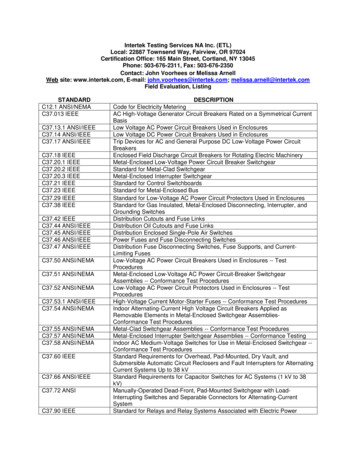

Transcription

ImmersionFlanged immersion heatersOverviewFlanged Immersion Heaters consist of hairpinbent tubular elements welded or brazed intoa flange and provided with wiring boxes forelectrical connections. Flange heaters are installed by bolting to a matching flange weldedto the tank wall or nozzle. A wide selection offlange sizes, kilowatt ratings, voltages, terminal enclosures and sheath materials makethese heaters ideal for all types of heatingapplications.ApplicationsFlanged immersion heaters are one of themost widely used methods for heating gasesand liquids (such as water, oil, heat transferfluid and corrosive solutions). Designed foruse in tanks and pressurized vessels, they areeasy to install and maintain to provide heatfor many processes. The direct immersionmethod is energy efficient and easily monitored and controlled.PED Hot Water Storage Tanks Warming Equipment Preheating All Grades of Oil Food Processing Equipment Cleaning and Rinsing Tanks Heat Transfer Systems Process Air EquipmentTypical Applications Boiler Equipment Freeze Protection of Any FluidFlange heaters mounted on each end of hotwater storage tank or for an efficient showersystem.Flange heaters in tank of water to heat innertank of viscous materials.ThermostatControlFlange heaters mounted angularly around tank bottom permitting free vertical work area.B-86

ImmersionFlanged immersion heatersApplication & SelectionGuidelinesThe selection of the proper FlangedImmersion Heater requires critical engineering judgement. After determining the heatrequirement (see the applications sectionof this catalog), the proper selection of theflange material, heating element sheath material and correct watt density is critical for longlife of a heater. The following table may beused as a guide to this selection along withthe Technical Information at the back of thiscatalog. Ultimate choice is determined by theknowledge of the process and engineeringacumen of the plant engineer.Heater application is influenced by the following parameters.1 The heated medium viscosity, specific heatdensity and corrosive properties.2Contaminants present in the medium.3 The heater sheath material corrosionresistant properties.4 Watt density of the heating element — theheat output per square inch.5Maximum sheath temperature — this isthe recommended maximum sheathtemperature of the element material. It isnot the operating temperature of theheated medium (sheath temperature isdependent on items 1 thru 4).Application Selection — Guidelines2Corrosive &High ViscousSolutionsSpecialty WaterOilOil ReservoirAir, Gases &SteamSee Selection Guidelines below for your application. Hot Water Storage Tanks Warming Equipment Preheating All Grades of Oil Food Processing Equipment Cleaning and Rinsing Tanks Heat Transfer Systems Process Air Equipment Boiler Equipment Freeze Protection of Any Fluid345SheathMaterialCopperWatt Density(W/In2)45Max. RecommendedSheath Temp.( F)350Stainless Steel14512004516004516005 - 15%INCOLOYINCOLOY w/Stainless FlangeStainless Steel123120010 - 25%INCOLOY 23120030 - 60%INCOLOY w/Stainless Flange151600TreatedINCOLOY , Copper—1600Low Viscosity OilMedium Viscosity OilHigh Viscosity tion Oil—1ApplicationWater & VeryMild SolutionsApplicationsSolution orHeater TypeClean WaterProcess WaterVery Weak solutionsWeak SolutionsDemineralized,De-ionized or pure waterMild Corrosive SolutionMore Severe CorrosiveSolutionSevere CorrosiveSolutionSteam BoilersAlkaline orAcid Content(Est. % by Volume)pH6 to pH8 NeutralpH5 to pH92 - 3%5 - 6%—Low TemperatureHigh Temperature Steel15750Stainless SteelINCOLOY 2323120016001. Passivated stainless steel recommended for water.B-87flangedSelection Guidelines

