Transcription

SEVENTH EDITIONHOT ROLLED ANDSTRUCTURAL STEELPRODUCTS

HOT ROLLED ANDSTRUCTURAL STEELPRODUCTSCONTENTSINTRODUCTION1TEST CERTIFICATES ANDCERTIFICATES OF COMPLIANCE2BUILD WITH STANDARDS AND ACRS4AVAILABILITYStructural Steel Sections5Merchant Bar Sections6DIMENSIONS AND DESIGN INFORMATIONWelded Beams10Welded Columns12Universal Beams14Universal Columns16Tapered Flange Beams18Parallel Flange Channels19Universal Bearing Piles20Equal Angles21Unequal Angles24STANDARD SPECIFICATIONSStructural Steel Sections27Merchant Bar Sections29CUSTOMER TECHNICAL SERVICEHRSSP 7th Ed. April 201430

INTRODUCTIONOneSteel has a long and significant presence in the Australian steel industry as an integrated manufacturer of steel and finishedsteel products that dates back to the establishment of steelmaking in Newcastle in 1915 and continues to the present day.OneSteel is Australia’s premier manufacturer of steel long products. The company manufactures and distributes a wide range ofsteel products including structural sections, rail, rod, bar, wire and pipe and tube products.OneSteel’s major manufacturing facilities for hot rolled products are located in Whyalla, South Australia; in Melbourne, Victoria andin Newcastle and Western Sydney, New South Wales.As part of OneSteel’s ongoing commitment to the Australian construction and manufacturing industry, this booklet is producedby OneSteel Manufacturing and is intended to provide general information on a range of hot rolled and structural steel products.Furthermore, this booklet will give you guidance on how OneSteel supports the quality and reputation of its products throughinitiatives such as our Build With Standards website and our EzyCommerce service.(N.B. for the sake of simplicity, the following text will refer to OneSteel Manufacturing as OneSteel.)HRSSP 7th Ed. April 20141

ONESTEEL COMMITMENT TO QUALITY AND SUSTAINABILITYOneSteel supplies products that are compliant to the relevant Australian Standards or OneSteel’s own high quality standards.OneSteel’s aim is to supply a consistent high quality product which delivers benefits to our customers by minimising variationand reducing waste.The quality of products is constantly checked in NATA endorsed testing laboratories, by skilled technical staff using provenequipment. Strict metallurgical control is maintained, from receipt of raw materials to despatch of the finished product.Products are rigorously tested and certified, with test certificates and certificates of compliance providing assurance thatOneSteel sections meet all required specifications. These are made available free of charge via our EzyCommerce website.At its manufacturing sites OneSteel has third party accreditation to Quality Management System ISO 9001 and EnvironmentalManagement System ISO 14001.Furthermore, through initiatives such as Build With Standards and ACRS, OneSteel is clearly committed to the ongoing supplyof quality product to the Australian and New Zealand marketplace.Test Certificates / Certificates of Compliance - EzyCommerceNATA endorsed test certificates are available for all AS/NZS 3679.1 product. Certificates of Compliance for Welded product suppliedunder AS/NZS 3679.2 are also available. The Steel Structures Design Standard – AS4100, acknowledges that these certificatesprovide designers and certifiers with sufficient evidence that they are acceptable steels for use in designs to AS4100.Fabricators can ensure they receive a copy of the relevant certificate covering the steel ordered and delivered by requestingthem at the time of order. The certificates can be provided manually, electronically or customers can access these viaOneSteel’s EzyCommerce website at https://ezycommerce.onesteel.comAll distributors of OneSteel AS/NZS 3679.1 & AS/NZS 3679.2 products have access to certificates via EzyCommerce – this is afree service that offers the flexibility to access and retrieve this information at anytime of the day.Access to EzyCommerce Online is free to approved customers of OneSteel Manufacturing – all you need is a loginname and password – please refer to: https://ezycommerce.onesteel.com/about.aspx for more information onobtaining access to the website.For more information:Ezycommerce: https://ezycommerce.onesteel.com2HRSSP 7th Ed. April 2014

