Transcription

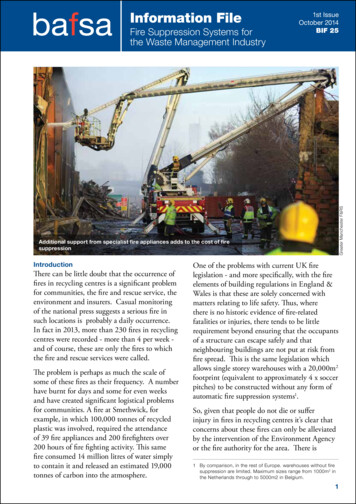

Fire Suppression Systems forthe Waste Management Industry1st IssueOctober 2014BIF 25Greater Manchester F&RSInformation FileAdditional support from specialist fire appliances adds to the cost of firesuppressionIntroductionThere can be little doubt that the occurrence offires in recycling centres is a significant problemfor communities, the fire and rescue service, theenvironment and insurers. Casual monitoringof the national press suggests a serious fire insuch locations is probably a daily occurrence.In fact in 2013, more than 230 fires in recyclingcentres were recorded - more than 4 per week and of course, these are only the fires to whichthe fire and rescue services were called.The problem is perhaps as much the scale ofsome of these fires as their frequency. A numberhave burnt for days and some for even weeksand have created significant logistical problemsfor communities. A fire at Smethwick, forexample, in which 100,000 tonnes of recycledplastic was involved, required the attendanceof 39 fire appliances and 200 firefighters over200 hours of fire fighting activity. This samefire consumed 14 million litres of water simplyto contain it and released an estimated 19,000tonnes of carbon into the atmosphere.One of the problems with current UK firelegislation - and more specifically, with the fireelements of building regulations in England &Wales is that these are solely concerned withmatters relating to life safety. Thus, wherethere is no historic evidence of fire-relatedfatalities or injuries, there tends to be littlerequirement beyond ensuring that the occupantsof a structure can escape safely and thatneighbouring buildings are not put at risk fromfire spread. This is the same legislation whichallows single storey warehouses with a 20,000m2footprint (equivalent to approximately 4 x soccerpitches) to be constructed without any form ofautomatic fire suppression systems1.So, given that people do not die or sufferinjury in fires in recycling centres it’s clear thatconcerns about these fires can only be alleviatedby the intervention of the Environment Agencyor the fire authority for the area. There is1 By comparison, in the rest of Europe. warehouses without firesuppression are limited. Maximum sizes range from 1000m 2 inthe Netherlands through to 5000m2 in Belgium.1

Perhaps the only encouraging aspects ofthis litany of fire and destruction are theinstances where enlightened operators havetaken the decision to install automatic firesuppression systems and where such systemshave successfully operated and significantlyminimised both the damage, the need for fireservice intervention and the downtime whichfollows so many fires.Fire Safety Management & GuidanceAt the time of writing, new guidance for the managementof fire safety is being prepared by a consortium of owners,operators, insurers, regulators and the fire service. Thiswill supplement the existing Environment Agencyguidance given in TGN 7.01. Other useful sources ofadvice include insurers, many of whom provide guidancefor their clients and from CFPA Europe2.As with all workplaces, it is essential for the operatoror owner of a recycling site to manage fire safety in astructured manner: Develop and issue a written fire safety policy. Effectiveinternal mechanisms should exist to ensure that thepolicy is properly implemented and covers not only thenormal operating regime of the location but take intoaccount special or occasional events. Undertake a fire risk assessment (FRA) and review itregularly and in the event that any material fact changes- for example, if you start accepting a different class ofmaterial.2 Confederation of Fire Protection Associations - Europe:European Guideline: Treatment and storage of waste andcombustible secondary raw materials: PA E GuidelineNo 32 2014 F1.pdf2 Take steps to eliminate or reduce any hazards disclosedby the FRA. Ensure that a single person is made responsible for allfire safety matters and that everyone on site knowswhom this is.Pyro Protection LtdSprinklers protect this reception areaSprinkler water supply for conveyor protection Each property should compile a fire safety manualsetting out its strategy and detailing its plans in case offire and as a basis for training. Locations should alsomaintain a logbook to record all fire-related eventssuch as training, drills, inspections and equipmentmaintenance. Upgrade and maintain both passive (fire separation,construction etc) and active fire safety measures(detection and suppression) as necessary. A systematic and effective training programme shouldbe introduced to ensure that all staff know how tominimise fire risks, how to raise the alarm in case of fireand to provide enough trained staff to tackle incipientfires quickly. ‘Hands-on’ training with portable fireequipment (including hose reels if fitted) shouldbe provided for any staff member who is likely toencounter a fire. Put in place effective precautions to manage contractorsand maintenance work and in particular, to control allhot work. Set up regular liaison meetings with the local fire andrescue service and, in the case of larger sites, considerinviting personnel from the nearest fire stations to visitthe site and familiarise themselves with its access roads,layout and equipment. Ensure that, where available, acopy of the fire and rescue service’s ‘tactical plan’ for thesite is obtained and understood.London Fire Brigadeevidence that such intervention can be effectivewith a prosecution in Derbyshire which resultedin the facility being closed and the managerimprisoned and barred from future employmentas a director.

