Transcription

SC70 SERIESARCHITECTURAL DIAGRAMSSC70 Series Top Jamb (Push Side)To 100 o101o to 120 o121o to 150 o151o to 180 o13Ó - 330mm12Ó - 305mm10Ó - 254mm9 1/2Ó- 241mmTo 100 o101o to 120 o121o to 150 o151o to 180 o6 15/16Ó- 176mm5 15/16Ó- 125mm3 15/16Ó- 100mm3 7/16Ó - 87mmButt Hinges should not exceed 5Ó (127mm) in width.Auxiliary Stop is recommended at hold-open point or wherea door cannot swing 180¡.Reveal should not exceed 31/4Ó (83mm) for regular arm orhold-open arm.Top Rail of 1 1/2Ó (38mm) required.Head Frame less than 3 7/8Ó (98mm) requires plate SC70-18.Delayed Action add sufÞx ÒDELÓ to selected cylinder (ex. SC70DEL). Delays closing from maximum opening to approx. 70¡,with adjustable delay time.SC70 Series Parallel (Push Side)To 100 o101o to 130 o131o to 150 o151o to 180 oTo 100 o101o to 130 o131o to 150 o151o to 180 o8 15/16Ó- 227mm7 7/16Ó - 189mm6 7/16Ó - 164mm5 7/16Ó - 138mm8 1/16Ó- 205mm6 9/16Ó- 167mm5 9/16Ó- 141mm4 9/16Ó- 116mmButt Hinges should not exceed 5Ó (127mm) in width.Auxiliary Stop is recommended at hold-open point or where adoor cannot swing 180¡.Top Rail less than 6Ó (152mm) measured from stop requiresplate SC70-18PA.Delayed Action add sufÞx ÒDELÓ to selected cylinder (ex. SC70DEL). Delays closing from maximum opening to approx. 70¡,with adjustable delay time.www.falcon.ingersollrand.com7

SC70 SERIESARCHITECTURAL DIAGRAMSSC70 Series Heavy Duty (Parallel)To 100 o101o to 130 o131o to 150 o151o to 180 oTo 100 o101o to 130 o131o to 150 o151o to 180 o8 7/8Ó- 225mm7 3/8Ó- 187mm6 3/8Ó- 162mm5 3/8Ó- 137mmTo 100 o101o to 130 o131o to 150 o151o to 180 o8 7/8Ó- 225mm7 3/8Ó- 187mm6 3/8Ó- 162mm5 3/8Ó- 137mm8 1/16Ó- 205mm6 9/16Ó- 167mm5 9/16Ó- 141mm4 9/16Ó- 116mmButt Hinges should not exceed 5Ó (127mm) in width.Auxiliary Stop is recommended at hold-open point, where a door cannotswing 180¡, or where Dead Stop or Spring-n-Stop arm is not used.Top Rail less than 6Ó (152mm) measured from stop requires plate SC70-18PA.Delayed Action add sufÞx ÒDELÓ to selected cylinder (ex. SC70 DEL). Delaysclosing from maximum opening to approx. 70¡, with adjustable delay time.SC70 Series Dead Stop HO (Parallel)To 100 o101o to 130 o131o to 150 o151o to 180 o8 1/16 Ó- 205mm6 9/16 Ó- 167mm5 9/16 Ó- 141mm4 9/16 Ó- 116mmButt Hinges should not exceed 5Ó (127mm) in width.Top Rail less than 6Ó (152mm) measured from stop requires plate SC70-18PA.Delayed Action add sufÞx ÒDELÓ to selected cylinder (ex. SC70 DEL). Delaysclosing from maximum opening to approx. 70¡, with adjustable delay time.8www.falcon.ingersollrand.comInformation in this catalog is subject to change without notice.

