Transcription

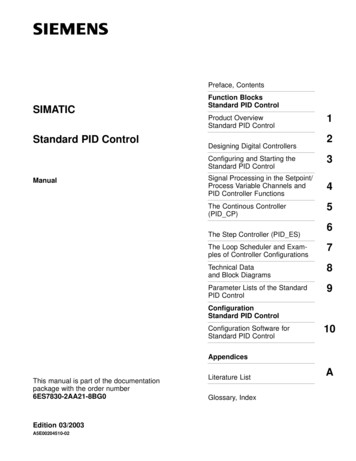

Preface, ContentsSIMATICStandard PID ControlManualFunction BlocksStandard PID ControlProduct OverviewStandard PID ControlDesigning Digital Controllers12Configuring and Starting theStandard PID Control3Signal Processing in the Setpoint/Process Variable Channels andPID Controller Functions4The Continous Controller(PID CP)5The Step Controller (PID ES)6The Loop Scheduler and Examples of Controller Configurations7Technical Dataand Block Diagrams8Parameter Lists of the StandardPID Control9ConfigurationStandard PID ControlConfiguration Software forStandard PID Control10AppendicesThis manual is part of the documentationpackage with the order number6ES7830-2AA21-8BG0Edition 03/2003A5E00204510-02Literature ListGlossary, IndexA

Safety GuidelinesThis manual contains notices intended to ensure personal safety, as well as to protect the products andconnected equipment against damage. These notices are highlighted by the symbols shown below andgraded according to severity by the following texts:!!!Dangerindicates that death, severe personal injury or substantial property damage will result if proper precautionsare not taken.Warningindicates that death, severe personal injury or substantial property damage can result if properprecautions are not taken.Cautionindicates that minor personal injury can result if proper precautions are not taken.Cautionindicates that property damage can result if proper precautions are not taken.Noticedraws your attention to particularly important information on the product, handling the product, or to aparticular part of the documentation.Qualified PersonnelOnly qualified personnel should be allowed to install and work on this equipment. Qualified persons aredefined as persons who are authorized to commission, to ground and to tag circuits, equipment, andsystems in accordance with established safety practices and standards.Correct UsageNote the following:!WarningThis device and its components may only be used for the applications described in the catalog or thetechnical description, and only in connection with devices or components from other manufacturers whichhave been approved or recommended by Siemens.This product can only function correctly and safely if it is transported, stored, set up, and installedcorrectly, and operated and maintained as recommended.TrademarksSIMATIC , SIMATIC HMI and SIMATIC NET are registered trademarks of SIEMENS AG.Third parties using for their own purposes any other names in this document which refer to trademarksmight infringe upon the rights of the trademark owners.Copyright W Siemens AG 2002 – 2003 All rights reserved Disclaim of LiabilityThe reproduction, transmission or use of this document or itscontents is not permitted without express written authority.Offenders will be liable for damages. All rights, including rightscreated by patent grant or registration of a utility model ordesign, are reserved.Siemens AGBereich Automation and DrivesGeschaeftsgebiet Industrial Automation SystemsPostfach 4848, D- 90327 NuernbergIndex-2AktiengesellschaftSiemensWe have checked the contents of this manual for agreementwith the hardware and software described. Since deviationscannot be precluded entirely, we cannot guarantee fullagreement. However, the data in this manual are reviewedregularly and any necessary corrections included insubsequent editions. Suggestions for improvement arewelcomed. Siemens AG 2003Technical data subject to change.A5E00204510-02Standard PID ControlA5E00204510-02

PrefacePurpose of the ManualThis manual will help you when selecting, configuring, and assigning parameters toa controller block for your control task.The manual introduces you to the functions of the configuration tool and explainshow you use it.Required Basic KnowledgeTo understand this manual, you should be familiar with automation and processcontrol engineering.In addition, you should know how to use computers or devices with similarfunctions (e.g programming devices) under Windows 95/98/2000 or NT operatingsystems. Since Standard PID Control is based on the STEP 7 software, youshould also know how to operate it. This is provided in the manual “Programmingwith STEP 7 V5.1”.Where is this Manual valid?This manual is valid for the software packages Standard PID Control V5.1 andStandard PID Control Tool V5.1.Standard PID ControlA5E00204510-02iii

