Transcription

AUSTRALIAN WINDOW ASSOCIATION GUIDE SERIESGUIDE TO GLASSAND GLAZINGA HANDBOOK TO AS 1288Murray Art Museum (MAMA)Source: DLG Aluminium & GlazingVERSION 2 2016

T AWAvDISCLAIMERvABOUT GLASS1GLASS TYPES3Float Glass3Tints and Tones4Decorative Glass4Low-E Glass4Insulating Glass Units4Safety Glass5Toughened Glass6Heat Strengthened Glass7Laminated Glass7GLASS STANDARDS8AS 1288 Glass in Buildings – Selection and Installation8AS/NZS 2208 Safety Glazing Materials in Buildings8AS/NZS 4666 Insulating Glass Units8AS/NZS 4667 Quality Requirements for Cut-To-Size andProcessed Glass8AS/NZS 4668 Glossary of Terms Used in the Glass andGlazing Industry8OTHER REGULATORY REQUIREMENTS9The National Construction Code9AS/NZS 1170 Series Structural Design Actions9AS 4055 Wind Loads for Housing9AS 2047 Windows and External Glazed Doors in Buildings 9AS 1926.1 Swimming Pool Safety Part 1 Safety Barriersfor Swimming PoolsCastle Circuit, Seaforth, NSWSource: EvolutionWindow Systemsii9DESIGN FOR WIND LOADS11Regional Wind Speed13Terrain Category13Local Topography13Building Height, Shape and Orientation14The Effects of Shielding14Span of Glazing14

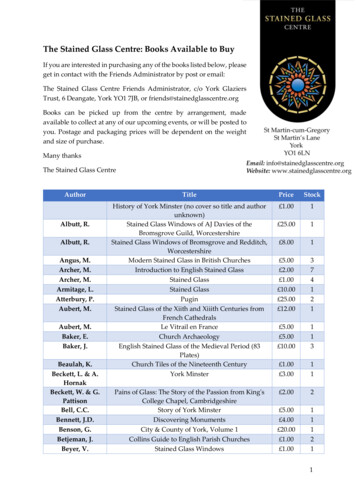

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2HUMAN IMPACT SAFETY17GLASS INSTALLATION45Critical Locations18Safe Handling of Glass45Making Glass Visible18Preparation and Planning46Doors and Side Panels19Sealants46Dry Glazing47Glazing Capable of Being Mistaken for a Doorway orOpening20Wet Glazing49Low Level Glazing and Windows that are Full Height20Butt-Joint Glazing49Bathroom, Ensuite and Spa Room Glazing20Structural Silicone Glazing50Glazing in Stairways20Setting Blocks50Internal and External Shopfronts and Partitions21Laminated Glazing Materials51Insulating Glass Units51Installation of Glass51Schools, Early Childhood Centres, Aged Care Buildingsand Nursing Homes21Insulating Glass Units21SLOPED OVERHEAD GLAZING23GLAZING FOR BALUSTRADES AND POOL FENCING25Balustrades25Swimming Pool Fences25GLASS CUTTING AND PROCESSING53DEFECTS IN GLASS58Feathering58Shells58Scratches58Starts and Runs58FRAMED, UNFRAMED AND PARTLY FRAMED GLASSASSEMBLIES27SHOWER SCREENS29NICKEL SULPHIDE AND HEAT SOAKING OFTOUGHENED GLASS59ENERGY EFFICIENT GLAZING31THERMAL STRESS GLASS BREAKAGE60About Energy Efficiency31Energy Efficient Glazing Assessment32U-Value32Solar Heat Gain Coefficient32Visible Transmittance32Energy Efficiency of Glass32Energy Efficiency of Window Systems32Regulatory Requirements33A Guide to Selection33Condensation on Glazing34ACOUSTIC GLAZING FOR NOISE ATTENUATION37Measurement of Sound37Regulatory Requirements38Acoustic Performance of Glass38High Performance Solutions39Noise Reduction by Glass Type39GLAZING IN BUSHFIRE PRONE AREASBAL TestingRisk FactorsCARE AND MAINTENANCE OF GLASS6061On-Site Protection61Cleaning61Notes61APPENDIX A: GLASS THICKNESS GUIDE TABLES FORWIND RATINGS ONLY63APPENDIX B: REFERENCED DOCUMENTS79APPENDIX C: GLOSSARY OF TERMS80LIST OF IMAGES AND TABLES884142iii

