Transcription

FENCING HANDBOOKlandmark.com.au

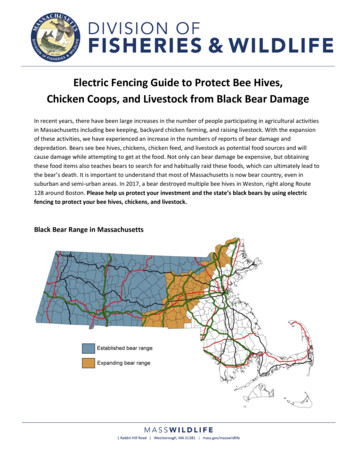

Traditional FencingTable of ContentsTraditional Fencing3Fence Plan3Steps to constructing a conventional fence4. Run out and strain the wire1. Plan your fence5. Attach the wire to posts2. Erect strainer assemblies3. Lay out and install line postsStrainer Assemblies3Fence Plan/DesignPosts and Droppers5As there are a number of different options, planning your fence will allow you todecide what materials are required and what quantity.Wire6Gates9Electric Fencing10The first step is to measure the lengthof the fence so the quantity of materialscan be calculated. When deciding uponmaterials take into account contour ofthe land, erosion and soil type, fire riskand coastal exposure, livestock, life spanrequired and budget.Key fence components are strainerassemblies, line or intermediate posts anddroppers, wire (prefabricated, plain orbarbed) and gates.The proposed fence line should be clearedof any obstructions prior to any fenceconstruction.Strainer AssembliesTypes of Energisers10Earthing11Permanent Fence12Portable Fence15Strainer assemblies also known as “end assemblies” are the most importantpart of the fence as they take the tension of the wire and eliminate any fencemovement. Strainers are required at the end of each fence line, gateways,corners and changes in fence direction, at the crest or hills and bottom of gullies.Strainer assemblies may also need to be included at intervals in long fences overflat ground. Strainer posts must be stayed for each fence line it is connected to,so that the fence does not pull the post over.16Strainer assemblies can be wooden, steel orconcrete.Repair and MaintenanceHint: Planning thedesign and layoutof your fence isthe key actionprior to beginningconstruction.Wood – select timber, preferably local,that is durable in the ground. Treatedtimber is light and easy to cut to length andis resistant to rot and termites.However galvanised options are availableand will extend the life of the post and arebecoming increasingly popular.Concrete – usually more expensive but arestrong and durable. Care needs to be takenas they can crack when overstrained.Steel – suitable for high fire risk areas,susceptible to rust and corrosionparticularly in coastal areas and acidic soils.2Landmark Fencing HandbookLandmark Fencing Handbook3

Hint: As strainerassemblies are likethe foundations of ahouse they need tobe spot on.The two main strainer assembly designs are theangle/diagonal stay and the box/horizontal assemblyAngle StaySuitable for firm soil and hightension straining.Consists of a strainer post, stayand stay block.The top end of the stay isconnected to the strainer post.The bottom end is inserted intothe ground onto a stay block toprevent sinking.Posts and DroppersLine posts are set at regular intervals between strainer assemblies and are usedto guide the line of wires and to provide additional support. Like the strainerassemblies, line posts can also be wooden, steel or concrete. The type of line postselected will depend on what you are trying to fence in and what life span yourequire from the fence. Different materials can be used in combination if suitable.The number of posts required isdetermined by the fence length (distancebetween strain assemblies) divided by theinterval between line posts. Post intervalswill be dependent on livestock type andstock pressure.A suspension fence can be used as analternative to using close interval postsand is best suited to flat country. This iswhere the line posts are set further apartand droppers are used in between lineposts to maintain fence integrity and helpspread stock pressure from a single wire, toall wires in the fence, reducing the risk ofoverloading and subsequent wire breakageBox AssemblySuitable for soft ground andhigh strains.Installing PostsTo ensure the fence is a straight as possibleit is recommended a sight wire be strainedclose to the ground between the endassemblies. Using this sight wire as a guidelay line post at predetermined intervalsalong the fence line.Wooden or concrete posts will need holesto be dug or a mechanical driver can beused. Steel Y shaped posts can be drivendirect into the ground using a post driver.Droppers are made from wood, steel,fibreglass or plastic.Consists of a strainer post,stay post, horizontal post anddiagonal wire brace.The wire brace goes from thebottom of the end post to thetop of the stay post.4Landmark Fencing HandbookLandmark Fencing Handbook5Hint: If using steel Yshaped post ensurethe sides with holesare all facing the sameway making it easierto attach the wire.

