Transcription

INSIGHTqc Controller

Simply InsightfulWhen trying to achieve simple manufacturing goals ina complex manufacturing world, taking control of andunderstanding the fastening process doesn’t have tobe complicated. The new Ingersoll Rand INSIGHTqc is different, by design. The INSIGHTqc controller isdesigned to be easy to use, easy to integrate, and providea common platform to meet the global assembly needs ofour customers. This controller offers advanced tighteningcontrol and a simple user experience to improve efficiency onproduction lines, and get the job done right, every time.WHY DO ICARE?SIMPLEFLEXIBLECAPABLEEXPERTS NOTREQUIREDEASILYIMPLEMENTCHANGEMEET YOURREQUIREMENTSy Reduce line rebalancing costsy Easy line integrationy Remove device dependencyy Get the job right, every timey Assurance via traceabilityy Optimize your productivityWHAT DOESTHIS MEAN TOME?y Save on selection, trainingand installation costsy Reduce errors and downtimey Remove user dependenciesHOW DOESINGERSOLL RANDOFFER THIS?y Intuitive, Visual ProgrammingInterfacey Plug and Play Accessoriesand Protocolsy Backwards Capabilityy Integrated Backup andRecoveryy Bundled Controller Optionsy Context Specific IntegratedHELPy Web Based programminguse any operating systemvia any browsery Meets current industrycommunication needsy Adjustable to meet anytightening controlrequirementsy Integrated logic controlsy Easy hardware and softwareupgradesy Touch Screen Interfacey Industry leading cycle datastoragey Robust audit and system logsy Advanced tightening strategiesand featuresy Onboard diagnosticsy Integrated statistical processcontrolsy Preventative maintenancealarmsy Configurable email alertsThe web-based software eliminates device dependencies and enables full programming capability with any devicethat can run an Internet browser, including smart phones, tablets or computers. The INSIGHTqc controller is easyto integrate with the manufacturing line, provides flexible logic controls for job sequencing, and helps reduce linerebalancing costs through a simple and intuitive user interface.Bottom line, the INSIGHTqc controller is a Simply Insightful solution.2www.ingersollrandproducts.com

CapabilitiesTorque/Angle ControlSoftware CapabilitySoftware FeatureHome ScreenStandard F M FM License Update License Activate& Time DateSettings SystemInitialization SpindleManagementAddress IPSettingsStandard F M FM JOB Setup PSET Setup ALL TighteingStrategies Quick Programming AdvancedProgramming Cycle Results JOB ResultsAudit Log Digital IOSettingsEOR Data OutBarcodeEvent Log User ManagmeentSystem Diagnostics Digital IO DiagnosticsStatistics SettingsStatistics SummaryStatistics AlarmSettingsStatistics AlarmSummary System LogsFieldbusDiagnosticsFieldbus SettingsEthernet IPProfiNet Tool Diagnostics ProfiBus DeviceNet Backup and Restore Firmware Update PreventativeMaintenance AlarmsTool CalibrationFactory ResetNetwork SystemDiscoveryEmail AlertsMES ProtocolsSettingsAtlas CopcoOpen ProtocolAtlas CopcoToolsNetVW XML 2.1Nissan Serial EOR Prevailing TorqueStick Slip DetectionStatistical Process ControlsStatisticStatusMeanCapabilityPass %Fail %Gradient/ Slope AnalysisDescriptionStatistical average - used to derive the central tendency of the tightening data ofa particular PSETCalculated as (6* sigma / Mean) * 100 on a particular PSETIndicates the % of the cycles that have a cycle result of PASS from the samplepopulation of a particular PSETIndicates the % of the cycles that have a cycle result of FAIL from the samplepopulation of a particular PSETCalculated as: MEAN Result Value - TARGET Result Value for a particular PSETCalculated as: MAX Result Value - MIN Result Value of a particular PSET.SLOPE A HIGH LIMITSLOPE A LOWLIMITMean ShiftRangeStandardDeviation (σ) The calculated standard deviation (σ) of the Result Value of a particular PSET.Process Performance, calculated as: (USL - LSL) / (6 * σ)PPCalculated as: (USL - USL) / (6* (W / d * S))CAMPPKProcess Performance Index, Calculated as: MIN (( MEAN - LSL) / (3 * σ) OR (USL- MEAN) / (3 * σ)www.ingersollrandproducts.com3

