Transcription

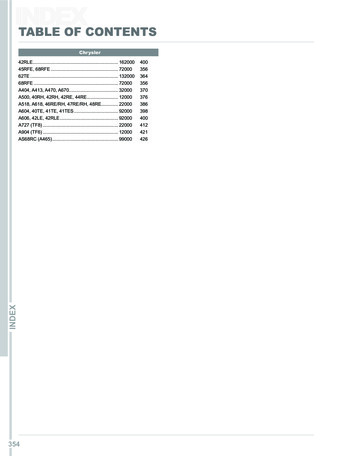

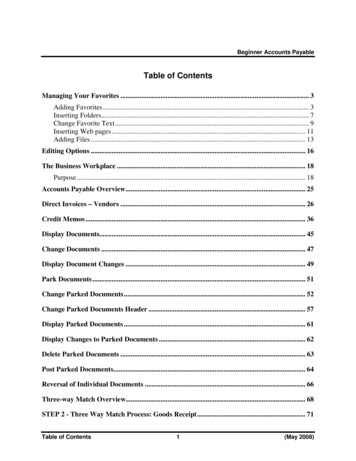

Table of ContentsGLOSSARY (Important terms and definitions). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2QUALITY CONTINUUM (What it takes to be Crosby or Equal, Product Bulletins). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11WIRE ROPE END TERMINATIONS (Clips, Sockets, Swage Fittings, Wirelock ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31SHACKLES (Anchor, Chain, Bolt-Type, Screw Pin, Round Pin, Wide Body). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73SLING SAVER FITTINGS (Shackles, Hooks & Accessories specifically for Web & Round Slings). . . . . . . . . . . . . . . . . . . . . . . . 95HOOKS & SWIVELS (Hooks, Latches, Swivels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109RIGGING ACCESSORIES (Thimbles, Links, Rings, Eyebolts, Turnbuckles). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155CHAIN & ACCESSORIES (Chain, Grade 80 and 100 Fittings, Alloy Fittings, Loadbinders) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217SHEAVES (McKissick and Western). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277MCKISSICK BLOCKS (Construction Blocks, Crane Blocks, Overhaul Balls, Snatch Blocks, Oilfield Blocks). . . . . . . . . . . . . . . 305WESTERN AND MARINE BLOCKS (Wood Blocks, Steel Blocks, Snatch Blocks, Construction Blocks). . . . . . . . . . . . . . . . . . 393CROSBYIP PLATE CLAMPS / CLAMP CO CLAMPS (Vertical, Horizontal, Beam, Drum and Special Lifting Clamps). . . . . . . 409CROSBY TRAWLEX AND ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 437SPECIAL PRODUCTS (Special Engineered Product Forms). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447RIGGING INFORMATION (Basic sling angle information, Inspection and Replacement Guidelines per ASME B30.9) . . . . . . . 467ALPHABETICAL INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477NUMERICAL INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480 CORPORATE OFFICES2801 Dawson Rd., Tulsa, OK 74110 P: 918.834.4611 F: 918.832.09402600 North Central Expressway, Suite100, Richardson, TX 75080thecrosbygroup.comUnited States FacilitiesCrosby-Tulsa2857 Dawson Rd.Tulsa, OK 74110-5042Crosby-Dallas2101 Exchange Dr.Arlington, TX 76011-7823Crosby-Longview2414 Crosby WayLongview, TX 75602Crosby-Little Rock2511 W. Main StreetJacksonville, AR 72076-4213Canada FacilityCrosby-Mississauga3660 Odyssey Drive, #4Mississauga, Ontario,Canada L5M 7N4P: (877) 462-7672F: (877) 260-5106Europe FacilitiesCrosby-Heist-op-den-BergIndustriepark Zone b N 262220 Heist-op-den-BergP: ( 32) (0)15 75 71 25F: ( 32) (0)15 75 37 64iiCrosby-Cergy21, rue du Petit AlbiParc d’Affaires Silic95800 Cergy - St. ChristopheP: ( 33) (0)1 34 201 180F: ( 33) (0)1 34 201 188Crosby-EdeCelsiusstraat 51P.O. Box 5186710 BM EdeP: ( 31) (0)318 690 999F: ( 31) (0)318 690 933Crosby-West MidlandsStation StreetCradley HeathWest Midlands B64 6AJP: ( 44) (0)1226 290 516F: ( 44) (0)1226 240 118

