Transcription

PRODUCT/PROCESSCHANGE NOTIFICATIONPCN AMS-APD/12/7571Dated 03 Dec 2012Wafer dimension change from 5’’ to 6’’ for CMOS metalgate technology in ST Singapore1/20

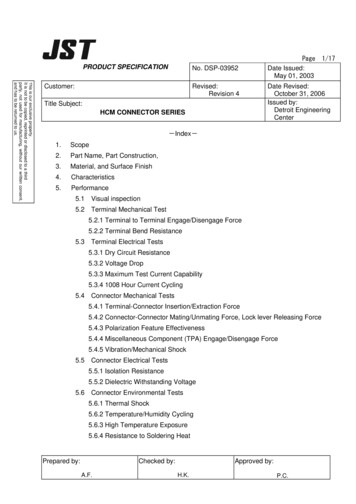

PCN AMS-APD/12/7571 - Dated 03 Dec 2012Table 1. Change Implementation ScheduleForecasted implementation date forchange31-Jan-2013Forecasted availability date of samplesfor customer30-Nov-2012Forecasted date for STMicroelectronicschange Qualification Plan results availabilityEstimated date of changed product firstshipment26-Nov-201204-Mar-2013Table 2. Change IdentificationProduct Identification(Product Family/Commercial Product)See attachedType of changeProduct marking changeReason for changeTo rationalize wafer manufacturing processes.Description of the changeProgressing on the activities related to CMOS metal gatemanufacturing processes, ST is glad to announce availability of 6inches wafer production line, for Standard & HiRel products of AnalogMems & Sensors group. Please note that samples of test vehicles areavailable upon request and other samples from mid-January uponrequest. You can enter a non-standard samples order in the systemwith in comment "PCN#7571 qualification". Then send the SO# toAngelique DUCHENE for samples availability management.Change Product IdentificationDate code & lot numberManufacturing Location(s) 2/20

PCN AMS-APD/12/7571 - Dated 03 Dec 2012Table 3. List of AttachmentsCustomer Part numbers listQualification Plan resultsCustomer Acknowledgement of ReceiptPCN AMS-APD/12/7571Please sign and return to STMicroelectronics Sales OfficeDated 03 Dec 2012Qualification Plan DeniedName:Qualification Plan ApprovedTitle:Company:Change DeniedDate:Change ApprovedSignature:Remark. 3/20

PCN AMS-APD/12/7571 - Dated 03 Dec 2012DOCUMENT APPROVAL NameFunctionGrillo, LionelMarketing ManagerDe marco, AlbertoProduct ManagerBugnard, Jean-MarcQ.A. Manager4/20

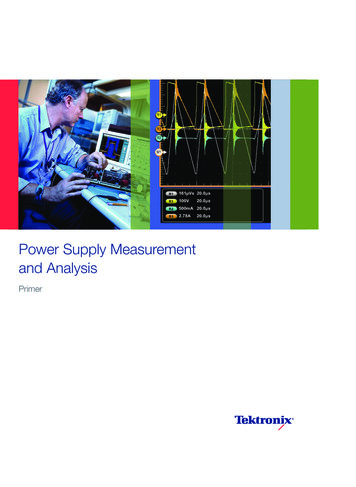

08-Nov-2012Report ID QFCMOS61PRODUCT/PROCESSCHANGE NOTIFICATIONPCN AMS-APD/12/7571Analog, MEMS and Sensor GroupWafer dimension change from 5 inches to 6 inches for CMOS metal gatetechnology in ST Singapore5 inches6 inchesCMOS metal gatePRODUCT/PROCESSPage 1/15

08-Nov-2012Report ID QFCMOS61WHAT:Progressing on the activities related to CMOS metal gate manufacturing processes, ST is glad to announceavailability of 6 inches wafer production line, for AMS products.Modified process6 inches CMOS MGCommentMaterialCurrent process5 inches CMOS MGdiffusion locationST Ang Mo Kio (Singapore) ST AMJ9ST Ang Mo Kio (Singapore) ST AMJ9No changeWafer dimension5 inches6 inchesOCR (Optical character recognition)NOYESMetallizationAlSiAlSiLaser marking onwafer, which allowbetter traceabilityNo changePassivationPvapoxPvapoxNo changeEWSST SingaporeST SingaporeNo changeFor the complete list of part numbers affected by the change, please refer to the attached Product list.Samples of test vehicles are available upon request and other samples from mid-January upon request.WHY:To upgrade manufacturing line from 5 inches to 6 inches in order to improve customer service.HOW:The change that covers AMS (Analog, Mems & Sensors) products is qualified based on qualification plan hereattached.Here below you’ll find the details of qualification plan.Qualification program and results:The qualification program consists mainly of comparative electrical characterization and reliability tests. Pleaserefer to Reliability evaluation plan for all the details.WHEN:Production in ST Singapore in 6 inches for AMS is forecasted in January 2013 for CMOS metal gate technology.PRODUCT/PROCESSPage 2/15