ONESTEEL COMMITMENT TO QUALITY AND SUSTAINABILITYTest Certificate sampleHRSSP 7th Ed. April 20143

ONESTEEL COMMITMENT TO QUALITY AND SUSTAINABILITYBuild With StandardsThe Build With Standards campaign is an initiative undertaken by OneSteel to improve compliance and generate increasedconfidence in structural steel quality in all end-use applications.Changes to Australian and New Zealand Standards for structural steel have been introduced to address industry concerns regardingproduct quality, identification, certification and traceability.These revised Australian/New Zealand Standards help ensure the quality of the structural steel specified is supplied.With the revised Standards and mandatory requirements around markings and test certificates, industry stakeholders can readilycheck if the steel used was produced to Australian/ New Zealand Standards and the specifications called up in the design.Visit OneSteel’s Build With Standards website for more information on the initiative and how OneSteel meets the Standards(www.buildwithstandards.com.au). In addition you will find valuable information regarding the Green Star Rating System as wellas information regarding OneSteel’s environmental management systems and membership of the WorldSteel Association ClimateAction group.ACRS - Third Party CertificationIn addition to our quality systems and NATA endorsed laboratories, OneSteel’s range of AS/NZS 3679.1 hot rolled products areall produced at mills with ACRS certification. ACRS is an expert, industry based, third party product certifier of reinforcing,prestressing and structural steels to Australian/New Zealand Standards. This certification gives designers and asset ownersadditional confidence that they are getting compliant steels on which their structural design has been based.Copies of our ACRS accreditation can be viewed at the ACRS website – www.steelcertification.com, or via the Build WithStandards website.For more information:Build with Standards: www.buildwithstandards.com.auACRS: www.steelcertification.com4HRSSP 7th Ed. April 20141

AVAILABILITYStructural Steel SectionsHot Rolled ProductsHot Rolled Structural Steel sections produced by OneSteel aremanufactured in accordance with the requirements of AustralianStandard AS/NZS 3679.1 Structural Steel – Hot Rolled Bars andSections.Grade Availability300PLUS Steel is the standard grade manufactured by OneSteel forhot rolled Structural Steel Sections for Australia.300PLUS Steel for hot rolled products is produced to exceed theminimum requirements of AS/NZS 3679.1 grade 300.Length AvailabilityThe majority of Structural Steel Sections produced by OneSteel areavailable in standard length and bundle configurations.We would recommend that attention be given to the standardlengths produced by OneSteel as they are more readily availablethan other lengths. Table 2 (page 6) indicates the standard lengthsproduced by OneSteel in Structural Steel Sections. For other lengths(including those in excess of 18 metres) please contact your nearestOneSteel Sales Office for further details (contact details on page 30).Welded ProductsIn New Zealand, 300PLUS S0 is the standard grade for the range ofuniversal beams and columns shown in Table 1.Table 1Standard 300PLUS S0 Grade sections in New ZealandOneSteel Manufacturing also markets a range of large WeldedProduct Structural Steel sections. These sections are welded fromplate and are manufactured in accordance with Australian StandardAS/NZS 3679.2 Structural Steel – Welded I Sections.Universal BeamsUniversal UC118530UB92.4310UC96.8300PLUS Steel is the standard grade manufactured for WeldedProducts. 300PLUS welded products are produced to exceed theminimum requirements of AS/NZS 3679.2 grade 300.530UB82.0250UC89.5A higher grade option of AS/NZS 3679.2 grade 400 is also r grades are subject to enquiry and this should be directed toyour nearest OneSteel Sales .7360UB56.7Grade AvailabilityLength AvailabilityLengths are available from a minimum of six metres to a maximumof 30 metres. Table 2 indicates the standard lengths produced.360UB50.7360UB44.7Other grades including 300PLUSL0, AS/NZS 3679.1-350 andAS/NZS 3679.1-350L0 may also be available depending on thesection and quantity required.For further information contact your nearest OneSteel Sales Office(contact details on page 30).HRSSP 7th Ed. April 20145

