Transcription

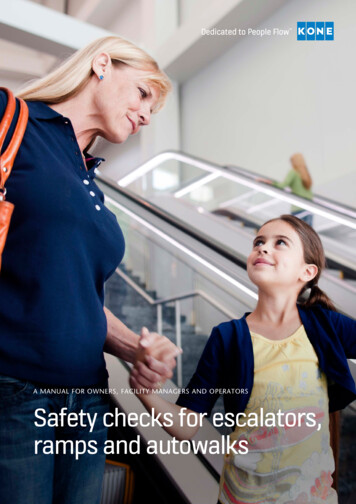

A MANUAL FOR OWNERS, FACILITY MANAGERS AND OPERATORSSafety checks for escalators,ramps and autowalks1

Contents1 Introduction32 Visual safety check before putting the equipment into operation53 Functional safety check when putting the equipment into operation104 Taking the equipment out of operation125 Safety around and on the equipment13Appendix: Daily safety check log for escalators, ramps and autowalks2

SAFET Y CHECKS FOR ESCAL ATORS, R AMPS AND AUTOWALKS1 IntroductionKONE moves millions of people with elevators,escalators, ramps and autowalks every day. To us,safety is of the utmost importance.Elevator and escalator safety is a joint effort. Technologyproducers must manufacture equipment that meetsapplicable codes and standards. Building owners andmaintenance service providers have a responsibility tomake sure the equipment is professionally maintainedand kept in good condition.If your equipment has been maintained by a serviceprovider other than KONE or is more than tenyears old, please contact your KONE representativeto order a KONE Care for Life assessment. Theassessment is a full evaluation of your equipment onsafety, accessibility, aesthetics, performance and ecoefficiency. It serves to enhance safety for end usersand helps prevent liability risks while also assistingyou in planning your budget for any necessarymodernisation.We constantly strive towards achieving our ultimategoal of zero accidents by paying rigorous attentionto our design, manufacturing, installation, andmaintenance processes. It is our strong belief that allaccidents are preventable.Little things matter in safety. This is a manual forowners, facility managers and operators which explainsimportant visual and functional safety checks that shouldbe completed on a daily basis before putting escalators,ramps or autowalks into use. By taking care to checkyour equipment regularly you can maintain safety andfacilitate smooth, uninterrupted journeys for everyone.Only personnel who have familiarised themselveswith this manual are allowed to inspect and startup escalators, ramps and autowalks. Do not takeescalators, ramps and autowalks into operation orpublic use before handover by KONE.KONE Customer Care Center For further information, please call the KONECustomer Care Center (1300 362 022 in Australiaand 0800 775 663 in New Zealand).Personal safety of the operator or inspectorThere is a risk of injury from being caught or pulledinto the machinery. Persons conducting visual andfunctional safety checks must cover their hair or tieit securely. Loose clothing such as scarves, ties orjewelry, including rings, must not be worn duringinspections. Personnel must wear gloves at all timeswhen checking the equipment.CAUTION: To avoid personal injury,always take the equipment out ofoperation before checking.Do not leave the key in the lock of the key-operatedswitch at any time. Misuse can result in personalinjury.3

Main components of escalatorsThe same components apply to ramps and autowalks.BalustradeAnti-climbbarrierDeckingSkirt brushSkirtStep(pallet inautowalks)FrontplateHandrailAccess coverStart/stop switchHandrail inletStart/stop switchCombsegments4Demarcationlights insidethe step bandCladdingCombsegmentsDemarcationlights insidethe step band

2 Visual safety check before putting theequipment into operationBefore allowing people to use the equipment, a visualsafety check and a functional safety check (see p. 10)must be completed.Safety guardsThe following visual inspection determines the presenceof any externally recognisable hazards such as: Damage caused by vandalism that may affectthe condition of the equipment Broken glass or sharp edges Missing components such as paneling orcovers that can affect the safety of usersDaily tests during the switch-on procedureThe building owner, facility manager or operator isstrongly advised to keep a record of the daily checks thatare performed during the switch-on procedure. Pleaseuse the daily safety check log attached (see Appendix).Head guardThese records should be saved for at least seven years.Anything conspicuous should be reported immediatelyto the KONE Customer Care Center.Safety guards and anti-slide devicesMake sure that the safety guards cover any gapsbetween the equipment and the building interfacesand that the guards are solid. Check also that anti-slidedevices are solid and securely attached to the escalator.Anti-slide devices are installed in between two parallelescalators or between an escalator and a wall to preventpersons or objects from sliding down. Check that thefall protection barrier is solid and in place.Anti-climb barrierFall protection barriers are installed outside the handrailsto prevent persons from leaning over the handrails andfalling.Check the anti-climb barrier and the head guards toensure that they are solid.CAUTION: There is a danger of fallingif safety guards are not secure. There isalso a danger of serious injury if headguards are not in place or are not secure.5

