Transcription

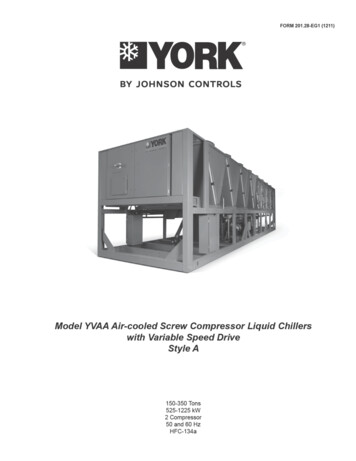

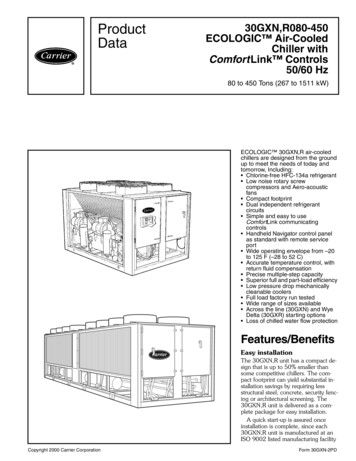

ProductData30GXN,R080-450ECOLOGIC Air-CooledChiller withComfortLink Controls50/60 Hz80 to 450 Tons (267 to 1511 kW)ECOLOGIC 30GXN,R air-cooledchillers are designed from the groundup to meet the needs of today andtomorrow, Including: Chlorine-free HFC-134a refrigerant Low noise rotary screwcompressors and Aero-acousticfans Compact footprint Dual independent refrigerantcircuits Simple and easy to useComfortLink communicatingcontrols Handheld Navigator control panelas standard with remote serviceport Wide operating envelope from –20to 125 F (–28 to 52 C) Accurate temperature control, withreturn fluid compensation Precise multiple-step capacity Superior full and part-load efficiency Low pressure drop mechanicallycleanable coolers Full load factory run tested Wide range of sizes available Across the line (30GXN) and WyeDelta (30GXR) starting options Loss of chilled water flow protectionFeatures/BenefitsEasy installationThe 30GXN,R unit has a compact design that is up to 50% smaller thansome competitive chillers. The compact footprint can yield substantial installation savings by requiring lessstructural steel, concrete, security fencing or architectural screening. The30GXN,R unit is delivered as a complete package for easy installation.A quick start-up is assured onceinstallation is complete, since each30GXN,R unit is manufactured at anISO 9002 listed manufacturing facilityCopyright 2000 Carrier CorporationForm 30GXN-2PD

