Transcription

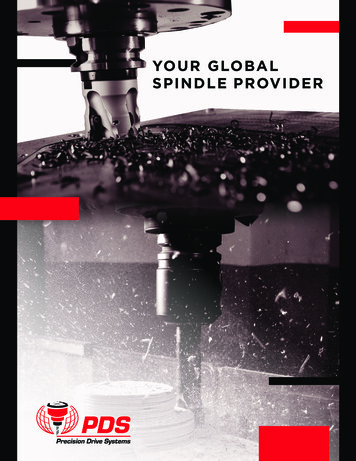

YO U R GLO B A LS PIN D L E PR OV ID E R

ABOUT PDSSAVING MANUFACTURERSTIME AND MONEYPrecision Drive Systems (PDS) is globally known for keeping the world’s highly tasked productionlines flowing smoothly.PDS operates worldwide service locations, providing manufacturers with better-than-new repairs(within 2 microns) on spindles for material removal precision machining applications. Since 1996,PDS’ factory-trained engineers and technicians have successfully rebuilt and globally supportedmore than 36,000 spindles.Our 300 years of aggregate spindle application experience have collectively saved our customersmillions of dollars with spindle root cause failure reports, ensuring significant savings compared tothe expense of factory equipment repairs, costly scrapped components and minimized downtime.LOHNE, GERMANY (GmbH)EUROPEAN HEADQUARTERSBESSEMER CITY, NCUSA HEADQUARTERS(NEAR CHARLOTTE, NC)2

APPLICATIONS WE SERVECAPABILITIES FOR ALLINDUSTRY APPLICATIONSPDS provides solutions to manufacturing challenges in the wood, robotics, plasticsand metal markets. With a stock of more than 150 types of spindles and the abilityto repair all makes and models of CNC spindles, moulder spindles and arbors, PDSis your partner in productivity.WOODROBOTICSPLASTICS &COMPOSITESMETALS &ALLOYED STEELSSTONE, MARBLE& GLASSwww.SpindleRepair.com 3

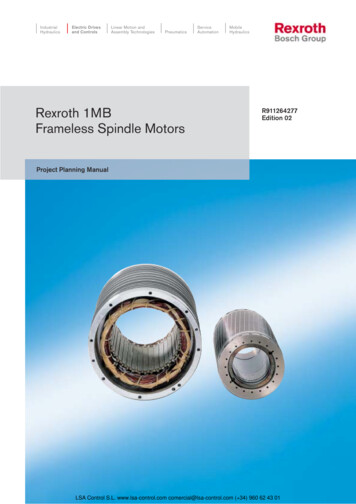

CNC SPINDLE REPAIRREBUILDING VIRTUALLY ANY SPINDLEBRAND FOR ANY MATERIALWe provide expert rebuilds for milling, turning, grinding, boring, reaming, drilling and tapping spindles.Our experience encompasses: Robotics Metalworking Woodworking Stone, marble and glass Plastics and compositesPDS operates a precision prototype machine shop (accuracy within 2 microns) for creating out-of-circulation partsand straightening or reconditioning parts to be used in rebuilds enabling superior quality control and expediterepairs and manufactured components.PDS engineers design and build customized, integrated machine tool spindles and robotic system end effectorsfor precision machining. Industries such as aerospace, automotive, agricultural, bearings, construction, andmore routinely rely on our engineers’ and technicians’ trusted advice. Customized PDS spindles, sensorsand related accessories now enable robotic systems to perform complex multiaxis machining.Save time and money with PDS precision spindle repair.4

