Transcription

DWFL & SWFLDouble & Single Wall Flanged Joining Pipe & FittingsØ6‘‘ - Ø36‘‘www.jeremiasinc.com

INDEXJEREMIAS CONTENTSDWFL& SWFL Double & Single Wall Joining Pipe & FittingsIntroduction3-4Technical specifications5-8DWFL ProductsAdapters9Supports11Straight lengths16Adjustable lengthsElbows2021Tees24Increasers / Reducers32Tee caps33Flashings35Terminations40Accessories47An offset calculator for all Jeremias products can be found on the Jeremias website underDownloads/Product data sheets and catalogs29 - 55

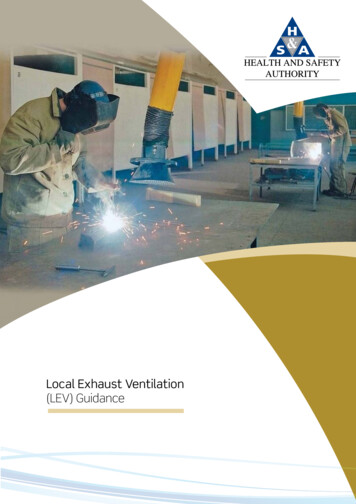

INTRODUCTIONJEREMIASEXHAUST SYSTEMSModels DWFL and SWFL are the fusion of world class DWKL (conical) with USA flanged pressure stack systems. Insulationoptions are 1.25” of air space, and fiber insulation options of 1.25”,2.25”, 3.25”, and 4.25”. Each may be intermixed in thesame stack, chimney, grease duct or vent system.Models DWFL and SWFL are intended for use in connecting heating and hot water appliances, engines, and turbines tothe outdoors. There are also many other applications and uses including, but not limited to the following: Chimney Liners,Chutes, Dryer Vents, Fume Venting, Industrial Oven and Process Stacks, Incinerator Exhausts, Paint Booth Exhausts,Particle Conveying, and Ventilation Ducts.STRONG – OPEN – INTERNATIONAL40 Years of ExperienceJeremias is one of the world s leading manufacturers of flue and chimney systems for the exhaust of gases and ventilation,covering all kinds of domestic, commercial and industrial applications. Jeremias Group product range includes over fifty(50) different CE or UL certified systems covering commercial and domestic applications complimented by freestandingIndustrial steel chimneys up to 10 feet in diameter. Jeremias offers its clients a wide range of high quality products,technical support for projects, and stack sizing software.With over 40 years of experience in the venting and component exhaust industries, Jeremias has seven (7) manufacturingplants in six (6) different countries worldwide. Jeremias today has more than 1,000 employees and is proud of its Germanengineering origins, and is now also manufactured in the USA from 100% local materials!3