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2FOREWORDThis handbook has been written to provide guidance for architects, building designers,engineers, fabricators, glaziers and associated industry professionals on the proper useand application of glass in the building and construction industry.Glass is one of the most practical, versatile and interesting building products. Despiteits transparent nature, glazing, when used to its full potential, is often the mostextraordinary architectural feature of a building. It can add interesting and uniqueelements to any building - adding character and improving the form and function of aspace. Glazing also provides significant benefits to building occupants through the useof natural light, creating a feeling of openness and providing expansive views of theoutside world.Glazing has a major impact on energy consumption. If applied improperly, it can be asignificant source of heat gain and loss. However, when selected carefully, glass can beused in such a way as to dramatically enhance a building’s energy efficiency.In today’s built environment, glazing does far more than keep out the wind and rain(although these have always been its primary function). It has become increasinglyimportant to consider the design, selection and installation of glazed elements.Performance characteristics such as safety, energy efficiency, acoustic attenuationand fire protection are but a few of the functions a well-considered glazing system canachieve.To this end, advances in technology have made available a host of new and excitingglazing products; high performance double and triple glazing systems, spectrallyselective films and Low-E coatings, and specially developed acoustic laminates toname a few.While this handbook includes references to a number of Australian Standards and theNational Construction Code, it is not, nor is it intended to be, a definitive prescriptionof the regulatory framework. This handbook provides guidance for the most commonapplications of glass and glazing and serves as an overview of current industry practice.The correct and proper assessment of glazing requirements requires a thoroughunderstanding and application of the relevant provisions.ACKNOWLEDGEMENTSThe Australian Window Association (AWA) would liketo acknowledge the contribution of the following in thepreparation of this guide: AWA Technical Committee Australian Fenestration Training Institute (AFTI)Special thanks to:iv Australian Glass Group DLG Aluminium & Glazing G.James Overseas Glass Agencies SCM Group Australia Viridian

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2ABOUT AWAWith over 600 member companies, the AWA is the peak association representingwindow and glazing manufacturers and their suppliers. It is a co-operative; all membershave one vote irrespective of size and financial contribution. The Association BusinessPlan is monitored and reviewed by an elected Board representing all states andterritories of Australia.The AWA provides a national technical voice through representation on Australian andInternational Standard Committees, the Building Code Committee, Residential andCommercial Building Regulation Committees and Committees for Mandatory EnergyRequirements. It keeps the window industry informed via magazines, website updates,meetings, conferences and industry exhibitions and promotes the industry throughmedia outlets, trade exhibitions and presentations at industry conferences.The AWA manages NATA accreditation and compliance programs for manufacturers,provides comprehensive proprietary training and technical support documents throughits training division the Australian Fenestration Training Institute (AFTI), handles disputeresolution with consumers, and owns the Window Energy Rating Scheme (WERS) thatprovides the industry with energy ratings for their fenestration systems.The AWA continues to work relentlessly, representing the industry in as many forumsand on as many work groups and committees as they practically can, on all industryissues.DISCLAIMERThis guide has been developed to provide general guidance, awareness and educationto AWA members, stakeholder groups and consumers. It should not be viewed as adefinitive guide. While every effort has been made to ensure the information is accurate,the AWA expressly disclaims all and any liability to any person for anything done inreliance on this publication. No responsibility is accepted by the AWA for any mistakes,errors or omissions in this publication.v

Agnew Street, Norman Park, QLDSource: Bretts Architectural Window Solutionsvi

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2ABOUT GLASSGlass is made by melting together severalminerals at very high temperatures. Silica,in the form of sand, is the main ingredientand is combined with other substances toform a ‘batch’ and melted in a furnace attemperatures of 1500 C.Figure 1The basic raw materials include: Former: Silica (quartz sand). Fluxing agent: Lime and soda ash(sodium carbonate). Stabiliser: Calcium oxide (CaO),magnesium oxide (MgO), alumina,etc. Cullet: Broken glass is also used inthe batch to speed up the meltingprocess. Other materials that are addedto produce different colours orproperties as required.Glass CompositionSource: ShutterstockSandSoda AshLimestoneOther (Cullet, Stabiliser, etc.)1

