weight: 10 kg (21.6 lbs)USBWidth, height, depth: 348 mm x 205 mm x 483 mm(13.7 in. x 8. in. x 19 in.)RS232CFilter TestsForward Flow TestBubble Point TestCombined Forward Flow / Bubble Point TestWater Intrusion TestOther TestsLeak Test (Flow measurement based for volume 50 L)Pressure Decay Test (Leak test for volumes up to 200 L)Function TestsSelf TestFlow Check TestEthernetWireless ethernet network (optional)AccuracyForward Flow test: 3% of value or 0.05 mL/min,whichever is the greaterWater Intrusion Test: 3% of value or 0.02 mL/min,whichever is the greaterMeasuring RangeForward Flow Test: 0.1 - 1000 mL/minWater Intrusion Test: 0.03 - 50 mL/minBubble Point Test: 400 - 6500 mbar (5.8 - 94 psi)Leak Test: 0.1 – 1000 mL/minPressure Decay Test: 50 – 6500 mbarPrinter TestNetwork TestOther FunctionsResolutionForward Flow Test: 0.1 mL/min(0.01 mL/min for flows below 10 mL/min)Cleaning functionWater Intrusion Test: 0.01 mL/minTest program Transfer functionBubble Point Test: 50 mbar (0.7 psi)Configuration Transfer functionPressure Decay Test: 1 mbarAccess management Transfer functionTest result export functionBackup functionCalibrationThe calibration of the Palltronic Flowstar IV instrumentincludes a calibration of the pressure transducers andLanguage OptionsEnglish, French, German, Italian, Spanish,US English, Japanesethe flow measurement calibration limits:Pressure measurement: 0.33% of full scaleFlow measurement: 3% of measurementLanguage files on the instrument are constructed suchthat other languages may be added as necessary.www.pall.com/biopharm11

Palltronic Flowstar IV Instrument (continued)Electrical DataVoltage: automatically adjusted between 100 - 240 V ACExternal USB printerInput Frequency: 50 Hz / 60 HzExternal Network printer (A printer type HP P1505Nor compatible is recommended. The printer should becapable of handling the printer language PCL5e)Power: typically 75 W (peak 150 W)Fuse: 3.15 A slow blowExternal Vent Valve: 24 V DCScreenSize: diagonal 264 mm (10.4 in.)Resolution: 1024 x 768 pixelsFeatures: Color, illuminated background,adjustable contrast, touch screenPneumatic ConnectionsCompressed air inlet: Stäubli NippleCompressed air outlet: Stäubli CouplingVent: Hose connection 8 mm outer diameterPneumatic SpecificationsMaximum gas supply pressure: 8000 mbar (116 psi)Minimum gas supply above test pressure (Standard):– Flow range: 0.01 - 150 mL/min 1000 mbar (14.5 psi)– Flow range: 150 - 1000 mL/min 2000 mbar (29.0 psi)Test pressure range: 50 - 6500 mbar (0.7 - 94 psi)Internal PrinterThermal printerPrinter resolution: 832 dots/lineLifetime of printout: 10 years dependingon storage conditionsPrinter Speed: 12 mm/sec (0.5 in./sec)printout with graphicPaper Width: 112 mm (4.4 in.)Paper roll diameter: 50 mm (1.9 in.)12External Printing FunctionVirtual printing to PDF or XMF file formatEnvironmental ConditionsSplash Proof: IP54Operating Temperature: 5 C to 50 CStorage temperature: -20 C to 70 CHumidity: 95% RH (no condensation)Operating SystemLinux (The source code which falls under the GNUGeneral Public License (GPL) is stored on the USBflash disk supplied with the instrument).

Palltronic Flowstar IV MUX ExtensionPhysical DimensionsWeight:– Palltronic Flowstar IV MUX extension (Master): 3.9 kg(8.6 lb)– Palltronic Flowstar IV MUX extension (Slave): 3.7 kg(8.2 lb)Width, height, depth: 218 mm x 146 mm x 285 mm(8.6 in. x 5.7 in. x 11.2 in.)Communication PortsMaster– Special CAN BUS port 1 for communication with slaveor Palltronic Flowstar IV instrumentSlave– Special BUS port 1 for communication with the PalltronicFlowstar IV instrument or the next slavePneumatic ConnectionsCompressed Air Inlet: Stäubli NippleCompressed Air Outlet: Stäubli CouplingVent: Hose ConnectionPneumatic SpecificationsMaximum gas supply pressure: 8000 mbar (116 psi)Test pressure range: 50 to 6000 mbar (0.7 to 87 psi)Environmental ConditionsSplash Proof: IP54Operating Temperature: 5 C to 50 CStorage Temperature: -20 C to 70 CHumidity: 95% RH (no condensation)– Special BUS port 2 for communication with next slaveor masterElectrical DataPalltronic Flowstar IV MUX System Master only– Voltage: automatically adjusted between 90 - 264 V AC– Input Frequency: 47 / 63 Hz– Power: typically 40 W– Fuse: 1 AMaster and Slave– Remote Vent Valve: 24 V DCTo see how Pall is helping enable a greener, safer and more sustainablefuture, visit www.pall.com/green.Visit us on the Web at www.pall.comE-mail us at biopharm@pall.comCorporate HeadquartersPort Washington, NY, USA 1.800.717.7255 toll free (USA) 1.516.484.5400 phonebiopharm@pall.com e-mailEuropean HeadquartersFribourg, Switzerland 41 (0)26 350 53 00 phoneLifeSciences.EU@pall.com e-mailAsia-Pacific HeadquartersSingapore 65 6389 6500 phonesgcustomerservice@pall.com e-mailInternational OfficesPall Corporation has offices and plants throughout the world in: Argentina, Australia, Austria,Belgium, Brazil, Canada, China, France, Germany, India, Indonesia, Ireland, Italy, Japan,Korea, Malaysia, New Zealand, Norway, Philippines, Poland, Russia, Singapore, SouthAfrica, Spain, Sweden, Switzerland, Taiwan, Thailand, United Kingdom, and Vietnam.Distributors in all major industrial areas of the world. To locate the Pall office or distributornearest you, visit www.pall.com/contact.The information provided in this literature was reviewed for accuracy at the time of publication. Product data may be subject to change without notice. For current information consultyour local Pall distributor or contact Pall directly. 2014, Pall Corporation. Pall,, and Palltronic are trademarks of Pall Corporation. indicates atrademark registered in the USA and TM indicates a common law trademark. ENABLING A GREENER FUTUREand Filtration. Separation. Solution. are service marks of Pall Corporation. Fieldbus is a trademark of theFieldbus Foundation. Stäubli is a trademark of Stäubli AG.1/14, PDF, GN13.5881USD2555a

control/automation options enable even greater flexibility. Developed in accordance with GAMP (Good Automated Manufacturing Practices) guidelines, and offering full compliance with 21 CFR Part 11, the Palltronic Flowstar IV instrument is supported by an extensive qualification documentation package, including guides for Installation