Transcription

Ymdinq global solutions to the world's most critical needsAbilene Christian UniversityNuclear Energy eXperfmental Testing LabACU Box 28208, Abilene, Texas 79699-8208acunextlab.o rgNE {TU.S. Nuclear Regulato ryCommiss ion ATTN:Documen t Control DeskWashing ton, DC 20555Subject: ubmltta l of the Abilene Christian University Quality Assurance Program DescriptionReferenc es:(1) Abilene Christian Universit y Regulato ry Engagem ent PlanDated 7/24/202 0Docket Number. 9990208 8ADAMS Accessio n Number. ML20241 A071Dear Ed Helvenston,Pursuant to Trtle 10 of the Code of Federal Regulations (CFR), Part 50, Section50.34(a)(7) (10 CFR 50.34(a)(7)), Nuclear Energy eXperimental Testing Laboratory(NEXT Lab) hereby submits the Quality Assurance Plan Description (QAPD) for NRCreview and approval.Enclosure 1 provides the QAPD of the Abilene Christian /University Quality Assuran ceProgram that complies with ANSI/ANS 15.8-1995 (R2005; R2013) "Quality AssuranceProgram Requirements for Research Reactors," (ANS-15.8) following the guidance inRegulatory Guide 2.5, Revision 1, "Quality Assurance Program Requirements forResearch and Test Reactors" (RG 2.5). An early NRC review and approval of thesequality concept s will result in a greater degree of regulatory certainty and will ensurethat the construction permit application review process can proceed in an efficient andtimely manner with alignment to the quality program.If there are any questions or a need for additional information, please contactDr. Rusty Towell at the address above, by telephone at (325) 674-2034, or by email atRusty.Towell@acu.edu.I declare under the penalty of perjury that the foregoing is true and correct. Executedon 03/18/2021.Very truly xours, Dr. Rusty Towell, Ph.D.Director of NEXT LabAttachment: Enclosure (1) NEXT Lab QAPDDate

Quality Assurance Program Description(NEXT Lab) QualityTitle: Abilene Christian University Nuclear Energy experimental Testing LaboratoryAbileneAssurance Program Descrip tion For Design, Licensing and Constru ction of theChristian Univers ity Molten Salt Research ReactorProgram Owner: Director of NEXT LabVersion NumberSafety-Re latedRevision ARevision Summary:Initial IssueEffective Date03-19-21