Ensure that the risk of arson (fire setting) is consideredand appropriate security precautions are in place toprevent intrusion. Consider the need for a business continuity plan.Fire FightingFighting fires is acknowledged as a dirty and dangerousactivity and fighting fires in recycling centres is noexception. Anything that facilitates a swift and effectiveresponse will provide significant benefits in terms ofreducing the damage on site, reducing the environmentalimpact of a fire, reducing the volume of water consumedand, most importantly minimising the risk of injury tofirefighters.The most effective way of dealing with any fire is rapidintervention; to attack it in its earliest stages. Not onlydoes this minimise the damage caused by heat andsmoke but also the collateral damage caused by water.It is a well established fact that the application of waterfrom a sprinkler system on to a developing fire two orthree minutes after it starts uses up to 90% less waterthan will be applied by the fire service when they arrive.Another significant benefit from early suppression isa reduction in the volume of fire water run-off whichin the quantities likely from fire and rescue serviceintervention is an environmental threat which theEnvironment Agency takes seriously.The options for fire fighting equipment are:Portable fire extinguishers: To be used by siteoperatives on small or incipient fires. Portables are mosteffective in trained hands. The type of extinguisher willdepend on the primary fire hazard present, but water or3waterspray is most effective on normal combustibles suchas paper, plastics and rubber.Larger wheeled extinguishers: Common in powerstations and refineries, these larger capacity (typically120 litres/80kg) units can be very effective on fires inoutdoor storage. Trolleys usually contain a foam/watermixture but powder units are available. More recentdevelopments include wheeled watermist extinguisherswhich when used by trained staff are very effectivein small - medium sized fires. Watermist back-packsare also available but should only be used by speciallytrained staff.Fire hose reels: These used to be very common inmost industrial and commercial properties and areavailable in 19mm or 25mm diameters. Hose reelsshould only be used by staff specifically trained in theiruse. Water applied through hoses in the form of a sprayor fog will reduce the amount of fire-water run-off andhence minimise the risks of pollution and minimise thecost of water treatment.Water supplies: Where the entrance to a site is morethan 90m from an existing fire hydrant, additionalprivate hydrants may be necessary. Alternatively,operators should consider installing a charged staticwater tank of at least 45,000 litres capacity with suitableconnections for fire & rescue service equipment3. Onlarge recycling sites it is worth considering the provisionof an internal fire water supply with its own pumpsfeeding a fire main through which fire hydrants aresupplied. The same fire main can be used to feed fire3 See Approved Document B Vol 2 Section 15 particularly forbuildings with a compartment more than 280m 2.GMF&RSFighting fires in waste management premises is often long drawn out