ImmersionFlanged Immersion HeatersSelection GuidelinesFlanged Immersion Heaters — Selection GuidelinesApplicationClean WaterProcess WaterSolution WaterMildly CorrosiveSolutionCorrosive Solution& GasSeverely CorrosiveSolutionDemineralizedor De-ionized WaterLight Weight OilMedium Weight OilHeavy Weight OilBoiler & WaterFood 3568101214356353568101214356352-1/2 Sq.2-1/2 Sq.4-1/2 Sq.3-1/4 pperCopperSSSSSSSSINCOLOY INCOLOY INCOLOY INCOLOY SSSSSSSSINCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY INCOLOY SteelSteelCopperINCOLOY -109B-109B-109B-111B-111B-112B-112B-112B-113B-114

ImmersionFlanged immersion heatersTechnical & Application DataThese thru-the-side immersion heaters utilizestandard pipe flanges ranging from 3 to 14"nominal pipe diameter to support high tankpressures of superheated steam, compressedgases or liquids. They are installed through amatching companion flange (obtainable fromlocal industrial supply houses) to the tankwall. A wide selection of watt densities, heating outputs and flange sizes and ratings makethis an excellent heater for all tanks, vats orirregularly shaped vessels. Rating — 300, 400, 600, 900, 1,500 and2,500 lb. pressure class.features — stock unitsImmersion Lengths up to 240 inchesElementStand-off Terminal Enclosures to isolate terminal housing from flange in high temperatureapplications Materials — Copper, steel, 304 stainlesssteel, INCOLOY . Number Elements in Flanges — 3, 6, 12,18, 27, 36 and 45. Element Diameter — 0.475". Watt Density — 6.5, 15, 23, 45 and 75 W/In2.Flange Material — Carbon steel, stainless steel. Rating — 150 lb. pressure class per ANSIB16.5 Sizes — 3, 5, 6, 8, 10, 12 and 14", 150 lb. Size — 16, 18" and larger.Optional FeaturesASME Section I, III, IV and VIII designed andcertifiedBaffles to distribute flow on elementsPassivation of stainless steelStock Status & AvailabilityS — Stocked in finished formAS — Assembly Stock. Items put togetherusing major stocked subassemblies requiringthree day shipping lead timeNS — Non Stock (made to order). Contactyour Local Chromalox Sales office for deliveryTerminal EnclosuresType E1 General Purpose, sheet metal(NEMA 1) painted with red enamel Materials — Copper, carbon steel, stainlesssteel, INCOLOY .Type E2 Combination Moisture Resistant,Explosion Resistant enclosures involve theuse of wiring enclosures for use in hazardouslocation conditions. 1/2" diameter.Type E4 Moisture ResistantSpecial FeaturesSafe operation of heaters equipped with theseenclosures depends on employment of electrical wiring meeting the National Electrical Codeand/or IEC for hazardous locations and limiting maximum operating temperatures (including temperatures on outside of vessel, piping,flanges, screw plugs, enclosures and otherheat conducting parts) as dictated by flammable liquids, vapors or gases present. Approvedpressure and/or temperature limiting controlsmust be used to assure safe operation in theevent of a system malfunction.Process Control ThermowellKilowatt Ratings — 500 kW and aboveavailable.Element Materials — 316, 321, 347 stainless steel,INCONEL and more.Flange Materials — 316, 321, 347 stainlesssteel, INCONEL , INCOLOY and more.Temperature Controls A thermostat protective well is standard onmost models. This well is installed throughthe flange, parallel with the heating elements. An AR type on-off mechanical controlcan be externally mounted to the heaterwith the capillary bulb installed in this well(order separately — see Controls section fordetails). A contactor is needed when the line voltageand/or current exceeds the thermostat rating. Other types of controls and sensors areavailable where a high degree of accuracy ora more versatile control scheme is required.Electronic controls and complete controlpanels are easily installed. See the Controlssection for details.Corrosion PolicyChromalox cannot warrant any electric immersion heater against failure by sheath corrosion if such failure is the result of operatingconditions beyond the control of the heatermanufacturer. It is the responsibility of thepurchaser to make the ultimate choice ofsheath material based on their knowledge ofthe chemical composition of the corrosivesolution, character of materials entering thesolution, and controls which he maintains onthe process.B-89flangeddescription

