Transcription

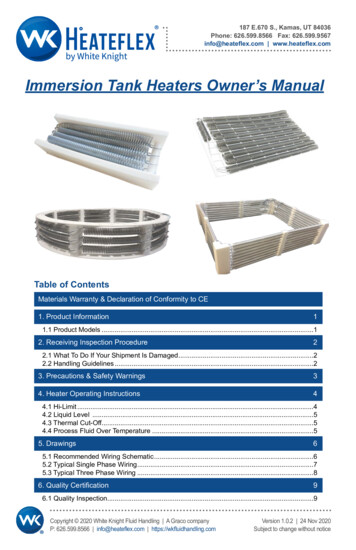

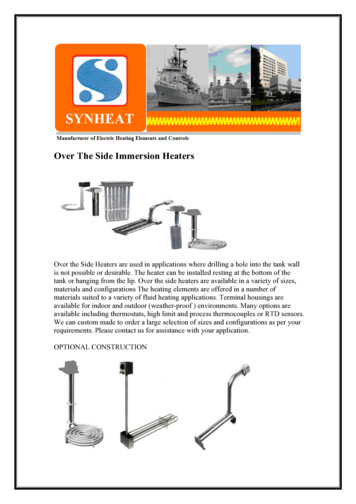

Over The Side Immersion HeatersOver the Side Heaters are used in applications where drilling a hole into the tank wallis not possible or desirable. The heater can be installed resting at the bottom of thetank or hanging from the lip. Over the side heaters are available in a variety of sizes,materials and configurations The heating elements are offered in a number ofmaterials suited to a variety of fluid heating applications. Terminal housings areavailable for indoor and outdoor (weather-proof ) environments. Many options areavailable including thermostats, high limit and process thermocouples or RTD sensors.We can custom made to order a large selection of sizes and configurations as per yourrequirements. Please contact us for assistance with your application.OPTIONAL CONSTRUCTION

Single ElementDesign L-ShapeImmersion TeflonHeaterSingle TubeVerticalImmersion Heater3 Element Design LShape TubularImmersion Heater3 Tube VerticalImmersion HeaterOver The Side Semi-BandTubular Immersion HeaterSingle Tube L-ShapeImmersion HeaterL-Shape 3 Tube HorizontalImmersion Heater6 Element Vertical TeflonImmersion HeaterSpiral Coil VerticalTeflon ImmersionHeaterOver the side immersion heaterOver the side ceramic immersion heaters are mainly used for heating of chemicalbaths an liquids in different types of vessels.Over the side ceramic immersion heaters consist of ceramic elements mounted intubes of porcelain, acid-proof steel, steel, titanium or quartz glass. The heater has aoptional terminal box of protection class IP55 and supply cord.

As an alternative, over the side immersion heaters can be made of tubular heatingelements in acid-proof steel and an adjustable thermostat.Application fields: Different types of bathsElectrical water heaterStandard product rangeTube from steel stainlessNon-Heating Zone 150 mm. Diameter 2”1500 mm with flexible connection cable.Power WVoltage V100020003000400050006000900012000240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415Insertionlength mm280430590740900102013801750

Three Tube from stainless steelNon-Heating Zone 150 mm. Diameter 2”1500 mm with flexible connection cablePower WVoltage V30006000900012000150001800024000240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415Insertionlength mm280430590740900102012003 Element Stainless Steel Immersion HeatersNon-Heating Zone 150 mm. Diameter 11.2mm1500 mm with flexible connection cable.Power WVoltage V100020003000400050006000900012000240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415Insertionlength mm30037045053062072010001300

6 Element Stainless Steel Immersion HeatersNon-Heating Zone 150 mm. Diameter 2”1500 mm with flexible connection cable.Power WVoltage V3000600090001200015000180002400027000240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415Insertionlength mm3004305807308801000126014503 Element Teflon Insulated Immersion HeatersNon-Heating Zone 150 mm. Diameter 13mm1500 mm with flexible connection cable.Power W300060007500Voltage V240 or 415240 or 415240 or 415Insertion-length mm100020002200

6 Element Teflon Insulated Immersion HeatersNon-Heating Zone 150 mm. Diameter 13mm1500 mm with flexible connection cablePower WVoltage V300060009000120001500018000240 or 415240 or 415240 or 415240 or 415240 or 415240 or 415Insertionlength mm6009001280160018502200Determining Specific Heating Requirements for Electric HeatersTo determine the heating requirement of a tank, first obtain the following information:1. Total cubic feet of tank. (Multiply the inside dimensions of the tank - depth xwidth x length.)2. Total gallons of solution. (Multiply by 7.48 the cubic feet of the tankoccupied by the solution. If the solution is normally 6" below the top of thetank, allow this when figuring.)3. Average ambient (room) temperature at which the tank will be used.4. Temperature level at which the solution is to be held.5. Heat up time desired.After this information is known, the following calculations can be made:Formula: A x 1.0* x 8.35** x B K3412 x CDxE W* Specific heat of water. Insert specific heat of your solution here.**Weight of water. Insert specific weight of your solution here.A Total gallons of solution.B Difference between ambient temperature and desired solution temperature.