GMF&RSsuppression systems with the agreement of insurers.Sizing of the water supplies, pumps and the fire mainis a specialist activity and advice from a competentsource is essential.Fixed manual systems: These consist of pipeworksupplying open deluge/waterspray projectors(nozzles) installed on the walls in (for example) thewaste reception area supplied with water from abreeching inlet connection (fire service inlet). Thistype of installation would not need a fixed watersupply such as a public fire hydrant and wouldenable the FRS to apply water/foam directly intothe waste which is burning. For such an option tobe viable, there would need to be an available watersupply a public fire hydrant (on or off site) within100 metres and suitable hardstanding for a fireappliance (see Water Supplies).Deluge/waterspray system – as above, butdirectly connected to a suitable water supply (firemain, pumped water storage tank etc). Systems caneither be manual or automatic (if automatic, theuse of heat detection rather than smoke sensors willreduce the possibility of spurious or false activations).The primary difference between a deluge systemand a sprinkler system is that in the former, wateris applied from all heads simultaneously whereas insprinkler systems only the heads in the immediatearea of the fire will open. Deluge systems will bemost useful for protecting specific items of plant andmachinery rather than large areas.Water monitors/cannon: Fixed or oscillatingmonitors can be located to cover outdoor storageand, when supplied with water from an internal firemain will provide extensive wetting of the outersurfaces of burning stacks. However, care should betaken when applying water at high pressure in a solidstream, as this may result in the waste on fire beingspread. Foam concentrate may be injected into thefire water stream to provide enhanced penetration ofstacks.Sprinkler systems: Will probably provide theoptimum level of protection inside buildings andstructures, including covering storage areas, sortingareas and provide optimum levels of protection4Protection of elevated conveyors is essentialand provides enhanced business continuityprovisionSpecial problemsThere is increasing interest in waste-derived fuelfor the generation of electricity and this effectivelymeans that some recycling centres contain smallpower stations - with all the hazards that impliesfrom steam or combustion turbines, large volumesof hot lubricating oil, oil-filled transformers androtating machinery. It is BAFSA’s views that thehazards of burning waste-derived fuels in generatingplants can be countered by following the advice inthis BIF.There are no specific UK or European standards orregulations in respect of the fire protection whichshould be provided for power generation sites.The best sources of guidance for this will be frominsurers or from the US National Fire ProtectionLFBGMF&RSIn the absence of automatic fire suppression,fire fighters have no alternative but to make aclose approachover conveyors and hoppers. Foam additives whichcan be injected into sprinkler systems may alsobe considered for sites accepting high volumes ofplastics or other higher risk wastes. The use of foamas a wetting agent will also reduce the volume ofwater needed to fight a fire.Watermist systems: In the context of recyclingplants, watermist is most likely to be effective whenutilised to protect plant and machinery rather thanopen spaces.Smoke ventilation: One potential problem withfighting fire in enclosed reception areas is smokeand experience suggests that most waste firesgenerate very large volumes of toxic smoke. Th iswill obscure the seat of the fire and make it difficultfor the fire service to direct water onto this. Subjectto your FRA assessment, consideration could begiven to the use of passive or automatic smokevents in the roof over reception areas – possibly inconjunction with some form of smoke barrier suchas a downstand or smoke curtain. However, suchvents can cause interaction problems with some firedetection and suppression systems resulting in adelay in activation – specialist advice on this issueshould be sought.

