Transcription

Air Compressor TrainingCompressor529 E. Business Highway 83Weslaco, TX. 78596Tel: 956-968-3121Email: .com

“Its what you learn after you know it ALLthat counts”- John Wooden

“The future belongs to those who see possibilitiesbefore they become obvious”- John Sculley

Compressor529 E. Highway 83 Weslaco, TX 78596 Ph 956-973-3260 Fax 956-973-9859 Email: compressors@burtoncompanies.comSales – Rentals - Parts - Service- InstalationsReciprocating CompressorsDryersRotary Screw Compressors 5-500 hpAir TreatmentEnergy Efficient Aluminum Piping for Compressed AirVacuum Pumps 1-200 hpOil Filters PartsPreventive Maintenance & Repairs

Compressed Air System Training

What is Air?Contains It is a gasIt is invisableHas no colorHas no oder78% Nitrogen21% Oxygen1% Other

Air Can Be Compressed!

What is Compressed Air?It is air that has been squeezed and stored into asmaller space which then increases its pressureabove atmospheric pressure.AIR

Compressed Air is Stored EnergyCompressedAirCompressed air performswork when it is releasedand expands backinto the atmosphere

Compressed Air is the Fourth UtilityIt is a utility similar to WATER, GAS, & Electricty.Energy from compressed air is used to powerpneumatic production equipment

Compressed Air Has Manny UsesExamplesAir CylindersPneumatic ToolsPainting

Why is Compressed Air Used? Compressed air is an excellent medium for storing andtransmitting energy in order to do work It is used to cool components or parts during fabrication It is used to blow off waste material It is used to move parts

Why is Compressed Air Used? Pneumatic tools cost less Pneumatic tools produce less heat Pneumatic tools are lighter in weight

Why is Compressed Air Used?It is less dangerous than electricityAn electrical short may kill you but an air leak is unlikely!

CFM Compressed air is measured in CFM (cubic feetper minute)VOLUME This is theof compressed airthat an air compressor produces in 1 minute1Cubic Foot

PSI Pounds per square inch This is the measure ofcompressed air appliesFORCE that the

What Happens When Air Is Compressed?The space it occupies is reducedand the air pressure increasesSame amountof air in asmaller spaceAtmospheric 0 PSIPressureCompressedAir 0 PSI

Relation of Pressure & VolumeIf the air in tank #1 is moved to tank #2what will the pressure be in tank #2?The pressure is reduced in half if the volume is doubledTank #1500Gallons100 PSITank #21,000Gallons50 PSI

PSI ForceHigher Pressure Increases the Applied ForcePSI x Diameter of Cylinder Applied Force1,000 lbs.Force(100 PSI x 10 1,000 lbs.)100 PSICompressor(200 PSI x 10 2,000 lbs.)2,000 lbs.Force10” pneumaticcylinder200 PSICompressor10” pneumaticcylinder

How Many Cubic Feet of Ambient Air Is Requiredto Increase the Pressure to 100 PSI?8 Cubic Feet100PSI

Ambient Air at Sea Level Air has weight Its weight compresses it and increasesits pressure At sea level the ambient air pressure isAir Pressure at Sea Level14.7 PSIA14.7 PSIA (pounds per square inchabsolute)

Air Pressure & VolumeChanges with Elevation At 29,000 feet above sea level there isless air and the air pressure is only 4.56PSIA The ambient air pressure is reduced by.5 PSIA for every 1,000 feet of elevation Also a compressor at higher elevationproduces less air volume because thereis less air. A 500 CFM compressor at sea levelproduces 500 CFM The same compressor at 5,000 feetelevation produces about 400 CFM

Types of Air Compressors Reciprocating 75% duty cycleDesigned to operate 75% of the timeloaded & 25% of the time unloadedso it can cool down Rotary Screw 100% duty cycleCan operate loaded 100% of the time

Types of Reciprocating CompressorsSingle StageTwo-Stage

Reciprocating Compressor Single Stage - Compressor in whichthe air pressure is raised from inletpressure to final discharge pressure inone compression cycle. As a rule ofthumb, 100 psig is usually themaximum continuous dischargepressure for single-stage reciprocatingcompressors.