C Desired heat-up time (hours).D Heat loss of tank - refer to the chart below.E Square feet of top of tank (multiply length x width).Add the results of both calculations. The total is the Kilowatt requirement of the tank.K W KWSample ProblemTank Specifications: Dimensions: 4' deep x 3' wide x 5' long or 448 gallonsOperating Temperature: 160 Heat-Up Time: 6 hoursAssume tank heat-up to be from room temperature (70 F to 160 F).Initial Heat-Up Formula Application448 gallons x 1.0 x 8.35 x 90336672 16KW3412 x 6 hours20472Surface Loss Calculation:15 sq. ft. (surface area) x .34 (open tank surface loss factor) 5KWTotal KW needed 16KW 5KW 21KW

IMMERSION HEATER SOLUTION GUIDESOLUTION TYPE OF HEATERAcetic . PTFE* or QuartzActane 70, 80 . PTFE*Actane Salt . PTFE*Acid Sulfate . PTFE* or QuartzAlcorite . PTFE* or QuartzAlkaline Cleaners (Electrified). 304 St. SteelAlkaline Soaking Cleaners . 304 St. SteelAlodine (most formulas) . 316 St. SteelAlstan . 304 St. SteelAluminum Bright Dip . PTFE* or QuartzAluminum Cleaners . 304 St. SteelAluminum Chloride . PTFE* or QuartzAluminum Sulfate . 304 St. SteelAmmonia . 304 St. SteelAmmonia Persulfate . PTFE* or QuartzAmmonium Bi Fluoride. PTFE*Ammonium Chloride . TitaniumAmmonium Nitrate . 316 St. SteelAnodizing (Aluminum) .PTFE* or QuartzARP 28, 80 Blackening Salts. PTFE* or QuartzArsenic . 304 St. SteelBarium Chloride . Quartz or TitaniumBenzoic Acid . TitaniumBlack Nickel . PTFE* or QuartzBlack Oxide (Hi-Temp) . 304 St. SteelBlack Oxide (Low-Temp) . TitaniumBonderizing . 316 St. SteelBoric Acid . TitaniumBrass Cyanide . 304 St. SteelBright Nickel . PTFE*, Quartz, TitaniumBright Copper Cyanide . 304 St. SteelBronze . 304 St. SteelBrown Oxide . TitaniumBurnite . PTFE* or QuartzButyric Acid . TitaniumCadmium Black . PTFE* or QuartzCadmium (Alkaline) . 304 St. SteelCadmium Fluoborate . PTFE*Calcium Chloride . TitaniumCalcium Hypochlorite . TitaniumCarbonic Acid . TitaniumCaustic Etch . SteelCaustics . SteelCaustics (highly concentrated 20%and over). SteelChlorine/Wet . PTFE* or QuartzChloride . PTFE*, Quartz or Titanium

Chlorosulfuric Acid . TitaniumChromic Anodizing . PTFE* or QuartzChromic Acetate . PTFE* or QuartzChromic Nickel . PTFE* or QuartzChromium(No Fluorides) PTFE*,Quartz,TitaniumChromium (Fluoride) . PTFE*Citric Acid . TitaniumClear Chromate . PTFE* or QuartzCobalt Nickel . PTFE*, Quartz, TitaniumCobalt Plating . 304 St. SteelCobra Etch . PTFE*Copper Acid . PTFE* or QuartzSOLUTION TYPE OF HEATERCopper Bright Acid . PTFE* or QuartzCopper Cyanide . 304 St. SteelCopper Fluoborate . PTFE*Copper Pyrophosphate . 304 St. SteelCopper Strike . 304 St. SteelCopper Sulfate . PTFE* or QuartzCyanide . 304 St. SteelDeionized Water . 316 St. Steel or TitaniumDeoxidizer (Etching) . QuartzDeoxidizer Non-Chromated . 316 St. SteelDichromic Seal .316 St. SteelDiethylene Glycol . 304 St. SteelDiversey, 511, 514 . PTFE*Dow Therm . 316 St. SteelDye Solutions . 304 St. SteelEbonal C . TitaniumElectroless Copper . PTFE*Electroless Nickel . PTFE* or TitaniumElectroless Tin (Acid) . PTFE* or QuartzElectroless Tin (Alkaline) . 316 St. SteelElectro Cleaner . 304 St. SteelElectro Polishing . PTFE* or QuartzEnthone 80 Acid . PTFE*Ethylene Glycol . SteelFerric Nitrate . 304 St. SteelFerric Sulfate . 304 St. SteelFerric Ammonium Oxide . 316 St. SteelFerric Chloride . PTFE*, Quartz, TitaniumFluborate . PTFE*Formic Acid . 316 St. SteelGlycerol . 304 St. SteelImmersion Gold . 304 St. SteelGold-Acid . PTFE*, Quartz, TitaniumGold Cyanide . 304 St. SteelGrey Nickel . PTFE*, Quartz, TitaniumHot Seal Dichromate . 316 St. SteelHydrogen Peroxide . PTFE* or Quartz

