Transcription

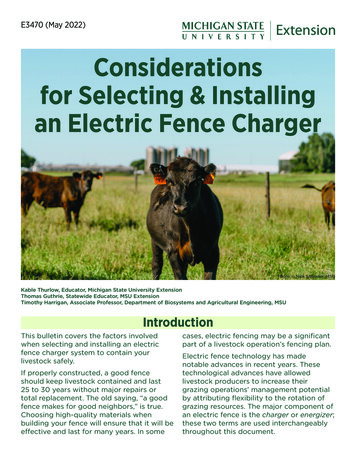

E3470 (May 2022)Considerationsfor Selecting & Installingan Electric Fence ChargerPhoto Nick Schrader, MSUKable Thurlow, Educator, Michigan State University ExtensionThomas Guthrie, Statewide Educator, MSU ExtensionTimothy Harrigan, Associate Professor, Department of Biosystems and Agricultural Engineering, MSUIntroductionThis bulletin covers the factors involvedwhen selecting and installing an electricfence charger system to contain yourlivestock safely.If properly constructed, a good fenceshould keep livestock contained and last25 to 30 years without major repairs ortotal replacement. The old saying, “a goodfence makes for good neighbors,” is true.Choosing high-quality materials whenbuilding your fence will ensure that it will beeffective and last for many years. In somecases, electric fencing may be a significantpart of a livestock operation’s fencing plan.Electric fence technology has madenotable advances in recent years. Thesetechnological advances have allowedlivestock producers to increase theirgrazing operations’ management potentialby attributing flexibility to the rotation ofgrazing resources. The major component ofan electric fence is the charger or energizer;these two terms are used interchangeablythroughout this document.

Considerations for Selecting& Installing an Electric Fence Charger2Low Impedance vs. High Impedance ChargersLow impedance chargers are the mostcommon fence chargers manufacturedtoday. They are much safer than theirpredecessors, the high impedance chargersthat used an AC high voltage output. Lowimpedance chargers can energize miles ofsingle- or multiple-wire fences. They outputa short-duration, high voltage DC current.The low impedance pulse is also extremelyshort compared to the long, slow pulse ofthe old high impedance chargers.High impedance chargers are the typicalfence chargers from years ago. Theydelivered a shock that was high voltagewith low amperage. An amp is the amountof electricity that flows through the wire;this provides the jolt that deters predatorsand keeps livestock in the fenced-in area.Old high impedance chargers, commonlyknown as “weed eaters” or “weed choppers,”may still be used but no longer marketed.These older chargers could potentiallystart a fire by burning through weeds. Theydeliver a shock long in duration with a highvoltage. High impedance chargers are easilygrounded out by vegetation, making themineffective. Once this happens, little to noshock value is left for keeping livestockwithin the fence boundaries.To overcome the problem of grounding outeasily, manufacturers lengthened the pulserate of these chargers. This made the pulserate much longer than the pulse rate of thelow impedance chargers. In some cases, thepulse rate could be 0.5 seconds, comparedto low impedance pulses, which often areonly 0.0003 seconds. Because of the longerpulse rate, these chargers sometimescaused fires.Low Impedance Charger TypesThe first step in determining what type ofcharger will work is to decide which type touse. The three main types of low impedancechargers for electric fencing include:» Plug-in chargers» Solar chargers» Battery chargersIf there is access to a 110- or 220-voltservice, plug-in chargers are probablythe best choice. Plug-in chargers tend tobe the most economical because thereare no batteries to replace or recharge,and there are no solar panels to maintain.Solar and battery-powered chargers canprovide sufficient output for livestockcontrol. Technology advances with batteryand solar-powered chargers have createdreliable options. They provide the addedflexibility of not needing an AC powersource, which is convenient when pasturesare in remote locations without electricity.FencingThe next step in selecting the size of thecharger is to determine what type of fencewill be energized. Several types of fencingmaterials are available:» High tensile single-strand wire fencingcan be installed in combinations varyingfrom a single-wire, interior, semipermanent situation to five or more wireson a perimeter fence. The number ofwires will vary depending on the speciescontained and the fence’s location.