ImmersionFlanged immersion heatersTechnical & Application DataATEX/IECEx/CSA Zone Classification Selection chart for terminal enclosurestandoff dimension based on 30 C rise over 40 C ambient70 C Cable SupplyTemperature CodeWet Face Temperature: FWet Face Temperature: 00215230260280300450Vertical Heater OrientationHorizontal Heater OrientationMinimum Standoff 2299229922910.526710.526710.526713.5343Minimum Standoff 152615261527.51919229ATEX/IECEx/CSA Zone Classification Selection chart for terminal enclosurestandoff dimension based on 10 C rise over 60 C ambient70 C Cable SupplyTemperature CodeWet Face Temperature: FWet Face Temperature: 00215230260280300450Vertical Heater OrientationHorizontal Heater OrientationMinimum Standoff .534315381153811538116.5419184571845724610Minimum Standoff 229922910.526710.526710.526710.526710.526712305CSA Class and Division Classification Selection chart for terminal enclosurestandoff dimension based on 85 C rise over 40 C ambient125 C Cable SupplyTemperature CodeWet Face Temperature: FWet Face Temperature: 00215230260280300450B-90Vertical Heater OrientationHorizontal Heater OrientationMinimum Standoff 2615261527.5191Minimum Standoff 1026152

ImmersionFlanged immersion heatersTerminal EnclosuresEnclosure Styles and Dimensions (Inches)Dimple for locatingchassis punchedconduit vice EntrancePlateE1 — General Purpose, for up to 5" FlangeDimple for locatingchassis punchedconduit opening(s)E1 — General Purpose, for 6" and Larger Flange26710-1/2"1" Conduit Outlet3-3/4"RemovableService EntrancePlate1-1/2"5E4 — Moisture Resistant Enclosure with Gasket 6" and LargerE4 — Moisture Resistant Enclosure with Gasket up to 5" Flange1" Conduit Outlet3-3/4"ConduitHub1-1/2"5E2 — Explosion Resistant Enclosure up to 5" FlangeE2 — Explosion Resistant Enclosure for 6" and Larger FlangeB-91

ImmersionFlanged immersion heatersTerminal EnclosuresThird Party Specifications by Housing StyleModelE1North AmericanDesignation(s)PurposeGeneral PurposeGeneric NEMA 1, NECAgency (s) UL/CSAusRatings General Duty OnlyE4*E2Moisture ResistantGenericNote: Temps overAgency (s)T3 (200 C) requirestandoffs for thirdRatingsparty listing. Referto IECex & ATEXcertifs. for standoffdimensionsMoisture Resistant/GenericExplosion ProofAgency (s)Ex de IIB H2 T1 toRatingsT6, 540 C, 600 CNote: Temps overT4 (135 C) requirestandoffs for thirdparty listing. Referto IECex & ATEXcertifs. for standoffdimensionsE5Moisture Resistant/GenericFlange Explosion ProofAgency (s)Size Ex de IIC T1 to T63"-8" 540 C, 600 CRatings8"-12" ATEX IIC Labeling12"-18" ReferenceCFP, CFP2, CFP4,CFP8, CFP12,CFP20Refer to EuropeanCatalog.CanadianDesignation(s)NEMA 1 IP32CSAGeneral Duty OnlyNEMA 4UL / CSAusNEMA 4CSAClass I Div. 2,Groups B, C, DGroups E, F: 200 C(T3)Group G 165 C (T3B)Class I Zone 2 AEx nA IIT1 to T6CSAusClass I Div. 2,Groups B, C, DClass II Division 2,Groups E, F: 200 C(T3)Group G 165 C (T3B)Class I Zone 2Ex nA II T1 to T6CSAClass I, Div. 1Groups B,C & DClass II, Div. 1Groups E, F & GClass I Zone 1AEx d IIB H2 T1 to T6Class I, Div. 1Groups B,C &DClass II, Div. 1Groups E, F & GClass I Zone 1Ex d IIB H2 T1 to )IP32CE: Manufacturer’sDeclarationGeneral Duty OnlyCE: Manufacturer’sDeclarationIP66CE: Manufacturer’sDeclarationIP66CE: Manufacturer’sDeclarationATEXIECexII 3 G Ex nA II T1 to T6 Ex nA II T1 to T6I 2 G EEx d IIB H2 T1 Ex d IIB H2 T1 to T6to T6ITSATEXIECexII 2 G EEx de IIC T1 to Ex de IIC T1 to T6T6, 540 C, 600 C540 C, 600 C* WARNING: Addition of sparking devices such as a Thermostat to an E4 housing will annul hazardous area rating.B-92General Duty Only