PrefacePlace of this Documentation in the Information rationManualThe “Standard PID Control” software product includes three separate products: The product ”Standard PID Controller FB” consists essentially of the twocontroller blocks PID CP and PID ES. The product “Standard PID Control Tool” consists essentially of the tools forconfiguring the controller blocks.This product is referred to simply as “configuration tool” in this manual. This manual is a separate product and describes both the product ”StandardPID Control FB” and the configuration tool ”Standard PID Control Tool”.The “Standard PID Control” Software PackageThe “Standard PID Control” software package provides a comprehensive conceptfor implementing control functions in the SIMATIC S7 programmable logiccontrollers. The controller is completely programmed with its full range of functionsand features for signal processing. To adapt a controller to your process, yousimply select the subfunctions you require from the complete range of functions.The time and effort required for configuration is therefore reduced to omittingfunctions you do not require. In all these tasks, you are supported by theconfiguration tool.Since configuration is restricted to selecting or, in some cases, extending basicfunctions, the concept of the Standard PID Control is easy to learn. Even userswith only limited knowledge of control systems will create high-quality controls.ivStandard PID ControlA5E00204510-02

PrefaceFinding Your Way Chapter 1 provides you with an overview of the Standard PID Control. Chapter 2 explains the structure and the functions of the Standard PID Control. Chapters 3 helps you to design and start up a Standard PID Control. Chapters 4 explains the signal processing in the setpoint/process-variablechannel and in the controller. Chapters 5 explains the signal processing in the continuous controller output. Chapters 6 explains the signal processing in the step controller output. Chapters 7 shows you how to work with the loop scheduler and introducesexamples of controller structures. Chapters 8 contains technical data and block diagrams. Chapters 9 contains parameter lists for the Standard PID Control. Chapters 10 provides you with an overview of the configuration tool. Appendices A contains the literature list. Important terms are explained in the glossary. The index helps you to access areas containing keywords easily and fast.AudienceThis manual is intended for the following readers: S7 programmers programmers of control systems operators service personnelStandard PID ControlA5E00204510-02v

PrefaceConventions in the TextTo make it easier for you to find information in the manual, certain conventionshave been used: First glance through the titles in the left margin to get an idea of the content of asection. Sections dealing with a specific topic either answer a question about thefunctions of the tool or provide information about necessary or recommendedcourses of action. References to further information dealing with a topic are indicated by (seeChapter x.y). References to other manuals and documentation are indicated bynumbers in slashes /./. These numbers refer to the titles of manuals listed inthe Appendix. Instructions for you to follow are marked by a black dot. Sequences of activities are numbered or explained as explicit steps. Alternative courses of action or decisions you need to take are indicated by adash.Further InformationThis manual is intended as a reference work that provides you with the informationyou will require to work with the standard controller. You do, however, require abroader scope of information that is available in the following manuals: /70/, /71/,/100/, /101/, /231/, /232/, /234/, /352/.Further SupportIf you have any technical questions, please get in touch with your Siemensrepresentative or agent nerTraining CentersSiemens offers a number of training courses to familiarize you with the SIMATICS7 automation system. Please contact your regional training center or our centraltraining center in D 90327 Nuremberg, Germany for details:viTelephone: 49 (911) 895-3200.Internet:http://www.sitrain.comStandard PID ControlA5E00204510-02