Steps and palletsComb segmentsMake sure that the steps (in escalators) and pallets(in ramps and autowalks) are dry, clean, and are notdamaged, broken or missing.Check that the combplate is parallel to the steps andthat the two fit closely together. Check the combsegments for missing or broken teeth.If there is oil, water or any other substance which maycause slips and falls on the steps or pallets, take thefollowing actions:Comb segments must not have two or more adjacentteeth missing. If this occurs, the equipment must notbe put into operation. Call the KONE Customer CareCenter immediately.A. Take the equipment out of operation and installsafety barricades to prevent anyone from enteringthe equipment.Check for objects between the combs and steps orpallets. Should you find any trapped objects, pleasecall the KONE Customer Care Center immediately.B. While wearing gloves, use a cloth to wipe all tracesof the substance off the equipment. If it cannotbe wiped away easily, call the KONE CustomerCare Center.CAUTION: There is a danger ofslipping, falling or entrapment whenthere are substances on steps.6CAUTION: There is a danger ofentrapment if a shoelace or otherpersonal item is exposed to comb segment.

Handrail inletsCheck for damage at the handrail inlets. If any isfound, the equipment must not be put into operation.There must always be a gap between the handrailand the inlet. If there is contact between the handrailand the inlet, call the KONE Customer Care Center.Check also that the exit area fulfills either of thefollowing requirements:A. There must be at least 80mm of free space oneach side when measured from the outer edge ofthe handrail. Also, there should be free space witha depth of 2.5m from the end of the balustrade.wThe inlet should be clean as debris may cause theequipment to stop suddenly.80mm2.5mEntry and exit areasMake sure that the entry and exit areas are dry,not slippery and are free of obstacles; for example,advertisement racks or shopping carts.B. If the depth of the free space from the end of thebalustrade is less than 2.5m, it must be a minimumof 2.0m. Also, the amount of free space from theouter edge of the handrail on each side should beat least as wide as the distance between the outeredges of the two handrails plus 80mm.w2.0m 2w 160mmCAUTION: There is a danger of injuriesor falls due to congestion if there areobstacles at the entry and exit areas.7

BalustradesSkirts and skirt deflector brushesThe steel balustrades must not have sharp edges orcorners. If there are any, please call the KONECustomer Care Center.Visually check that no corners or edges are stickingout on the skirts and that they are free from excessivewear or scratches, which can occur suddenly. Checkfor sharp edges, damaged, loose or missing parts. Ifany of these issues are found, call the KONE CustomerCare Center.If a glass panel is broken or missing, the equipmentmust not be put into operation. Barricadethe equipment and call the KONE Customer CareCenter.CAUTION: There is a danger of injury,falling or entrapment when glass panelsare broken or pieces are missing.8

Vertical clearanceSafety labels or pictogramsMake sure that there is a minimum of 2.3m ofclearance between the steps and the ceiling andremove any obstacles such as monitors, advertisingor decoration over the entire travel length of theequipment. If there is less than 2.3m of clearancethe equipment should not be put into operation.Verify that the safety labels are in place. If the safetynotices are missing, the equipment must not be putinto operation.If the safety labels are damaged, contact theKONE Customer Care Center to order new stickersimmediately.2.3m2,3mCAUTION: Do not carry very long ortall objects like ladders or poles on theequipment. There is a danger of the objectgetting trapped between the ceiling andescalator step or pallet, causing damage orpersonal injury.9