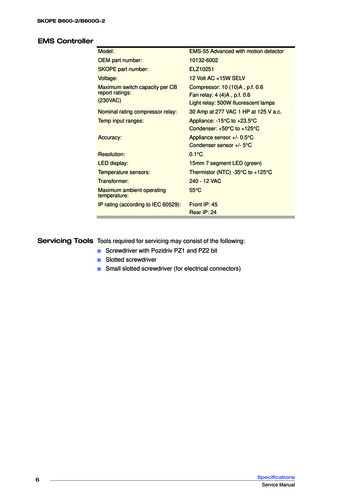

SpecificationsIntegrated carryinghandlePower indicatorIntegrated wallmount7-in full color touch screenSSD cardSystem indicatorsnFactory connectionnWireless connection (future)nLink statusnFault detectedWhiteboard &QR codeEthernet ports10/100 & 10/100/1k6 Position connector1. 24V2. 24vcom3. E-stop4. E-stop comUSB 2.0ports (4)5. High speed stop6. High speedstop comFieldbus card slotIP resetbuttonGFI/20 AMPcircuit breakerTool rnet LE

In si gh tq c ControllerBy the NumbersSoftwareNOTRequired256JOBs & PSETs31Steps5User LoginsAlarmsLogic rules for JOB sequencingBarcode function: USB, Serial, EthernetManual barcode entry optionTubenut controls (configurable modes)Quick programming modeAdvanced programming modeWeb-BasedProgrammingUnrestricted programming from controller or remoteEmbedded, context-specific helpEmail statistics alarms direct from controllerMulti-language supportOnboard tool diagnosticsONBOARD DATA STORAGERemovable SSD Card that stores ALL settings and dataComplete controller settings and data recovery through SSD swapTightening curve displayed on Home screen of controllerFull USB Backup and Restore Function50,000 Audit Logs Tightening Results Event Logs Tightening Curves System LogsConnectivity45Ethernet IP, ProfiNet,ProfiBus, DeviceNetFieldbusOptionsMES ProtocolOptionsOpen Protocol, ToolsNet, ToyotaPokeYoke, VW XML, IR EthernetEOR, Nissan Serial EORHardware40secBoot Time40 SecondsSimpleFlexible810.9Families10.9 dm3ToolVolume4USB2.0 Ports7”Touch Screen7 Inch Color2Ethernet Ports10/100, 10/100/1KCa pablewww.ingersollrandproducts.com5

