Transcription

Overview on use of a Molten SaltHTF in a Trough Solar FieldD. KearneyB. KellyR. Cable,N. PotrovitzaKearney & AssociatesNexant, Inc.KJC Operating Co.U. Herrmann, P. NavaFlabeg Solar InternationalR. Mahoney, J. Pacheco Sandia Natl Labs LabD. Blake, H. PriceNRELNREL Parabolic Trough Thermal Energy Storage WorkshopGolden, CO, February 20-21, 2003NREL/PR-550-40028

Disclaimer and Government LicenseThis work has been authored by Midwest Research Institute (MRI) under Contract No. DE-AC36-99GO10337 with the U.S.Department of Energy (the “DOE”). The United States Government (the “Government”) retains and the publisher, by acceptingthe work for publication, acknowledges that the Government retains a non-exclusive, paid-up, irrevocable, worldwide license topublish or reproduce the published form of this work, or allow others to do so, for Government purposes.Neither MRI, the DOE, the Government, nor any other agency thereof, nor any of their employees, makes any warranty, expressor implied, or assumes any liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus,product, or process disclosed, or represents that its use would not infringe any privately owned rights. Reference herein to anyspecific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not constitute orimply its endorsement, recommendation, or favoring by the Government or any agency thereof. The views and opinions of theauthors and/or presenters expressed herein do not necessarily state or reflect those of MRI, the DOE, the Government, or anyagency thereof.NREL TES Workshop-Golden-Feb032

Concept & ObjectivesUtilize a molten salt asthe heat transfer fluidin a parabolic troughsolar field to improvesystem performanceand to reduce theLevelized ElectricityCost (LEC)NREL TES Workshop-Golden-Feb033

Potential Advantages Can raise solar field output temperatureto 450-500 C– Rankine cycle efficiency increases to 40% range– ΔT for storage up to 2.5x greater Salt is less expensive and more environmentallybenign than present HTF Thermal storage cost drops 65% to 20/kWhtcompared to VP-1 HTF plant (no oil-to-salt HX) Solar Two experience with salts pertinent andvaluable (piping, valves, pumps)NREL TES Workshop-Golden-Feb034

Potential Disadvantages High freezing point of candidate salts– Leads to significant O&M challenges– Innovative freeze protection concepts required More expensive materials required in HTF systemdue to higher possible HTF temperatures Selective surface durability and salt selection willdetermine temperature limits Solar field heat losses will rise, though emissivity of0.075 (from 0.1) would regain performanceNREL TES Workshop-Golden-Feb035

Some Key Questions What is the practical upper temperature limit? Is the O&M with salt feasible in a trough field, particularlyfreeze protection? Do materials, O&M, performance, etc. push the solar systemcapital cost too high, or in fact will the cost be reduced? Can we lower electricity cost with this approach? And addimportant flexibility with thermal storage?NREL TES Workshop-Golden-Feb036

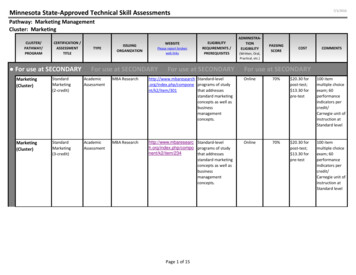

General System ConditionsPower block type:Steam Rankine cyclePower block capacity: 50 MW grossSteam turbine inlet conditions:Pressure 66 bar, 100 barTemperature nominally 400-500CSteam turbine cycle efficiency: determined by GateCyclecalculation, nominally 38.5-41.1% for these conditions.Solar field outletNominal450 Csalt temperature:Maximum 500 COptical:Overall optical efficiency 0.75Power BlockCapacity, MW55 grossPerformance runs:Thermal storage capacity 6hAnnual InsolationBarstowCollector typeGeneric SEGS type withadvanced featuresε 0.1@ 400CReceiverCurrent Solel ReceiverOperating scenario Solar onlyNREL TES Workshop-Golden-Feb037

Characteristics of the Nitrate Salts andTherminol omposition, %NaNO36077KNO3405345NaNO240Ca(NO3)248Freezing Point, C22014212012013Upper Temperature, C600535500550400Density @ 300C, kg/m3189916401992815Viscosity @ 300C, cp3.263.166.370.2Heat capacity @ 300C, J/kg-K1495156014472319NREL TES Workshop-Golden-Feb038