MSU Extensionwww.extension.msu.edu» Woven wire fences are made up ofhorizontal wires connected by verticalwires called stays. The distance betweenthe horizontal wires will vary from aslittle as two wires to as many as nine.The smaller spaces are used for smalleranimals and the larger spaces for largerlivestock. The overall height of fence wireswill also vary depending on the class orspecies of livestock you need to contain.» Barbed wire comprises two or morestrands of smooth wire twisted togetherwith usually four barbs spaced every 4to 5 inches. Barbed wire should never beelectrified. Livestock or a person couldget entangled in the wire and unable toescape the electric shock.» Temporary portable fencing consists ofpolywire, polytape, braided twine, andelectric netting. This fencing is used inrotational grazing systems and is notsuitable for permanent fencing. It isused inside of a good perimeter fence.The polywires usually have three to ninestrands inside them that conduct theelectricity. Electric net fencing is used inmany poultry and small ruminant grazingsystems. Netting is one of the betterfence types for controlling predators.Single-wire fences require less energy thanmultiple-wire fences. The multiple-wiresystems will likely carry a higher vegetativeload on the lower wires. Also, with multiplewire fences, such as the standard five-wirehigh tensile fence, charging every otherwire will reduce the total length of chargedwire and the resulting load on the fencecharger. You need to calculate the miles offence using the total linear feet of all thehot wires, not just the length of the fence.The type of fence can also affect theperformance of the energizer and will helpdetermine what output joules are required.3Grazing experts recommend a 12.5-gaugehigh tensile wire to achieve the mostsatisfactory results on a permanent exterioror semi-permanent interior fence. Manytypes of fences and fencing products areavailable for portable fences.The type of animals grazed can alsodetermine the fencing material or wireused. Some cow-calf producers prefer thewoven wire style, nonelectric fence forsafety instead of the high tensile singlestrand wires. These fences are found mainlyalong a busy roadway or near a residentialarea.The area you plan to fenceWhen selecting the size of the charger,consider the type and total length ofthe fence. According to the University ofMissouri Forage Systems Research Center,one joule of output per mile of energizedfence wire is generally sufficient (Gerrish &Roberts, 1999). Therefore, before selectingan electric fence charger, acquiring aclose estimate of the total distance of wirestrands you plan to electrify will aid inselecting a charger with a mileage ratingthat meets those needs.Example: You have a 15-acre pastureshaped like a rectangle that you need tofence with a 5-wire fence; three wires willbe electrified. The total distance around theperimeter is 3,430 ft. X 3 wires 10,290 ft.of energized wire divided by 5,280 ft./mile 1.9 miles. Select a charger suitable for twomiles of fence.Once you choose the size of the charger,decide which type of charger to purchase.The installation location and availabilityof power will influence your choices. Aplug-in charger will be the best choicewhen accessing 110- or 220-volt AC. These

Considerations for Selecting& Installing an Electric Fence Charger4chargers eliminate the need to maintainbatteries and solar panels for operation.Because they do not rely on a battery orsunlight for operation, plug-in chargers tendto be the more reliable and cheaper option.A higher joule output is often available forlarge acreage pastures with AC chargers.GroundingAn electric fence system that is notadequately grounded will not perform upto its potential. It may not safely containthe livestock or keep predators out. Whendetermining how to ground an electricfencing system properly, consider two mainfactors:» The output capacity (joules) of theenergizer» The conductivity (siemens/meter) of thesoilAn energizer must be adequately groundedto energize to its potential. The greaterthe charger’s output, the more groundingFigure 1. All Live Grounding Systemrods are needed. A general rule is to installa minimum of 3 feet of grounding rodper joule of output capacity. Therefore, a15-joule fence charger requires a minimumof 45 feet of grounding rod. Groundingrods must be installed at least 10 feetapart, and the wetter the ground, thebetter the grounding rod performance willbe. Most grounding rods are made fromgalvanized steel or copper. The type of wireconnecting the energizer to the groundingrod should be the same as the groundingrod to minimize corrosion from electrolysisresulting in poor performance.You must be aware of any other groundingrods in the vicinity that may be used fora building’s electrical system. As a safetyprecaution, ensure the ground wire is notFigure 3. A Digital Voltmeter, a Type ofFence Tester(Diagram courtesy Speedrite by Datamars)Figure 2. Live/Grounding System(Diagram courtesy Speedrite by Datamars)(Photo courtesy Speedrite by Datamars)

MSU Extensionwww.extension.msu.educonnected to any grounding rods used forother utilities such as those for electricalboxes. Locate the charger grounding rods atleast 50 feet from other grounding rods andunderground telephone or power cables.5Figure 4. A Fault Finder, a Type of FenceTesterSoils for grounding rodsSandy or rocky soils will not be asconductive as loamy soils, so a systeminstalled on these soils may need to be anearth-return grounding system. An earthreturn system is one in which alternatewires in the fence are ground wires.Charged wires on a system need to beconnected back to the output connector onthe energizer. (See Figure 1, which shows anall live grounding system.)Earth-ground, noncharged wires need to linkback to the ground terminal on the chargeror to grounding rods in the fence lines.Experience at Michigan State University’sLake City Research Center has shown thatit’s better to place grounding rods belowroof eaves on buildings in sandy soils tomaintain the maximum moisture possible.However, keep a safe distance from othergrounding rods used for the building’selectrical system. (See Figure 2, which showsan earth, or live/ground system.)Earth-return systems typically controlsheep or goats better. All other livestockcan generally be managed without usingthe earth-ground system, provided the soilisn’t sandy, rocky, or extremely dry.VoltageA joule is the energy used to create voltage.In contrast, voltage refers to the current’spressure moving throughout the fence line.Higher voltage increases the wire’s ability toshock an animal that touches an energizedwire. Table 1 illustrates a representative(Photo courtesy Speedrite by Datamars)voltage paired with the level of animalcontainment. Recommended voltageranges for different animal species will vary.This can primarily depend on the hair coatthickness of animals and overall animalbehavior. For example, horses can typicallybe deterred with 1,500 to 3,000 fencevoltage, whereas 4,000 to 5,000 volts maybe more appropriate for safely containingsheep and goats.Table 1. Level of Animal ContainmentBased on VoltageLevel of animalcontainmentVoltage rangeExcellent5,000 vGreat4,000 vAdequate3,000 vPoor2,000 vVery limited1,000 vMonitor voltage levels periodically using afence tester. Do this in multiple locations toensure adequate voltage. (See figures 3 and4.)