QualityContinuumCrosby Group products generally are intended for tension or pull.Side loading must be avoided, as it exerts additional force or loadingwhich the product is not designed to accommodate.Responsibility for the use and application of the products restswith the user. The Crosby Group disseminates products warningsand end user application information through various channels. Inaddition, Crosby provides formal product training seminars and ourengineering personnel are readily available to answer your technicalquestions. For more information read the Crosby General Catalog,refer to Crosby’s website at www.thecrosbygroup.com, or contactyour Crosby distributor or Crosby direct at 918-834-4611.Welding Crosby load support parts or products can be hazardous.Knowledge of materials, heat treatment, and welding proceduresare necessary for proper welding. Crosby Group should beconsulted for information.Load Limit ratings indicate the greatest force or load a product cancarry under usual environmental conditions. Shock loading andextraordinary conditions must be taken into account when selectingproducts for use in a system.In general, the products displayed in Crosby Group literature areused as parts of a system being employed to accomplish a task.Therefore, we can only recommend within the Working Load Limits,or other stated limitations, the use of products for this purpose.The Working Load Limit, or Design Factor, or Efficiency Rating ofeach Crosby product may be affected by wear, misuse, overloading,corrosion, deformation, intentional alteration, and other useconditions. Regular inspection must be conducted to determinewhether use can be continued at the catalog assigned WLL, areduced WLL, or whether the product must be withdrawn from service.Sling SaverFittingsThe recommended Proof Load on all items in this catalog is 2 timesthe Working Load Limit unless otherwise shown.Hooks &SwivelsProducts that Crosby intends for swaging are identified in thiscatalog. For proper swaging machine training, operations and dieselection, refer to specific product section in this manual. To developother product for swaging requires knowledge of materials, heattreatment, product design, die design and performance of the finalproduct.Use only new genuine Crosby parts as replacements whenservicing or repairing Crosby products.RiggingAccessoriesRatings shown in Crosby Group literature are applicable only to newor in "as-new” condition products.The Working Load Limit of a sling must not exceed the lowestWorking Load Limit of the components in the system.Crosby products are to be considered as sparking, unlessotherwise noted.Product Label Replacement - In accordance with ANSI Z535.4,“Product Safety Labels” should be periodically inspected andcleaned. “Product Safety Labels” should be replaced when they areno longer legible. Current Crosby warning and application labels, forapplicable products, are available from The Crosby Group LLC.Chain &AccessoriesThere are numerous government and industry standards thatcover products made by Crosby. This catalog makes no attempt toreference all of them. We do reference the standards that are mostfrequently asked about.The assigned Ultimate Load Rating of Crosby Group products forthe reeving of wire, manila, or synthetic rope is based upon design;the catalog ultimate strength for the rope parts, when totaled, mayexceed the assigned Ultimate Load Rating.Two decimal and fractional dimensions shown in catalog areintended as nominal dimensions only. If three decimal dimensionsare shown, contact Crosby for tolerance information.Specific warning and application instructions are included in this catalog. The instructions canbe found at the end of each product section. The symbol shown to the right can be found on thepage for products that have application instructions included in this catalog. The page numbersthat the specific product information can be found are shown in the box for easy reference.McKissickSheavesFailure of the product can occur due to misapplication, abuse,or improper maintenance. Product failure could allow the load tobecome out of control, resulting in possible property damage,personal injury or death.ShacklesAll products manufactured by The Crosby Group LLC, are sold withthe express understanding that the purchaser is thoroughly familiarwith the safe and proper use and application of the product.UNDERSTANDING THE CROSBYGROUP PRODUCT WARNINGSOn Page 27Para Español: www.thecrosbygroup.comMcKissickBlocksGENERAL CAUTIONS AND WARNINGSWire RopeEnd FittingsGeneral InformationLOW TEMPERATURE SERVICE Crosby forged and cast steel products can be used in general service conditions down to temperatures of -40 F (-40 C).Western &Marine Blocks McKissick blocks can be used in general service conditions down to temperatures of -4 F (-20 C). For usage of the products above at temperatures 0 F (-18 C) and colder, good rigging practice requires special attention in thefollowing areas:1. Lifting should be performed at a steady rate. Shock loading should be avoided.Crosby LiftingClamps2. Equipment containing bearings should have increased inspection and maintenance schedule, and may require special lubrication.3. All lifting equipment should be given a thorough visual inspection before each lift.4. Remove nicks, gouges, or cracks by grinding (5% maximum material removal).5. Do not use fittings that have been welded or modified after leaving the factory.TrawlexProducts6. If determined to be necessary by the user, lifting equipment should undergo periodic inspection by dye penetrant or magnetic particlesurface inspection.For operation at temperatures below -40 F (-40 C), consider “Cold Tuff” products or contact Crosby Engineering.ELEVATED TEMPERATURE SERVICECrosby forged and cast steel products can be used in general service conditions up to temperatures of 400 F (204 C). The followingshould be considered when operating up to temperatures of 400 F (204 C).SpecialProducts1. Products that contain non-ferrous materials, and lubricants, plastics, etc. may be adversely affected by high temperatures, andtypically should not exceed 200 F (93 C).2. Galvanized, plated or painted fittings may suffer some or total degradation of the surface finish.For other operating temperatures or products, contact Crosby Engineering.Copyright 2019 The Crosby Group LLC All Rights Reserved1RiggingInfo3. Extended exposure to elevated temperatures can cause severe surface scaling and significant permanent reduction of properties.