Window ProfileSource: Shutterstock2

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2GLASS TYPESFLOAT GLASSIn the batch process, the raw materialsare mixed, then fed together with suitablecullet in a controlled ratio, into a furnacewhere it is heated to approximately1500 C.urnaceRefining FurnaceFloat BathBatching Raw MaterialsMelting FurnaceAnnealing LehrThe principal reactions between the rawmaterials take place within the meltingzone, which occupies about a third ofthe tank. The melting process is crucialto glass quality. Once molten, the glassthen flows in a continuous ribbon from theglass furnace onto a bath of molten tin.The glass, which is highly viscous, floatson top of the flat surface of the tin to formperfectly smooth surfaces on both the topand bottom with uniform thickness. This iswhere the name ‘float’ glass comes from.As the glass flows along the tin bath, thetemperature is gradually reduced untilthe sheet is sufficiently solidified and canbe transferred (at a controlled speed)from the tin onto rollers. Variation in theflow speed and roller speed enables theformation of glass sheets of differentthicknesses.Once off the bath, the glass sheet passesthrough an annealing chamber called aLehr where it is cooled gradually to avoidstrain and cracking from the temperaturechange. On exiting, the glass is inspectedfor defects and then cut to size.The entire process operates continuouslyfor the duration of the ‘campaign’ which,for most plants, will be roughly 12 to 15years. A float line can be nearly half akilometre long and will produce around6,000 kilometres of glass annually, inthicknesses between 0.4 mm and 25 mmand in widths up to three metres.Refining FurnaceFloat BathAnnealing LehrFigure 2Inspection & CuttingPackingInspection & CuttingFloat Glass ProcessSource: Australian Window AssociationPacking3

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationGLASS TYPESVERSION 2TINTS AND TONESLOW-E GLASSDuring the batching process, additionalmaterials may be added to alter theproperties of the float glass. Tinted glassis produced by the addition of smallamounts of metal oxides and is commonlyproduced in bronze, green, blue or grey.The addition of the tint does not affect thebasic properties of the glass except forlowering the amount of visible light andsolar energy transmittance.Low-E stands for low emissivity glass. It ismanufactured by the addition of a specialthin metal coating on one side of theglass. Low-E glass increases the energyefficiency of windows by reducing thetransfer of heat or cold through the glass.This means that in winter, a house stayswarmer, and in summer, it stays cooler.There are two types of Low-E glassavailable; hard coat (pyrolytic) and softcoat (sputtered).DECORATIVE GLASSDecorative glass comes in many formsand has many uses. It may be patterned,etched, coloured or formed (slumped).Most commonly, decorative glass is usedto enhance privacy by making the glassobscure or translucent for bathrooms,ensuites, front entries and the like.Coloured glass is common in leadlightsand heritage windows. Printed glass hasan image printed onto one side of theglass and is commonly used in foyersof commercial buildings and for kitchensplashbacks. There are literally thousandsof decorative glass options.Hard coat, often referred to as pyrolyticLow-E coating, is bonded to the glasswhile it is in a semi-molten state. Theprocess by which the coating is appliedto the glass is called chemical vapourdeposition. The result is a baked-onsurface layer that is quite hard and thusvery durable - which is why pyrolyticLow-E is sometimes referred to as ‘hardcoat Low-E’.A pyrolytic coating can be ten to twentytimes thicker than a sputtered coating butis still extremely thin. Pyrolytic coatingscan be exposed to air and cleaned withtraditional glass cleaning products andtechniques without damaging the coating.Sputtered coatings are multilayeredcoatings that are typically comprised ofmetals, metal oxides and metal nitrides.These materials are deposited on glassor plastic film in a vacuum chamber.Although these coatings range from threeto possibly more than thirteen layers, thetotal thickness of a sputtered coating isonly one ten thousandth the thickness of ahuman hair.Sputtered coatings often use one ormore layers of silver to achieve their heatreflecting properties. Since silver is aninherently soft material that is susceptibleto corrosion, the silver layer(s) must besurrounded by other materials that actas a barrier to minimise the effects ofhumidity and physical contact.Historically, sputtered coatings weredescribed as ‘soft-coat Low-E’ becausethey offered little resistance to chemicalor mechanical attack. Most sputteredcoatings are not sufficiently durable tobe used in single glazed applications.However, when the coated surface ispositioned facing the air space of a sealedinsulating glass unit, the coating shouldlast as long as the sealed glass unit.INSULATING GLASS UNITSOne of the shortcomings of glass is itsrelatively poor insulating qualities. Multiplepanes of glass with air spaces in betweenimprove the insulating value considerably.An Insulating Glass Unit (IGU) consistsof two or more glass panes separatedby a spacer and sealed to preventhumid outside air from entering the unit.Typically, spacers are filled with or containa desiccant to remove moisture trappedin the gas space during manufacturing toprevent condensation forming.Figure 3A Range of Glass Tints andTonesSource: Shutterstock4Figure 4A Selection of DecorativeGlass TypesSource: Glass BlockConstructions (top),Shutterstock (bottom)Double glazing (two panes of glass)is the most common form of IGU andcan reduce heat loss (or gain) by morethan 50 per cent in comparison tosingle glazing - although visible lighttransmittance and solar heat gain for adouble-glazed unit with clear glass willremain relatively high. Adding a Low-Ecoating to a surface of the double-glazedunit will increase the energy performanceas will adding a gas fill between the layersof glass.Double glazing often incorporates special