AVAILABILITYTable 2 Standard LengthsLength lllllllllllllllllllllllllllllllllllWelded Sections1200 WB, 1000 WB, 900 WB, 800 WB, 700 WB500 WC, 400 WC, 350 WCUniversal Beams610 UB, 530 UB, 460 UB, 410 UB, 360 UB310 UB 46.2, 40.4310 UB 32.0250 UB200 UB 29.8, 25.4, 22.3200 UB 18.2180 UB, 150 UBlUniversal Columns310 UC 158, 137, 118310 UC 96.8250 UC200 UC, 150 UC100 UClllllTaper Flange Beams125 TFB, 100 TFBParallel Flange Channels380 PFC, 300 PFC250 PFC230 PFC, 200 PFC, 180 PFC, 150 PFC125 PFC, 100 PFC, 75 PFClllllllllllllllllllllllllllUniversal Bearing Piles310 UBP 149, 110†310 UBP 78.8200 UBP 122llllEqual Angles200 EA, 150 EA, 125 EA100 EA, 90 EA, 75 EA65 EA, 55 EA, 50 EA, 45 EA, 40 EA **30 EA, 25 EAllllllllllllUnequal Angles150 x 100 UA, 150 x 90 UA125 x 75 UA, 100 x 75 UA75 x 50 UA65 x 50 UAlllllllllThe Section/Length combination is available in Standard Bundle configurations*By enquiry – delivery to capital cities only** Certain thicknesses may not be available in both lengths. Confirm availability with a OneSteel Manufacturing Sales Office.†6By enquiryHRSSP 7th Ed. April 2014l

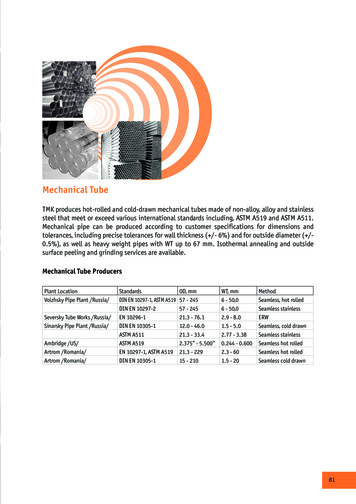

AVAILABILITYMerchant Bar SectionsRounds, Squares and FlatsAvailabilityMerchant bar rounds, squares and flats are available in a variety of steel grades and sizes.Due to process limitations not all grades are available in all sizes. For new applications we recommend you confirm product availability with aOneSteel Sales Office at an early stage of design. Other specifications and sizes may also be available on enquiry.SpecificationsMerchant bar sections are available in the following standards: 300PLUS and AS/NZS 3679.1 – Structural Steel – Hot Rolled Bars and Sections. AS 1442 – Carbon Steels and Carbon Manganese Steels – Hot Rolled Bars and Semifinished Products. AS 1444 – Wrought Alloy Steels Standard, Hardenability (H) Series and Hardened and Tempered to Designated Mechanical Properties. AS 1447 – Hot-Rolled Spring Steels. OneSteel grades (based on AISI-SAE nomenclature).Table 3 Rounds – Size Availability and MassDiameter 657590Mass 26.034.749.9Table 4 Squares – Size Availability and MassThickness (mm)10*1216202540Mass (kg/m)0.7901.132.013.144.9112.5Standard Length: 6 Metres* Confirm availability with sales office.Standard Length: 6 MetresHRSSP 7th Ed. April 20147

AVAILABILITYTable 5 Flats — Size Availability and Mass (kg/m)Width rd Length: 6 Metres8HRSSP 7th Ed. April .615.718.8Thickness .529.49.8114.7

AVAILABILITYTable 6 Merchant Bar Sections – Regular GradesSteel TypeStructural SteelsCarbon and Carbon-Manganese SteelsStandardOneSteelAS/NZS 3679.1AS 1442Spring SteelsAS 1447OneSteel GradesOneSteelGrades 1S1015X4K92M61SNoteGrade availability can vary with section.Table 7 Rods Size AvailabilityRods and Light BilletsRods and light billets are available in a wide range of OneSteel grades,and selected grades from AS 1442, AS 1444 and AS 1447 specifications.Diameter (mm)5.5 6.5 7.0 8.0 9.0 10.0 11.2 12.5 13.0 14.0 15.0 16.0 17.0 18.0These sections are not available in structural grades 300PLUS or 350. Due to process limitations not all grades are available in all sizes.Confirm product availability with a OneSteel Sales Office at an earlystage of design.Table 8 Light Billets Size AvailabilitySizes Available mm x mm45 x 4550 x 5063 x 6375 x 75HRSSP 7th Ed. April 20149

