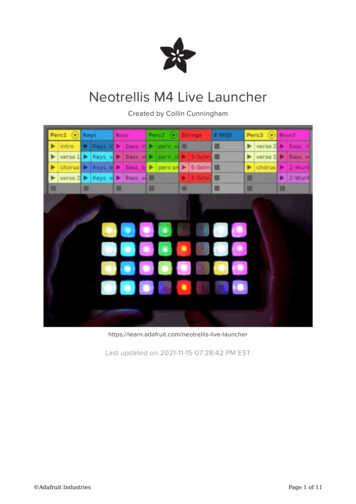

Transcription

Advanced LWRsJacopo BuongiornoAssociate Professor of Nuclear Science and Engineering22.06: Engineering of Nuclear Systems

OutlinePerformance goals for near-term advanced LWRsTechnical features of advanced LWRs:- US-EPR (Evolutionary Pressurized Reactor)- USUS-APWR-APWR (Advanced Pressurized Water Reactor)- AP1000 (Advanced Passive 1000)- ABWR (Advanced BWR))- ESBWR (Economic Simplified BWR)Summaryy of common characteristicsConclusions2

Nuclear Reactor Timeline3

Mission/Goals for Advanced LWRsBaseload generation of electricity (hydrogen is not emphasized)Improved economics. Targets:- Increased plant design life (60 years)- Shorter construction schedule (36 monthsmonths*))- Low overnight capital cost ( 1000/kWe** for NOAK plant)- Low O&M cost of electricity ( 1 /kWh)* First concrete to fuel loading (does not include site excavation and pre-service testing)** Unrealistic target set in early 2000s. Current contracts in Europe, China and US have overnight capital costs 3000/kWeImproved safety and reliability- Reduced need for operator action- Expected to beat NRC goal of CDF 10-4/yr- Redducedd llarge rellease probbabilitbility- More redundancy or passive safety4

U.SS. NRC Certifitificatition off AdAdvancedd Advanced Passive PWR1100 MWeABWRGE-HitachiAdvanced BWR1350 MWeESBWRGE-HitachiUS-EPRAREVAUS APWRUS-APWRMit bi hiMitsubishiAdvanced Passive BWR1550 MWeAdvanced PWR1600 MWeAdAdvancedd PWR1700 MWeStatusCertified,amendment underreviewCertified,Constructed inJapan/TaiwanUnder reviewUnder reviewU d reviewUnderi

U.S. Economic PressurizedReactor (US(US-EPR)EPR)b AbyAreva6

US-EPR Overview1600 MWe PWRTypical PWR operatingconditions in primarysystem, pressure,temperatures linear powertemperatures,power,etc.4 loopsHi h pressure iin SGHigherSGsresults in somewhat higherefficiency (35% net)Safety systems are activeHigh redundancy7

US EPR ParametersUS-EPRParameterDesign life,life yrsNet electric output, MWeReactor power, MWtPlant efficiency,y, %Cold/hot leg temperature, CReactor pressure, MPaTotal RCS volume, m3Number of fuel assembliesType of fuel assembliesActive length, mLiLinearpower, kW/mkW/Control rodsSteam pressure, MPaRadial reflectorSG secondary inventory, tonCurrent 4-loop PWR401100341132.2292/32515.535019317x173.6618 x174.2016 416.4897.7Yes83

US-EPR SafetyyFour identical dieseldriven trains, each100%, provideredundancy formaintenance or singlefailure criterion (N 2)Physical separationagainst internal hazards(e.g. fire)Shield building extendsairplane crash andexternal explosionprotection to twosafeguard buildings andfuel building (blue walls)9

US-EPR Safetyy (2)U.S. NRCSafety Goal1 x 10-4Current U.S.LWR Plants5 x 10-5EPRI UtilityRequirement1 x 10-54 x 10-7Core Damage Frequency Per Year10

US-EPR ContainmentInner wall pre-stressedconcrete withi h steell linerliOuter wall reinforced concreteProtection against airplanecrashProtection against externalexplosionsAnnulus sub-atmospheric andfiltered to reduce radioisotoperelease11

US-EPRUSEPR Severe Accidents MitigationIRWSTCoriumSpreading AreaEx-vessel core catcherconcept (passive)- Molten core is assumedto breach vessel- Molten core flows intospreading area and iscooled by IRWST water- Hydrogen recombinersensure no detonationwithin container12

EPR is beingg built nowOlkiluoto – September 2009Taishan – September 2009Olkiluoto 3 (Finland) - construction start 2004Flamanville 3 (France) - construction start 2007Taishan (China) – construction start 2008Flamanville – October 2009 source unknown. All rights reserved. This content is excluded from our Creative Commons license. For more information, see http://ocw.mit.edu/fairuse.