INTRODUCTIONJEREMIASEXHAUST SYSTEMSResearch and DevelopmentJeremias has over fifty (50) CE Certified exhaust and chimney systems worldwide for domestic, commercial, and industrialapplications. “CE Certification” is the mandatory conformity safety testing for products sold throughout Europe and otherparts of the world. In North America, Jeremias employs only Underwriters’ Laboratories (UL) for testing, certifications, andlistings to all applicable UL and ULC Standards.Opened in 2013, the Jeremias R&D Lab in Logan, OH has the industry’s most experienced lab technicians on staff andincorporates the latest equipment and technologies. This laboratory enables Jeremias to provide industry leadershipwith a continued focus on new factory-built exhaust applications and unique listings. Jeremias is constantly bringing newinnovations to the marketplace and our Logan laboratory enables us to accomplish these changes quickly and effectively.All Stainless Steel ConstructionJeremias incorporates the finest stainless steel grades required by each individual application for our inner liners. Thesesteels are carefully chosen according to the specific needs for each UL Listing. These steels incorporate various advantagesover others including resistance to corrosion, heat expansion, forming, welding, and lower work hardening, among otherfactors. The standard model Jeremias outer jacket is also constructed of high grade stainless steel with a bright annealed(BA) finish, giving our projects a very distinctive appearance. All Jeremias accessories (including support plates and anglerings) are also made of stainless steel. This means that there is no rusting of materials in any outdoor applications, and nocross contamination in the factory from carbon steel cutting or welding. Jeremias cleans all external welds to assure thecustomer clearly sees the quality standard that we are setting. Jeremias backs our exhaust systems with a Twenty-Five(25) Year Standard Warranty.Best InsulationJeremias uses the most advanced ceramic fiber blanket materials. Our industry leading ceramic fiber has improvedhandling strength, enhanced termal performance, and improved handling properties. Large nuisance dust particles havebeen effectively eliminated making the product soft to the touch and less irritating during use. Our insulation containsneither binder nor lubricant and does not emit any fumes or smells during the first high temperature firing.Jeremias uses ¼” thicker insulation then all others in the industry. This delivers the best clearances and skin temperaturesthan all others. The ½” larger footprint is easily compensated for best clearance to combustibles, Jeremias Model DWFLclearly is the industry leader in the smallest required footprint.Easiest Install, Yet most Reliable Flanged SystemModels DWFL and SWFL are cylindrical, factory-built, modular venting systems that incorporate a 1.25” steel overlap withadded vee band for easiest assembly.DWFL and SWFL are the only flanged pressure stack systems with a continuous overlapping inner, as the flange isadded to the outside of the inner liner. This is important, because the male end extends completely through and past theactual joint into the female end. On the inside, the joint is smooth and anything liquid flows downhill past the joint withno interference. This male extension protects the joint and provides a stable connection which holds the two pipe endstogether so that the flanges can be connected and sealed on the outside of the inner liner without slipping apart duringassembly. Once assembled, a strong, liquid-tight seal is completed and protected by 1.25 inches of steel overlap fromdamage like corrosion from condensate, grease, pressure, or cleaning fluids.DWFL and SWFL are the most rugged and easiest stack systems to install, yet still the most reliable as the inner overlapprotects the silicone seal against condensate and high-pressure washings in commercial kitchen exhaust.4

TECHNICAL SPECIFICATIONSTECHNICALSPECIFICATIONSUnderwriters Laboratories ListingsUL File Number for All Listings: MH59917United States:DWFL1. UL 103 Standard, Building Heating Appliance Chimney2. UL 2561 Standard, 1400F Chimney Listing3. UL 103 & UL 2561 Standards, Additional PositivePressure Listing to 90” WC after 1400 F4. UL 1978 Standard, Grease Duct5. UL 1738 Standard, Venting Systems for Gas-BurningAppliances, Categories II, III and IV6. UL 441 Standard, Gas Vents7. UL 641 Standard, Type L Low-Temperature Vent4. ULC S636 Standard for Type BH Gas Venting Systems5. ULC S605 Standard for Gas Vents6. ULC S609 Standard for Low-Temperature Vents Type LSWFL Single Wall1. ULC S662 Standard for Factory-Built Grease Ducts2. ULC S636 Standard for Type BH Gas Venting Systems3. ULC S635 Standard for Lining Systems for ChimneysDWFL 1, DWFL 2. DWFL 3 & DWFL 41. UL 103 Standard, Building Heating Appliance Chimney2. UL 103 Standard, Additional Type HT Listing3. UL 2561 Standard, 1400F Chimney Listing4. UL 103 & UL 2561 Standards, Additional PositivePressure Listing to 90” WC after 1400 F5. UL 1978 Standard, Grease Duct6. UL 1738 Standard, Venting Systems for Gas-BurningAppliances, Categories II, III and IV7. UL 441 Standard, Gas Vents8. UL 641 Standard, Type L Low-Temperature VentDWFL-ZC1. UL 103 Standard, Building Heating Appliance Chimney2. UL 103 Standard, Additional Type HT Listing3. UL 2561 Standard, 1400F Chimney Listing4. UL 103 & UL 2561 Standards, Additional PositivePressure Listing to 90” WC after 1400 F5. UL 1978 Standard, Grease Duct6. UL 1738 Standard, Venting Systems for Gas-BurningAppliances, Categories II, III and IV7. UL 441 Standard, Gas Vents8. UL 641 Standard, Type L Low-Temperature Vent9. UL 2221 Standard, Fire Resistive Grease Duct EnclosureAssembly.SWFL Single Wall1. UL 103 Standard, Building Heating Appliance Chimney2. UL 103 Standard, Additional Positive Pressure Listing to90” WC3. UL 1978 Standard, Grease Duct4. UL 1738 Standard, Venting Systems for Gas-BurningAppliances, Categories II, III and IV5. UL 1777 Standard, Chimney LinersCanada:Operating PressuresDWFL, DWFL 1, DWFL 2. DWFL 3 & DWFL 41. ULC/ORD-C959 Industrial Type 540 C Chimney2. ULC/ORD-C959 Industrial Type 760 C Chimney3. ULC S662 Standard for Factory-Built Grease DuctsAll Jeremias Inc. DWFL & SWFL models have beenevaluated and Listed by UL for positive pressures up to 90”W.C. internal static pressure with exposure up to 1400 Finternal continuous temperatures.5