MOULDER SPINDLEAND ARBOR REPAIRMOULDER SPINDLEREPAIRUsing original factory parts, PDS can repair any make or model ofmoulder spindle including Weinig PowerlockTM. We also reengineerand fabricate hard-to-find components for out-of-production units.We back our work with a 12-month warranty.We’ll restore your moulder spindle to like-new condition, enhancingaccuracy on mill profiles for dependable production.ARBOR REPAIROEMs often recommend the wholesale replacement of damagedmain and scoring arbors. The experienced team at PDS will bringyour arbors back to better-than-factory standards at a fraction ofOEM replacement costs. Each rebuilt unit comes with a 12-monthwarranty.PDS straightens and rebuilds horizontal milling machine arbors tolike-new condition. We frequently repair arbors that have beenbent, overloaded or crashed for a fraction of replacement costs.www.SpindleRepair.com 5

NEW SPINDLES, REBUILTSPINDLES AND ACCESSORIESHIGH-SPEEDPRECISION SPINDLESAs your global spindle partner, PDS has created a “Spindle Hub of TechnicalData” at www.SpindleRepair.com where you can access anything youneed to minimize downtime and maximize production. Our line of newand rebuilt spindles includes automatic, manual, high-speed, 5-axis anddouble-ended spindles built by PDS, Giordano Colombo, Hiteco, IMA Tecnoand Spintec. Our experienced sales consultants can help you select the rightindustrial spindle for your specific application.ONE-STOPSPINDLE SHOPThe PDS online store offers a complete line of top-quality tool holders,accessories and rebuilt spindles.The following products are available for purchase on ShopCNCProducts.com:» Rebuilt Spindles» Tool Forks» Collet Nuts» Tool Holders» Collets» Wrenches» Grippers» Variable Frequency Drives» Pull Studs» Multi-Spindle Boring Units» Service Kits6

PREDICTIVE MAINTENANCEAND TRAININGSPINDLE HEALTHMONITORING SYSTEMThe Spindle Health Monitoring System is used to expand and enhance spindle diagnostics according to vibration and temperatureanalysis. The miniaturized system can be affordably installed directly or retro-fitted within your spindle ensuring real-time monitoring,as well as reducing the machine downtimes by predicting malfunctions.For maintenance and production personnel to monitor machine spindles at scale for emerging symptoms of bearing andtemperature anomalies. Data record check-up predicts spindle life to avoid emergency repairs.BENEFITS FOR YOUSTOPTailor to specific machines.EMERGENCY STOPS/ALERTSShutdown machineexceeding thresholdswithin 1 millisecondminimizes damage.CHECK-UPMaintain the spindle in optimumhealth utilizing the continuousspindle life monitoring algorithmwhich is computed by usingreal-time vibration andtemperature values.HISTORICAL DATA & TRENDSReview events to look atspindle history, all alarmsand warnings, check-up,power on, shutdowns andmodifications to thedevice parameters.DASHBOARDVisualize real-timemonitoring of all machines.www.SpindleRepair.com 7

MULTI-SPINDLEDRILLING UNIT REPAIRMulti-spindle boring units are disassembled andall parts are measured against manufacturerspecifications. PDS will provide a thorough reportregarding inspection results and also, whenpossible, deliver a failure analysis. To correct poorperforming units, all bearings are replaced alongwith new seals. Gears and drive couplings arechecked, verified and replaced as needed.After final assembly, PDS will test and completea run-in procedure to bring the unit up tooperating temperature to confirm vibrationand temperature are within manufacturer’sspecifications.OUR EXPERIENCEDTECHNICIANS AREHERE FOR YOU.PDS is a global supplier. For your convenience, weoperate eight offices across three continents. You canlearn more about our full range of services, accessories,and solutions at www.SpindleRepair.com. Our trainedspindle experts are standing by to help you with repairsor to choose tools for maximized production.PDS USA4367 Dallas Cherryville Hwy.Bessemer City, NC 28016704-922-1206www.SpindleRepair.comPDS GmbHTichelbrink 6832584 Löhne, Germany 49 (0)5731/744889-0www.PDSspindeln.deAll contents 2020 Precision Drive Systems

Save time and money with PDS precision spindle repair. Using original factory parts, PDS can repair any make or model of moulder spindle including Weinig Powerlock. TM. We also reengineer and fabricate hard-to-find components for out-of-production units. We back our work with a 12-month warranty.