U.S. Advanced PWR (US-APWR)by Mitsubishi14

US-APWR Overview(fundamentally similar to US-EPR)1700 MWe PWRTypical PWR operating conditionsin primary system, pressure,temperatures etctemperatures,etc.Long (14 ft.) fuel assemblies withreduced power density for 24months operation4 loopsHigh efficiency turbine (70" blades)results in 35% thermal efficiencyof plantRPV with no bottom penetrationsSafety systems are active with highredundancy15

US-APWR SafetyyHP16

US-APWR Safetyy (2)( )Accumulator design with flow damper eliminates need foractive high-pressure injection systemSevere accididentts mitiitigatition basedd on core-cattcherh concepttsimilar to US-EPR17

Advanced Passive 1000(AP1000)b WbyWestinghti house-ToshibaT hib18

AP1000 Overview1100 MWe PWRTypypical PWR opperatinggconditions, pressure,temperature, flow rates,linear power, etc.RPV with no bottompenetrations2 loops, 2 SGs4 recirculation pumps(canned motor pumps, noshaft seals)Large pressurizer 50% larger thanoperating plantsAll safety-grade systemsare passive19Courtesy of Westinghouse. Used with permission.

AP1000 Passive Core Cooling SystemPRHR HX Natural circ. heat removalPassive Safety Injection Core Makeup Tanks (CMT) Accumulators Kick in at intermediate pressureIRWST Injection Full press, natural circ. injectReplaces HPCI pumpsLow press (replaces LPCI pumps)Automatic RCS DepressurizationCourtesy of Westinghouse. Used with permission.20

AP1000 Passive Containment CoolinggS yystem21Courtesy of Westinghouse. Used with permission.

AP1000 Severe Accidents MitigationCore-Concrete Interaction In-Vessel Retention (IVR) / ex-vesselcooling Means of cooling damaged coreREACTOR VESSEL Tests and analysis of IVR reviewed byU S NRCU.S.High Pressure Core Melt REACTOR VESSELSUPPORT STEELSTEAM VENTSTYPICAL 4 PLACESCOREEliminated by redundant, diverse ADSSHIELD WALLHydrogen Burn, Detonation Hydrogen vent paths from RCS keptaway from containment shell Redundant, diverse igniters4.8 mVesselINSULATIONWaterCorium meltWATER INLETSteam Explosions Ex-vessel prevented by IVR22 cmWWaterCourtesy of Westinghouse. Used with permission.22

AP1000 m/ap1000 psrs .com/ap1000 psrs om/ap1000 safety ircd.html

AP1000 Safety Margins and RiskTypical PlantAP1000 Loss Flow Margin toDNBR Limit 1 - 5% 16%o Feedline Break ( F)Subcooling Margin 0o F 140o FOperator actionsrequired in 10 minOperator actionsNOT required Small LOCA3 LOCA3"core uncoversPCT 1500oF 88" LOCANO coreuncoveryo Large LOCA PCT ( F)with uncertainty2000 - 2200o F 1600o F(1) SG Tube RuptureCore Damage FrequencyAt-PowerShutdownInternal EventsInternal FloodsInternal FiresSub-TotalsGrand-TotalsNRC Safety GoalsLarge Release FrequencyAt-PowerShutdown2.41E-07 /yr8.80E-10 /yr5.61E-08 /yr1.23E-07 /yr3.22E-09 /yr8.52E-08 /yr1.95E-08 /yr7.10E-11 /yr4.54E-09 /yr2.05E-08 /yr5.40E-10 /yr1.40E-08 /yry2.98E-07 /yr2.11E-07 /yry2.41E-08 /yry3.50E-08 /yry5.09E-075.92E-081 E-41 E-624Courtesy of Westinghouse. Used with permission.