Considerations for Selecting& Installing an Electric Fence Charger6Training Livestock to Electric FencesLivestock must be trained to an electricfence before turning out in a pasture wherea single- or multiple-wire fence may betheir only barrier. Electric fences are apsychological barrier. If livestock are nottrained before being put out to pasture,they may go through the fence when theyreceive their first shock. Introducing themto an electric fence involves exposing themto the electric wire where there is an actualphysical barrier, such as a woven wire fenceor corral and a charged electric wire.Installation Tips & Safety HazardsLow amperage and a short-duration,pulsating current make electric fencingrelatively safe.» When installing, be aware of anyfactors that could cause stray voltage.In many cases, this may be hard topinpoint. However, a few places to bemindful of are around gates, waterers,and wellheads. If animals refuse or arereluctant to drink from a waterer, a strayvoltage problem may exist. For moreinformation on stray voltage, visithttp://maec.msu.edu/pub.htm.Figure 5. Lightning Coil/Diverter and Lightning ArrestorPhoto courtesy Rod Schaub, Kansas State University Extension

MSU Extensionwww.extension.msu.edu7» Installing a lightning coil or lightningchoke on the lead wire near the energizerwill help guard against damage from alightning strike. Lightning coil: six to eight wraps of aheavily insulated 12-gauge wire in an8-inch to 12-inch diameter loop Lightning choke: a 10- to 12-loop coil ofhigh tensile wire spaced approximately2 inches apart on a mounting boardmade of wood or plastic (see Figure 5)» Installing a lightning diverter where thelead-out wire connects to the fence willdrain some energy from a lightning strikeby sending it directly to the ground. Italso serves as a route to ground for anyenergy diverted back to the fence by thelightning choke or lightning coil.» In sporadic cases, an animal may dieif it gets tangled in the fence for sometime and is unable to release itself.Never electrify a barbed-wire fence; thepossibility of animals or people gettingentangled in the wire and injured is high.» Appropriate signage makes it clear thatthe fence is electrified. Caution signsmay be especially important if you havevisitors to the farm, live in a communitywith many children, or have neighborswith pets.In SummaryLow impedance chargers are safer andmore efficient than their older highimpedance counterparts. The three maintypes of low impedance chargers are plugin, solar, and battery. To select the size ofthe charger, determine the type of fenceyou will need as well as the area you planto fence. After you determine size, selectthe type of charger. Make sure your systemis adequately grounded, keeping in mindthe output capacity of the energizer as wellas the conductivity of the soil. Train yourlivestock to an electric fence before turningthem out to pasture. Read and follow themanufacturer’s recommendations duringinstallation. A properly constructed electricfence made with high-quality materials willkeep your livestock safe and contained.ReferenceGerrish, J. R., & Roberts, C. A. (Eds.). (1999).Missouri grazing manual. MU Extension,University of Missouri–Columbia.Header photo credits: istockphoto.com/Stephen Barnes (left) and istockphoto.com/LordRunar (right).Considerations for Selecting and Installing Electric Fence Chargers. 2022Michigan State University. MSU is an affirmative-action, equal-opportunityemployer, committed to achieving excellence through a diverse workforceand inclusive culture that encourages all people to reach their full potential.Michigan State University Extension programs and materials are open to allwithout regard to race, color, national origin, gender, gender identity, religion, age, height, weight, disability, political beliefs, sexualorientation, marital status, family status or veteran status. Issued in furtherance of MSU Extension work, acts of May 8 and June 30, 1914,in cooperation with the U.S. Department of Agriculture. Quentin Tyler, Director, MSU Extension, East Lansing, MI 48824. This informationis for educational purposes only. Reference to commercial products or trade names does not imply endorsement by MSU Extensionor bias against those not mentioned. This bulletin was produced for MSU Extension by the Extension Educational Materials Team.1R-1P-Web-05:2022-PA/RM WCAG 2.0 AA

2 & Installing an Electric Fence Charger Low Impedance vs. High Impedance Chargers Low impedance chargers are the most common fence chargers manufactured today. They are much safer than their predecessors, the high impedance chargers that used an AC high voltage output. Low impedance chargers can energize miles of single- or multiple-wire fences.