to ensure quality. In addition, all unitsare factory run tested under full load toprovide reliable start-up.Easy to live withThe 30GXN,R units have a quiet, lowvibration design featuring rotary screwcompression and “aero-acoustic” fansthat reduce sound levels and improvesound quality. Lower sound levels helpavoid the need for costly sound barriersthat may be needed with other screwcompressor chillers. The 30GXN,Rcontrols are fully automatic. Theleaving-fluid temperature is directlycontrolled, and the entering-fluidtemperature is continuously monitoredto detect load and flow changes.This combination (an exclusiveComfortLink controls advantage)provides the most precise temperaturecontrol available. In addition, the30GXN,R units can handle both quickand slow-loading applications. The30GXN,R units use chlorine-freeHFC-134a refrigerant to help protectthe Earth’s ozone layer and your investment. From a service standpoint,the 30GXN,R units offer the followingfeatures: Use of HFC-134a refrigerant, a single compound refrigerant that iseasy to handle, readily available, andnot subject to phase out Mechanically cleanable cooler Twin screw compressors require little routine service or maintenance Easy viewing of suction and discharge pressures and temperaturesusing either standard or accessorydisplay moduleRotary screw compressionCarrier chillers utilize the CarrierCarlyle 06N Geared Twin screw compressor. Built in a state-of-the-art facilityin Syracuse, New York (U.S.A.), thesethird generation rotary-screw compressors are designed, tested, and built to thehigh standards that are expected fromthe world leader in comfort cooling.Since operating pressures withHFC-134a are about 30% lower thanconventional systems using HCFC-22,internal rotor blowby is reduced, thereby increasing compression efficiencyand reducing chiller plant size. And,since the Carlyle 06N compressor isliquid cooled, it has a low internal pressure drop that makes it ideally suitedfor use with HFC-134a. All 06N2compressors used in 30GXN,R chillersare equipped with the advancedComfortLink Compressor ProtectionModule (CPM). The CPM protectscompressors from phase-loss, reverserotation, over or under current conditions and ground current failures thatcan lead to motor burnout, systemcontamination and costly systemclean-outs.ComfortLink controlComfortLink is your link to a world ofsimple and easy to use air-cooled chillers that offer outstanding performanceand value. The 30GXN,R liquid chillersemploy more than the latest advancedmicroprocessor controls, they utilize anexpandable platform that grows asyour needs change. From stand-aloneoperation to remotely monitoredand operated multi-chiller plants,ComfortLink controls can keep youplugged in.ComfortLink controls are fully communicating, and are cable ready forconnection to a Carrier Comfort Network (CCN). Occupancy scheduling,temperature and pressure readouts,and the ComfortLink handheld Navigator clear language display compliment the standard features, linking youto a world of carefree comfort. The30GXN,R chillers are built on the legendary performance of the Carriermodel 30G Flotronic chiller andshare many of the same time-provenfeatures and technologies providingeasy operation, quick installation andstart-ups that save you money!Superior temperature controlequals potential for greaterproductivityWhether in the classroom, on theproduction floor, or in the office,ComfortLink controls can help you toadapt to changing weather and business conditions. Accurate temperaturecontrol provided by the CarrierComfortLink system helps to maintainhigher levels of indoor air quality, thermal comfort, and productive space.While many air-cooled chillers useonly leaving fluid temperature control,the 30GXN,R chillers utilize leavingfluid temperature control with astandard entering fluid temperaturecompensation. This Carrier exclusiveprovides smart control and intelligentmachine capacity staging. Unlike manychillers, Carrier model 30GXN,Rchillers do not require constant fluidflow. The ability to operate with variable flow also allows building owners torealize even greater overall system energy savings in the chilled water pumping system, and not just at the chiller.Energy management madeeasyWhile 30GXN,R chillers have manystandard features such as network communications capability and temperaturereset based on return fluid temperature, they can also expand as needschange. Supply temperature resetbased on outside air or space temperature is as easy as adding a thermistor.The Energy Management option canallow you to take advantage of changing utility rate structures with easy touse load shedding, demand limiting andtemperature reset capabilities. Resettriggered via 4 to 20 mA signal makesintegrating from an existing buildingmanagement system simple.The 30GXN,R comes standard withthe ComfortLink Navigator display,available with optional remote serviceconnection port, and GFCI convenience outlet (60 Hz only). TheNavigator displays information in aclear language format. The 4-line20-character display can be pluggedinto the unit at either the control panelor at the remote service port. Thisallows the service technician to operatethe unit from where the maintenanceor service work is being performed,minimizing downtime and ensuring thesystem is ready for operation in theshortest amount of time.Features Simple and easy to use ComfortLinkcommunicating controls. Wide operating envelope from –20to 125 F (28 to 52 C). Accurate temperature control withreturn fluid compensation. Built-in dual chiller control, resetfrom return. Superior full and part-loadefficiency. Precise multiple-step capacity. Low noise operation. Dual independent refrigerantcircuits. Full load factory run tested. Wide range of sizes available fromstock. Compact size.

Table of contentsPageFeatures/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-14Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-36Detail Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-30Mounting Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31-36Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37ARI Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39-51Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52-58Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59Typical Control Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61-65Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66,67Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68-713

Features/Benefits (cont)NAVIGATOR DISPLAY MODULEComNAL e a viMOfortVIGLinATOR ng Wa te r4 4 . 0 Te m p era tu FENVIRONMENTAL LEADERSHIPkreDEAl arRunStatusService TestTemperaturesPressuresSetpointsInputsm ESCAlarmENTERHFC-134aLOW-NOISE AERO-ACOUSTIC FAN30GXN,R QUIET OPERATIONSOUND POWER dBA, ARI-370114- COMPETITIVE CHILLER- CARRIER 30GXN,R- 30GXN,R w/SOUND ESIGN1041021009896945075100 125 150 175 200 225 250 275 300 325 350TONSREMOTE SERVICE PORT OPTION/ACCESSORYNEW SMALLER FOOTPRINTNEW 30GXN,R4PREVIOUS MODEL