Hydrochloric Acid . PTFE* or QuartzHydrofluoric Acid . PTFE*Indium . PTFE* or QuartzIridite (4-75,4-73,14,14-2,14-9). 316 St. SteelIridite (1,2,3,4-C,7,8,15) . PTFE* or QuartzIron Fluoborate . PTFE*Iron Phosphate . 316 St. SteelIsoprep (186,187,188) . 316 St. SteelIsoprep Acid Salts . PTFE*Jetal . 304 St. SteelLead Acetate . 304 St. SteelLime Saturated Water (Alkaline) . 316 St. SteelLinseed Oil . 304 St. SteelMagnesium Hydroxide . 304 St. SteelMagnesium Nitrate . PTFE* or QuartzManganese Phosphate . 316 St. SteelMcDermid 629 . PTFE*Mercuric Chloride . TitaniumMuriatic Acid . PTFE* or QuartzNickel (Plating Solution)(Watts) . PTFE*, Quartz, TitaniumNickel Acetate Seal . 316 St. SteelNickel Chloride . TitaniumSOLUTION TYPE OF HEATERNitric Acid . PTFE* or QuartzNitric Hydrochloric Acids . PTFE* or QuartzNitric Phosphoric . QuartzOil . SteelOleic Acid . PTFE* or QuartzPaint Stripper (Alkaline) . 304 St. SteelPerchlorethylene . 316 St. SteelPhosphoric Acid (No Fluoride) . PTFE* or QuartzPhosphate Cleaner . 304 St. SteelPhosphate . 316 St. SteelPotassium Acid Sulfate . PTFE* or QuartzPotassium Cyanide . 304 St. SteelPotassium Hydroxide . 304 St. SteelPotassium Hydrochloric . PTFE* or QuartzPotassium Permanganate . PTFE* or TitaniumRhodium . PTFE* or QuartzRochelle Salt Cyanide . 304 St. SteelRuthenium . PTFE* or QuartzSalt (Actine) . PTFE*Sea Water . TitaniumSilver Bromide . 316 St. SteelSilver Cyanide . 304 St. SteelSilver Lume . 304 St. SteelSilver Nitrate . 316 St. SteelSodium Bisulfate . PTFE* or QuartzSodium Carbonate . Titanium

Sodium Chlorate . TitaniumSodium Chloride . TitaniumSodium Cyanide . 304 St. SteelSodium Dichromate (Hot Seal) . 316 St. SteelSodium Hydroxide . SteelSodium Hypochlorite . PTFE*Sodium Persulfate . PTFE* or QuartzStannate . SteelStanostar . PTFE* or QuartzStearic Acid . QuartzSulfamate Nickel . PTFE*, Quartz, TitaniumSulfur . PTFE* or QuartzSulfuric Acid . PTFE* or QuartzSulfur Peroxide . PTFE* or QuartzSulphamic Acid . PTFE* or QuartzTannic Acid . TitaniumTin Nickel . PTFE*Tin Plating (Acid)(Stanus/Sulphate) . PTFE* or QuartzTin Plating Acid (Fluborate) . PTFE*Tin Plating (Alkaline) . 304 St. SteelTrichlorethylene . 316 St. SteelTrioxide (Pickle) . PTFE* or QuartzTurco (4181, 4338) . 316 St. SteelUnichrome . PTFE* or QuartzWater . 316 St. Steel or QuartzWood’s Nickel Strike . Titanium, PTFE*,QuartzYellow Dichromate . PTFE* or QuartzZinc Acid . PTFE* or TitaniumZinc Ammonium Chloride. Quartz or TitaniumZinc Cyanide . 304 St. SteelZinc Phosphate . 316 St. SteelZinc Phosphate (Fluoride) . PTFEZincate . 304 St. SteelTHE DATA LISTED IS PROVIDED GRATIS AND IS OFFERED AS A GUIDE ONLY.IT IS NOT INTENDED TO BE USED AS THE SOLE BASIS OFDESIGN OR TO ESTABLISH SPECIFICATION LIMITS. WE ASSUMES NOOBLIGATION OR LIABILITY FOR ANY ADVICEFURNISHED BY IT OR FOR RESULTS OBTAINED FROM USE. DUE TO THECOMPLEXITIES OF SOLUTIONS AND APPLICATIONS. CUSTOMERSMUST CONTACT THEIR CHEMICAL SUPPLIER FOR HEATER MATERIALCOMPATIBILITY AND RECOMMENDATIONS. FOR APPLICATIONSINVOLVING SOLUTION CONCENTRATIONS EXCEEDING 50%, CONSULTFACTORY FOR WATT DENSITY RECOMMENDATIONS

Over the side immersion heater Over the side ceramic immersion heaters are mainly used for heating of chemical baths an liquids in different types of vessels. Over the side ceramic immersion heaters consist of ceramic elements mounted in tubes of porcelain, acid-proof steel, steel, titanium or quartz glass. The heater has a