Transcription

JBS&G 55279-11737 Rev AL02 (Walsh Bay Environmental Audit Program) Rev A18 September 2018Environmental Audit Program - Walsh Bay Arts Precinct, Pier 2/3 and Wharf 4/5, Hickson Road,Walsh Bay, NSW1.IntroductionJBS&G Australia Pty Ltd (JBS&G) has been engaged by Richard Crookes Construction Pty Ltd (RCC, theclient) to undertake Environmental Compliance Auditing of the works being undertaken at the WalshBay Arts and Cultural Precinct located at Pier 2/3 and Wharf 4/5, Hickson Road, Walsh Bay, NSW (thesite).It is understood that, in accordance with the State Significant Development (SSD) developmentconsent for the site, independent environmental audits are required to be completed in line withAS/NZS ISO 19011-2014: Guidelines for Auditing Management Systems and that the audits must beconducted by a suitably qualified, experienced and independent team of experts. It is additionallyunderstood that an audit report is required which needs to: assess the environmental performanceof the development and the effect on the surrounding environment; assess whether thedevelopment is complying with the terms of consent; review the adequacy of any documents; andrecommend measures or actions to improve the environmental performance of the development.A draft Construction Environmental Management Plan (CEMP) has subsequently been prepared byRCC that details the required procedures to be implemented during construction works to ensurethe protection of the environment and the surrounding community. The CEMP further identifies thatthe following sub-plans are to be reviewed as part of the environmental auditing program: Community Communications Strategy; Construction Environmental Management Plan; Construction Noise and Vibration Management Plan; Construction Waste Management Plan; Hazardous Materials Management Plan; Construction Traffic and Pedestrian Management Plan; and Complaints and Enquiries Procedure and Management System.This correspondence details the Environmental Audit program to be undertaken as part of thereview of environmental procedures outlined in the CEMP to be implemented during constructionworks. It is noted that details of the Environmental Audit program could be subject to change,depending on amendments to the CEMP. JBS&GAustralia Pty Ltd www.jbsg.com.au ABN 62 100 220 479

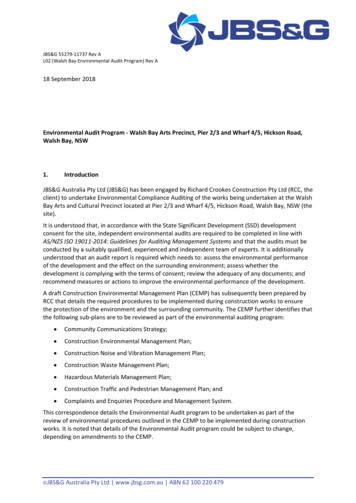

L02 (Walsh Bay Environmental Audit Program) Rev A2.Audit FrequencyIt is proposed to undertake a site inspection / audit of the site every 6 months to inspect RCC’senvironmental controls and ensure compliance with the site specific CEMP. Audits of documentationwill be undertaken during the audit to determine if any updates/amendments of the CEMP arerequired and to ensure implementation of any additional CEMP requirements.Within three months of commencing the Environmental Audit, or within another timeframe agreedby the Secretary, a copy of the audit report will be submitted (by RCC) to the Secretary, and anyother NSW agency that requests it, together with a response to any recommendations contained inthe audit report and a timetable for the implementation of the recommendations. Therecommendations must be implemented by RCC to the satisfaction of the Secretary. ‘3.Audit Compliance ChecklistA draft Audit compliance checklist has been provided in Attachment 2. The checklist is subject tochange following finalisation of the CEMP.4.ClosingShould you require clarification, please contact the undersigned on 02 8245 0300 or by emailcbielby@jbsg.com.au.Yours sincerely:Chris BielbySenior Environmental ConsultantJBS&G Australia Pty LtdLachlan WilkinsonCEnvP IA Specialist, PrincipalJBS&G Australia Pty LtdAttachments:(1) Limitations(2) Audit Compliance Checklist JBS&GAustralia Pty Ltd www.jbsg.com.au ABN 62 100 220 479

L02 (Walsh Bay Environmental Audit Program) Rev AAttachment 1– LimitationsThis report has been prepared for use by the client who has commissioned the works in accordancewith the project brief only, and has been based in part on information obtained from the client andother parties.The advice herein relates only to this project and all results conclusions and recommendations madeshould be reviewed by a competent person with experience in environmental investigations, beforebeing used for any other purpose.JBS&G accepts no liability for use or interpretation by any person or body other than the client whocommissioned the works. This report should not be reproduced without prior approval by the client,or amended in any way without prior approval by JBS&G, and should not be relied upon by otherparties, who should make their own enquires.Sampling and chemical analysis of environmental media is based on appropriate guidancedocuments made and approved by the relevant regulatory authorities. Conclusions arising from thereview and assessment of environmental data are based on the sampling and analysis consideredappropriate based on the regulatory requirements.Limited sampling and laboratory analyses were undertaken as part of the investigations undertaken,as described herein. Ground conditions between sampling locations and media may vary, and thisshould be considered when extrapolating between sampling points. Chemical analytes are based onthe information detailed in the site history. Further chemicals or categories of chemicals may existat the site, which were not identified in the site history and which may not be expected at the site.Changes to the subsurface conditions may occur subsequent to the investigations described herein,through natural processes or through the intentional or accidental addition of contaminants. Theconclusions and recommendations reached in this report are based on the information obtained atthe time of the investigations.This report does not provide a complete assessment of the environmental status of the site, and it islimited to the scope defined herein. Should information become available regarding conditions atthe site including previously unknown sources of contamination, JBS&G reserves the right to reviewthe report in the context of the additional information. JBS&GAustralia Pty Ltd www.jbsg.com.au ABN 62 100 220 479