08-Nov-2012Report ID QFCMOS61Marking and traceability:Unless otherwise stated by customer specific requirement, the traceability of the parts assembled with the newmaterial set will be ensured by datecode and lot number.The changes here reported will not affect the electrical, dimensional and thermal parameters keeping unchangedall information reported on the relevant datasheets.There is as well no change in the packing process or in the standard delivery quantities.Lack of acknowledgement of the PCN within 30 days will constitute acceptance of the change. After acknowledgement, lack of additional response within the 90 day period will constitute acceptance of the change (JedecStandard No. 46-C).In any case, first shipments may start earlier with customer’s written agreement.PRODUCT/PROCESSPage 3/15

08-Nov-2012Report ID QFCMOS61Change Qualification PlanCMOS metal gate transfer 5 to 6 inchesTest vehicleP51B, P541, P10BProduct Lines:LocationsWafer Diffusion Plants:ST SingaporeProduct Families:LogicEWS Plants:ST M013TRAssembly Plants:ST BouskouraT&F Plants:ST BouskouraProduct Groups:AMSReliability Lab.:ST CataniaProduct Divisions:AnalogProduct BUs:Hirel&standard products.Packages:SO14/SO16Silicon Process techn.:CMOS metal gateDOCUMENT d byJM BugnardCommentFirst issueReference document :REL-6043-304W-12REL-6043-332W-12Note: This report is a summary of the qualification trials performed in good faith by STMicroelectronics in order to evaluate the potential qualification risks during theproduct life using a set of defined test methods.This report does not imply for STMicroelectronics expressly or implicitly any contractual obligations other than as set forth in STMicroelectronics general terms andconditions of Sale. This report and its contents shall not be disclosed to a third party without previous written agreement from STMicroelectronics.PRODUCT/PROCESSPage 4/15

08-Nov-2012Report ID QFCMOS61TABLE OF CONTENTS1 APPLICABLE AND REFERENCE DOCUMENTS . 52 GLOSSARY . 53 QUALIFICATION EVALUATION OVERVIEW . 53.1 OBJECTIVES . 53.2 CONCLUSION . 54 CHANGE CHARACTERISTICS . 64.1 CHANGE DESCRIPTION . 64.2 CHANGE DETAILS . 64.3 TEST VEHICLES DESCRIPTION . 65 TESTS RESULTS SUMMARY . 75.1 TEST VEHICLES . 75.2 TEST PLAN AND RESULTS SUMMARY . 76 ANNEXES. 86.1 COMPARISON DATA RESULTS . 86.1.1Electrical Data . 8TESTS DESCRIPTION .13PRODUCT/PROCESSPage 5/15

1 APPLICABLE AND REFERENCE DOCUMENTSDocument rt descriptionStress test qualification for automotive grade integrated circuitsStress test qualification for automotive grade discrete semiconductorsGuidelines for part average testingGuidelines for Characterizing the Electrical Performance of IC ProductsStress-Test-Driven Qualification of Integrated Circuits2 GLOSSARYDUTPCBSSDevice Under TestPrinted Circuit BoardSample Size3 QUALIFICATION EVALUATION OVERVIEW3.1ObjectivesThrough this qualification plan, the CMOS metal gate technology transfer is evaluated, to be diffusedat ST Singapore in 6 inches instead of 5 inches.3.2ConclusionQualification Plan requirements must be fulfilled without exception. It is stressed that reliability testsmust show that the devices behave correctly against environmental tests (no failure). Moreover, thestability of electrical parameters during the accelerated tests must demonstrate the ruggedness of theproducts and safe operation, which is consequently expected during their lifetime.Octobre 20125