Hint: The thickness(gauge) and tensilestrength of the wirerequired is dependenton the pressuresituation on the fence.WirePrefabricated WireThere are three types of wire that are commonly used and again are dependenton what you are trying to fence in. These wires also have different variants withintheir type. Plain Barbed PrefabricatedPlain WireBarbed WireStandard galvanised wire is suitable formost fences and has a single coating.Heavy galvanised wire with its thickercoating is more resistant to corrosion andshould be considered in higher rainfall andcoastal areas.As with plain wire, barbed wire can bestandard or heavy galvanised, low or hightensile.Low tensile wire (soft wire) is used in mostconventional fences with close spacedposts. Thicker wire should be used inhigher pressure situations.High tensile wire has a higher breakingstrain providing more strength to the fenceand suitable for high pressure situations,longer fence strains and wider postspacing’s.High tensile requires more accuratestraining and are more difficult to handleand knot than soft wire.6Landmark Fencing HandbookPrefabricated wire consists of picket(vertical) wires attached to line (horizontal)wires. The picket wire acts as a dropperproviding support and strength to thefence.Netting - soft wires are woven into ahexagonal mesh. Suited to lower pressureapplications or for use as an apron at thebottom of a fence for a barrier in feralanimal control.Hint: UsingPre-Fabricated wirewill reduce theamount of time ittakes to erect a fencetherefore is a verycost effective option.Ringlock uses single, continuous picketwires attached to the line wires by steelrings. Resists high stock pressure andsuitable for long spans and suspensionfence designs.High tensile barbed wire is made fromhire tensile wire in a reverse-twistpattern providing optimum strength andtensioning.Prefabricated wire comes in varioussizes. Ringlock and hingejoint wire size isindicated as e.g. 7/90/30 – 7 line wires;90cm fence height; 30cm picket spacing’s.Netting wire size is indicated as e.g.90/4/1.4 – 90cm fence height; 4cm meshspacing; 1.4 wire diameter.Iowa barbed wire is made from low tensilewire in a continuous twist pattern. It iseasier to handle than high tensile withgreater fire resistance making it suitablefor fire prone areas.Hingejoint - individual picket wires arewrapped around the line wires. Resistshigh stock pressure and suitable for longstrains and use over undulating countryand through gullies.Landmark Fencing Handbook7

Hint: The mosteffective way tojoin wires is to use aGripple – this will takeaway the need to use aknot and will give thefence greater strength.Straining WireOnce end strainer assemblies and line postshave been installed, the wires can be rolledout, strained and attached.1. Tie off the wire to the strainer assemblyand roll out the wire to the nextstrainer assembly.2. Using wire strainers to attach thewire to the second strainer assembly.Two options are available. Firstly youcan secure the wire to both strainerposts leaving enough slack to cut thewire and strain it away from one ofthe strainer posts then rejoin the wirewith an appropriate knot. Alternativelyyou can strain the wire directly off astrainer post using a separate shortlength of straining wire with the knotbeing tied close to the strainer.Wire should be strained to the tensionrecommended by the manufacture. Underor over strained wire will reduce the fencespotential life span and increase ongoingmaintenance requirements. A tensionmeasuring tool should be used to ensurewires are strained to the recommendedtension.Joining WireVarious knots can be used to secure wire.Two common knots are the figure eightand the double loop (pictures).Figure eight – join plain wires of thesame gauge8Landmark Fencing HandbookDouble loop – joining barbed wire andquick repairs.However the safest, best and mostprofessional way to join wires is to usegripple fasteners. Wires are fed fromopposite ends through the gripple andthen secured using a gripple tensioningtool. Use of a gripple will allow restrainingat a later date if required. Gripples are notrecommended for use with barbed wire.GatesHint: The size of thegate is dependent onyour requirements,but a good measureis it should be wideenough to fit throughyour widest bit ofmachinery.Gates allow livestock, vehicles, machinery and people to move in and out ofpaddocks, leaving the paddock secure once the gate is closed. When planningyour fence and installing your strainer posts ensure sufficient room is allowed forthe gate and allowance on either side.Swinging a gate1. Place the gate ona set of blocksevenly between thetwo strainer posts.Temporarily securewith wire.2. Attach gate hingesto the strainer postand gate.Attach to PostsOnce the wire has been strained it can beattached to the line posts.To attach the wire to wood posts usebarbed staples. For steel posts use tie wireor post clips put through the hole in postand twist around wire. Threading the wirethrough the holes on the post should beavoided as this can remove the galvanisedcoating on the wire making it moresusceptible to corrosion.Fence droppers can now be installed whererequired using the recommended clips.3. Attach gate fastener toopposite post to allowgate to be securedwhen shut.Numerous options of gatehardware are available tosuit varying requirements.Gaps between the gate andpost should be sufficientenough for the gate toswing smoothly but preventsmall livestock from gettingthrough. A gate should notdrag on the ground andideally open both ways.Landmark Fencing Handbook9