\Qoality Aasurance Program DcacripeionReactorFor Design JAcensing and Constructlon of tbe NEXTMolten Salt R.eaean:bQAPD-001-AQuality Assurance ProgramPolicy Statementry (NEXT Lab) shallAblJene Chrlst'lan University (ACU) and the Nuclear Energy eXperlmental Testlng LaboratoIn a manner that will emu re,design, procure, and operate the AO.I Molten Salt Research Reactor (MSRR)In oompllance 'With thethe health and safety of the pubUc and woricers. These acttvffles shaD be performedry CommissionRegulatoNuclearU.S.lerequirements of the U.S. Code of Federal Regulations, the apphcabrsgulatlons of the state of Texas andConstruc tion Permitand Faclflty Operating l.lcense, and applicable laws and.local governments.''(-Assurance ProgramThe ACU NEXT Lab Project Quality Assurance Program (OAP) Is comprised of the Qualltynts. Together theydocumenglmpl .DescrtptJon (QAPD} provided In this document and the associatedsystems, andes,structurrelatedprovide for control of NEXT Lab actMtles that affect the quality of safetyconfidence that 1Ucheadequatcomponents and Include an planned and systematic actMtJes necessary to provide"1sses wtll perform satlsfactorHy In service.'ls be achleved andThe OAPD Is the top-level poncy document that establishes the manner lr:i w h qualityof quality. Implement! eassurancandmentpresents the staff of NEXT Lab's ·overall philosophy regarding achievetlonaJ Interfacesorganlzathedefinedocuments assign more detailed responsibilities and requirements andInvolved In conducting actMtles within the scope of the QAP.g the authority to stop workNext Lab personnel have authority commensurate with their responslblfrty, includinbe exercised In accordance wlththat does not conform to estabnshed requirements. Thls stop work authortty mayestablished OAP as lmplemented In the NEXT Lab Quality PrQCedures.)Phil Schubert, Ed.D.DateRustyTowell, Ph.D.DateDirector of NEXT LabPresidentAbilene Ouistla n UniversityRevision ANEXT LabQuality Assurance Program Desatptlo n1Page 2 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-001-AVersion NumberEffective DateRevision A03/15/21Approved By:Rusty Towell, Ph.D.Director of NEXT'Lab. .DateDateifects Lead - Engineering, Construction and Technical Services. .,NEXT LabQualtty Assurance Program DescriptionRevlslonAPage 3 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-OOl;A,, Table of ContentsIntroduction . 61.1.1Scope . 6 '1.ZApplication .'. . 62. Qeslgn, Construction, and Modifications . 3Z.1Organization . 3Z.ZQUALITY ASSURAN ::E PROGRAM . . 7Z.3Design Control . 82.3.1:2.3.22.3.32.3.42.3.52.3.6Design Requirements . 8Design Process.·.:. 8Design Verification . 8Design Documents and Records .'. 9Commercial Grade Items . . 9Change Control .,. 9)Z.4Procurement Document Control . 10z.sProcedures, Instructions, and Drawings . ; . . ., . 11, Z.6Document Control . 12Z.7Control of Purchased Items and Services .·. 132.7.1Supplier Selection . : .: 132.7.22.7.3Work Control .:. 13Verification Activities . 132.7.4Item or Service Acceptance .:. 13Z.8Identification and Control of Items . 14Z.9Control of Special Processes ., . 15Z.10Inspection . 16Z.11Test Control .:.: . 17Z.12Control of Measuring and Test Equipment . . 18IZ.13Handling Storage and Shipping . 19Z.14Inspection, Test, and Operating Status . ! . ZOZ.15Control of Nonconforming Items . 21NEXT LabQualrty Assurance Program Description.\Revision APage 4 of 27

Quality Assurance Program Descriptio nFor Design, Licensing and Constructi on of the NEXT Lab Molten Salt Research ReactorQAPD-001-A2.16. 22Corrective Action .-.2.17. 23Quality Assurance Records . .2.18.Assessments/Audits .2. 1924. 25Experimental Equipment.-. :.Sectlo11 3. Facility Operations .Section 4i Applicability to Existing Facilities .26. 26·················Section 5. Decommissioning. . . . . . . . . ····· �············26. . 27Section 6. Reference Documents .! . . . ;.rNEXT LabQualrtyAssurance Program DescriptionRevision APage 5 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-001-A-1.Introduction1.1ScopeThe Abilene Christian University (ACU) Nuclear Energy eXperimenta l Testing Laboratory (NEXT Lab) QualityAssurance Program Document (QAPD) is the top-level policy document that establishes the Quality AssuranceProgram (QAP) and assigns major functional responsibilities for alf activities associated with the Molten SaltandResearch Reactor (MSRR) Project conducted by or for the NEXT Lab staff. The QAPD describes the methodsestablishes Quality Assurance (QA) and administrativ e control requirements that meet Title 10 of the Code ofFederal Regulations (CFR), Part 50, Section 50.34(a)(7) (10 CFR 50.34{a)(7)). ACU has determined that ANSI/At:JS15.8-1995 (R2005; R2013) "Quality'Assu rance Program Requirements for Research Reactors," (ANS-15.8) followingTestthe guidance In Regulatory Gulde 2.5, Revision 1, "Quality Assu rance Program Requirement s for Research andReactors" (RG 2.5) Is sufficient for use In developing the QAPD for the MSRR.1.2ApplicationThe QAP applied by ACU at the NEXT Lab to MSRR activities Is consistent with the Importance of activities affecting.safety and reliability. Activities included In the QAP are those affecting the q allty and performance of safetyrelated Structures, Systems, and Components (SSCs). The QAP applies to those activities and items which couldaffect the quality of SSCs of the MSRR and Its activities, lndudlng, but not limited InstallingInspectingTestingPre-Operatio nal e NEXT Lab QAP is Implemented In a graded approach process to ensure that the levf;!I of analysis,''(1)documentati on, and ap:lons used to comply with a requlreme t, defined in ANS 15.8, are commensura te with:lifethe relative importance to safety, safeguards, and security; (2) the magnitude of any hazard, involved; (3) thescycle stage of the MSRR facility; (4) the programmati c mission of the MSRR facility; (5) the particular characteristicof the MSRR facility; (6) the relative importance of radiological and non-radiolog ical hazards; and (7) the qualityNEXT LabQualrty Assurance Program DescriptionRevision APage 6 of 27,.-