TECHNICAL SPECIFICATIONSTECHNICALSPECIFICATIONSModel and Part IdentificationsSWFLSingle Wall FlangedConnectionDWFLDouble Wall FlangedConnection With 1.25‘‘ AirSpacePart numbers include the Model, diameter, item code, thenvariation (if any). Example 1: DWFL8-36L for an 8 inch inner diameterModel DWFL double wall 36 inch length of pipe with 1.25”insulating air space. Example 2: DWFL20-45EL 4 for a 20 inch inner diameterModel DWFL double wall 45 Elbow with 4.25” thickinsulation. Example 3: SWFL36-48L for a 36 inch inner diameterModel SWFL single wall 48” Length.Material Options and ThicknessesDWFL 1Double Wall FlangedConnection With 1.25‘‘Insulation 8 PCF CeramicFiberDWFL 2Double Wall FlangedConnection With 2.25‘‘Insulation 8 PCF CeramicFiberDWFL 3Double Wall FlangedConnection With 3.25‘‘Insulation 8 PCF CeramicFiberDWFL-ZCDouble Wall FlangedConnection With 3.25‘‘Insulation 10 PCF CeramicFiberDWFL 4Double Wall FlangedConnection With 4.25‘‘Insulation 8 PCF CeramicFiber6Inner Liner of DWFL & SWFL: 0.035” thick Type 444 stainless steelInsulation of DWFL: 1.25” air spaceInsulation of DWFL 1: 1.25” blanket 8 PCF ceramic fiberInsulation of DWFL 2: 2.25” blanket 8 PCF ceramic fiberInsulation of DWFL 3: 3.25” blanket 8 PCF ceramic fiberInsulation of DWFL-ZC: 3.25” of 10 PCF ceramic fiberInsulation of DWFL 4: 4.25” blanket 8 PCF ceramic fiberOuter Jacket for all variations of DWFL: 0.025” thick Type 304 stainless steel with BA Finish fordiameters 5” through 24” 0.035” thick Type 304 stainless steel with BA Finish fordiameters 26” through 36”