SC70 SERIESACCESSORIESAll SC70 Series closers come with full cover, standard arm and screw pack.Arm TypesRegular Arm, SC70-3077PANon-handed arm with adjustable forearmassembly to accommodate a range of doorsand frame reveal conditions. Mounts hingeside, top jamb or parallel arm. PA shoeincluded to allow installation in a parallelarm conÞguration.Dead Stop Hold-Open Arm, SC70-3049DSOptional, non-handed, stamped, heavy duty, hold-openparallel arm includes a positive mechanical stop andnon-adjustable forearm assembly for high volume trafÞcor potentially abusive installation conditions. Alsoincludes a manually selective hold-open function.Hold-Open Arm, SC70-3049PAOptional, non-handed, hold open arm withadjustable forearm assembly to accommodatea range of doors and frame reveal conditions.Mounts hinge side, top jamb or parallel arm. PAshoe included to allow installation in a parallelarm conÞguration.Spring-n-Stop Arm, SC70-3077SSOptional, non-handed, extra heavy-duty, forged parallelarm includes an integral spring stop and non-adjustableforearm assembly for high volume trafÞc or potentiallyabusive installation conditions.Heavy Duty Regular Arm, SC70-3077HDOptional, non-handed, stamped, heavy duty,parallel arm for use in high-trafÞc applications.Spring-n-Stop Hold-Open Arm, SC70-3049SSOptional, non-handed, extra heavy-duty, forgedparallel arm includes an integral spring stop andnon-adjustable forearm assembly for high volumetrafÞc or potentially abusive installation conditions.Also includes a manually selective hold-open function.Dead Stop Arm, SC70-3077DSOptional, non-handed, stamped, heavyduty, parallel arm includes a positivemechanical stop and non-adjustableforearm assembly for high volume trafÞc orpotentially abusive installation conditions.Installation AccessoriesSofÞt Shoe Support, SC70-30Provides anchorage for Þfth screw usedwith sofÞt shoe, where reveal is less than3 1/16Ó (78mm).Plate, SC70-18Required for hinge side mount where top rail is lessthan 3 7/8Ó (98mm). Required for top jamb mountingwhere head frame is less than 3 7/8Ó (98mm).Blade Stop Spacer, SC70-61Required to lower parallel arm shoe toclear 1/2Ó (13mm) blade stop.Plate, SC70-18PARequired for parallel arm mounting where top rail isless than 6Ó (152 mm), measured from the stop.Plate requires 1 3/4Ó (44mm) minimum top railmeasured from stop.Auxiliary Shoe, SC70-62ARequires a top rail of 7Ó (178mm). Optionalshoe replaces PA shoe for parallel armmounting of regular arm with overheadholder/stop.Cover, SC70-72Standard, non-handed, full plastic cover encloses thecloser body.www.falcon.ingersollrand.com9

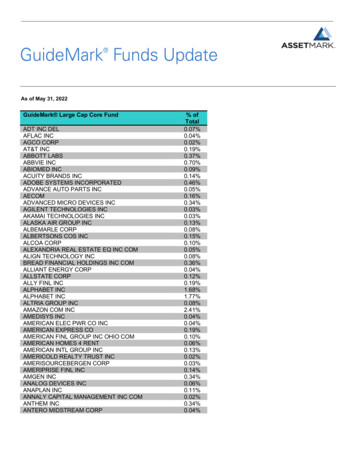

SC70 SERIESF E AT U R E S A N D S P E C I F I C AT I O N SSC70 SeriesFalcon SC70 Series heavy duty closers are built for busy commercial applications that demandreliable door control and easy maintenance. Designed for use with aluminum storefronts, SC70Series closers are ANSI Grade 1, ADA compliant and deliver tough performance. Choose the SC70for interior or exterior doors in retail shops, restaurants and small ofÞces.Standard Features Meets ANSI A117.1 ANSI/BHMA A156.4, Grade 1 UL Listed 11/2Ó diameter piston Closer mounts hinge side, top jamb or parallel armwhen either the Rw/PA or Hw/PA arm is speciÞed. Adjustable sizes 1-6 Single piece cast aluminum body Staked valves Non-handed for left or right swinging doors Fast and easy installation Separate adjustable general speed, latch speedand backcheck Heat-treated forged steel piston Double heat-treated pinion Cover is high-impact UL Listed Þre retardant plasticthat meets UL 10C and UBC 7-2 (1997) Þre test UL 10C approved ßuid Universal screw pack 10-year warrantyListings and CertiÞcationsThe Falcon SC71 is UL approved and compliant with the UL 10C and UBC 7-2 (1997) Þre test. Additionally,the SC71 is rated ANSI/BHMA A156.4, Grade 1 and designed to meet the American Disabilities Act (ADA) andANSI A117.1SC70 Series Hinge (Pull Side)To 100 o101o to 120 o121o to 150 o151o to 180 o13Ó - 330mm12Ó - 305mm10Ó - 254mm9 1/2Ó- 241mmTo 100 o101o to 120 o121o to 150 o151o to 180 o6 15/16Ó- 176mm5 15/16Ó- 125mm3 15/16Ó- 100mm3 7/16Ó - 87mmButt Hinges should not exceed 5Ó (127mm) in width.Auxiliary Stop is recommended at hold-open point or where a doorcannot swing 180¡.Reveal should not exceed 3/4Ó (19mm) for regular arm or hold-open arm.Top Rail less than 3 7/8Ó (98mm) requires plate SC70-18.Clearance of 2 1/8Ó (54mm) behind door required for 90¡ installation.Delayed Action add sufÞx ÒDELÓ to selected cylinder (ex. SC70 DEL). Delaysclosing from maximum opening to approx. 70¡, with adjustable delay time.6www.falcon.ingersollrand.comInformation in this catalog is subject to change without notice.