Reciprocating Compressor Two Stage- Compressors inwhich the air pressure is raisedfrom inlet pressure to final dischargepressure in two compression cycles.Staged compressors have intercoolersbetween stages to dissipate the heatgenerated by the first stage compressioncycle. They typically operate at amaximum 175 psi.

Rule of ThumbA reciprocating compressor produces 3.5 CFM per HPFor example: a 5 HP two-stage reciprocating compressordelivers about 17 CFM at 175 PSIA screw compressor produces 4.5 to 5 CFM per HPFor example: a 100 hp screw compressor delivers 500cfm at 100 psi

Reciprocating CompressorsTYPICAL HORSEPOWER RANGE1 - 30 HP

Single Stage Quincy Compressor 2 – 3 hp110-135 PSIStart-StopReed valve design75% Duty Cycle

Quincy Two-Stage Reciprocating CompressorsGOOD QTBETTER QPBESTQRSPLASH LUBEPRESSURE LUBEHEAVY DUTY PRESSURE LUBE

QT Quincy CompressorSplash Lubricated 2 – 15 hpSplash lubricatedReed valve design75% Duty Cycle

QP Quincy CompressorPressure Lubricated 5 – 15 hpPressure lubricatedOil filterReed valve design

QR Quincy CompressorHeavy Duty Industrial Pressure Lubricated 1 - 30 hpPressure lubricatedHeavy Duty Cast IronOil filterTapered roller bearingsSlow speed100% Duty CycleSuperior valve designOversized components

Reciprocating CompressorsCONTROLS Start/Stop– the compressor motorstarts and stops based on the pressureswitch cut in and cut out settings,typically no more than 8 motor startsper hourConstant Run – compressor motor runscontinuously based off a pilot valve andhead unloader or valve unloader. Usedwhen electric motor starts are morethan 8 per hour also used on gas engineunitsPressureSwitchUnloaderValvePilotValve

Reciprocating CompressorIn tankCheck ValveUnload LineAUTOMATICSTART STOPCONTIUOUSRUN

Reciprocating CompressorDUAL CONTROLIn tankCheck ValveAUTOMATICSTART STOP

Reciprocating CompressorsDUTY CYCLE The percentage of time the compressorruns loaded in a given time period A typical reciprocating compressor has a75% duty cycle. The compressor can be loaded 75% of thetime and unloaded or turned off 25% of thetime allowing it to cool down

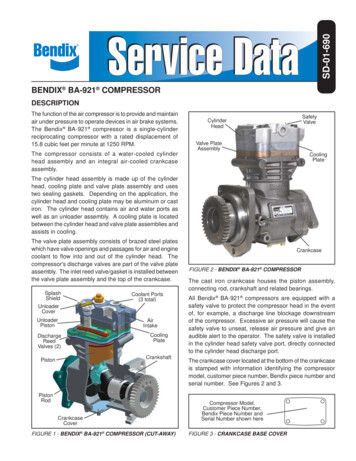

Reciprocating Compressor ComponentsQT Splash LubeSafety ValveValve PlateIntercoolerFlywheel

Reciprocating Compressor ComponentsQT Splash LubeHighPressurePistonLowPressurePistonDippers

Reciprocating Compressor ComponentsAir FilterMotorBelt GuardBasicASME in Valve

Reciprocating CompressorsPressure SwitchPressureAdjustmentClockwiseto increasepressureUnloadValve

Reciprocating Compressor ComponentsIEC Magnetic StarterAn electromechanically operated switch that provides a safe method ofstarting an electric motor with a large load. Also provides under-voltageand overload nThermalOverloadRequired on all 3 phase motorsand most 5 and 7.5 hp single phase

Reciprocating CompressorMotor TypesODP MotorTEFC Motor

Reciprocating CompressorMotor Tag and TypesTag Information Cat. No. Spec. HP Volts Amps RPM Frame HZ PH Ser.F. (service factor) Encl. (enclosure) Bearings SN

ElectricityVoltages and Phases for 60 hzSingle Phase115 volts230 volts3 Phase200 or 208 volts230 volts460 volts Incoming voltage can vary 10% Compressor motors 10 hp and larger are 3 phase

Determining Compressor PSIThe equipment that requires the highestoperating pressure determines thecompressor operating pressure set point.