Effective Storage Fluid CostSaltHitec (a) [142 C]Solar Salt (b) [220 C]Calcium Nitrate[HitecXL] (c) [120 C]Therminol VP-1 (d)TemperatureRiseCost perKgStorageCost C /kg 5.815.220.130.057.5a) 7:53 Na:K Nitrate, 40 Na Nitriteb) 60:40 Na:K Nitratec) 42:15:43 Ca:Na:K Nitrated) Diphenyl/biphenyl oxideNREL TES Workshop-Golden-Feb039

Candidate Thermal Storage Systems 2-Tank Configuration– Hot and Cold Tanks– Used at Solar Two good engineering experience– Judged to ready for commercial use Single Tank Thermocline– Good option - costs estimated to be 65% less– Requires further development– 20 MWth prototype operated at SNLA Freeze protection in storage systems less complexthan in field piping With VP-1, an expensive oil-to-salt HX isrequired. A molten salt HTF eliminates that need.NREL TES Workshop-Golden-Feb0310

HTF System Layout2-100% CapacityCold Salt PumpsVSVSCollector FieldCold Salt TankHot Salt TankReheater2-100% CapacityHot Salt PumpsVSReheater OutletTemperatureControl Valve2-100% CapacityCold SaltAttemperation PumpsVSVSSuperheaterEvaporatorVSPreheaterSteam GeneratorRestart Bypass ValveHot Salt TankCold Salt TankNREL TES Workshop-Golden-Feb0311

Comparative Levelized Electricity CostNREL TES Workshop-Golden-Feb0312

Engineering on solar field pipinglayout and design of major equipmentwas carried out for use in theperformance and cost modelsNREL TES Workshop-Golden-Feb0313

Solar Field Layout1155 mQuad 1Quad 2PowerBlock857 mSolar Field Parameters for 55 MWe Plant125.0 Solar field peak thermal outpu MWt879.0 Total salt HTF mass flowrate kg/s28.4 Header corridorm100.5 Total length per SCAm12.2 Outer road corridorsm69.6 Allowance E-W for power blockm402 Length of 1 row with 4 SCAs m1155 E-W total widthm857 N-S total widthmhot HTF in header and illustrative loopscold HTF in header and illustrative loopsQuad 3Quad 4NS ALT HTF S OLARFIELD LAYOUTP O WER B LO C KN O T T O S C A LE270,320496626217.45.7648989,94999245NREL TES Workshop-Golden-Feb03SF aperture areaTotal SCAsTotal rowsTotal loopsSolar row spacingMirror apertureSCAs/rowSCAs/loopTotal land areaTotal land areaTotal land aream2m2hectaresacres14

Optical Efficiency BackupOptical EfficiencyComparisonSandiaSEGS VILS-2 Test LS-2 1999New LS-2CollectorAdvancedTroughBellows Shadowing0.9740.9710.9740.974Tracking Error & Twist0.9940.9940.9940.994Geometric Accuracy0.980.980.980.98Mirror Reflectivity0.9350.9350.9350.95Dust on Mirrors0.9740.9310.950.97Dust on HCE0.990.9770.9830.99Envelope 370.960.97Unaccounted0.960.960.970.98Optical Efficiency0.730.700.750.80NREL TES Workshop-Golden-Feb0315

Final ComparisonCase IDVP-1 No StoVP-1 66bar 2T VP-1 66bar TC Salt 450 C 2T Salt 450 C TC Salt 500 C 2T Salt 500 C TCSolar Field Size ,100Investment Cost [M Thermal Storage Cost [M ]021,33015,89719,6748,39014,1416,117Annual O&M cost [k /yr]3,5834,0884,0884,2824,2824,2824,282Net Electric [GWh]107.5169.2169.1183.9182.9185.7184.4Mean Solar to electric %LEC .3%14.2%18.5%17.6%20.6%Thermal Storage Cost /kWh el0.064.648.259.625.442.918.5Thermal Storage Cost /kWh th0.023.717.723.610.117.47.5LEC ReductionNREL TES Workshop-Golden-Feb0316