HOW TO ORDERHow to Order SC60 SeriesSTDDELStandardDelay (optional, available with SC60/61 only, please specify)1-42-545SC61SC60SC64SC65SlimSC60-72 (optional, available with SC60/61 only, please derSizeCoverFinishArmAccessoriesAluminumDark BronzeBrassRw/PAHw/PAHDDSDS/HOSSSS/HORegular with Parallel Arm ShoeHold Open with Parallel Arm ShoeHeavy Duty ArmDead Stop ArmDead Stop Hold Open ArmSpring Stop ArmSpring Stop Hold Open ArmSofÞt Shoe SupportBlade Stop SpacerAuxiliary ShoePlatePlate PASC60-30SC60-61SC60-62ASC60-18SC60-18PAHow to Order SC70 mDark BronzeBrass28Rw/PAHw/PAHDDSDS/HOSSSS/HORegular with Parallel Arm ShoeHold Open with Parallel Arm ShoeHeavy Duty ArmDead Stop ArmDead Stop Hold Open ArmSpring Stop ArmSpring Stop Hold Open ArmSofÞt Shoe SupportBlade Stop SpacerAuxiliary ShoePlatePlate .ingersollrand.comInformation in this catalog is subject to change without notice.

COMPETITIVE CROSS REFERENCEA N D S A M P L E S P E C I F I C AT I O N SCompetitive Cross ReferenceSurface Closer Cross ReferenceDor-O-Matic SC711Concealed Closer Cross Reference223SC80 , SC81SC60 , SC61CorbinDC60003210M76 (3210)Dorma8916861622Norton17500 /77003640BCPA3/730232P8300 (P8500)23P1600BC4SC94 , SC91Dor-O-MaticOHC100 ternationalSeries 100 and Series tanleyD-4550D-35501650KawneerHusky IIYaleP400P3300 (P3500)2P51BC3Rixson608, 0608, 700, 0700, 800Sentinel30 SeriesStanley30 Series12P2304BC443Indicates identical footprint, Indicates identical footprint, Indicates identical footprint,Indicates identical footprint4Sample SpeciÞcationsLarge Cylinder Closer2.01 Closers and Door Control DevicesA. Where manual closers are indicated for doors required to be accessible to the physically challenged, provideadjustable units complying with ANSI A117.1 provisions for door opening force and delayed action closing.B. Shall conform to ANSI A156.4, Grade 1, NFPA 80, NFPA 101 and UL10C.C. Closers shall be aluminum construction with steel lever arms, independent adjusting valves for closing,latching and back check. Hydraulic regulation controlled by tamper-proof, non-critical screw valves. All closeradjustments shall be shielded by plastic cover after installation. Pressure relief valve, PRV, doors closers willnot be permitted.D. Full rack-and-pinion type closer, single-piece forged piston, chrome silicon steel spring, non-critical screwvalves; backcheck, main speed and latch.E. Closers to be non-sized, Þeld adjustable from size 1 to 6.F. Furnish all large cylinder non-sized closers with minimum 1 Ó diameter piston.G. Install closers to allow maximum degree of opening, position backcheck to activate well in advance of thestop position to cushion the swing and prevent door and frame damage. Do not use door closer to stop doortravel. Unless speciÞed, install closers with thru-bolt mounting method on metal and wood doors. Do notthru bolt if there has been special blocking speciÞed in the wood door speciÞcation. Coordinate with thewood door speciÞcation.H. Available manufacturers: Subject to compliance with requirements. See competitive cross reference above.30www.falcon.ingersollrand.comInformation in this catalog is subject to change without notice.

