Transcription

Crosby ShacklesSHACKLESW i t hP r o d u c tW a r n i n ga n dA p p l i c a t i o nI n f o r m a t i o n

SHACKLES"There is No Equal"TheG-209Market Leader: Yesterday Today and TomorrowShacklesDESIGNThe theoretical reserve capability of carbon shackles shouldbe as a minimum 5 to 1, and alloy shackles a minimum of 5 to1*. Known as the DESIGN FACTOR, it is usually computed bydividing the catalog ultimate load by the working load limit. Theultimate load is the average load or force at which the productfails or no longer supports the load. The working load limit isthe maximum mass or force which the product is authorizedto support in general service. The design factor is generallyexpressed as a ratio such as 5 to 1. Also important to thedesign of shackles is the selection of proper steel to supportfatigue, ductility and impact properties.CLOSED DIE FORGEDThe proper performance of premium shackles depends ongood manufacturing techniques that include proper forging andaccurate machining. Closed die forging of shackles assuresclear lettering, superior grain flo , and consistent dimensionalaccuracy. A closed die forged bow allows for an increasedcross section that, when coupled with quench and tempering,enhances strength and ductility. Closed die bow forgingscombined with close tolerance pin holes assures good fatiguelife. Close pin-to-hole tolerance has been proven to be criticalfor good fatigue life, particularly with screw pin shackles.QUENCHED AND TEMPEREDQuench and tempering assures the uniformity ofperformance and maximizes the properties of the steel. Thismeans that each shackle meets its rated strength and hasrequired ductility, toughness, impact and fatigue properties.The requirements of your job demand this reliability andconsistency. This quench and tempering process developsa tough material that reduces the risk of brittle, catastrophicfailure. The shackle bow will deform if overloading occurs,giving warning before ultimate failure.THE COMPETITIONAsk: What is the Working Load Limit and designfactor for shackles?Ask: Is deformation upon overloading a criticalconsideration in their design?Ask: Do they jeopardize other properties byhaving hardness high in order to increaseworking load or design factor?The proper application of shackles requires that thecorrect type and size of shackle be used. The shackle’sworking load limit, its size, a traceability code and themanufacturer’s name should be clearly and boldly markedin the bow. Traceability of the material chemistry andproperties is essential for total confidence in the product.Material chemistry should be independently verified prior tomanufacturing.Crosby carbon shackles have the highest design factor(6 to 1) in the industry. All of Crosby’s design factors aredocumented. Crosby purchases only special bar forgingquality steel with cleanliness and guaranteed harden ability.All material chemistry is independently verified prior tmanufacturing. The design of Crosby shackles assures thatstrength, ductility and fatigue properties are met.THE COMPETITIONAsk: Are their shackles closed die forged with closetolerance pin holes?Ask: Do their shackles have good fatigue life?Ask: Do their shackles have a fatigue life that meetsthe new world standards?Many forge bows utilize an open die forgingprocess which allows for inconsistent dimensionalaccuracy and increased pin hole clearance, thusjeopardizing the fatigue life of the shackle in actualuse.Each shackle is closed die forged. Closed die forging producesconsistent dimensions. A closed die forged bow allows for anincreased cross section that, when coupled with quench andtempering, enhances strength and ductility. Close toleranceholes and concentric pins with good surface finishes areprovided by Crosby and are proven to provide improved fatiguelife in actual use. Crosby shackles are fatigue rated as well asload rated. Close pin to hole tolerance has been proven to becritical for good fatigue life, particularly with screw pin shackles. THE COMPETITIONAsk: Are their bows and pins quenched andtempered?Ask: If not, are they willing to accept the increasedrisk of inconsistency?Ask: If not, why are they willing to accept inferiorimpact, toughness, and product deformation?Ask: Why do many manufacturers not recommendnon-heat-treated shackles for overhead lifting?Ask: Why do some recommend Quench andTempering for alloy but not carbon grades?Many normalize the shackle bows. As a result,desired properties are not achieved. A few evenprovide bows in an “as-forged” condition, resultingin the possibility of brittle failure.IDENTIFICATION ANDAPPLICATION INFORMATIONG-2130All Crosby shackle bows and pins are quenched and tempered,which enhances their performance under cold temperatures andadverse field conditions. Crosby s Quenched and Temperedcarbon shackles are recommended for all critical applicationsincluding overhead lifting. Alloy shackles are recommended whenspecific dimensional requirements dictate a size that requirehigher working load limits. Crosby’s Quenched and Temperedshackles provide the tensile strength, ductility, impact and fatigueproperties that are essential if they are to perform time after timein adverse conditions. These properties assure that the inspectioncriteria set forth by ANSI will effectively monitor the ability of theshackles to continue in service.THE COMPETITIONAsk: Do they have an active traceability systemused in manufacturing?Ask: Is the material chemistry independentlyverified?Ask: What training support is provided?Crosby forges “Crosby” or “CG”, the Working Load Limit, andthe Product Identification Code (PIC) into each bow and“Crosby” or “CG”, and the Product Identification Code (PIC)into each pin of its full line of screw pin, round pin, and bolt typeanchor and chain shackles. Seminars conducted by Crosbyprovide training on the proper use of shackles. Crosby trainingpackets, supplied free to attendees of Crosby seminars,provide training materials needed toexplain the proper use of shackles.* G-2160 Wide Body Shackles are metric rated at 5 to 1. G-2140 Shackles, 200 ton and above, are rated at 4 to 1 in short tons.74Remember: “When buying Crosby, you’re buying more than product, you’re buying Quality.”