Quality Assurance Program DescriptionFor Design, Licensmg and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-00,1-Alevels defined in the NEXT Lab implementing procedures. The QAP Implementation strategy supports the gradedapproach by considering the tangible and Intangible attributes of replacement costs, schedule delays and·MSRRfacility availability for research.The development and implementation of the MSRR facility QAP for NEXT Lab began during the design phase andwill continue through construction activities of the MSRR. The QAP focuses on-the development of appropriate\controls that ensure the MSRR is properly designed and fabricated to meet regulatory and universityrequirements. The majority of these controls provide documentation attesting to NEXT Lab quality to support theapplication for a construction permit. These design and construction program requirements are defined InSection 2 of this QAPD.NUREG-1537, HGuidelines fqr Preparing and Reviewing Applications for the Licensing of Non- Power Reactors/Section 12.9, "Quality Assurance, H recommends the applicant for licensure consider the guidance in RegulatoryGuide 2.5, "Quality Assurance Program Requirements for Research and Test Reactors" and ANSI/ANS 15.8, "Quality- Assurance Program Requirements for Research Reactors." As stated above, ACU's QAP follows Revision 1 ofRG 2.5. RG 2.5 states that the 1995 version of ANS-15.8 reaffirmed in 2005 provides an acceptable method ofcomplying with the program requirements of 10 CFR 50.34. ANS-15.8 was reaffirmed again In 2013. The NEXT LabQAP is consistent with this guidance and meets or exceeds the requirements of ANSI/ANS 15.8-1995 (R2005;R2013)./Guidance contained in RG 2.5 does not limit research reactor licensees from including useful guidance in theregulatory Information developed for power reactor licensees. As such, the NEXT Lab Quality Procedures (QPs)Iinclude additional layers of optional guidance in a manner consistent with ANS-15.8 and the relative Importance ofthe item or activity. Any optional guidance will be reviewed during the development of QPs to confirm it meetsthe guidance of ANS-15.8 and the QAP.The definitions provided in ANS-15.8-1995, Section 1.3, "Definitions," apply to terms as used in this document.NEXT LabQualrty Assurance Program DescrlptlonRevision A. Page 2 of 27