CYLINDER OPTIONSAND WARRANTYCylinder OptionsStandard Cylinder (STD) Ð Standard cylinder provides a main speed function to control the motion of thedoor from maximum opening angle until the door is a few inches from the latch where latch function controlsthe Þnal closing motion. The opening swing is controlled by the hydraulic backcheck function from about 70¡ tomaximum opening angle.Without Backcheck (WOBC) Ð Special cylinder provides a main speed function to control the motion of thedoor from maximum opening angle until the door is a few inches from the latch where latch function controlsthe Þnal closing motion.Delayed Action Cylinder Ð Special cylinder provides a separate adjustable delayed closing motion frommaximum opening angle to approximately 70¡. Then the main speed function controls the door motion until thedoor is a few inches from the latch where latch function controls the Þnal closing motion. During the openingswing the door is controlled by the hydraulic backcheck function from about 70¡ to maximum opening angle.WARRANTYFalcon Door Hardware warrants its mechanical offering of locks, exit devices and door controls productsmanufactured to be free from defects in materials and workmanship for a period of TEN (10) YEARS from the dateof manufacture with the exception of the products detailed in the table below. The terms and conditions of this newwarranty apply to Falcon Door Hardware shipments made on or after November 1st, 2008.This limited warranty does not cover products that (i) are not the proper size for the application; (ii) are not installedin accordance with FalconÕs published installation instructions; (iii) are installed with improper or incorrect parts; (iv)have been, in the opinion of Falcon, modiÞed, repaired, or altered in any way without the express written consentof Falcon; (v) are used for purposes which they are not designed or intended; (vi) are subjected to misuse, abuse,negligence, or accident; or (vii) are grade 2 products used in educational facilities. The following costs and expensesare not covered by the provisions of this limited warranty; (i) labor costs for the removal and reinstallation ofproducts; (ii) shipping and freight expenses required to return products to Falcon; (iii) normal maintenance; and (iv)economic losses.THE PREVISIONS OF THIS WARRANTY DO NOT APPLY TO FINISHES.Falcon will replace the products which, in the opinion of Falcon, are found to be defective, provided said products arereturned to Falcon.FALCON SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, ORPUNITIVE DAMAGES FOR ANY CLAIM WHETHER BASED ON CONTRACT; WARRANTY, TORT (INCLUDING, BUTNOT LIMITED TO, STRICT LIABILITY OR NEGLIGENCE), PATENT INFRINGEMENT, OR OTHERWISE, EVEN IFADVISED OF THE POSSIBILITY OF SUCH DAMAGES.This limited warranty is in place of all other warranties, expressed or implied, and excludes any warranties of Þtnessfor a particular purpose or merchantability. No agent, representative, dealer, or employee of Falcon has the authorityto increase or alter the obligations of this limited warranty.Note: Should the Product be considered a Òconsumer productÓ as may be covered by the Magnuson-Moss FederalWarranty Act, please be advised that: (1) Some states do not allow limitations on incidental or consequentialdamages or how long an implied warranty lasts, so that the above limitations may not fully apply; and (2) Thiswarranty gives speciÞc legal rights and a user may have rights which may vary from state to state.Falcon, Ingersoll Rand Security Technologies, 121 West Railroad Avenue, Princeton, Il 61356PRODUCT EXCEPTIONWARRANTYOHC100A CONCEALED CLOSERSELECTRONICS/ELECTRIFIED5 YEARS1 YEARwww.falcon.ingersollrand.com31

SC70 Series Heavy Duty (Parallel) Butt Hinges should not exceed 5Ó (127mm) in width. Auxiliary Stop is recommended at hold-open point, where a door cannot swing 180¡, or where Dead Stop or Spring-n-Stop arm is not used. Top Rail less than 6Ó (152mm) measured from stop requires plate SC70-18PA.