10HRSSP 7th Ed. April 2014Welded BeamsTable 9 Welded Beams – Dimensions and PropertiesDesignationDepth 0 WB 317117640028161120278117035025161120Gross Areaof CrossSectionAbout x-axisAgIxmmZxSx10 mm10 076101300026433About y-axisrx10 002800001200 WB 04641791020160071.15090587002786410 mmIw10 mm310 mmJDesignationmm33WarpingConstant333mm410 mm10 44987.0633102052.44310285002491000 WB 1710262091.39740841001000 WB 60296157.5289021700215900 WB 710259097.5887067900900 WB 163.5206017400175800 WB 128071.9442019600800 WB 79216280122700 WB 6108066.4402011500700 WB 884770115Notes1. All welds to AS/NZS 1554.1 Category SP (deep penetration).2. Web to flange joints develop the minimum tensile strength of the web.3. Flame cut surfaces not incorporated in welds have a minimum surface roughness of class 2, as defined in WTIA Technical Note 5.

Welded BeamsTable 10 Welded Beams – Properties for Assessing Section CapacityDesignationYield StressFlangeWebfyfyMPaMPaForm FactorAbout x-axisCompactnessAbout y-axisCompactnesskfZexFlangeWebfyfy10 mmMPaMPaZey10 mm33Yield Stress33Form FactorAbout x-axisAbout y-axisCompactnesskfCompactnessZexZey10 mm3300PLUS *Designation10 mm333AS/NZS 3679.2-400 1200 WB 0 WB 91000 WB 0 WB 00 WB 2822803100.845C13600C25603604000.830N13500C2560900 WB 81753003100.744C7500C9013804000.721N7320N882175800 WB 1922803100.824C8060C12603604000.808N7850C1260800 WB 03100.718N4530N4983804000.695N4340N486122700 WB 1732803100.850C6390C10603604000.833C6390C1060700 WB 03100.767C3790N4983804000.742C3790N486115* 300PLUS welded sections are produced to exceed the minimum requirements of AS/NZS 3679.2-300.NotesHRSSP 7th Ed. April 20141. For 300PLUS sections the tensile strength (fu) is 430 MPa.2. For Grade 400 sections the tensile strength (fu) is 480 MPa.3. C: Compact Section; N: Non-compact Section; S: Slender Section.11

12HRSSP 7th Ed. April 2014Welded ColumnsTable 11 Welded Columns – Dimensions and PropertiesDesignationDepth f-tw)tw2tfWidthThicknessdbftftwd1kg/mmmmmmmmmmm500 WC 63240012.5Gross Areaof CrossSectionAbout x-axisAgIxZxmm10 mm5.75560005.85528006.50Sxrx10 mm10 4333About y-axis3mmIyZySyTorsionConstantryIw10 ation10 mm610 mmWarpingConstant410 mm10 mm639500 WC 0571020841716702540120388023000228400 WC 0334096.52480016300400 WC 71854130096.315805720144350 WC 280350 WC 001140174089.357504600197Notes1. All welds to AS/NZS 1554.1 Category SP (deep penetration).2. Web to flange joints develop the minimum tensile strength of a 16mm web only.3. Flame cut surfaces not incorporated in welds have a minimum surface roughness of class 2, as defined in WTIA Technical Note 5.