such standards, the owner of a site can demonstratethat he or she has effectively discharged anystatutory duty in this respect.At the same time, utilising the services of aninstaller who is subject to a third party certificationprocess and who will install equipment which hasitself been tested independently and certificatedwill demonstrate the highest standards of care incomplying with the responsibilities of a dutyholder.For more information on third party certificationrefer to BAFSA Information File No 206.Association’s Code of Practice NFPA 950:2010.4 FMGlobal, an international insurer also publishes usefuldata sheets on fire protection of turbines and relatedpower generation equipment5.For specialist storage systems, the selection of theoptimum levels of fire suppression will depend onthe specific situation. For example, in the case ofsilos storing wood chips or pellets great care shouldbe taken that the way in which water applied doesnot generate a solid mass of material which couldshelter a fire generating a very dangerous situationfor firefighters. Watermist or a gas inerting systemmay be more appropriate in such case cases. This isone area where specialist advice from your insurerthe fire service or other competent source of advice isessential.Systems which generate or move large amountsof dust may need to be provided with explosionsuppression systems - usually based on drypowder. Specialist advice should be sought in thiscase. Bag fi ltration systems and cooling towersand related plant should also be considered tobe at high risk and a fi re suppression provided asindicated by the FRA.LFBLarge and expensivemechanical handlingplant can onlybe protected byan automatic firesuppression systemSpecific StandardsPortable extinguishers should be designed andmanufactured to BS EN 3 and installed andmaintained in accordance with BS 5306 Part 8.Sprinkler systems where installed, should bedesigned, installed, commissioned and maintained inaccordance with an appropriate standard. At present,in the UK this would be one of the following: BS EN 128457 FM Global Datasheets 2.0 Installation Guidelinesfor Automatic Sprinklers8 NFPA 139 CEA 400110Note that systems being installed to satisfy UKinsurers’ conditions may also have to comply withthe LPC Sprinkler Rules for Automatic SprinklerInstallations which incorporate the contents ofBS EN 12845 together with additional TechnicalBulletins11.Note that in certain circumstances, for example,where there is a very high roof and a dry sprinklersystem, the design requirements set out in BSEN 12845 for non-storage hydraulic criteria andchoice of sprinkler heads might not be adequateor appropriate. In such cases, specialised insuranceinput is essential.Watermist systems should be installed to BS8489 - note that Part 1 of this standard requires thatall such systems should be designed in accordancewith the tests specified in Parts 2-7 or subject toan independent test for the specific occupancy.Alternatively, systems designed to EN TS 14972 orFM Global data sheets may be called for.Standards and Third Party CertificationThe utilisation of British and European (CEN)standards is essential when procuring fireprotection systems. By purchasing equipmentwhich is designed and installed in accordance with6 92.pdf4 NFPA 850:2010 Recommended Practice for FireProtection for Electric Generating Plants. Chapter 9 coversthe use of WDF and biomass.10 01?cntnt01hideAllFilters 15 ter.aspx?action new11 asp?id 47&Blue True7 Some insurers may request the use of other standardssuch as NFPA 13 or the FM Global datasheets.8 http://www.fmglobal.com/page.aspx?id 040102009 formation-pages?mode code&code 135

Pyro Protection LtdSorting equipment also benefits from automatic fire suppression protectionDeluge/waterspray systems should be designed to NFPA15 or EN DD TS 14816.Other components and equipment: hydrants, hosesand fire service inlets should be fitted with instantaneouscouplings to BS 336, but above ground hydrants used inthe UK tend to be of US manufacture so will normallycomply with ANSI C503 (wet barrel) or C502 (drybarrel). Hose reels should be manufactured to BS EN671-1 but their design and installation should followBS 5301 Part 1 - which also covers foam inlets andfire service connections. The standard for wet and dryrisers is presently being revised. Where no specific BS orEN standard exists then equipment with a UL or FMapproval should be specified.The ProofSome far sighted and enlightened operators of recyclingoperations have in fact installed fire suppression systems intheir plants and in 2013, successful actuations of sprinklersystems prevented serious damage to a wood pellet plantin Bridgend, recycling plants in Stockport and Shropshireand a paper recycling plant on Deeside. A major fire wasaverted in March 2014 in a Westbury, Wiltshire, plant.In the latter case, the fire service said: “The sprinklersystem saved the day - a number of sprinkler heads wereoperating, containing the fire to one area”.All of these protected plants were back in businessalmost immediately with little or no damage to thestructures and equipment. Is it any wonder that someinsurers now insist on fire suppression in recycling plantsas a condition of providing insurance cover?ConclusionsWhile recycling is an essential part of the UK’s economyand critical in enabling the country to comply withits international obligations to reduce the volume ofrefuse going to landfill, proper management of centresreceiving, processing and converting waste is essential.The number of serious fires in such premises over thepast five years demonstrates the need for a re-think inthe design, construction and operation of such centresand this must include the provision of modern automaticfire protection and suppression systems where necessary.Presented byBritish Automatic Fire Sprinkler AssociationRichmond House, Broad Street, Ely, Cambridgeshire CB7 4AHTel: 01353 659187 Fax: 01353 666619Email: info@bafsa.org.uk Web: www.bafsa.org.uk 2014 BAFSA6

the Waste Management Industry 1st Issue October 2014 BIF 25 Introduction ere can be little doubt that the occurrence of res in recycling centres is a signi cant problem for communities, the re and rescue service, the environment and insurers. Casual monitoring of the national press suggests a serious re in such locations is probably a daily occurrence. In fact in 2013, more than .