TECHNICAL SPECIFICATIONSTECHNICALSPECIFICATIONSband groove to create a seal. This vee band is protected bythe above mentioned inner extension.Outer Locking Band is secured with integrated worm gear,so no loose hardware to install in the field.Models DWFL & DWFL Joint Assembly DetailCode and StandardsWhen installed per their instructions, all Jeremias Inc. DWFL& SWFL models are code compliant with the followingcodes and standards: NFPA 31 NFPA 37 NFPA 54 NFPA 96 NFPA 211 UMC ULC S650 CSA B139 CSA B149 IMC IFGC CMCThe following agencies or associations produce codes,standards, or guidelines by which all Jeremias Inc. Modelsmay be installed and used: ASHRAE (American Society of Heating, Refrigerating andAir Conditioning Engineers) CSA (Canadian Standards Association) IAPMO (International Association of Plumbing andMechanical Officials) ICC (International Code Congress) NFPA (National Fire Protection Association) UL (Underwriters Laboratories, Inc.) ULC (Underwriters’ Laboratories of Canada)Operating TemperaturesCRITERIAFurther features of the Jeremias double wall insulatedsystems include:a) Reduced clearance to combustiblesb) Reduced outer pipe skin temperaturesc) Reduced building heat gaind) Increased efficiencies of energy recovery systemse) Reduced noise levels caused by high velocity exhaustsf) Enhanced chimney draftModel SWFL Joint Assembly DetailPERMITTED TEMPERATURESUL 103 Building Heating Appliance1000 F (540 C) ContinuousChimney ULC/ORD-C959 Industrial Type1400 F (760 C) Intermittent540 C ChimneyAdditional UL 103 Type HT2100 F (1150 C) for 10 MinutesUL 2561 1400 F Chimney ULC/ORD-C959 Industrial Type 760 CChimney1400 F (760 C) Continuous 1800 F(980 C) IntermittentUL 1978 Grease Duct ULC S662 Standard 500 F (260 C) Continuousfor Factory-Built Grease Ducts2000 F (1093 C) for 30 MinutesUL 1738 Special Gas Vent ULC S636 GasVent550 F (288 C) ContinuousOptional 400 F UL 1738 Special Gas Vent 400 F (204 C) ContinuousOptional Plastic Applications UL 1738Special Gas Vent148 F (64 C) Continuous for PVC194 F (90 C) Continuous for CPVC248 F (120 C) Continuous for PPUL 441 Gas Vents, ULC S605 Gas Vents480 F (249 C) ContinuousUL 641 Type L Vent ULC S609 VentsType L570 F (300 C) ContinuousUL 1777 Chimney Liner ULC S635 LiningSystems for Existing ChimneysUL 1777: 570 F ContinuousULC S635: 650 C ContinuousUL 2221Fire Resistive Grease Duct EnclosureAssembly500 F (260 C) Continuous2000 F (1093 C) for 30 MinutesFurther features of Jeremias single wall systems include:a) No field weldingb) All stainless steel constructionc) Smooth flowing inner liner compared to welded steeld) Wide array of accessories such as supports and drainse) May be interconnected with the double wall modelsJoint DetailSizing/Pressure CalculationsAll Jeremias Inc. DWFL & SWFL models are cylindrical,factory-built, modular venting systems that incorporate anextended inner that self-aligns and a ½” flange / vee bandsystem for quick and easy assembly in the field. A Jeremiassupplied high temperature sealant is applied to the veeJeremias’ engineering uses its own software based uponthe “Chimney, Gas Vent, and Fireplace Systems” chapterof the ASHRAE Handbook to assure that the exhaust andchimney system is sized in accordance with the appliancemanufacturers’ installation instructions.7

TECHNICAL SPECIFICATIONSTECHNICALSPECIFICATIONSPipe Weight per FootSealant Usage Chart:The approximate installed weight of the DWFL and SWFLexhaust systems can be found using this table. This tabledoes not include accessories such as supports and guides,nor shipping packaging or palletizing weight.Shows expected number ofjoints sealed per tube.Pipe Weight in Lbs. per Foot:Jeremias can also provide submittals that show all requiredaccessories, including drains, supports etc., to be inaccordance with any specific appliance manufacturers’installation instructions.ØSWFLDWFLDWFL 1 DWFL 2 DWFL 3 DWFL-ZC DWFL 936“15.029.238.944.852.764.761.0Ø# of Joints6“108“ - 10“911“ - 12“813“ - 16“718“ - 20“622“ - 24“526“ - 28“430“ - 32“334“ - 36“2Joint AssemblyThe Jeremias double wall models joint system is designedfor a quick and easy installation. Follow Steps 1 through 3for general pipe and fittings assembly.Step 1:Apply sealant to flange surface. Join flanges together.Apply sealant to the inner groove of the V-Band. PositionV-Band around the flanges and tighten screws on V-Band.Sealant and UsageJeremias also provides two options for sealants basedupon temperature of the flue gases:J-2000 Sealant, for temperatures up to 2000 F. Use forcaulking/sealing V-bands and flange surfaces within thistemperature range.J-600 Sealant, for temperatures up to 600 F. Use forcaulking/sealing V-bands and flange surfaces within thistemperature range.J-400 SILV Sealant, for temperatures up to 400 F. Use forcaulking/sealing Locking Bands on exterior installations.8Step 2:Wrap the joint insulationaround the V-Band.Step 3:PositiontheLockingBand in place. Tighten theLocking Band hardware.Caulk the top of theLocking Band with J-400on exterior installations.