Model number nomenclature30GXN125M30GX – ECOLOGIC Air Cooled Chillerwith ComfortLink ControlsCompressor Start OptionN – Across the Line StartR – Wye-Delta StartNominal Sizes (60 Hz Only)080 125 174 264 350090 135 204 281106 150 225 301114 160 249 32560 Hz Duplex Sizes370390415450Nominal Sizes (50 Hz Only)080 125 175 265 350090 135 205 281106 150 225 301115 160 250 32550 Hz Duplex Sizes220 345240 365275 395300 410320 440Cooler Head Option– – Standard Cooler HeadM – Minus One PassP – Plus One PassA – Standard Cooler HeaterHead Duplex “A” ModuleB – Standard Cooler HeaterHead Duplex “B” ModuleElectric Service Rating & Control Options125 F Electric Service Rating (Available on all sizes):A – Navigator (Standard)F – Navigator and Energy Management ModuleT – “Service Option” Includes Navigator, EnergyManagement Module, Service Port and GFI ConvenienceOutletV – “Service Option” Includes Navigator, EnergyManagement Module and Service Port (50 Hz and380-3-60 Only)115 F Electric Service Rating (Sizes 080-125, 220, 240 Only):– – Navigator (Standard)E – Navigator and Energy Management ModuleS – “Service Option” Includes Navigator, EnergyManagement Module, Service Port and GFI ConvenienceOutletU – “Service Option” Includes Navigator, EnergyManagement Module and Service Port (50 Hz and380-3-60 Only)S–641AAFactory Installed Options (FIOP)Packaging1 – Standard Domestic (Coil Cover)2 – Coil Cover and Bottom Skid3 – Standard Export with Coil Cover, Top and Bottom Skid& Shipping Bag4 – Full Export Crate5 – Option #1 above with Factory Installed Security Grilles6 – Option #2 above with Factory Installed Security Grilles7 – Option #3 above with Factory Installed Security Grilles8 – Option #4 above with Factory Installed Security GrillesSeries – 4Voltage1 – 575-3-602 – 230-3-604 – 230-3-605 – 208/230-3-606 – 460-3-602 – 380-3-60 (Export Only)8 – 230-3-509 – 380/415-3-50Enviro-Shield Corrosion Protection Options– – Standard Copper Tube/Aluminum FinK – Copper Tube/Aluminum Fin PrecoatedC – Copper Tube/Copper Fin and Copper Tube SheetE – Copper Tube/Aluminum Fin with E-CoatF – Copper Tube/Copper Fin and Copper Tube Sheetwith E-Coat5

Physical data — English60 Hz UNITSUNIT SIZE 30GXN,ROPERATING WEIGHT (lb)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (lb)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (gal)Maximum RefrigerantPressure (psig)Maximum Fluid SidePressure (psig)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†High Static TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†CONDENSER COILSFins/in.No. RowsTotal Face Area (sq ft)Maximum WorkingPressure 00Victaulic 74324450450450450Shrouded Axial Type, Vertical r Type, Vertical 078,40098,0003/ -in. OD Copper Tubes with Aluminum 32450LEGEND204202020202015101010101010Flooded Type Shell and Tube with Enhanced Copper Tubes33.433.42428.528.538.54Ckt— CircuitCu-Al — Standard Coils with Copper Tubes and Aluminum FinsCu-Cu — Optional Coils with Copper Tubes and Copper Fins17487849,072983410,172HFC-134a681/2CONDENSER FANSStandard/Low Noise TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†High Static TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†CONDENSER COILSFins/in., StdNo. RowsTotal Face Area (sq ft)Maximum Working Pressure (psig)6684COMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (gal)Maximum Refrigerant Pressure (psig)Maximum Fluid Side Pressure (psig)FLUID CONNECTIONS (in.)Inlet and OutletCooler Interconnecting (in.)Drain (Qty.NPT)160175/175156/228181/243Semi-Hermetic, Twin Screw222YesYesYes1/2UNIT SIZE 30GXN,ROPERATING WEIGHT (lb)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge Hermetic, Twin 01010875543.5Flooded Type Shell and Tube with Enhanced Copper ulic d Axial Type, Vertical 18.28.8182,400205,200205,200Propeller Type, Vertical 03/ -in. OD Copper Tubes with Aluminum 16.25.6182,400*Each cooler is shipped with approximately 5 gallons of propolyene glycol to providefreeze protection during storage and shipment.†Based on rated external static pressure of 0.4 in. wg or 0.8 in. wg as appropriate.**Module A.††Module B.