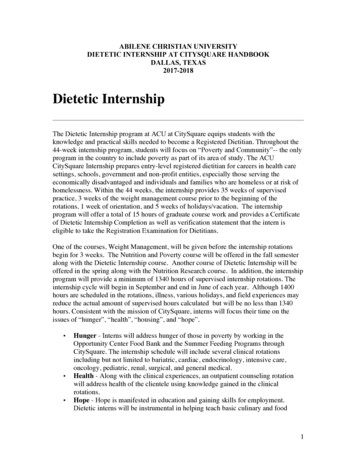

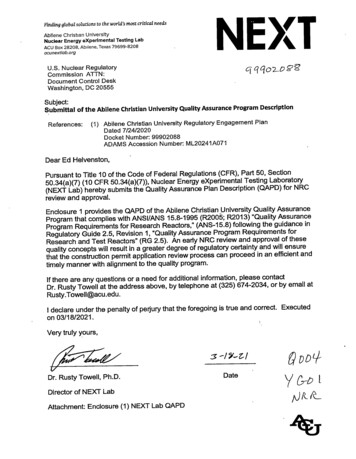

, Quality Assuran Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD--001-ADesign, Construction, and Modifications2.This Section provides requirements for establishing, managing, conducting, and assessing the program of controlsover the design, construction, and modification of the NEXT Lab MSRR. This QAPD recognizes that the describedcontrols are Integral to the management of a MSRR project or facility and do not cause the establishment of aseparate program. The QAP is established administratively by this QAPD and implemented by a series ofimplementing QPs, that are applicable to the specific sections of the QAPD and the scope of work activities.Organization2.1It is recognized that for most research reactor facilities, the owner/operator organization is small, with itspersonnel performing multiple functions. During the design, construction, or modification of a research reactor,most of the work may be performed by outside organizations or support contractors. The owner/operator's role isthen primarily one of providing requirements and verifying compliance with those requirements. The followingsections define and document the organizational structure and assignment of responsibilities of the NEXT Laborganization such that: (a) quality is achieved and maintained by those who have been assigned responsibility forperforming work; and (b) quality achievement is verified by persons not directly performing the work. NEXT Labstaff responsible for ensuring that appropriate controls have been estabhshed, and for verifying that activities havebeen correctly performed, need sufficient authority, access to work areas, and freedom to: (a) identify problems;(b) Initiate, recommend, or provide corrective action; and (c) ensure corrective action implementation.The MSRR NEXT Lab quality organization is shown below {Figure 1.1).1.President of ACUThe President of ACU is responsible for overall corporate policy of NEXT Lab and provides executive direction andguidance for the NEXT Lab activities as well as for the promulgation of ACU corporate policy through the Directorof NEXT Lab. Staff responsibility for developing, Implementing, and verifying execution of the NEXT Lab QAP isdelegated to the Director of NEXT Lab.\NEXT LabQuality Assurance Program DescriptionRevision APage 3 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEJCT Lab Molten Salt Research ReactorQAPD--001-ANuclear Research and Development Organization-2.ACU Vice President of Research This position reports to the President 9f ACU and is responsible for promulgating the university's visionand policies to promote and facilitate scholarship and research, strengthen external funding and strategicpartne,rshlps, and enhance the research Infrastructure.'Director of NEXT Lab This position reports to the President of ACU and coordination of the NEXT Lab university researchactivities are managed with the ACU Vice President ,of Research. This organizational relationship isreflected in th e NEXT Lab Organization Chart as an interdepende nt relationship. The Director of NEXT Lab as overall responsibility for the implementat ion of the NOO Lab QAPD and for NEXT Lab activitiesincludes setting andIncluding responsibility for overall MSRR nuclear safety. This responsibility,),',implementin g pollcles, objectives, and priorities to ensure activities are performed in accordance with the·,NEXT Lab QAP. Responsibility for implementin g the NEXT Lab QAP is delegated to the Director NEXT Labfrom the President of ACU.(3.Technical and Engineering ervlces Organization'.The Technical and Engineering Services organization Is responsible for support of NEXT Lab activities andthe MSRR nuclear development by providing engineering, licensing, project, and document controlsupport where applicable. Reactor Project LeadThe Reactor Project Lead reports to the President of ACU and the }\CU Vice President of Research throughthe Director of NEXT Lab and Is responsible for the administratio n and overall safe and efficient licensing,engineering, construction, and pre-operation al testing of the MSRR Nuclear Project, and for theImplementat ion of QA requirements in the areas specified by the QAP. This position is the interfacebetween the MSRR project and the Director of NEXT Lab.NEXT LabQuality Assurance Program Descr1ptlqnRevision APage 4 of 27

Quality Assurance Program DescnptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-001-AProject Manager The Project Manager reports to the Reactor Project Lead, is responsible for managing the overalllicensing, engineering, construction, andyre-oper atlonal testing of the MSRR Nuclear Project, and for theimplementat ion of QA requirements m the areas specified by the QAP.Engineering Manager The Engineering Manager reports to the Reactor Project Lead and is'responsible for the day-to-dayoversight of the engineering effort as the MSRR Is designed, constructed, and tested. This position Is alsoresponsible for the implementat ion of QA requirements in the areas specified by the QAP. Procurement ManagerThe Procurement Manager reports to the Reactor reject Lead and Is responsible to interface with nglneerlng and design support staff on all activities related to quality item procurement. This position Isresponsible for the day-to-day oversight of purchased items and services, including procurementdocument control, and coordinating with QA and engineering staff for the selection and approval ofvendors supporting NEXT Lab.4., ACU University Services OrganizationsThe ACU Services organizations are responsible for supporting the NEXT Lab organization throughperforming activities related to procurement, safety and health and Information technology whereapplicable.5.Quality Assurance OrganizationThe NEXT Lab QA Organization is responsible for Independently planning and performing activities to/verify the developmen t and effective implementation of the NEXT Lab QAP including but not limited tothe developmen t and verification of implementation of the QAP, oversight qf engineering, licensing,document control, corrective action program and procurement activities that support MSRR activities andprojects.NEXT LabQualrty Assurance Program DescrlptmnRevision APage 5 of 27