LEC Gains from Use ofCalcium Nitrate Salt as HTF160140140120VP-1132128Salt 450 C120114Salt 500 C115111100806040200VP-1No StoVP-1 66bar VP-1 66bar Salt 450 C Salt 450 C Salt 500 C Salt 500 C2TTC2TTC2TTCNREL TES Workshop-Golden-Feb0317

Concept Overview Study concluded that no overriding barriers prevent its adoptionat 450 C. R&D is needed, particularly to reach 500 C operation. Feasible solutions have been put forward for system charging,freeze protection, recovery from freezing, and routinemaintenance tasks. Selective surface and ball joints presentgreater challenges. There is no compelling economic advantage to using molten saltin a trough solar field for a system without thermal storage There appears to be significant economic advantages for a moltensalt HTF with storage. Preliminary estimates on reductions inLEC from the reference VP-1 case (w/o storage) are significant.NREL TES Workshop-Golden-Feb0318

Engineering IssuesNREL TES Workshop-Golden-Feb0319

Issues addressed Routine Freeze ProtectionSolar Field Preheat MethodsCollector Loop Impedance HeatingMaterials ConsiderationsNREL TES Workshop-Golden-Feb0320

Freeze Protection Methods Heat Collection Element––––Cold salt circulation in routine overnight operationImpedance heating for maintenance outageResistance heating cable internal to the HCEDrain loop to service truck for loop pipingmaintenance HTF Header Piping– Cold salt circulation in routine overnight operation– Electric heat tracing for maintenance outageNREL TES Workshop-Golden-Feb0321

Overnight Cooling350Cooling curves for Solar Fields with Salt HTF3002502001501000h TES1h TES506h EL TES Workshop-Golden-Feb0322

HCE Heating Internal resistance heating– Considered possible but cumbersome Impedance heating– Circumferentially uniform– Higher power densities possible– Electric system requirements highNREL TES Workshop-Golden-Feb0323

Collector Loop Maintenance Drain hot HTF into maintenance truckunder slight vacuum Perform maintenance, e.g., HCEreplacement Heat loop with impedance heating, andpump salt mixture into loopNREL TES Workshop-Golden-Feb0324

Normal Maintenance & Operation Within the solar field, O&M practices will change forHTF system and flow loop only, requiring differentprocedures for:–––––HCE replacement, requiring taking loops out of serviceMaintenance of valves, interconnections, and other fittingsHeat trace systemsMajor equipment: Pumps; steam generator; TESInstrumentation to monitor salt temperatures and heat tracesystem operation Conservative but preliminary cost adders included inO&M budgetNREL TES Workshop-Golden-Feb0325

Materials ConsiderationsASTM a DesignationPeak fluidtemperature,325 CBasicmaterialCarbon steel450 C500 CPipeA 106,Grade BFittingsA 234,Grade WPAFerritic steelA 335,Grade P22Ferritic steelA 335,Grade P91A 234,GradeWP22A 234,GradeWP91ValvesA 216,GradeWCBA 217,GradeWP22A 217,GradeWP91Tubes bA 192Plate cA 516,Grade 70A 213,Grade T22A 387,Grade 22A 213,Grade T91A 387,Grade 91Notes: a) American Society for Testing and Materials; b)For steam generator heat exchangers;c) For thermal storage tanks and heat exchanger shellsNREL TES Workshop-Golden-Feb0326

Lower solar field HTF Velocitieswith Molten Saltdue to higher temperature rise and salt propertiesSalt HTF in HCE2.50HTF velocity, m /s2.001.50Re 5*10 4 to 10 51.000.50Heat transfer characteristics are acceptable;VP-1 velocity3.45 m/spower is reducedpumping0.00100125150175200SF Tem perature Rise, CNREL TES Workshop-Golden-Feb0327

Therminol VP-1. Property Solar Salt Hitec Hitec XL (Calcium Nitrate Salt) LiNO. 3. mixture. Therminol VP-1 Diphenyl biphenyl . Composition, % oxide NaNO. 3. 60 7 7 KNO. 3. 40 53 45 NaNO. 2. 40 Ca(NO. 3) 2. 48 Freezing Point, C 220 142 120 120 13 Upper Temperature, C 600 535 500 550 400 Density @ 300C, kg/m. 3. 1899 1640 1992 815 Viscosity @ 300C, cp 3.26 3.16 6.37 0.2 Heat capacity @ 300C, J .File Size: 302KBPage Count: 27