GlossaryDEFINITIONSSTATIC LOAD - The load resulting from a constant applied force or load.WORKING LOAD LIMIT - The maximum mass or force which the product is authorized to support in general service when the pull is appliedin-line, unless noted otherwise, with respect to the centerline of the product. This term is used interchangeably with the following terms: WLL, RatedLoad Value, Resultant Working Load.WORKING LOAD - The maximum mass or force which the product is authorized to support in a particular service.PROOF LOAD - The average force applied in the performance of a proof test; the average force to which a product may be subjected beforedeformation occurs.PROOF TEST - A test applied to a product solely to determine injurious material or manufacturing defects.ULTIMATE LOAD - The average load or force at which the product fails or no longer supports the load. Interchangeable with Ultimate Strength.SHOCK LOAD - A force that results from the rapid application of a force (such as impacting or jerking) or rapid movement of a static load. A shockload significantly adds to the static loadDESIGN FACTOR - An industry term denoting a product’s theoretical reserve capability; usually computed by dividing the catalog ultimate load bythe Working Load Limit. Generally expressed as a ratio, e.g., 5:1.COMMERCIAL SURFACE QUALITY - The surface condition of the products shown in this catalog. The surface condition associated with thenormal methods of production of raw material and machined surfaces. More refined surface qualities are considered as specialFATIGUE RATED - Tested to a minimum standard of 20,000 cycles at 1.5 times the Working Load Limit. Will meet the requirements of theEuronorm standards for fatigue.ADJUSTED WORKING LOAD LIMIT - The reduced maximum mass or force which the product is authorized to support for specificnon-standard loading applications.Ton (T) - North American unit of measure, equals 2,000 pounds. Also referred to as a short ton. Abbreviated by capital T.Tonne (t) - Metric unit of measure, equals 1,000 kg. Abbreviated by lower case t.LIMITED WARRANTY AND LIMITATIONS OF LIABILITYPurchaser and Crosby expressly agree that Crosby’s warranty with respect to sale of its products is LIMITED solely to Crosby’s choice of repair,replacement or refund of the purchase price of any product or part thereof determined by Crosby to be defective within the first 12 months followingthe transfer of title of the product from Crosby to the purchaser. Installation or operation of the product in any manner other than as recommendedby Crosby, shall void the warranty. No warranty is made for components and accessories made by others when such items are warranted bytheir respective manufacturer. Purchaser and Crosby expressly agree that upon termination of the aforementioned 12-month period, thepurchased product carries no warranty whatsoever. Purchaser and Crosby expressly agree that the remedies provided in this section are thepurchaser’s exclusive remedies in connection with the purchase or use of the product.Neither Purchaser, user nor any third party shall be entitled to recove

addition, Crosby provides formal product training seminars and our engineering personnel are readily available to answer your technical questions. For more information read the Crosby General Catalog, refer to Crosby’s website at www.thecrosbygroup.com, or contact your Crosby distributor or Crosby direct at 918-834-4611.