Quality Assurance Program DescriptionFor Design, Licensing and ConstructJ.on of the NEXT Lab Molten Salt Research ReactorQAPD-001-AQuality Assurance Manager The NEXT Lab Quality Assurance Manager (QAM) reports to the President of ACU and the Director ofNEXT Lab and Is responsible for the developmen t and verification of implementat ion of the QAPDdescribed in this document. Authority for developing and verifying exeq.1tlon of the QAP is delegated tothe NEXT Lab QAM by the NEXT Lab Director. The QAM Is responsible for verifying compliance withregulatory requirements and QPs through audits and technical reviews; for monitoring organization, processes to ensure confonnance to commitment s and licensing document requirements; and forverifying that vendors who provide services, parts, or materials to the MSRR project are meeting therequirements of the QAP. The QAM has sufficient independence from other NEXT Lab priorities to bringforward Issues affecting safety and quality and make judgments regarding quality in' all areas necessaryregarding NEXT Lab's nuclear developmen t activities. Quality Assurance AuthorityI 'StopWorkAli NEXT Lab personnel including QA and Inspection personnel have the authority and theresponsibility to stop work in progress which is not being done In accordance with approved NEXT LabQPs or where'safety-related SSC quality may be jeopardized. This extends to off-site work perfonnedby suppliers that furnish materials and services to NEXT Lab. Quality Assurance Organizational IndependenceFor construction, independence shall be maintained between the organization or organizationsperforming the checking (quality assurance and control) functions and the organizations perfonnlngthe functions. This provision Is not applicable to design review/verific ation.NEXT LabQuality Assurance Program DesaiptlonRevision APage 6 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD--001-A/Figure 1-1ACU NEXT Lab Quality Organization for Design Licensing and Construction,I.f- ; Nudear Research and Development. ,,ACU UNIVERSITY SERVICESACU Vice President of Research'-I,, -,.--Director of NEXT Lab.·. ,\-·-·-·-·CTechnical and Engineering ServicesNuclear Projects Lead;------:.- -- -!-Reporting - - - - ,.Project Manager2.2I.I,,,,Quality Assurance Manager-. - .,. -- - -- ·;.-. -Quality Assurance,IPresident of ACU. --,I:I Engineering Manager ICommunication - - - - -!Procurement ManagerSupport Services - - - -QUALITY ASSURANCE PROGRAMAs documented In this QAPD the NEXT Lab QAP shall be established in accordance with the requirements of thisQAPD, or portions thereof, at the earliest time consistent with the schedule for accomplishing quality-affectingactivities. This QAPD identifies the items and activities to which it applies and the extent of program applicationfor each item and activity. The program provides for the appropriate and necessary indoctrination and training ofNEXT Lab staff who perform activities that affect quailty, to ensure that suitable proficiency Is achieved andmaintained.NEXT LabQuality Assurance Program Descrlpt1onRev1s1on APage 7 of 27I