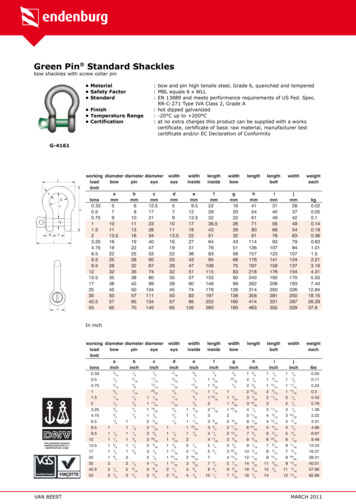

VALUE ADDED Charpy impact properties: Crosby’s Quenched and Tempered shackles have enhanced impact properties for greatertoughness at all temperatures. If requested at the time of order, Crosby can provide Charpy impact properties. Fatigue properties: Fatigue properties are available for 1/3 to 55 metric ton shackles. These Crosby shackles are fatiguerated to 20,000 cycles at 1-1/2 times the Working Load Limit. Ductility properties: Typical ductility properties are available for all sizes upon special request. Hardness levels and material tensile strengths: Typical values are available for all sizes of shackles, and actual values canbe furnished if requested at the time of order. Proof Testing: If requested at the time of order, shackles can be proof tested with certificates. Mag Certification: If requested at the time of order, shackles can be Mag inspected with certificates. Certification: Certification to world class standards is available upon special request at the time of order; American Bureau ofShipping, Lloyds Register of Shipping, Det Norske Veritas, American Petroleum Institute, RINA, Nuclear RegulatoryCommission, and several other worldwide standards. Applications: Round Pin Shackles can be used in tie down, towing, suspension or lifting applications where the load isstrictly applied in-line. Screw Pin Shackles can be used in any application where a round pin shackle is used. Inaddition, screw pin shackles can be used for applications involving side-loading circumstances. Reduced working load limitsare required for side-loading applications. Bolt-Type Shackles can be used in any application where round pin or screw pinshackles are used. In addition, they are recommended for permanent or long-term installations and where the load may slideon the shackle pin causing the pin to rotate. Material analysis: Crosby can provide certified material (mill) analysis for each production lot, traceable by the ProductIdentification Code (PIC). Crosby, through its own laboratory, verifies the analysis of each heat of steel. Crosby purchases onlyspecial bar forging quality steel with specific cleanliness requirements and guaranteed hardenability. Field inspection: Written instructions for visual, magnaflux, and dye penetrant inspection of shackles are available fromCrosby. In addition, acceptance criteria and repair procedures for shackles are available. QUIC-CHECK : Shackles incorporate two marking indicators forged into the shackle bow at 45 angles from vertical. Theseare utilized to quickly check the approximate angle of a two-legged hitch or check the angle of a single leg hitch. If the load isoff vertical or side loaded a reduction in the working load limit of the shackle is required.G-209Screw pin anchorshackles meet theperformance requirementsof Federal SpecificationRR-C-271G, Type IVA, GradeA, Class 2, except for thoseprovisions requiredof the contractor.G-210Screw pin chain shacklesmeet the performancerequirements ofFederal SpecificationRR-C-271G, Type IVB,Grade A, Class 2,except for thoseprovisions requiredof the contractor.G-213Round pin anchorshackles meet theperformancerequirements ofFederal SpecificationRR-C-271G, Type IVA,Grade A, Class 1, exceptfor those provisionsrequired of thecontractor.G-215Round pin chain shacklesmeet the performancerequirements ofFederal SpecificationRR-C-271G, Type IVB,Grade A, Class 1, exceptfor those provisionsrequired of thecontractor.G-2130Bolt-type anchorshackles meet theperformancerequirements ofFederal SpecificationRR-C-271G, Type IVA,Grade A, Class 3,except for those provisionsrequired of the contractor.G-2150Bolt-type chainshackles meet theperformance requirementsof Federal SpecificationRR-C-271G, Type IVB,Grade A, Class 3,except for thoseprovisions requiredof the contractor.