CFM Required by ToolTool½” Impact1” ImpactPaint SprayerAir SanderCFM Required512105

Guide to Selecting a ReciprocatingAir CompressorCONSIDERATIONSAPPLICATIONSTATIONARY OR PORTABLESIZE: CFM, HPCONTINUOUS DUTYPRESSURELOCATION: INDOORS, OUTDOORS# OF COMPRESSORS NEEDEDMOTOR ENCLUSUREOIL FREE AIRTANK SIZE AND VERTICAL OR HOR.ELECTRIC MOTOR OR GAS ENGENESIMPLEX OR DUPLEXVOLTAGE AND PHASEHOW SOON NEEDED

Compressor Selection Guide

Compressor Selection Guide

Compressor Selection Guide

Compressor Selection Guide

Effects of Increasing Operating Pressure CFM output decreases More hp required 1% more energy used for every 2 psiincrease in pressure The motor draws more amps.The Oposite Happens When Operating Pressure is Lowered

Reciprocating Compressors We Stock

Reciprocating Compressors We Stock

Quincy Gas Engine Compressors14 hp Kohler13 hp Honda

Duplex Compressor

Quincy Compressor Warranty

Quincy Compressor WarrantySeriesStandard WarrantyExtended WarrantySingle Stage &Pro units1 year package2 years pump2 years package3 years pumpQR units5 year on majorcomponents otherparts 1 yearQGS, QGD5 years airend,drive motor, oiltank, cooler, flexcoupling, 1 yearpackageQGV & QSI10 year airend, 5years drive motor,oil tank, cooler, flexcoupling, 1 yearpackage

Quincy Compressor Warranty RequirementsSeriesRequirements for WarrantyReciprocating Register compressor on line,Compressors do maintenance, useoriginal parts and oilRotary Screw Start-up by Burton, useCompressors original parts and oil, domaintenance, send oilsamples every 2,000 hours

Reciprocating Quick Start Guide

Reciprocating Quick Start GuideBefore installing compressor – read andunderstand instruction manual1. Remove from shipping crate and installin a suitable location2. Check the fluid level3. Have a qualified electrician verify thatthe supply voltage matches the motorrequirements and checks wire size andcircuit breakers and overload relays forproper size

Reciprocating Quick Start Guide4. Check piping installation5. Jog the motor to check the rotation ofthe compressor6. Register your warranty online atQuincycompressor.com

Reciprocating CompressorQuin-Cip Lubricant112543Q100, Quart112543G100, Gallon112543P100, 5-Gallon112543D100, 55-Gallon

Reciprocating CompressorMaintenanceIntervalProcedure8 hrs.Check oil level8 hrs.Drain water from tank40 hrs.Clean or replace air filter100 hrs.Replace breaking oil with Quin Cip or Quin Cip D160 hrs.Check belt tension500 hrs. or 3 mos. Change oil Quin Cip1000 hrs.Change oil Quin Cip D if using2000 hrs.Inspect pressure switch, contacts on motor starter

Compressed Air Treatment

Ambient Air Contains Humidity

HumidityIt is the amount of water vapor in the air

A 100 hp Compressor Can Produce25 gallons in 24 hours

Compressed Air TreatmentCompressed air has to be clean and drybefore it can be used

Compressed Air Contains Contaminents Atmospheric air naturally contains several impurities such as dust,hydrocarbons and water. Lubricated compressors contaminate the compressed air with oilDustWaterDirtDustOilWaterDirtOil

Impurities in Compressed Air Can Cause Damage to distribution lines, may cause leaks, cloglines and cause pressure drops Increase maintenance cost Reduce eficiency and life of pneumatic devices Deterioration of final product quality Limits the reliability of the production process andall of its components Decreases overall profitability

Harmful ContaminationWater in compressed air damages equipmentWater foundinside impactwrench

Harmful ContaminationWater in compressed air damages equipmentWear

Harmful ContaminationWater in compressed air damages equipmentRust &Pitting

Compressed Air Treatment Solid particulate and oil can be removed by filtration Water cannot be removed completely by filtrationalone as it remains in a vapor state until it cools andcondenses A dryer is required to remove the water incompressed air

Dew Point Atmospheric temperture (varying according topressure and humidity) below which water dropletsbegin to condense and dew can form It is the measure of dryness we want the compressedair to be Typical dew point for automotve shops is 50 F Typical dew point for industry is 40 F

Relation of Temperature & Humidity Hot air holds more moisture than cool air Humidity in air is reduced by 50% for every 20 Freduction in temperature A dryer cools the compressed air to a certaintemperature and the moisture in the air condenses.The condensed water is removed with an automaticdrain.