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationGLASS TYPESVERSION 2Low-E CoatingSolar HeatVisible LightFigure 5Interior RoomHeatLow-E GlazingAn example illustrating thetypes of radiation that Low-Ecoating deflects, enablinggreater energy efficiency of thewindow system.Source: Australian WindowAssociationcoatings. In order to identify specificsurfaces a numbering system is used. Theexterior surface is numbered 1 and eachglass surface is then numbered up tothe interior surface. The same numberingsystem is also used for laminates. Referto Figure 6 for the illustrations of surfacenumbering.Building InteriorBuilding Interior654433SAFETY GLASS2Ordinary glass when broken can formlarge, sharp, dangerous shards. Safetyglass incorporates additional features thatmake it less likely to break or less likely topose a threat when broken.Common types of safety glass includetoughened glass (also known astempered glass), laminated glass, wiremesh glass (also known as wired glass)and vinyl backed safety mirror. Althoughsafety glazing materials may breakunder sufficient impact, their fracturecharacteristics are such that if broken, thelikelihood of injuries will be minimised.211Building ExteriorFigure 6Building ExteriorInsulating Glass UnitsExamples of Double Glazed and Triple Glazed Units, illustrating surfacenumbering.Source: ShutterstockAS 1288 Glass in Buildings requiresthe use of safety glass when glazing issituated where accidental breakage due tohuman impact is reasonably foreseeable.5