Welded ColumnsTable 12 Welded Columns – Properties for Assessing Section CapacityDesignationYield StressFlangeWebfyfyMPaMPaForm FactorAbout x-axisAbout y-axisCompactnessCompactnesskfZexFlangeWebfyfy10 mmMPaMPaZey10 mm33Yield Stress33Form FactorAbout x-axisAbout y-axisCompactnesskfCompactnessZexZey10 mm3300PLUS *Designation10 mm333AS/NZS 3679.2-400 500 WC 02801.00C10100C50103603601.00C10100C5010500 WC .00N5210N22003803800.964S4920N2100228400 WC 361400 WC 800.964S2440N1070144350 WC 280350 WC 350C17203603801.00C3350C1720197* 300PLUS welded sections are produced to exceed the minimum requirements of AS/NZS 3679.2-300. Notes1. For 300PLUS sections the tensile strength (fu) is 430 MPa.2. For Grade 400 sections the tensile strength (fu) is 480 MPa.3. C: Compact Section; N: Non-compact Section; S: Slender Section.HRSSP 7th Ed. April 201413

14HRSSP 7th Ed. April 2014Universal BeamsTable 13 Universal Beams – Dimensions and PropertiesDesignationDepth langesd1(bf-tw)GrossArea mmmmmmmm610 UB 7251.110160222814.810.614.0572530 UB 92.453320915.610.214.082.052820913.29.614.0460 UB 82.146019116.09.974.645719014.567.145419012.7410 UB 59.740617812.8kg/mAbout x-axisAbout y-axisIxZxmm10 542080237021723.822835544.97751590530 UB 60 UB 9.7337467410 UB 59.7333643310 mmJ875310 mmry98643Designation10 mm610 mmSyWarpingConstant10 mm2mmIyTorsionConstant3mm410 mm10 mm639610 UB 6510.311517938.623439453.7360 UB 1.012819839.0338330360 UB 0 UB 0110916639.0233197310 UB 32.0250 UB 6677.511934.515885.2250 UB 725.7200 UB 8657.588.431.810537.6200 UB 82.61.1423.035.722.138.610.418.2180 UB 2227.142.320.881.68.71180 UB 8816.1150 UB 7217.928.217.160.53.56150 UB .10.49513.220.816.628.12.5314.0

Universal BeamsTable 14 Universal Beams – Properties for Assessing Section CapacityDesignationYield StressFlangeWebfyfyMPaMPaForm FactorAbout x-axisAbout y-axisYield StressCompactnessFlangeWebfyfy10 mmMPaMPakfCompactnessZexZey10 mm3333Form FactorAbout x-axisAbout y-axisCompactnesskfCompactnessZexZey10 mm3300PLUS *Designation10 mm333AS/NZS 3679.1-350 610 UB 000.926C3290C4513403400.891C3290C451610 UB 01530 UB 92.4530 UB 03200.902C2070C2893403600880C2070C28982.0460 UB 82.13003200.979C1840C2923403600.956C1840C292460 UB 410 UB 59.73003200.938C1200C2033403600.918C1200C203410 UB .7360 UB 56.73003200.996C1010C1933403600.974C1010C193360 UB 44.73203200.930N770N1403603600.911N762N13944.7310 UB 46.23003200.991C729C1633403600.972C729C163310 UB 0 UB 37.33203201.00C486C1163603601.00C486C116250 UB 00 UB 29.83203201.00C316C86.33603601.00C316C86.3200 UB 3203200.990C180C34.43603600.970C180C34.418.2180 UB 22.23203201.00C195C40.73603601.00C195C40.7180 UB 22.218.1HRSSP 7th Ed. April 3203201.00C138C28.43603601.00C138C28.416.1150 UB 18.03203201.00C135C26.93603601.00C135C26.9150 UB * 300PLUS replaced Grade 250 as the base grade for these sections in 1994.300PLUS hot rolled sections are produced to exceed the minimum requirements of AS/NZS 3679.1-300.Notes1. For 300PLUS sections the tensile strength (fu) is 440 MPa.2. For Grade 350 sections the tensile strength (fu) is 480 MPa.3. C: Compact Section; N: Non-compact Section; S: Slender Section.15