Moisture is Removed From Compressed AirUsing a Systems Approach Aftercoolers – 75% removal Mechanical Separators Filters Air Dryer Receivers & Pipe Filters Drains & Drip Legs

Compressed Air Treatment

Components of a Compressed Air System

Aftercoolers for Reciprocating CompressorsStand Alone AftercoolerBeltguard AftercoolerMechanicalMoistureSeparator

Air DryersHigh Temperature Dryer Dew point 40 F or 50 F Inlet Temperature up to 180 F Used with Reciprocating CompressorsStandard Refrigerated Dryer Dew point 39 F Used with Screw CompressorsDesiccant or Regenerative Dryer Dew point -40 F

Refrigerated Air Dryer Flow SchematicMoistAir INDryAir Out

Refrigerated Air Dryer Components

Sizing a Standard Refrigerated Air DryerFactors that affect dryer efficiency1. Inlet Air Pressure2. Inlet Air Temperature3. Ambmient Air Temperature4. Dew Point Desired

Correction Factors for Sizing a Refrigerated Air DryerPSI

High Temperature Refrigerated Air Dryer

High Temperature Refrigerated Air Dryer

Sizing a Refrigerated Air Dryer

Dryer Installation3-Way Bypass

Air Purity Classes – ISO 8573-1

Air FiltersParticulate Filter Removes solid particles Efficiency 90%Coalescing Filter Removes solid particles, liquidwater, and oil Efficiency 99.9%Activated Carbon Filters Oil vapor, hydrocarbon odors Efficiency 99.997%

QCS Quincy Oil Water Separators

We Sell

We Sell

Related That Go With the Compressor Extended Warranty Kit Line Filter Air Dryer Flex Hose Vibration Pads FRL Tank Drain Service Agreement

Information Required when Requestinga Quote for Parts Customer Name and location Model Serial Number Record of Change on Quincy Recips

Information Required when Requestinga Quote for Parts From Store 90 Contact Name and location Model Serial Number Record of Change on Quincy Recips

TroubleshootingAn air system with a refrigerated air dryerhas no air downstreem of the dryerDryer is Frozen?

TroubleshootingA customer comes in to buy a pressure switchbecause it bleeds all of the air from the air tankthrough the unloader valve on the pressure switch.Intank check Valve is Bad

TroubleshootingA customer says he is finding a lot of waterin the crankcase of the compressor.Compressor may be to big for the applicationChange oil more often

TroubleshootingA customer says his compressor does not makethe same amount of air it used to.Bad valves

Safety ValveProtects the air tank, piping, andother equipment connected to thecompressed air system fromexplosion should the air pressureexceed designed working pressure.

What can happen if the system doesnot have an safety valve?

What can happen if the safety valve isnot the correct one?

How do you select the correct safety valve? The safety valve should protect the system from theworst case situation PSI – the safety valve can be set for the MAWP(maximum allowable working pressure) of the airtank. CFM – the safety valve flow should be greater thanthe flow of all of the air compressors connected tothe tank.

Use lock out/tag out equipment whenworking with compressor equipment toprevent accidents.

Hearing ProtecitonHard HatSafety ShoesSafety Glasses

Is it ok to clean yourselfwith compressed air?

Dangers of Pointing Compressed Air on the Body The noise of spraying air can cause hearing loss Air blown into the mouth can rupture the lungs or stomach Compressed air can enter the blood stream and cause death It only takes 12 psi to blow out an eyeball from its socket

less air and the air pressure is only 4.56 PSIA The ambient air pressure is reduced by .5 PSIA for every 1,000 feet of elevation Also a compressor at higher elevation produces less air volume because there is less air. A 500 CFM compressor at sea level produces 500 CFM The same compressor at 5,000 feet elevation produces about 400 CFM