DWFL & SWFLADAPTERSRaw Collar Inside Adapter / DWFLØ-RCI2.603.546.50Raw Collar Outside Adapter / 32323434343436363636Includes Locking Band with Latch ClampIncludes Locking Band with Latch Clamp9

DWFL & SWFLADAPTERSRaw Collar Inside Adapter-Small / DWFLØ-RCI-SM2.603.546.50Raw Collar Outside Adapter-Large / DWFLØ-RCO-LGØA-0,25‘‘ØA 34343436363636Includes Locking Band with Latch Clamp10Includes Locking Band with Latch Clamp

DWFL & SWFLSUPPORTSLight Support Band / DWFLØ-LSB2.01C1.183.06.340.44Ø0.330.791.55Wall Brackets for Anchor Plate Support & Full Angle Ring / DWFLØ-WBD0.750.581.501.55ØBØBØ68.6613.78 22.24CD79.6713.78 22.24810.6815.75 24.21911.6917.72 24.211012.61017.72 24.211113.61117.72 26.181214.612 19.69 26.181315.6131416.614 21.65 26.181618.616 23.62 28.151820.618 25.59 28.152022.620 27.56 30.1221.65 26.182224.622 29.53 30.122426.624 29.53 30.122628.626 31.50 34.062830.628 33.46 36.023032.630 35.43 37.993234.632 37.40 39.963436.634 39.37 41.933638.636 41.34 43.90Included bolts and nuts M6x20. Wire not included11

DWFL & SWFLSUPPORTSElbow 90 with support leg / DWFLØ-90ESElbow 87 with support leg / DWFLØ-87ESØBØAØB5.505.50ØA01.6Ø6ØAØBE.0 875.50CCØBØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 10.93ØADE9.8 20.73Ø6D5.505.50D5.50ØBØAE01.6.0 90ØBØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 10.679.47 20.719.97 13.515.511.148810.512.514.516.511.9310.8 22.738810.512.514.516.511.62 10.48 22.729911.513.515.517.5 12.4311.3 23.739911.513.515.517.5 12.09 10.98 23.72101012.514.516.518.511.8 24.73101012.514.516.518.5 12.56 11.48 24.7219.5 13.4319.5 13.04 11.98 25.72111113.515.517.5121214.516.518.5 20.5131315.517.519.5141416.518.520.5161618.5 20.522.5181820.522.5202022.524.512.9312.3 25.73111113.515.517.513.9312.8 26.73121214.516.518.5 20.521.5 14.4313.3 27.73131315.517.519.522.5 14.9313.8 28.73141416.518.520.522.5 14.46 13.49 28.7324.515.9314.8 30.73161618.5 20.522.524.524.526.5 16.9415.8 32.74181820.522.524.526.5 16.3626.528.5 17.9416.8 34.74202022.524.526.528.513.51 12.48 26.7221.5 13.99 12.99 27.7215.41 14.49 30.73222224.526.528.5 30.5 18.9417.8 36.74222224.526.528.5 30.5 18.25242426.528.530.518.8 38.74242426.528.530.5Works with SBP1232.5 19.94Works with SBP32.515.5 32.7417.31 16.51 34.7417.51 36.7519.2 18.51 38.75

DWFL & SWFLSUPPORTSAnchor Plate Support / DWFLØ-APSPlate Support / 1812.43nØAØ6ØAØB6C8.5 14.561.00Ø6ØCØDE6.7 12.56 14.56779.5 15.5677.7 13.56 15.568810.5 16.5688.7 14.56 16.569911.5 17.5699.7 15.56 17.56101012.5 18.561010.7 16.56 18.56111113.5 19.561111.7 17.56 19.56121214.5 20.561212.7 17.56 20.56131315.5 21.561313.7 19.56 21.56141416.5 22.561414.7 20.56 22.56161618.5 24.561616.7 22.56 24.561818 20.5 26.561818.7 24.56 26.562020.7 26.56 28.56202022.5 28.56222224.5 30.562222.7 28.56 30.56242426.5 32.562424.7 30.56 32.56262628.5 34.562626.7 32.56 34.562828 30.5 36.562828.7 34.56 36.5630303030.7 36.56 38.5632.5 38.563232 34.5 40.563232.7 38.56 40.563434 36.5 42.563434.7 40.56 42.5636363636.7 42.56 44.5638.5 44.5613