ImmersionFlanged Immersion HeatersTemperature Control —Mechanical DevicesAn integral on-off process temperature controlthermostat can be factory installed into thehousing of the heater. The sensing bulb ofthe thermostat is inserted into a thermowellin the center of the heating bundle. AR typemechanical controls (see Controls section fordetails) are utilized.Mechanical DevicesOptionNumberTIT2T3ThermostatRange0 - 100 F60 - 250 F200 - 550 FNotes —A. The controls are for pilot dutyonly and must be connected to aremote mounted magnetic contactor.B.For explosion resistant heaters, anintegral thermostat can only bespecified on a 3, 5 and 6" flangeimmersion heater.Temperature Control —Electronic DevicesA process control thermocouple can be factoryinstalled into a thermowell in the center ofthe heating bundle for process control. Thisthermocouple must be connected to a remotemounted electronic temperature controller.Overtemperature Protection —Electronic DevicesA thermocouple can be attached to the heatingelement sheath to switch the heater off in theevent of a high temperature condition. Thisthermocouple must be connected to a remotemounted electronic high limit temperaturecontroller.Please refer to the Controls section for anoverview of power control panels.Mechanical Device Temperature ControlThermostat Temperature ControlThermowell with Capilary BulbProcess Control ThermocoupleThermowell with Bayonet ThermocoupleOverheat Protection ThermocoupleThermocouple Attached to SheathB-93flangedProcess Temperature &Overtemperature Controls

ImmersionFlanged Immersion HeatersProcess Temperature & Overtemperature ControlsFlanged Immersion Heater Model DescriptionsModelTMTMANSI Flange Immersion HeaterCode Element Sheath Material(Blank) CopperOCarbon SteelS304 Stainless SteelIIncoloy 800XOther MaterialCode Flange Material(Blank) Carbon SteelS304 Stainless SteelXOther MaterialCode Baffled Flow(Blank) No BafflesBBaffled FlowCode Number of Elements03Three Heating Elements06Six Heating Elements12Twelve Heating Elements18Eighteen Heating Elements27Twenty-Seven Heating Elements36Thirty-Six Heating Elements45Forty-Five Heating ElementsCodeWattage004P5 4.5 kW (use actual kilowatt in 3 digits)Code Terminal Housing StyleE1General PuposeE4Moisture ResistantE2Explosion / Moisture ResistantE5Explosion / Moisture Resistant - addition of Group IIC w/ Acetylene (IEC only)Code Non-Standard Feature(Blank) Catalog PCN itemXXCustom FeatureCode Voltage208 208V240 240V380 380V415 415V480 480V575 575VCode Number of circuits1One2Two3Three4FourCode Phase1PSingle Phase3PThree PhaseCode Kilowatts4.5kWI- 03- 004P5- E4480V1- 3P4.5kWExample of Final Model Description: TMI-03-004P5-E4 480V 1-3P 4.5kWNote: Shaded sections of the model build table are not a finite list. Items such as Number of Elements, Wattage, Voltage, Circuits,and Phase should be adjusted to match design.B-94Typical Model Number

Immersion B-90 Flanged immersion heaters Technical & Application Data 70 C Cable Supply Vertical Heater Orientation Horizontal Heater Orientation Temperature Code Wet Face Temperature: F Wet Face Temperature: C Minimum Standoff Dimension Minimum Standoff Dimension Inches mm Inches mm T6 185 85 3 76 1 25 T5 212 100 3 76 2 50 T4A 248 120 5 .