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationGLASS TYPESAll safety glass used in Australia mustbe compliant to AS/NZS 2208 SafetyGlazing Materials in Buildings which setsout the test requirements and proceduresfor testing glazing material safety afterbreakage. There are two categories ofsafety glass specified in AS/NZS 2208,Grade A and Grade B, with Grade Ahaving the higher performance level. Thetest requirements for the different glazingmaterials are designed to promote safetyand to reduce or minimise the likelihood ofcutting and piercing injuries from humanimpact.Compliant glazing materials must belegibly and permanently marked witha stamp or sticker with the followinginformation:(a) The name or registered trademark ofthe manufacturer or supplier.(b) The number of the Australian/NewZealand Standard, i.e. AS/NZS 2208.(c) A letter or other code to indicate theplant of manufacture or supply.(d) Grade A or Grade B to indicate thegrade of the material.(e) A number indicating the nominalthickness for standard glazing materialin milimetre or a number indicating theminimum thickness for non-standardglazing material to the nearest tenth ofa milimetre.(f)A letter or word or combinationsthereof to indicate the type of glazingFigure 7Toughened GlassWhen broken, toughenedglass fractures into smallgranules.Source: Shutterstock6VERSION 2material used in the product, forexample:wide, on all sharp edges and corners.(i)Toughened glass is commonly used in thefollowing applications:The letter ‘T’ or word ‘toughened’,indicating a toughened safetyglass.(ii) The letter ‘L’ or the word‘laminated’ indicating a laminatedsafety glass.(iii) The letters ‘TL’ indicating that thematerial is toughened laminatedsafety glass.TOUGHENED GLASSWhen broken, toughened glass crumblesinto small granular chunks of similar sizeand shape, which are less likely to causeinjury compared to ordinary glass whichsplinters into random, jagged shards.Toughened glass is made by a controlledprocess of heating the glass to about600 C followed by rapid cooling usingcompressed air. This cooling processcauses the surface to contract, forming arigid outer layer around the glass - makingit much stronger than conventional glassand far more resistant to impact stressand temperature change. Toughenedglass has four to five times more strengththan ordinary glass of the same thickness.Prior to furnacing, the edges must befinished to a minimum standard wherebyall edges are arrissed by grinding achamfer or bevel, approximately 1 mm Human impact areas for safety, asdefined in AS 1288 Shopfronts and entrances Frameless glass doors Balustrades Structural glass assemblies andfaçades Overhead glazing Shower enclosures Interior partitions Spandrel glazing To minimise the risk of thermal stressfracturesToughened glass, due to the nature ofthe process, is not as flat as float glass.Deviation or roller wave bow can vary withsubstance, tint or surface treatment andshape of the glass. Reflective, enamelledand sandblasted glasses have a greatertendency to bow. Bow tolerances arespecified in AS/NZS 2208.The edges of toughened glass must behandled with care. Particular attentionmust be taken to avoid edge damagewhich can result in spontaneous glassfracture.Toughened glass can be specified tobe Heat Soak treated. Heat soaking

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationGLASS TYPESis a quality control check that detectsand rejects most glass nickel sulphideinclusions. This significantly reduces therisk of toughened glass breakage.Heat Soaking is recommended andshould be specified in structural glassassemblies, overhead glazing, spandrelglass, balustrading and anywheretoughened glass is situated more than fivemetres above ground level.HEAT STRENGTHENED GLASSHeat strengthened glass is manufacturedusing the same process as toughenedglass but is NOT a safety glass. It hasroughly twice the strength of ordinaryglass of the same thickness and has thesame thermal resistance properties oftoughened glass. If broken, it forms largepieces. This product is used in buildingspandrels and windows not requiringsafety glass.Figure 8VERSION 2LAMINATED GLASSLaminated glass is two (or more) piecesof glass, separated by an interlayer. Theinterlayer, typically polyvinyl butyral (PVB),keeps the layers of glass bonded, evenwhen broken, and prevents the glass frombreaking up into large sharp pieces. Thisproduces a characteristic ‘spider web’cracking pattern when the impact is notsufficient to completely pierce the glass.Laminated glass is normally usedwhen there is a possibility of humanimpact or where the glass could fall ifshattered. Skylight glazing and automobilewindshields typically use laminated glass.In geographical areas requiring cycloneresistant construction, laminated glass isoften used in exterior storefronts, curtainwalls and windows. The PVB interlayermay give the glass an improved soundinsulation rating, particularly at highfrequencies, due to the damping effect,and also blocks up to 99 per cent ofincoming UV radiation.The performance of laminated glasscan be varied by changing the number,thickness and type of each of the glasslayers and the PVB interlayers to give awide choice of products with one or moreof the following functional benefits: Safety Security Bullet resistance Cyclone and explosion resistance Solar control and UV protection Noise control Privacy and decorationStandard PVB interlayer thicknessesare 0.38, 0.76 and 1.52 mm. SpecialPVB interlayer thicknesses are availablethrough specialist glass suppliers.Laminated GlassSource: Australian WindowAssociation7