DWFL & SWFLSUPPORTSDrain Tee Cap for support / DWFLØ-DCSSFull Angle Ring / BØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 9.96779.5ØØA11.513.515.5 9.9616.5 9.968810.512.514.59911.513.515.517.5 9.96101012.514.516.518.5 9.96111113.515.517.519.5 9.96121214.516.518.5 20.5 9.96131315.517.519.5141416.518.520.522.5 9.96161618.5 20.522.524.5 9.96181820.522.524.526.5 9.96202022.524.526.528.5 9.9621.5 9.96222224.526.528.5 30.5 9.96242426.528.530.5262628.5 30.532.5 34.5 11.22282830.532.534.536.5 11.22303032.5 34.536.538.5 11.2232.5 9.96323234.5 36.538.5 40.5 11.22343436.538.540.542.5 11.22363638.5 40.542.544.5 11.22Works with SBP. Includes Locking Band with gear Clamp14ØA68.5 A 1/8 ØA 2.3 ØA 4ØAØBØC79.5 A 1/8 ØA 2.3 ØA 4810.5 A 1/8 ØA 2.3 ØA 4911.5 A 1/8 ØA 2.3 ØA 41012.5 A 1/8 ØA 2.3 ØA 41113.5 A 1/8 ØA 2.3 ØA 41214.5 A 1/8 ØA 2.3 ØA 41315.5 A 1/8 ØA 2.3 ØA 41416.5 A 1/8 ØA 2.3 ØA 41618.5 A 1/8 ØA 2.3 ØA 41820.5 A 1/8 ØA 2.3 ØA 42022.5 A 1/8 ØA 2.3 ØA 42224.5 A 1/8 ØA 2.3 ØA 42426.5 A 1/8 ØA 2.3 ØA 42628.5 A 1/8 ØA 2.3 ØA 42830.5 A 1/8 ØA 2.3 ØA 43032.5 A 1/8 ØA 2.3 ØA 43234.5 A 1/8 ØA 2.3 ØA 43436.5 A 1/8 ØA 2.3 ØA 43638.5 A 1/8 ØA 2.3 ØA 4

DWFL & SWFLSUPPORTSHalf Angle Ring / DWKLØ-HARGuy Wires Band / DWKLØ-GWB0.06 Thickness0.4380.187ThicknessØAØA68.5 A 1/8 ØA 2.3 ØA 4ØAØBØC68.579.5 A 1/8 ØA 2.3 ØA 479.5810.5 A 1/8 ØA 2.3 ØA 4810.5911.5 A 1/8 ØA 2.3 ØA 4911.51012.5 A 1/8 ØA 2.3 ØA 41012.51113.5 A 1/8 ØA 2.3 ØA 41113.51214.5 A 1/8 ØA 2.3 ØA 41214.51315.5 A 1/8 ØA 2.3 ØA 41315.51416.5 A 1/8 ØA 2.3 ØA 41416.51618.5 A 1/8 ØA 2.3 ØA 41618.51820.5 A 1/8 ØA 2.3 ØA 41820.52022.5 A 1/8 ØA 2.3 ØA 42022.52224.5 A 1/8 ØA 2.3 ØA 42224.52426.5 A 1/8 ØA 2.3 ØA 42426.52628.5 A 1/8 ØA 2.3 ØA 42628.52830.5 A 1/8 ØA 2.3 ØA 42830.53032.5 A 1/8 ØA 2.3 ØA 43032.53234.5 A 1/8 ØA 2.3 ØA 43234.53436.5 A 1/8 ØA 2.3 ØA 43436.53638.5 A 1/8 ØA 2.3 ØA 43638.515

DWFL & SWFLSTRAIGHT LENGTHS12“ Fixed Length / DWFLØ-12L18“ Fixed Length/ 6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 .516.58810.512.514.516.5ØØAØ6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 7.519.5111113.515.517.5121214.516.518.5 20.5121214.516.518.5 .518.520.522.5141416.518.520.522.5161618.5 20.522.524.5161618.5 26.528.5 30.5222224.526.528.5 30.5242426.528.530.532.5242426.528.530.5262628.5 30.532.5 34.5262628.5 30.532.5 .5 34.536.538.5303032.5 34.536.538.532.5323234.5 36.538.5 40.5323234.5 36.538.5 .5 40.542.544.5363638.5 40.542.544.5*Installed Lengths. Part includes V-Band and Locking Band.16*Installed Lengths. Part includes V-Band and Locking Band.