50 Hz UNITSUNIT SIZE 30GXN,ROPERATING WEIGHT (lb)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (lb)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (gal)Maximum RefrigerantPressure (psig)Maximum Fluid SidePressure (psig)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†High Static TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†CONDENSER COILSFins/in., StdNo. RowsTotal Face Area (sq ft)Maximum WorkingPressure (psig)UNIT SIZE 30GXN,ROPERATING WEIGHT (lb)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (lb)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (gal)Maximum RefrigerantPressure (psig)Maximum Fluid SidePressure (psig)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†High Static TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†CONDENSER COILSFins/in., StdNo. RowsTotal Face Area (sq ft)Maximum WorkingPressure .92020202010101010Flooded Type Shell and Tube with Enhanced Copper 0300300300300Victaulic 50450Shrouded Axial Type, Vertical ,80058,80058,800Propeller Type, Vertical 66.24.66.24.66.24.658,80058,80058,80078,4003/ -in. OD Copper Tubes with Aluminum 318,82822,033339/195385/385Semi-Hermetic, Twin 01055Flooded Type Shell and Tube with Enhanced Copper ,000173270173270174270450450450— Circuit— Standard Coils with Copper Tubes and Aluminum Fins— Optional Coils with Copper Tubes and Copper /123160/141Semi-Hermetic, Twin Screw22YesYes56.156.1220220220220300300Victaulic Connections681/1/22300300300220Shrouded Axial Type, Vertical 25.6117,600117,600156,800Propeller Type, Vertical 16.65.6117,600117,600158,6003/ -in. OD Copper Tubes with Aluminum 450450*Each cooler is shipped with approximately 5 gallons of propolyene glycol to providefreeze protection during storage and shipment.†Based on rated external static pressure of 0.4 in. wg or 0.8 in. wg as appropriate.7

Physical data — English (cont)50 Hz DUPLEX UNITSUNIT SIZE 30GXN,ROPERATING WEIGHT (lb)Cu-AlCu-CuREFRIGERANT CHARGECircuits QtyModule A Ckt A/Ckt B (lb)Module B Ckt A/Ckt B (lb)COMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (gal)Max Refrigerant Pressure (psig)Max Fluid Side Pressure (psig)FLUID CONNECTIONSInlet and Outlet (in.)Cooler Interconnecting (in.)Drain — Qty.Size (in.)CONDENSER FANSStandard/Low Noise TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†High Static TypeFan Speed (rpm)No. Blades.Dia. (in.)No. Fans.Total kWTotal Airflow (cfm)†CONDENSER COILSFins/in., StdNo. RowsTotal Face Area (sq ft)Maximum Working Pressure .8220300882.1/2Victaulic 117,600173297450173324450174324450LEGEND— Circuit— Standard Coils with Copper Tubes and Aluminum Fins— Optional Coils with Copper Tubes and Copper 5263/207173/235263/207Semi-Hermetic, Twin 7.54.5553.5Flooded Type Shell and Tube with Enhanced Copper 2.1/2882.1/2882.1/2Shrouded Axial Type, Vertical ropeller Type, Vertical / -in. OD Copper Tubes with Aluminum Fins8171717174433/4378432540486450450450450*Each cooler is shipped with approximately 5 gallons of propolyene glycol to providefreeze protection during storage and shipment.†Based on rated external static pressure of 0.4 in. wg or 0.8 in. wg as appropriate.

Physical data — SI60 Hz UNITSUNIT SIZE 30GXN,ROPERATING WEIGHT (kg)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (kg)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (L)Maximum RefrigerantPressure (kPa)Maximum Fluid SidePressure (kPa)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (r/s)No. Blades.Dia. (mm)No. Fans.Total kWTotal Airflow (L/s)†High Static TypeFan Speed (r/s)No. Blades.Dia. (L/s)No. Fans.Total kWTotal Airflow (L/s)†CONDENSER COILSFins/m, StdNo. RowsTotal Face Area (sq m)Maximum WorkingPressure No2No2No2Yes79/7971/10382/110Semi-Hermetic, Twin 01010101010Flooded Type Shell and Tube with Enhanced Copper 1/21/21/21/219.011.7624.6.421 52119.011.7624.6.421 52119.011.7626.9.632 28119.011.7626.9.632 28119.011.7626.9.632 28129.212.7624.16.418 50029.212.7624.16.418 50029.212.7626.24.627 75129.212.7626.24.627 3UNIT SIZE 30GXN,ROPERATING WEIGHT (kg)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (kg)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (L)Maximum Refrigerant Pressure (kPa)Maximum Fluid Side Pressure (kPa)FLUID CONNECTIONS (in.)Inlet and OutletCooler Interconnecting (in.)Drain (Qty.NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (r/s)No. Blades.Dia. (mm)No. Fans.Total kWTotal Airflow (L/s)†High Static TypeFan Speed (r/s)No. Blades.Dia. (L/s)No. Fans.Total kWTotal Airflow (L/s)†CONDENSER COILSFins/m, StdNo. RowsTotal Face Area (sq m)Maximum Working Pressure 71517151720692069Victaulic 661/21/21/21/21/219.011.76210.1653 80219.011.76210.1653 80219.011.76212.19.264 56319.011.76212.19.264 56329.212.76210.4146 25129.212.76210.4146 25129.212.76212.49.255 50129.212.76212.49.255 ouded Axial Type, Vertical Discharge19.019.019.019.011.762 11.76211.76211.7626.9.68.12.88.12.810.1632 28143 04243 04253 802Propeller Type, Vertical Discharge29.229.229.229.229.212.762 12.762 12.76212.76212.7626.24.66.24.68.32.88.32.810.4127 75127 75137 00137 00146 2519.53-mm. OD Copper Tubes with Aluminum .686 08419.011.76216.25.686 08429.212.76216.65.674 00229.212.76216.65.674 002669440.13103669440.13103LEGEND— Circuit— Standard Coils with Copper Tubes and Aluminum Fins— Optional Coils with Copper Tubes and Copper Fins68310331033709 87410 ic, Twin Screw45YesYes101214183904154509 80510 89410 42111 69111 78013 107 60529.212.76220.32107 6051918.76220.8292 5031918.76220.8292 503669450310366945031031010875543.5Flooded Type Shell and Tube with Enhanced Copper 069Victaulic Connections8888——881111. /21. /22. /22.1/2Shrouded Axial Type, Vertical 8.818.28.886 08496 84596 845Propeller Type, Vertical .616.65.618.73.818.73.874 00274 00283 25283 2529.53-mm. OD Copper Tubes with Aluminum .011.76216.25.686 084*Each cooler is shipped with approximately 18.9 liters of propolyene glycol to providefreeze protection during storage and shipment.†Based on rated external static pressure of 100 Pa or 200 Pa as appropriate.**Module A.††Module B.9