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2GLASS STANDARDSThere are a number of AustralianStandards relevant to glass and glazingthat specify the minimum compliancerequirements. The main standards are:AS 1288 GLASS IN BUILDINGS –SELECTION AND INSTALLATIONAS 1288 sets out the data andprocedures for determining the glasstype and thickness requirements for allbuildings. It is referenced in the NationalConstruction Code (NCC). Glass designrequirements are given for glazing basedon the tensile stresses developed onthe surface of the glass. The objectiveof the Standard is to provide uniformdirection for the use and installation ofglazing throughout Australia, to allow itsuse in legislation and to clarify technicaldefinitions. In general, glazing must satisfythe design requirements for ultimateand serviceability limit states and humanimpact safety in accordance with theprocedures given in the Standard.AS/NZS 2208 SAFETY GLAZINGMATERIALS IN BUILDINGSAS/NZS 2208 sets out the testrequirements for the classification of safetyglazing materials for use in buildings. Thetest requirements for the different glazingmaterials are designed to promote safetyand to reduce or minimise the likelihoodof cutting and piercing injuries fromhuman impact. This applies to all safetyglazing materials for compliance withAS 1288. The impact test assesses thefracture characteristics of a safety glazingmaterial that has been broken under testconditions.8AS/NZS 4666 INSULATING GLASSUNITSAS/NZS 4666 sets out the requirementsand guidelines for long-term testing,glazing, periodic manufacturing testingand other associated aspects of insulatingglass units. Completed and fully curedunits are subjected to a defined laboratorybased testing regime of long-term cyclic,accelerated weathering and UV typetests that utilise laboratory controlledtemperature ranges.AS/NZS 4667 QUALITYREQUIREMENTS FOR CUT-TO-SIZEAND PROCESSED GLASSAS/NZS 4667 specifies the requirementsfor cut sizes of flat, clear, ordinaryannealed glass; tinted heat-absorbingglass; glass used for Grade A safetyrequirements (i.e. toughened orlaminated); patterned; decorative andwired glass; and processed laminated andtoughened glass that is used for generaland architectural glazing.AS/NZS 4668 GLOSSARY OF TERMSUSED IN THE GLASS AND GLAZINGINDUSTRYAS/NZS 4668 provides manufacturers,suppliers and users of glass withdefinitions of terms used in the glass andglazing industry, specifically in buildingapplications. It includes definitions ofterms used in glass-related Australian andNew Zealand Standards.