DWFL & SWFLSTRAIGHT LENGTHS24“ Fixed Length / DWFLØ-24L30“ Fixed Length / 6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 .516.58810.512.514.516.5ØØAØ6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 7.519.5111113.515.517.5121214.516.518.5 20.5121214.516.518.5 .518.520.522.5141416.518.520.522.5161618.5 20.522.524.5161618.5 26.528.5 30.5222224.526.528.5 30.5242426.528.530.532.5242426.528.530.5262628.5 30.532.5 34.5262628.5 30.532.5 .5 34.536.538.5303032.5 34.536.538.532.5323234.5 36.538.5 40.5323234.5 36.538.5 .5 40.542.544.5363638.5 40.542.544.5*Installed Lengths. Part includes V-Band and Locking Band.*Installed Lengths. Part includes V-Band and Locking Band.17

DWFL & SWFLSTRAIGHT LENGTHS42“ Fixed Length / DWFLØ-42L36“ Fixed Length / 6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 .516.58810.512.514.516.5ØØAØ6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 7.519.5111113.515.517.5121214.516.518.5 20.5121214.516.518.5 .518.520.522.5141416.518.520.522.5161618.5 20.522.524.5161618.5 26.528.5 30.5222224.526.528.5 30.5242426.528.530.532.5242426.528.530.5262628.5 30.532.5 34.5262628.5 30.532.5 .5 34.536.538.5303032.5 34.536.538.532.5323234.5 36.538.5 40.5323234.5 36.538.5 .5 40.542.544.5363638.5 40.542.544.5*Installed Lengths. Part includes V-Band and Locking Band.18*Installed Lengths. Part includes V-Band and Locking Band.

DWFL & SWFLSTRAIGHT LENGTHS48“ Fixed Length / DWFLØ-48L2.4848.0046.75ØBØAØ6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 121214.516.518.5 .5 .5222224.526.528.5 30.5242426.528.530.5262628.5 30.532.5 34.5282830.532.534.536.5303032.5 34.536.538.532.5323234.5 36.538.5 40.5343436.538.540.542.5363638.5 40.542.544.5*Installed Lengths. Part includes V-Band and Locking Band.19

DWFL & SWFLADJUSTABLE LENGTHS24“ Adjustable Length with gasket / DWFLØ-24ALG3.3024“ Adjustable Length / DWFLØ-24AL6xØ0.3329.8524.00 max. - 8.00 min.22.75 max. - 6.75 min.22.75 max. - 6.75 min.29.8524.00 max. - 8.00 BFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 .516.58810.512.514.516.5ØØAØ6ØBØBØBØBFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 7.519.5111113.515.517.5121214.516.518.5 20.5121214.516.518.5 .518.520.522.5141416.518.520.522.5161618.5 20.522.524.5161618.5 26.528.5 30.5222224.526.528.5 30.5242426.528.530.532.5242426.528.530.5262628.5 30.532.5 34.5262628.5 30.532.5 .5 34.536.538.5303032.5 34.536.538.532.5323234.5 36.538.5 40.5323234.5 36.538.5 .5 40.542.544.5363638.5 40.542.544.5*Installed Lengths. Part includes V-Band and Locking Band.20*Installed Lengths. Part includes V-Band and Locking Band.

DWFL & SWFLELBOWS15 Elbow / DWFLØ-15EL30 Elbow / DWFLØ-30ELØB30.0 DDØAØBØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 11.93DØ1.576779.511.513.515.5 12.051.598810.512.514.516.5 .0 ØBØAØBØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 12.413.33779.511.513.515.5 12.663.398810.512.514.516.5 12.91 3.46ØAD9911.513.515.517.5 12.311.629911.513.515.517.5 13.163.53101012.514.516.518.5 12.441.64101012.514.516.518.5 13.413.5919.5 12.5719.5 13.66 3.66111113.515.517.5121214.516.518.5 20.51.66111113.515.517.512.71.67121214.516.518.5 20.5 13.91131315.517.519.53.7321.5 8.5 20.522.522.5 12.961.71141416.518.520.522.5 14.41 3.8624.5 13.221.74161618.5 20.522.524.5 14.91181820.522.524.526.5 13.4841.77181820.522.524.526.5 15.424.13202022.524.526.528.5 13.74222224.526.528.5 30.528.5 15.92 4.26242426.528.530.5262628.5 30.5282830.532.5303032.5 34.536.521.5 14.161.81202022.524.526.5141.84222224.526.528.5 30.5 16.4232.5 14.261.88242426.528.530.532.5 34.5 14.511.91262628.5 30.532.5 34.5 17.42 4.6734.536.5 14.771.95282830.532.534.536.5 17.9238.5 15.031.98303032.5 34.536.538.5 18.42 4.934.432.5 16.92 4.534.8323234.5 36.538.5 40.5 15.292.01323234.5 36.538.5 40.5 18.92343436.538.540.542.5 15.55 2.05343436.538.540.542.5 19.42363638.5 40.542.544.5 15.81 2.08363638.5 40.542.544.5 19.92 5.34Includes Locking Band with gear Clamp.5.075.2Includes Locking Band with gear Clamp.21