Use of passive safety systems simplifies the plantplanSafety ValvesPumpsSafety PipeSeismic Building VolumeCableReduced Number of Components:1000 MW ReferenceSafety ValvesAP 1000Reduction2844140051%Pumps28018434%Safety Piping11.0 x 104 feet1.9 x 104 feet83%Cable9.1 mil. feet1.2 mil. feet87%Seismic Building Volume12.7 mil. ft35.6 mil. ft356%Image by MIT OpenCourseWare.25

anddRReducesdSSafety/Seismicf t /S i i BBuildingildi VVolumelLEGEND:1. CONTAINMENT/ SHIELD BUILDING62. SAFEGUARD BUILDING3. FUEL BUILDING4. AUXILIARY BUILDING5. DIESEL GENERATOR BUILDING6. ESSENTIAL SERVICE WATER/CIRCULATINGWATER PUMP HOUSE7. LIQUID RADWASTE BUILDING222 45512243EPRSafetSafet y / SeismicSei smi c StStructuresr ct res020406080100M173 7AP1000SafetySf/ Seismic StructuresSCourtesy of Westinghouse. Used with permission.26

AP1000 Construction Simplification of Systems Reduction in bulk materials and field laborMaximum Use of Modularization 300 rail-shippable equipment and piping modules50 llarge structuralt t l moddulles (assemblbleddon-s itite))- Under construction at Taishen (China) since 2008Courtesy of Westinghouse. Used with permission.- 4 P&E orders in US

Advanced BWR (ABWR) andEconomic Simplified BWR (ESBWR)b GbyGenerall ElElectric-Hitachit i Hit hi28

ABWR OverviewSteam dryerSteam nozzleSteam separatorFeedwaternozzleFuel assembliesPressure vesselVessel supportskirtControl rodguide tubesControl rod drivesRecirculation pumpCourtesy of GE Hitachi Nuclear Systems. Used with permission.1350 MWe BWRTypical BWR operatingconditiditions, pressure,temperature, linear power,etc.Internal recirculation pumps(no jet pumps) no externalloopLarge vessel with largewater inventory no largepiping no core uncoveryRedundant active safetysystemsProven technology (built andoperated for over ten yearsin Japan and Taiwan) 29

ESBWR OverviewClosure HeadSteam DryerDPV/ IC OutletMain Steam LineFlow RestrictorSteam SeparatorsRPV StabilizerRWCU/ SDCOutletFeedwater InletIC ReturnChimneyyGDCS InletChimney PartitionsSupport(sliding block)Core Top GuideFuel AssembliesGDCS EqualizingLi InletLinelCoCore PlateShroud SupportCore ShroudCRD HousingControl RodGuide TubesControl Rod Drives (CRD)In-core HousingESBWR ReactorCourtesy of GE Hitachi Nuclear Systems. Used with permission.1550 MWe BWRT i l BWR operatitingTypicalconditions, pressure,temperature, linear power,etc.etcNatural circulation reactor No reactor pumpsLarge vessel with largewater inventoryCore at lower elevationwithin vesselAll safety-grade systems arepassive30

BWR Primaryy SystemyEvolutionDresden 1KRBOyster CreekDresden 2ABWRSBWRESBWR31Courtesy of GE Hitachi Nuclear Systems. Used with permission.

ABWR & ESBWR Balance of Plant is TraditionalCourtesy of GE Hitachi Nuclear Systems. Used with permission.32

ABWR & ESBWR ParametersBWR/4-MkI(Browns Ferry 3)BWR/6-Mk III(Grand Vessel height/dia. (m)21.9/6.421.8/6.421.1/7.127.7/7.1Fuel Bundles (number)7648008721132Active Fuel Height (m)3.73.73.73.0Power density (kW/L)5054 254.25154Recirculation pumps2(large)2(large)10zeroNumber of CRDs/type185/LP193/LP205/FM269/FMSafety system pumps9918zeroSafety diesel generator233zeroCore damage freqfreq./yr/yr1E 51E-51E 61E-61E 71E-71E 71E-7Safety Bldg Vol (m3/MWe)115150160 100ParameterPower (MWt/MWe)33Courtesy of GE Hitachi Nuclear Systems. Used with permission.