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2OTHER REGULATORYREQUIREMENTSAs well as the Australian Standards thatspecifically relate to glass and the glazingproducts used in the building industry,there are also other requirements in theregulatory framework that affect glass andglazing. They include:THE NATIONAL CONSTRUCTIONCODEThe National Construction Code (NCC)is an initiative of the Council of AustralianGovernments developed to incorporateall on-site construction requirements intoa single code. The NCC is a uniform setof technical provisions for the designand construction of buildings and otherstructures and plumbing and drainagesystems throughout Australia. The NCC ispublished in three volumes: The BuildingCode of Australia (BCA) is Volume Oneand Volume Two and the Plumbing Codeof Australia (PCA) is Volume Three.VOLUME ONE contains the requirementsfor:(a) All Class 2 to 9 buildings.(b) Access requirements for peoplewith a disability in Class 1b and 10abuildings.(c) Certain Class 10b structures includingaccess requirements for people witha disability in Class 10b swimmingpools.VOLUME TWO contains the requirementsfor:(a) Class 1 and 10a buildings (otherthan access requirements for peoplewith a disability in Class 1b and 10abuildings).(b) Certain Class 10b structures (otherthan access requirements forpeople with a disability in Class 10bswimming pools).(c) Class 10c private bushfire shelters.VOLUME THREE contains therequirements for plumbing and drainageassociated with all classes of buildings.The goal of the NCC is to enable theefficient achievement of nationallyconsistent, minimum necessary standardsfor safety (including structural safety andsafety from fire), health, amenity andsustainability objectives.AS/NZS 1170 SERIES STRUCTURALDESIGN ACTIONSAS/NZS 1170 provides designerswith general procedures and criteriafor the structural design of buildingsand structures. It outlines a designmethodology that is applied in accordancewith established engineering principles. Itis comprised of 5 parts (numbered 0 – 4):Part 0: General PrinciplesPart 1: Permanent, Imposed andOther ActionsPart 2: Wind ActionsPart 3: Snow and Ice ActionsPart 4: Earthquake ActionsThe selection of wind speed class for ahouse depends on the conditions at thesite:(a) The geographic wind speed region ofthe site (Region A, B, C or D, as givenin AS/NZS 1170.2).(b) The terrain category that surrounds itor is likely to surround the site withinthe next five years (TC1, TC1.5, TC2,TC2.5 or TC3).(c) The topographic class of the site (T0,T1, T2, T3, T4 or T5).(d) The shielding class of the house (FS,PS or NS).AS 2047 WINDOWS AND EXTERNALGLAZED DOORS IN BUILDINGSAS 2047 sets out the requirements for theconstruction and installation of windows,sliding and swinging glazed doors(including French and bi-fold), adjustablelouvres, shopfronts and window walls withone-piece framing elements. It provideswindow designers and manufacturerswith generic requirements for windowsin buildings, setting out the performancerequirements and specifications in thedesign and manufacture of all windows,regardless of materials.AS 4055 WIND LOADS FOR HOUSINGAS 4055 provides designers, buildersand manufacturers of building productsthat are affected by wind loading with arange of wind speed classes that canbe used to design and specify suchproducts for use in housing as definedwithin the limitations in this standard. Thestandard relates specifically to buildingClasses 1 and 10 (as defined by the NCC)and within geometric limits given in thestandard. A system of 10 classes of windloads is set out in the standard for theserviceability and ultimate limit states andincorporates both non-cyclonic (N) andcyclonic (C) regions.AS 1926.1 SWIMMING POOL SAFETYPART 1 SAFETY BARRIERS FORSWIMMING POOLSAS 1926.1 provides the requirements forsafety barriers, including glass barriers,around pools. Glass barriers under thisstandard must also meet the requirementsof AS 1288.9

Cyclonic WindsSource: Shutterstock10

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationVERSION 2DESIGN FOR WINDLOADSThe principal load applied to glass in anexterior wall is, in most cases, the netpressure difference caused by local windconditions. It is important to understandthis type of loading to ensure properdesign.The design wind load can be determinedusing these primary documents:AS 4055 – the ultimate and serviceabilitylimit state design wind pressures forglass in walls that are within the AS 4055definition for housing.AS/NZS 1170.2 – the ultimate andserviceability limit state design windpressures for glass in walls that are withinthe limitations of AS/NZS 1170.2.Figure 9The design wind load is determined usingthese standards and is dependent on thefollowing:1.Regional wind speed.2.Terrain category.3.Local topography.4.Height, size, shape and orientation ofthe building.5.The effects of shielding.Alternately, guidance is provided inthe secondary documents AS 1288Appendix A and AS 2047 Appendix A.For all buildings and structures that arenot covered by AS/NZS 1170.2, anengineered solution is required.Storm Over the Gold Coast,2010Photographer: Paul Bica11

A GUIDE TO GLASS AND GLAZINGAustralian Window AssociationDESIGN FOR WIND LOADSVERSION 2Figure 10 Australian Wind RegionsSource: AS 2047Darwin20 25 27 Brisbane30 PerthAdelaideSydneyCanberraMelbourneRegion A1Region A2Figure 11 Terrain Category 1: EnclosedWater SurfacesThis includes rivers, canals,lakes and enclosed bays,extending more than 200 m.Photographer: Chris ClarkeFigure 12 Terrain Category 2: OpenWater and OceansPhotographer: Gary TindaleFigure 13 Terrain Category 3: SuburbanHousingSource: ShutterstockFigure 14 Terrain Category 4: City CentreSource: Shutterstock12Region A3Reg

then flows in a continuous ribbon from the glass furnace onto a bath of molten tin. The glass, which is highly viscous, floats on top of the flat surface of the tin to form perfectly smooth surfaces on both the top and bottom with uniform thickness. This is where the name 'float' glass comes from. As the glass flows along the tin bath, the