L02 (Walsh Bay Environmental Audit Program) Rev AAttachment 2 – Environmental Audit Checklist JBS&GAustralia Pty Ltd www.jbsg.com.au ABN 62 100 220 479

Ref.No.1Requirement (DA/EIS/other)Is the development generally inaccordance with the CEMP?2Is the Environmental Policy displayedat the project/site office andinduction sheds?General Duty of Care3Is there any evidence on the site thatRCC has taken all practicablemeasures to prevent or minimizeharm to the environment?4Are processes in place to ensurecontractors and sub-contractors areaware of, and comply with, theconditions of consent and otherrelevant approvals?Site induction and Education5Was evidence of site inductions,training of site personnel, noticeboards, site inspections, prestartmeetings, subcontractor meetingsand team meetings identified?6Have Site Induction Record Formsbeen completed?Community Communications Strategy7Is a current CommunityCommunications Strategy in place forthe project?8Are records of complaints and actiontaken maintained and reported tothe Project Director, and ifapplicable, relevant authorities?9Have complaints been addressed in areasonable period?Noise and Vibration10Is a current Noise and VibrationManagement Plan in place for theproject?11Were works that generate highvolumes of noise scheduled for a lesssensitive time?12Was all plant not in use throttleddown or shut down when not in use?13Are vehicles and mobile plant fittedwith a non-tonal reversing ations/SupportingDocumentationAction (A) address non-compliancesRecommendations (R) address observations

Ref.No.14Requirement (DA/EIS/other)23Are all roads surrounding the accessand egress from the site free of dustand mud?Are all vehicles transporting spoil onsite covered?Do records demonstrate thecommunity has been informed inrelation to noise intensive activitiesin the immediate area?15Has Council approval been obtainedfor any construction activities outsideEPA specified daytime constructionhours?16Has an investigation of any noisecomplaints been carried out and thecomplaint satisfactorily resolved?17Has noise monitoring beenundertaken in accordance with thenoise and vibration managementplan?18Has there been any exceedances ofthe permissible noise levels asdocumented in the Plan? If so, isthere evidence of appropriatemitigation measures beenimplemented?19Are the works areas, vehicle andplant parking areas and equipmentstorage areas in locations wherepotential noise/vibrations impactswill be minimized?Traffic and Access20Is a current Traffic Management Planin place for the project?21Do records demonstrate thesurrounding land owner have beennotified of the works?22Are vehicles using designated accessroads?2425Is there a dedicated vehicle washdown tions/SupportingDocumentationAction (A) address non-compliancesRecommendations (R) address observations

Ref.No.26Requirement (DA/EIS/other)29Is there evidence that newly exposedsurfaces are stabilised as soon aspossible?Are all fuels and hazardous liquidsbeing stored in designated area?Are all chemicals being stored andused in accordance with the relevantMSDS?Is there an emergency spill kit on thesite?If applicable, has a dilapidationreport been prepared for roads,kerbs, gutters and footpaths?Soil, Erosion and Water Quality27Is construction in accordance withthe Erosion and Sediment ControlPlan?28Are all erosion and sediment controldevices properly installed andmaintained?30313233Are all existing storm water pits anddrains around the site silt protectedwith geo-fabric and/or granularsocks?34Are sediment fences installed atrequired locations around theperimeter of the site?Archaeology and Cultural Heritage35Have any archaeological or culturallysignificant items been documentedand reported to the relevantauthority?Hazardous Materials and Site Contamination36Has a Soil Contamination Assessmentbeen undertaken on BIM 360?37Has any contaminated/hazardousmaterial been identified on site? Ifso, has it been tested by a suitablyqualified environmental consultant?38If a risk from contaminated materialwas identified, was the rvations/SupportingDocumentationAction (A) address non-compliancesRecommendations (R) address observations

Ref.No.Requirement (DA/EIS/other)removed from site to an EPAapproved landfill site (Subject toClient Approval)?Waste Management39Was waste on site placed in correctbins provided?40Are the waste collection pointsnominated on the site layout plan?41Are the company’s waste reductionobjectives being achieved?42Have records been maintained oftransport of waste and delivery to awaste facility?Environmental Complaints43Are records of complaints and actiontaken maintained and reported tothe Site Manger and if relevant,appropriate authorities?44Have complaints been addressed in areasonable period?Environmental Incidents and Emergencies45Have any environmental incidents oremergencies been investigated andpreventative measures put in placeto ensure they do not occur again?Additionally, have they beendocumented, reported to therelevant authority?Environmental Monitoring46Have environmental site inspectionsbeen undertaken at a frequencylisted in the Site Task Checklist?Were any non-conformancesappropriately rvations/SupportingDocumentationAction (A) address non-compliancesRecommendations (R) address observations

the audit report and a timetable for the implementation of the recommendations. The recommendations must be implemented by RCC to the satisfaction of the Secretary. ' 3. Audit Compliance Checklist A draft Audit compliance checklist has been provided in Attachment 2. The checklist is subject to change following finalisation of the CEMP. 4. Closing