SHACKLESCrosby Round Pin Shackles Capacities 1/2 through 35 metric tons.Forged - Quenched and Tempered, with alloy pins.Working Load Limit permanently shown on every shackle.Hot Dip galvanized or Self Colored.Sizes 3/8 inch and below are mechanically galvanized.Fatigue rated.Shackles 25t and larger are RFID EQUIPPED.Shackles can be furnished proof tested with certificates to des gnated standards,such as ABS, DNV, Lloyds, or other certification. Charges for proof testing andcertification available when requested at the time of orde . Shackles are Quenched and Tempered and can meet DNV impact requirementsof 42 Joules (31 ft Ibf) at -20 C (-4 F). Look for the Red Pin . . . the mark of genuine Crosby quality.G-213 / S-213G-213 Round pin anchorshackles meet the performancerequirements of FederalSpecification RR-C-271G, TypeIVA, Grade A, Class 1, exceptfor those provisions required ofthe contractor. For additionalinformation, see page 452.G-215 / S-215G-215 Round pin chain shacklesmeet the performance requirementsof Federal Specification RR-C-271GType IVB, Grade A, Class 1, exceptfor those provisions required of thecontractor. For additional information,see page 476.SEE APPLICATION INFORMATION On Page 92 of the General CatalogPara Español: www.thecrosbygroup.comG-213 / S-213 Round Pin Anchor 4.81Tolerance 06.06.06.06.06.06.06.13.13.13.13* NOTE: Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. DO NOTSIDE LOAD ROUND PIN SHACKLES.G-215 / S-215 Round Pin Chain .696.301.819.002.0312.00 2.2516.15 2.3829.96 2.8843.25 rance .06.06.06.06.13.13.13.13.13* NOTE: Maximum Proof Load is 2 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load Limit. DO NOT SIDELOAD ROUND PIN SHACKLES.76Copyright 2019 The Crosby Group LLC All Rights Rese

Crosby shackles are fatigue rated as well as load rated. Close pin to hole tolerance has been proven to be critical for good fatigue life, particularly with screw pin shackles. All Crosby shackle bows and pins are quenched and tempered, which enhances their performance under cold temperatures and adverse field conditions. Crosbys Quenched and Tempered carbon shackles are recommended for all .File Size: 5MBPage Count: 22