Physical data — SI (cont)50 Hz UNITSUNIT SIZE 30GXN,ROPERATING WEIGHT (kg)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (kg)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (L)Maximum RefrigerantPressure (kPa)Maximum Fluid SidePressure (kPa)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (r/s)No. Blades.Dia. (mm)No. Fans.Total kWTotal Airflow (L/s)†High Static TypeFan Speed (r/s)No. Blades.Dia. (L/s)No. Fans.Total kWTotal Airflow (L/s)†CONDENSER COILSFins/m, StdNo. RowsTotal Face Area (sq m)Maximum WorkingPressure (kPa)UNIT SIZE 30GXN,ROPERATING WEIGHT (kg)Cu-AlCu-CuREFRIGERANT TYPERefrigerant Charge (kg)Ckt-A/Ckt-BCOMPRESSORSQuantityEconomizedNo. Capacity StepsStandardOptional (maximum)Min. Capacity Step (%)StandardOptionalCOOLER*Net Fluid Volume (L)Maximum RefrigerantPressure (kPa)Maximum Fluid SidePressure (kPa)FLUID CONNECTIONS (in.)Inlet and OutletDrain (NPT)CONDENSER FANSStandard/Low Noise TypeFan Speed (r/s)No. Blades.Dia. (mm)No. Fans.Total kWTotal Airflow (L/s)†High Static TypeFan Speed (r/s)No. Blades.Dia. (L/s)No. Fans.Total kWTotal Airflow (L/s)†CONDENSER COILSFins/m, StdNo. RowsTotal Face Area (sq m)Maximum WorkingPressure 010Flooded Type Shell and Tube with Enhanced Copper 92069Victaulic Connections551/1/224451/21/21/215.811.7624.6.418 50015.811.7624.6.418 50015.811.7626.9.627 75124.112.7624.16.418 50024.112.7624.16.418 69206920695451/21/21/215.811.7628.12.837 00115.811.7628.12.837 00124.112.7628.32.837 00124.112.7628.32.837 s4Yes10121012101215151010101055Flooded Type Shell and Tube with Enhanced Copper 6210.1646 25115.811.76210.1646 25115.811.76210.1646 25124.112.76210.4146 25124.112.76210.4146 25124.112.76210.4146 25166932566932566942531033103310326431032811/2— Circuit— Standard Coils with Copper Tubes and Aluminum Fins— Optional Coils with Copper Tubes and Copper Fins1517Shrouded Axial Type, Vertical .9.627 75127 75127 751Propeller Type, Vertical .24.66.24.66.24.66.24.627 75127

control provided by the Carrier ComfortLink system helps to maintain higher levels of indoor air quality, ther-mal comfort, and productive space. While many air-cooled chillers use only leaving fluid temperature control, the 30GXN,R chillers utilize leaving fluid temperature control with a standard entering fluid temperature compensation.