DWFL & SWFLELBOWS45 Elbow / DWFLØ-45EL87 Elbow / DWFLØ-87ELD87.0 D45.0 6ØBØBØBØBCFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 12.43779.511.513.515.5 12.785.29779.511.513.515.5 11.748810.512.514.516.5 13.14 5.448810.512.514.516.5 12.24 11.62ØØADØ5.156ØBØBØBØBCDFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 11.24 10.67ØA11.149911.513.515.517.5 13.495.599911.513.515.517.5 12.74 12.09101012.514.516.518.5 13.845.73101012.514.516.518.5 13.24 12.5619.519.5 13.74 13.04111113.515.517.514.2 5.88111113.515.517.5121214.516.518.5 20.5 14.55 6.03121214.516.518.5 20.5 14.24 1.5 14.74 13.99141416.518.520.522.5 15.266.32141416.518.520.522.5 15.24 14.46161618.5 20.522.524.5 15.976.61161618.5 20.522.524.5 16.24 15.41181820.522.524.526.5 16.686.91181820.522.524.526.5 17.24 16.36202022.524.526.528.5 17.387.2202022.524.526.528.5 18.24222224.526.528.5 30.5 18.097.49222224.526.528.5 30.5 19.24 18.25242426.528.530.57.79242426.528.530.5262628.5 30.532.5 34.519.5 8.08262628.5 30.532.5 34.5 21.23 20.15282830.532.534.536.5 20.218.37282830.532.534.536.5 22.23303032.5 34.536.538.5 20.92 8.66303032.5 34.536.538.5 23.23 22.0532.518.832.5 20.2317.3119.221.1323234.5 36.538.5 40.5 21.63 8.96323234.5 36.538.5 40.5 24.23 22.99343436.538.540.542.5 22.339.25343436.538.540.542.5 25.23 23.94363638.5 40.542.544.5 23.04 9.54363638.5 40.542.544.5 26.23 24.89Includes Locking Band with gear Clamp.22Includes Locking Band with gear Clamp.

DWFL & SWFLELBOWS90 Elbow/ DWFLØ-90ELD2.485.501.605.50CØB90.0 1.25ØAØ6ØBØBØBØBCDFL, FL 1 FL 2 FL 3, ZC FL 468.5 10.512.5 14.5 10.93 10.93ØA779.511.513.515.5 11.43 11.438810.512.514.516.5 11.93 11.939911.513.515.517.5 12.43 12.43101012.514.516.518.5 12.93 12.9319.5 13.43 13.43111113.515.517.5121214.516.518.5 20.5 13.93 13.93131315.517.519.521.5 14.43 14.43141416.518.520.522.5 14.93 14.93161618.5 20.522.524.5 15.93 15.93181820.522.524.526.5 16.94 16.94202022.524.526.528.5 17.94 17.94222224.526.528.5 30.5 18.94 18.94242426.528.530.5262628.5 30.532.5 34.5 20.94 20.94282830.532.534.536.5 21.94 21.94303032.5 34.536.538.5 22.94 22.9432.5 19.94 19.94

5. UL 1777 Standard, Chimney Liners Canada: DWFL, DWFL 1, DWFL 2. DWFL 3 & DWFL 4 1. ULC/ORD-C959 Industrial Type 540 C Chimney 2. ULC/ORD-C959 Industrial Type 760 C Chimney 3. ULC S662 Standard for Factory-Built Grease Ducts Operating Pressures All Jeremias Inc. DWFL & SWFL models have been