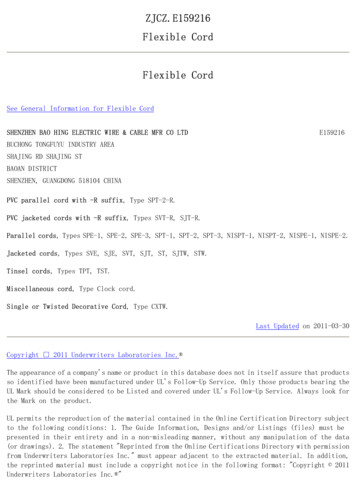

PCN AMS-APD/12/75714 CHANGE CHARACTERISTICS4.1Change descriptionTransfer of CMOS metal gate technology from 5 inches to 6 inches4.2Change detailsCurrent process5 inches CMOS MGModified process6 inches CMOS MGCommentMaterialdiffusion locationST Ang Mo Kio (Singapore) AMJ9ST Ang Mo Kio (Singapore) AMJ9No changeWafer dimension5 inches6 inchesOCR (Optical er marking on wafer,which allow better traceabilityNo changePassivationPvapoxPvapoxNo changeEWSST SingaporeST SingaporeNo change4.3Test vehicles 4010YM013TRST SingaporeST SingaporeST SingaporeCMOS Metal gateCMOSMGLapped silicon1480x1780AlSiPvapoxCMOS Metal gateCMOSMGLapped silicon1608 *1764AlSiPvapoxCMOS Metal gateCMOSMGLapped silicon1294x1088AlSiPvapoxST SingaporeST SingaporeST SingaporeASL1000TP51BYW 2CTS600C4541E2 00ASL1000TP10BYW 1ST BouskouraSO16Sumitomo G700KCopperEpoxy glueAbklestick 8601-S25Thermosonic ball bondingST BouskouraSO14Sumitomo G630AYCopperEpoxy glueAbklestick 8601-S25Thermosonic ballbondingCopper 1 milST BouskouraSO16Sumitomo G700KCopperEpoxy glueAbklestick 8601-S25Thermosonic ball bondingCopper 1 milWafer/Die fab. informationWafer fab manufacturing locationTechnologyProcess familyDie finishing back sideDie sizeBond pad metallization layersPassivation typeWafer Testing (EWS) informationElectrical testing manufacturing locationTesterTest programAssembly informationAssembly sitePackage descriptionMolding compoundFrame materialDie attach processDie attach materialWire bonding processWires bonding materials/diametersLead finishing processLead finishing/bump soldermaterialFinal testing informationTesting locationTesterCopper 1 milPreplated frameNiPdAgAuST BouskouraASL1KElectroplatingSnST BouskouraASL1K Preplated frameNiPdAgAuST BouskouraASL1K6

PCN AMS-APD/12/75715 TESTS RESULTS SUMMARY5.1Test 0YM013TR35.2Process/ eCommentsP51BP541P10BTest plan and results summaryTestPCDie Oriented TestsHTBNHigh Temp. BiasHTSLHigh Temp. Stor- Nage LifeELFREarly Life Failure NRatePCPreconditioningACAuto Clave (Pres- Ysure Pot)TCTemperature Cy- YclingTHBTemperature Hu- Ymidity BiasOther TestsESDElectro Static Discharge-Std ref.ConditionsSSStepsFailure/SSLot 1 Lot 2 Lot 3JESD22A-108Tj 125 C, BIAS77168H500H0/770/77JESD22A-103Ta 150 C45168H500 H0/450/45160048H0/800AEC Q100 0080/77(1)(1)0/800(1)JESD22A-113Drying 24 H @ 125 CStore 168 H @ Ta 85 C Rh 85%Oven Reflow @ Tpeak 260 C 3times231FinalPASS(1)JESD22A-102Pa 2Atm / Ta 121 C77168 H0/77(1)JESD22A-104Ta -65 C to 150 C77100cy200cy0/770/77(1)JESD22A-101Ta 85 C, RH 85%, BIAS77168H500 H0/770/77(1)HBMCDM1KV750VMM150V3 (2kV)33(200V)AEC Q101001, 002 and005Note33(1)(1)3(1)(1) Electrical characterization only 7

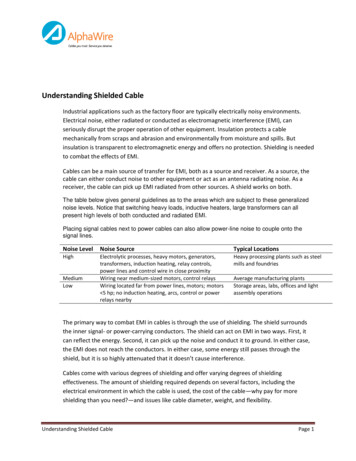

PCN AMS-APD/12/75716 ANNEXES6.1Comparison Data Results6.1.1 Electrical DataTest vehicle 1: HCF4051YM013TRResultsParametertest parameterIL (Quiescent Device current) @ Vdd 10VIL (Quiescent Device current) @ Vdd 10VIL (Quiescent Device current) @ Vdd 10VIL (Quiescent Device current) @ Vdd 10VIL (Quiescent Device current) @ Vdd 20VIL (Quiescent Device current) @ Vdd 20V

Change Implementation Schedule Forecasted implementation date for 31-Jan-2013 change Forecasted availability date of samples 30-Nov-2012 for customer Forecasted date for STMicroelectronics change Qualification Plan results availability 26-Nov-2012 Estimated date of changed product first 04-Mar-2013 shipment Table 2. Change Identification Product Identification See attached (Product Family .