PrefaceA&D Technical SupportWorldwide, available 24 hours a day:NuernbergJohnson CityBeijingTechnical SupportWorldwide (Nuernberg)Technical Support24 hours a day, 365 days a yearPhone: 49 (0) 180 5050-222Fax: 49 (0) 180 5050-223E-Mail:adsupport@siemens.comGMT: 1:00Europe / Africa (Nuernberg)United States (Johnson City)Asia / Australia (Beijing)AuthorizationTechnical Support andAuthorizationTechnical Support andAuthorizationLocal time: Mon.-Fri. 8:00 to 17:00Local time: Mon.-Fri. 8:00 to 17:00Local time: Mon.-Fri. 8:00 to 17:00Phone:Fax: 49 (0) 180 5050–222 49 (0) 180 5050-223Phone: 1 (0) 423 262 2522Phone: 86 10 64 75 75 75Fax: 1 (0) 423 262 2289Fax: 86 10 64 74 74 74adsupport@siemens.com MT:–5:00GMT:adsupport.asia@siemens.com 8:00E-Mail:GMT:The languages of the SIMATIC Hotlines and the authorization hotline are generally German and English.Standard PID ControlA5E00204510-02vii

PrefaceService & Support on the InternetIn addition to our documentation, we offer our Know-how online on the internet rtwhere you will find the following: The newsletter, which constantly provides you with up–to–date information onyour products. The right documents via our Search function in Service & Support. A forum, where users and experts from all over the world exchange theirexperiences. Your local representative for Automation & Drives via our representativesdatabase. Information on field service, repairs, spare parts and more under “Services”.viiiStandard PID ControlA5E00204510-02

Contents1234Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iiiContents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ixProduct Overview Standard PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11.1The Product ”Standard PID Control” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11.2The ”Standard PID Control Software Product ” . . . . . . . . . . . . . . . . . . . . . .1-31.3The Application Environment and the Field of Application . . . . . . . . . . . . .1-5Designing Digital Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12.1Process Characteristics and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12.2Identifying Process Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-52.3Feedforward Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72.4Multi-Loop Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-82.5Structure and Mode of Operation of the Standard PID Control . . . . . . . . .2-112.6Signal Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15Configuring and Starting the Standard PID Control . . . . . . . . . . . . . . . . . . . . . . .3-13.1Defining the Control Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13.2Configuring a Project ”Configuring” (Checklist) . . . . . . . . . . . . . . . . . . . . . .3-73.3Configuring the Standard PID Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-103.4The Sampling Time CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-143.5How the Standard PID Control is Called . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-163.6Range of Values and Signal Adaptation (Normalization) . . . . . . . . . . . . . .3-18Signal Processing in the Setpoint/Process Variable Channels andPID Controller Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14.14.1.14.1.24.1.34.1.44.1.54.1.64.1.7Signal Processing in the Setpoint Branch . . . . . . . . . . . . . . . . . . . . . . . . . . .Setpoint Generator (SP GEN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ramp Soak (RMP SOAK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Normalization of the External Setpoint (SP NORM) . . . . . . . . . . . . . . . . . .FC Call in the Setpoint Branch (SPFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Limiting the Rate of Change of the Setpoint (SP ROC) . . . . . . . . . . . . . . .Limiting the Absolute Value of the Setpoint (SP LIMIT) . . . . . . . . . . . . . . .Setpoint Adjustment Using the Configuration Tool . . . . . . . . . . . . . . . . . . . .4-14-14-34-124-154-174-194-214.24.2.14.2.2Signal Processing in the Process Variable Branch . . . . . . . . . . . . . . . . . . .Normalizing the Process Variable Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Damping the Process Variable (LAG1ST) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-224-224-24Standard PID ControlA5E00204510-02ix

Contents564.2.34.2.44.2.54.2.64.2.7Extracting the Square Root (SQRT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FC Call in the Process Variable Branch (PVFC) . . . . . . . . . . . . . . . . . . . . .Monitoring the Process

graded according to severity by the following texts: . This manual is intended for the following readers: S7 programmers programmers of control systems operators service personnel. Preface vi Standard PID Control A5E00204510-02 Conventions in the Text To make it easier for you to find information in the manual, certain conventions have been used: First glance through the .