Controller ModelsThe INSIGHTqc Controller is 100% compatible with our QE and QM tools. With the INSIGHTqc , these toolswill have 50K tightening records and 50K tightening traces – compared to 10 to 30K in competitors’ products– which will let users understand all facets of the tightening process – torque, angle, time and date.SYSTEM OPTIONSModelSeries DisplayFIELDBUS rdStandard plusProfiBus layDisplayDisplay120V AC120V AC120V AC120V ACQCD12-FQCDisplay120V ACQCD12-FMQCDisplay120V ACStandard plusProfiBus CardQCD13-FQCDisplay120V ACStandard plusDeviceNet CardQCD13-FMQCDisplay120V ACQCD21QCD21-FQCQCDisplayDisplay230V AC230V ACQCD21-MQCD21-FMQCQCDisplayDisplay230V AC230V ACQCD22-FQCDisplay230V ACQCD22-FMQCDisplay230V ACQCD23-FQCDisplay230V ACStandard plusDeviceNet CardStandardStandardStandardStandardStandard plusProfiBus CardStandard plusProfiBus CardStandard plusDeviceNet CardQCD23-FMQCDisplay230V ACStandard plusDeviceNet CardEthernet/PProfiNet MES OPTIONSIR Ethernet Atlas CopcoProfBUS DeviceNETOpenToolsNetEORProtocol VWXML2.1NissanSerialEOR DC Electric NutrunnersQE2 Series DC electric nutrunnersQE Series DC electric nutrunnersQEQEMotorSeriesQE2 T S 010 P 11 S04BodyToolStyle Activation2A AngleS InlineT Inline(Push to Start)P PistolInline002003005007010Maximum Mounting OutputTorque (Nm)Angle003005007010015T TriggerL LeverP Trigger PushS Push to StartC Remote Start6AngleA1 Size 1 AngleheadA3 Size 3 AngleheadDriveQ04 1/4” QuickChangeH04 1/4” InternalHexS04 1/4” SquareS06 3/8” SquareInline / Pistol10 Pistol Solid11 Push to Start,Trigger Push30 50 mm Spindle, no float32 50 mm Spindle, 19 mm floatMotorM000 Motor (Inline, Pistol)P Standard GearcaseF Flanged 468A AngleS InlineT Inline(Push to Start)Z OffsetM MotorP PistolT TriggerL LeverE Extended LeverP Trigger PushS Push to StartC Remote Start4 A T 013 P A2 S04BodyToolStyle ActivationMaximum Mounting OutputTorque (Nm)QE4QE6Angle ine020028033050P Standard GearcaseF Flanged GearcaseR Reaction BarB Bolt on Flange, 1pc.J Bolt on Flange, 2pc.AngleA2 Size 2 AngleheadA4 Size 4 AngleheadA5 Size 5 AngleheadA6 Size 6 AngleheadA7 Size 7 AngleheadA8 Size 8 AngleheadDriveQ04 1/4” QuickChangeH04 1/4” InternalHexS04 1/4” SquareS06 3/8” SquareS08 1/2” SquareS12 3/4” SquareInline / Pistol10 Pistol Solid11 Push to Start, Trigger Permit20 50 mm Spindle, no float21 50 mm Spindle, 19 mm float41 100 mm Spindle, 19 mm float61 150 mm Spindle, 38 mm float81 200 mm Spindle, 38 mm float62 150 mm Spindle, 50 mm float82 200 mm Spindle, 50 mm float02 250 mm Spindle, 50 mm float22 300 mm Spindle, 50 mm float

System AccessoriesThe INSIGHTqc Controller provides optimal flexibility for the workstation with compatibility to a variety ofplug n play accessories to maximize productivity for your manufacturing line. A variety of cables and extensioncables are available to customize your production tionOrder NumberSocket Tray,4 PositionUSB Tower LightSerial InterfaceAdaptorDigital I/O Box,8 ChannelBar Code Scanner,Cabled USB; HDBar Code Scanner,Cabled USB; LDBar Code Scanner,HD, Wireless withUSB CradleDIO Box MountingBracket Kit4761582800147601629001DIO Box47601630001USB to Serial Adapter476173320014762575400147625755001Socket TrayBar Code Scanners4762575600147628739001Bit TrayLight TowerTool Cables(3m)(6m)(10m)DC Tool CablesTool Cable (QE2)90 tool cable (qe2)Tool cable (qm, qe4/6/8)90 cool cable (qm, (10m)(20m)(40m)DC Tool Extenson CablesExtension cable90 extension EXT-40MGEA40-INT-01*** 90 degree extension cable requires a tool cable. Other lengths available.www.ingersollrandproducts.com7

ingersollrand.comIngersoll Rand (NYSE:IR), driven by an entrepreneurial spirit and ownership mindset, is committed to helping make life better. We provide innovativeand mission-critical industrial, energy, medical and specialty vehicle products and services across 40 respected brands designed to excel in even themost complex and harsh conditions where downtime is especially costly. Our employees connect to customers for life by delivering proven expertise,productivity and efficiency improvements.We are committed to using environmentally conscious print practices.We are committed to using environmentally conscious print practices.www.ingersollrandproducts.com8 2020 Ingersoll RandIRITS-0517-026-0220

GFI/20 AMP circuit breaker 1. 24V 2. 24vcom 3. E-stop 4. E-stop com 5. High speed stop 6. High speed stop com n Ethernet IP n Profinet n Profibus n Devicenet n Others . Full USB Backup and Restore Function 50,000 Tightening Results Tightening Curves Audit Logs Event Logs System Logs Software 31 Steps 5 Alarms