16HRSSP 7th Ed. April 2014Universal ColumnsTable 15 Universal Columns – Dimensions and PropertiesDesignationDepth langesd1(bf-tw)GrossArea mmmmmmmmmmmm310 UC 916.527728.0250 UC 00 UC 8122.746.220320311.07.311.418124.8150 UC 1.023.41521526.86.18.9139100 UC 14.897997.05.010.083.0About x-axisAbout y-axisIxZxSxrxmm10 9Syry125807123078.938102860310 UC 100123011248.437857565.21040713250 UC 465689.720.419930351.7477195200 UC 473022.227431068.47.0191.013938.519739.6150 UC 34.92.30100 UC 14.833643310 mmmmIw13733J139410 mmZyDesignation10 mm610 mmIyWarpingConstant10 mm23TorsionConstant3410 mm10 mm639

Universal ColumnsTable 16 Universal Columns – Properties for Assessing Section CapacityDesignationYield StressFlangeWebfyfyMPaMPaForm FactorAbout x-axisAbout y-axisCompactnesskfCompactnessZexFlangeWebfyfy10 mmMPaMPaZey10 mm33Yield Stress33Form FactorAbout x-axisAbout y-axisCompactnesskfCompactnessZexZey10 mm3300PLUS *Designation10 mm333AS/NZS 3679.1-350 310 UC 1582803001.00C2680C12103403401.00C2680C1210310 UC 3201.00N1560N6943403601.00N1550N68496.8250 UC 89.5250 UC 201.00N986N4543403601.00N977N44872.9200 UC 59.53003201.00C656C2993403601.00C656C299200 UC .23003201.00N494N2233403601.00N490N21946.2150 UC 37.23003201.00C310C1373403601.00C310C137150 UC .43203201.00N176N73.53603601.00N174N72.323.4100 UC 14.83203201.00C74.4C34.43603601.00C74.4C34.4100 UC 14.8* 300PLUS replaced Grade 250 as the base grade for these sections in 1994.300PLUS hot rolled sections are produced to exceed the minimum requirements of AS/NZS 3679.1-300.Notes1. For 300PLUS sections the tensile strength (fu) is 440 MPa.2. For Grade 350 sections the tensile strength (fu) is 480 MPa.3. C: Compact Section; N: Non-compact Section; S: Slender Section.HRSSP 7th Ed. April 201417

18HRSSP 7th Ed. April 2014Tapered Flange BeamsTable 17 Tapered Flange Beams - Dimensions and PropertiesDesignation Mass per Depth mmmmmmmmd1(bf-tw)GrossArea ofCrossSectiontw2tfAgAbout x-axisIxZxSxrxmm10 mm10 mm10 mmmm264333About y-axis3IyZy10 mm64Sy10 mm33Torsion Warping DesignationConstant ConstantryJIw310 mmmm10 mm33410 mm69125 0.350.90.33710.417.214.240.21.14125 TFB100 139.90.07953.536.009.3111.60.176100 TFBTable 18 Tapered Flange Beams - Properties for Assessing Section CapacityDesignationYield StressForm FactorAbout x-axisAbout y-axisFlangeWebfyfyCompactnessMPaMPa125 TFB3203201.00C80.3100 TFB3203201.00C34.1kfCompactnessYield StressForm aC15.63603601.00C80.3C15.6125 TFBC5.303603601.00C34.1C5.30100 TFBkfCompactnessZexZey103mm3103mm3AS/NZS 3679.1-350* 300PLUS replaced Grade 250 as the base grade for these sections in 1997.300PLUS hot rolled sections are produced to exceed the minimum requirements of AS/NZS 3679.1-300.1. For 300PLUS sections the tensile strength (fu) is 430 MPa.2. For Grade 350 sections the tensile strength (fu) is 480 MPa.3. C: Compact Section; N: Non-compact Section; S: Slender Section.DesignationZex300PLUS *NotesAbout x-axisAbout y-axis

Parallel Flange ChannelsTable 19 Parallel Flange Channels – Dimensions and PropertiesDesignationMasspermetrekg/mDepth w)twtfGross Coordinate CoordinateAbou

Standard AS/NZS 3679.1 Structural Steel – Hot Rolled Bars and Sections. Grade Availability 300PLUS Steel is the standard grade manufactured by OneSteel for hot rolled Structural Steel Sections for Australia. 300PLUS Steel for hot rolled products is produced to ex