Hint: When comparingenergisers, use outputenergy as the basis foryour comparison.Electric FencingWhy use electric fencing?Electric fencing provides a numberof benefits. It is: Effective in animal control and pasturemanagement Cost Effective Easily constructed and maintained Easily modified to suit requirements Light weight and easy to construct Long-lasting due to low physicalcontact from animal leaning on fenceHow electric fencing worksElectric energy from an energiser is pulsedalong a fence wire. When an animaltouches the electrified wire it completesEarthingthe circuit resulting in an electric shock tothe animal. This shock is memorable sothat the electric fence becomes more of apsychological barrier rather than a physicalbarrier.The earth is half of an electric circuit.The type of earthing system selected willbe dependent on the soil conductivityand fence location. Location for anearthing system:Types of fencing Located in damp, high mineral soil At least 10m away from any other earthsystem (telephone, house mains power) Protected from livestock or machinerydamageThere are two types of electric fences,permanent and portable.Unless a temporary or removable fenceis required a permanent electric fenceis recommended. Permanent fences areeconomical, easy to install and operate.Portable fences are suitable for shortterm animal control and rotational orcell grazing.When an animal standing on the ground touches the fence the circuit is completed andthe animal gets a shock.EnergiserSelecting the right energiser for yourfence is the key ingredient to achievingthe best performance. When choosingyour energiser you need to consider thefence length, area to be fenced, numberof wires and vegetation load.3. Solar powered energisers use a solarpanel to convert light into electricitywhich is stored in a battery usedto power the fence. Suitable forpermanent or portable fences inremote areas where mains power is notavailable.There are 3 types of energisers tochoose from:Energisers will have 2 energy determinants– stored and output energy.1. Mains energisers are connected toa mains power supply. Most costeffective and reliable.Stored energy - the amount of energystored in the energiser. The higher thestored energy the more powerful theenergiser.2. Battery energisers are usually poweredby a 9 or 12V battery. Suitable forportable fence and when mainspower is not available.10 Landmark Fencing HandbookHigh powered energisers and dry soilwill require more stakes compared tolow powered energisers and wet soil.Information supplied with your energiserswill provide the correct number of earthstakes to use. Earth stakes should be 2min length, 3-4 meters apart and connectedby one insulated cable.All Live System – suited for moist soil that is conductive.EnergisersTypes of energisers Accessible for maintenanceFence TerminalLIVEEarth TerminalLIVELIVEOutput energy – the amount of energythat is delivered to the fence from theenergiser.Landmark Fencing Handbook 11Hint: The numberof earth stakesrequired for yourearthing system willbe dependent on thepower of the energiserand soil type.

Hint: 4,3,2,1 Earthingrule – earthing stakes4 metres apart, at least3 stakes, 2 metres longand connected by 1continuous wire.Earth Wire Return System – suited for dry or sandy soils that is not conductive.LeadoutThe fence contains both electrified and earth wire. When an animal touches both a live andearth wire at the same time the circuit is completed and the animal will receive a shock.The leadout wire/cable connects theenergiser to the fence and can be installedeither underground or overhead. A leadoutshould have as little resistance as possibleto maintain the voltage between theenergiser and the fence. The length andthe diameter of the leadout will affect theres

Permanent fences are economical, easy to install and operate. Portable fences are suitable for short term animal control and rotational or cell grazing. Types of energisers Selecting the right energiser for your fence is the key ingredient to achieving the best performance. When choosing your energiser you need to consider the fence length, area to be fenced, number of wires and vegetation .