ABWR SafetyySteam lineCSSCSSFeedwater lineFeedwater ndensateStorage PoolRHRRCICG DDivision 1Division 2G DDivision 2RHRDivision 1RHRDivision 3G DDivision 3RHRECCSCourtesy of GE Hitachi Nuclear Systems. Used with permission.34

ESBWR Enhanced Natural Circulation4.5ABWR LUNGMENABWR4.0Average Powerr per Bundle (MWt)BWR/6CLINTON3.5ESBWRESBWR1132 - a3.02.52.01.51.00.50.00.01.02.0N Power Flow - 1132-4500.XLS Chart1 (5)3.04.05.06.07.08.09.010.0Average Flow per Bundle (kg/s) Higher driving head Chimney/taller vessel Reduced flow restrictions Shorter core Increase downcomer areaCourtesy of GE Hitachi Nuclear Systems. Used with permission.35

ESBWR StabilityyESBWR is designed to operate with significantmargin to any instability regionsCourtesy of GE Hitachi Nuclear Systems. Used with permission.36

ESBWR Passive Safetyy37Courtesy of GE Hitachi Nuclear Systems. Used with permission.

ESBWR Passive SafetyyDecay Heat HX’sAbove DrywellAll Pipes/ValvesInside ContainmentHigh ElevationGravity Drain PoolsRaised SuppressionPool38Courtesy of GE Hitachi Nuclear Systems. Used with permission.

ESBWR Passive SystemsIsolation Condensers System (ICS) High pressure residual heat removalSafety Relief Valves (SRV) Prevent reactor overpressurization discharging steam intosuppression poolSuppression Pool Absorbs blowdown energy during LB-LOCA.Gravity Driven Cooling System (GDCS) Low pressure residual heat removal following LB-LOCA.Keepps the core covered.Passive Containment Cooling System (PCCS) Long-term heat removal from containmentNo operator action needed for 72 hours39

ESBWR Severe Accident Mitigation Containment filled with inert gasIn-vessell rettentition is complilicattedd byb CRDMpenetrations, so it is not done.Quench molten core byy delu ge from the GDCStanksIf molten material drips through vessel, there is asacrificial concrete shield (core catcher) on thecontainment floorEasy to refill PCCS pool and continue to removethe heatt fromthftheth vessell indi definitfi itellyFission Product Control Hold up and filtering40

Comparisonpof Safetyy Syystem - Passive vs. ActiveEmergencyBus LoadingProgramDG RoomVentilationSystemDiesel Generator Room 1 of 3CrankcaseVentilationGGeneratortControl andProtectionEngineGoverningControlDG LubricationOil SystemPlantServiceWaterDieselStarting AirGeneratorAir Intake& ExhaustBreakerCloses 10 sPlantService WaterBreaker Pump MotorDCPwrDG Fuel OilStorage andTransfer SystemLoadsADSLogicADSAux.AuxWaterSourceWater SourceHVACReactorComponentCooling WaterBreaker PPump MotorM tRPVQS/PLoadsCoreMRCCWHVACDG FuelOil SystemDCPwrQHVACEmergencyy BusDG CoolingWater SystemInitiationSignalEmergency CoreC li SysttemCoolingBreaker Pump MotorTypical of HPCS,LPCS, & ssive PlantConventional Active Plant41Courtesy of GE Hitachi Nuclear Systems. Used with permission.

Reduction in Systems & Buildings with Passive Systems ABWRESBWR(higher power, smaller building)42Courtesy of GE Hitachi Nuclear Systems. Used with permission.

Summary Features of Advanced LWRsReactorUS-EPRUS-APWRAP1000ABWRESBWRNeutron EU pinsLEU pinsLEU pinsLEU pinsLEU pins Use of proventechnologyPlant simplification M d l constructionModulart ti Economy of scale High thermal efficiency Passive safetygof severeMitigationaccidents CorecatcherCorecatcherIn-vesselretention -Corecatcher

Potential Issues for DepploymentyofAdvanced LWRs in the U.S. No capabilities for manufacturing heavycomponents left. Need to buy from overseas. Shortage of specialized workforce experiencedin nuclear construction ((e.g.,g , welders)). Slow licensing process FinancialFii l riiskk iin deregulatedl t d marketsk t44

MIT OpenCourseWarehttp://ocw.mit.edu22.06 Engineering of Nuclear SystemsFall 2010For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.

ESBWR GE-Hitachi Advanced Passive BWRAdvanced Passive BWR Under review 1550 MWe Under review US-EPR AREVA Advanced PWR 1600 MWe . Reactor power, MWt 3411 4500 Plant efficiency, % 32.2 35.6 Cold/hot leg temperature, C 292/325 296/329 Reactor pressure, MPa 15.5 15.5