Quality Assurance Program DescriptionReactorFor Design, Licensing and Construction of the NEXT Lab Molten Salt ResearchQAPD-001-A2.3Design Controls the design of the SSCs of the MSRRNEXT Lab Design Engineering prescribes, develops, documents, and preservefacility subject to the aspects of the QAP.2.3.1Design Requirementsregulatory requirements,Applicable design Inputs, such as design bases, performance requirements,codes, and standards are Identifie d and documented.2.3.2Design Processbe coordinated among theDesign interfaces are identifie d and controlled, and,the design efforts willor previously proven designs, withNEXT Lab participating organizations. The applicability of standardizedon. Known problemsrespect to meeting pertinen t design inputs, shall be verified for each application other features, shall beaffecting the standardized or previously proven designs, and their effectsincluding the reasons for theconsidered. Deviations from the established and documented design Inputs,changes, shall be documented and controlled.in sufficien t detail to permitThe final design shall: (al be relatable to the design input by docume ntationcomponents that are part of thedesign traceabi lity and verificat ion; and {bl Identify assemblies and/orportions of the facility designItem being designed. When a compute r design program is used to developnted, validated, a nd controlle dor to analyze a design for acceptability, that program shall be fully documebe developed, the program shall beto ensure the correctness of its output. When a design program mustto previously validcontrolled to assure that It is fully documented and validated. Where changesfor the change. Verification ofcompute r programs are made, documented revalidation shall be requiredtesting.design-unique compute r programs shall include appropriate benchm ark2.3.3Design Verificationby one or more of theIndependent design reviews shall be used to verify the a-dequacy of designe calculations, {cl the perform ancefollowing: {al the performance of design reviews, {bl the use of alternatLab Engineering shall identifyof qualification tests, or {dl comparison to similar proven systems. NEXTverification shall be perform ed byand docume nt the design verificat ion method or methods used. Designdesign, but who may be from thequalified NEXT Lab staff or groups other than those who perform ed- the-NEXT LabQuality Assurance Program DescriptionRevision APage 8 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-001-Athe SSC orsame organization. In all cases the design verification shall be completed prior to reliance uponcomputer prog m to perform Its function.,IThe need for or the use of a qualification test shall be defined In a formal test plan that shall Includeappropriat e acceptance criteria and shall demonstrate the adequacy of performance under conditionsbythat simulate the most adverse design conditions. Test results shall be documente d and evaluatedNEXT Lab Design Engineering to assure that test requirements have been met.2.3.4 Design Documents and RecordsprocessDesign documents and records, which provide evidence that the design and design verificationare performed , shall be collected, stored, and kept for the life of the safety-related Item.2.3.5 Commercial Grade ItemsthatThe use of Commercial Grade Items (CGls) In safety-related application shall be reviewed to assurethis equipment can adequately perform its Intended function.toWhen a CGI, prior to its installation, is modified or selected by special inspection and/or testing componen trequirements that are more restrictive than the supplier's published product description, theofpart shall be represented as different from the CGI in a manner traceable to a documente d definitionthe difference.2.3.6Change ControlModificatio ns to MSRR facility SSCs or computer codes wlll be based on defined "as-exists" design.Changes to verified designs will be documented, justified, and subject to design control measuresthat thecommensurate with those applied to the original design. These measures shall include assurancedesign analyses for the SSCs or computer codes are still valid.change,Where significant design changes are necessary because of an incorrect design, or MSRR facilitythe design process and verification procedure shall be reviewed and modified as necessary.NEXT LabQuality Assurance Program DescriptionRevision APage 9 of 27

Quality Assurance Program DescriptionFor Design, Licensing and Construction of the NEXT Lab Molten Salt Research ReactorQAPD-001- A2.4Procurement Document Controlthat all Items orProcurement documents shall contain sufficient technical and quality requirements to ensurent documentsservices satisfy the needs of the NEXT Lab procureme nt document or specification. The procureme, review, orat all procureme nt levels shall Identify the documenta tion required to be submitted for informationprocureme ntapproval by the NEXT Lab QAM and Procurement Manager. At each level of a procureme nt, theor audit by thedocuments shall provide for access to the supplier's plant facilities and records, for InspectionAuditor qualifiedNEXT Lab assigned Quality Assurance Lead Auditor, the designated representative, or other LeadNEXT Labparties authorized and qualified by the NEXT Lab QAM. The procureme nt documents shali Includewith the items orrequirements for reporting and approving disposition of supplier nonconformances associatedsupply ofservices being procured. The procureme nt documents

Abilene Christian University Nuclear Energy eXperfmental Testing Lab ACU Box 28208, Abilene, Texas 79699-8208 acunextlab.org U.S. Nuclear Regulatory Commission ATTN: Document Control Desk Washington, DC 20555 Subject: NE {T ubmlttal of the Abilene Christian University Quality Assurance Program Description

![INDEX [library.hsutx.edu]](/img/23/index.jpg)