SAFET Y CHECKS FOR ESCAL ATORS, R AMPS AND AUTOWALKS3 Functional safety check when putting theequipment into operationAfter performing the visual safety check and rulingout any externally recognisable faults, proceed withthe functional safety check. Use the attached dailysafety check log for escalators, ramps and autowalks.The following should be completed before puttingthe equipment into use.CAUTION: Never start the equipmentwhen any persons or objects are on it.To switch the equipment on, insert the key into thekey-operated switch on the control panel. Start theequipment in the operational direction required byturning the key. Key switch at lower right side:Turn the key clockwise to run the unitdownwards and counter-clockwise to runthe unit upwards. Key switch at upper left side:Turn the key clockwise to run the unitupwards and counter-clockwise to run theunit downwards.NOTE: If the equipment has run in asingle direction for a long term period itis recommended to continue to run theequipment in that direction.10After switching the equipment on and before allowingpeople to use it, allow the equipment to revolve atleast twice during the functional safety check.Inspect the step or pallet band and make sure thatthe equipment is running faultlessly (see p. 6 Stepsand pallets). Check the handrail condition and makesure the handrail is running at the same speed withthe step band. Be alert for any damaged or missingsteps or pallets, unusual noises or vibrations.Check that the demarcation lights as well as theambient lighting (optional) are working correctly.Procedure in case the equipmentdoes not startIf the equipment does not start, check the informationdisplay for fault messages. For further instructions callthe KONE Customer Care Center. The informationdisplay is located on the inner deck, on the innerbalustrade, or on the column.CAUTION: To avoid injury, always switchthe equipment off before checking it.

Traffic lightsPreventing traffic jamsWhen the equipment starts up, the traffic lights(optional) will simultaneously indicate the operationaldirection. Check that the display is correct:In the case of two successive units without intermediateexits, make sure that both units are traveling in thesame direction. This prevents traffic jams, congestionand possible injuries from falls at the landing betweenthe two units. In the correct direction of travel the trafficlights must be green. In the opposite direction of travel the trafficlights must be red.CAUTION: There is danger of injuriesfrom falls due to congestion.11

4 Taking the equipment out of operationOperational stopEmergency stopPress the stop button to switch the equipment off, orstop the equipment with the key turned to the stopposition. The equipment will make a controlled stop.In case the equipment doesn’t stop, call the KONECustomer Care Center.If an unforeseen emergency situation occurs whilethe equipment is in operation, the equipment mustbe switched off immediately.The stop button should only be used in the event ofan emergency. In this event, press the stop buttonwhether or not any users or objects are on theequipment. The equipment will make a controlledstop. The equipment can be switched on again afterthe situation is resolved and a visual safety check hasbeen completed.For long escalators, ramps or autowalks, there are alsoemergency stop switches in the middle of the unit.The number of switches is dependent on the verticalrise or horizontal length of the unit.CAUTION: Never start or stop theequipment when any persons orobjects are on it.12

5 Safety around and on the equipmentSafe behavior on the equipment and in its vicinityDOs When entering an escalator, face forward andhold the handrail. Refrain from riding, pullingor leaning over the handrail or balustrade, orplacing heavy or bulky objects on it. Stand in the middle of the step and keep feet,hands, clothing items, and shoelaces awayfrom the skirts. Never use the equipmentwhile barefoot. Children should always be accompanied byadults. Hold young children by the handduring the ride. The emergency stop button should beused only in case of an incident or escalatormalfunction. Step on or off the equipment promptly whenentering and exiting so that no congestionoccurs.13

DON’Ts14 Never take wheeled objects like strollers orshopping carts on the equipment. Use thenearest elevator instead. Do not play or run on the equipment or inits vicinity. Riding on the handrail is strictlyprohibited. People in wheelchairs or users with walkingaids should not use the equipment. Directthem to the nearest elevator. Observe the movement of the steps anddo not enter or exit the equipment in thewrong direction. Do not transport long, bulky or heavyobjects on the escalator. Always stand on the escalator and do notsit, kneel, or support yourself with hands onthe steps.

Daily safety check log for escalators, ramps and autowalksBuilding:Address:Unit ID:Starting date (DD.MM.YYYY):Person responsible:KONE Customer Care Center:Complete this form for each u

Elevator and escalator safety is a joint effort. T echnology producers must manufacture equipment that meets applicable codes and standards. Building owners and maintenance service providers have a responsibility to make sure the equipment is professionally maintained and kept in good condition. If your equipment has been maintained by a service provider other than KONE or is more than ten .